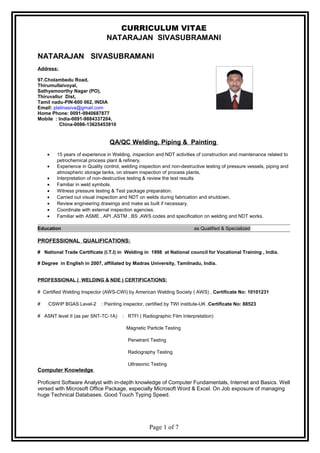

Curriculum Vitae for Welding Inspector

- 1. CURRICULUM VITAE NATARAJAN SIVASUBRAMANI NATARAJAN SIVASUBRAMANI Address: 97.Cholambedu Road, Thirumullaivoyal, Sathyamoorthy Nagar (PO), Thiruvallur Dist, Tamil nadu-PIN-600 062, INDIA Email: platinasiva@gmail.com Home Phone: 0091-9940687877 Mobile : India-0091-9884337204, China-0086-13625453910 QA/QC Welding, Piping & Painting • 15 years of experience in Welding, inspection and NDT activities of construction and maintenance related to petrochemical process plant & refinery. • Experience in Quality control, welding inspection and non-destructive testing of pressure vessels, piping and atmospheric storage tanks, on stream inspection of process plants. • Interpretation of non-destructive testing & review the test results • Familiar in weld symbols. • Witness pressure testing & Test package preparation. • Carried out visual inspection and NDT on welds during fabrication and shutdown. • Review engineering drawings and make as built if necessary. • Coordinate with external inspection agencies. • Familiar with ASME , API ,ASTM , BS ,AWS codes and specification on welding and NDT works. Education as Qualified & Specialized PROFESSIONAL QUALIFICATIONS: # National Trade Certificate (I.T.I) in Welding in 1998 at National council for Vocational Training , India. # Degree in English in 2007, affiliated by Madras University, Tamilnadu, India. PROFESSIONAL ( WELDING & NDE ) CERTIFICATIONS: # Certified Welding Inspector (AWS-CWI) by American Welding Society ( AWS) , Certificate No: 10101231 # CSWIP BGAS Level-2 : Painting inspector, certified by TWI institute-UK .Certificate No: 88523 # ASNT level II (as per SNT-TC-1A) : RTFI ( Radiographic Film Interpretation) Magnetic Particle Testing Penetrant Testing Radiography Testing Ultrasonic Testing Computer Knowledge Proficient Software Analyst with in-depth knowledge of Computer Fundamentals, Internet and Basics. Well versed with Microsoft Office Package, especially Microsoft Word & Excel. On Job exposure of managing huge Technical Databases. Good Touch Typing Speed. Page 1 of 7

- 2. CURRICULUM VITAE NATARAJAN SIVASUBRAMANI Skill Summary NTC & NAC in Welding Technology, Graduate in English & certified Welding Inspector by AWS, Certified Painting Inspector by CSWIP BGAS Level-2 & ASNT level 2 ( RTFI,PT, UT, RT,MPT) holder having well exposure & experience in the Field of Engineering, Procurement, Construction, Management, Planning, Supervision, Inspection, Execution, Operation & Maintenance of Process Plant Piping Fabrication, Structural LNG module Inspection, Erection and Installation; In plant Piping Survey, Distribution Pipeline with Clear understanding of Technical Drawings, Specifications, Codes & Standards as well as Proficiency in Computers & Internet Technology; and has been part of variety of Projects in various National & Multi-National Organization based in India, Dubai, Thailand, Iraq & China. Quality Inspection Tank– Welding(Storage Tank), Piping, Pipeline & Equipment, NDT ,Structural LNG module Hands on experience of pre-welding, in-process, and post welding surveillance, inspection & supervision of all welding operations and associated variables for Butt, Fillet and Socket welds of materials such as CS, SS, Alloy,Inconel & dissimilar materials etc; made with welding processes such as SMAW, GTAW or TIG, GMAW, SAW, etc; using essential inspection aids, as per applicable application and relevant standards e.g. ASME B31.3, ASME B31.1, ASME Sec VIII, ASME Sec IX, ASME Sec V, ASME Sec IIC, AWS D1.1, API 650,API620, etc; including signing the daily Welding & NDT reports, witnessing all applicable NDT (VT, RT, PT, MT, UT ) and daily radiographs review, interpretation & evaluation. Piping & Pipeline experience in projects includes participation in ongoing operations to Randomly Check / Witness / Monitor / Review / Inspect / Interpret / Evaluate / Accept / Approve / Reject the Construction to commissioning activities of Distribution Pipeline and process Plant Project; as per technical drawings. EMPLOYMENT HISTORY 1) Employee : NPC ( NORWEGIAN PETROLEUM CONSULTANTS PTE LTD) For EVT- Joint Venture ( ENTREPOSE+VINCI+THESIS) Client : BECHTEL – Australia Pty Ltd., Designation : QA/QC ENGINEER (STRACTURAL,PIPING,COATING & DOCUMENTATION) 2014 NOVEMBER TO TILL DATE ( Penglai – Shandong Province (China) ) LNG Wheatstone Module Fabrication. Project overview 1. Full containment, Liquefied Natural Gas (LNG) Storage tanks with capacity of 150000m3 (Cold). 2. Field Erected Condensate Tanks ( Two (2) 120,000 cubic meter Condensate storage Tank 3. Full containment Cryogenic & Non cryogenic Piping for LNG storage tank ( Module fabrication) & LNG module fabrication The tank constructed as per API-620, API-625, AS-3961 and NFPA-59A codes & specification. LNG Storage tank with capacity of 150000 cubic meter net capacity (cold), Page 2 of 7

- 3. CURRICULUM VITAE NATARAJAN SIVASUBRAMANI Pipe line related to process line and utilities , with less than 1” diameter through 42” diameter with Cold Insulation for all the Cryogenic Lines. Structural Fabrication, Welding & NDE Inspection as per codes & specification Responsibilities • Welding & NDE Procedures Review/Approval, • Reviewing the QA/QC reports and approval ( Accreditation & code requirements) • Monitoring the site activities NDT (PT,MT,RT,UT),. • Monitoring consumable issuing, handling and storing. • Daily Observation and monitoring the in process activities and Inspection • RT film Interpretation and approval. • Pneumatic & Hydro test Packages review and approval. • Well versed in reading of P&ID and isometric drawings, process of operation of all plants. • LNG module Structural fabrication inspection • Coating (painting & HDG) and Cold Insulation Inspection and approval • Receiving material Inspection & Approval ( MTC & Random Check) • ITP signoff for ( PIPING, STRUCTURAL ,COATING & INSULATION ) • Red Line mark up drawing Review & Approval ( With reference to RFI & VDDR ) • MRB Index preparation (Manufacture Record Book) Compiling / Review & Approval • Responsible person for Final document preparation and compiling as per requirement • Organise periodic QA/QC toolbox talk & Quality Alert meeting to ensure and improve the process & product quality 02. Employer : ROSCO & ENTREPOSE CONSORTIUM, IRAQ Client : LUKOIL , IRAQ Designation : WELDING INSPECTOR (TANK & PIPING) JANUARY 2013 TO MARCH 2015 – 1.3Year Project overview 1. Full containment Floating Roof Crude Oil storage tank with capacity of 66000m3. The tank design code API-650 11th Edition, Atmospheric Pressure Crude Oil Storage tank with Diameter of 91693mm, Height-10015mm and Geometric volume of 66104m3 with maximum working volume of around 44223m3. . 2. Full containment Piping for storage tanks (crude oil) & Fire water line. Pipe line related to storage tank and fire water , with 1” diameter through 36” diameter with a overall welding inch diameter around 25000 inch diameter. Responsibilities • Welding & NDE Procedures Review/Approval, Page 3 of 7

- 4. CURRICULUM VITAE NATARAJAN SIVASUBRAMANI • Preparation of QA/QC documents, • Reviewing the QA/QC reports, • Monitoring the site activities NDT (PT,MT,RT), • Vacuum box testing and reviewing reports. • Monitoring consumable issuing, handling and storing. • Welder qualification test witnessing, • Preparation of welders ID • Coordinate the site NDT activities, sub contractors and supervise the site welding inspector duties, • Planning and Permit request for RT for pipe joints • Reviewing the RT Film. • Maintain and update the QA/QC Records. • Preparing the final weld NDT summary and prepare the Hydro test Packages. • Well versed in reading of P&ID and isometric drawings, process of operation of all plants. 03. Employer : FUSION FABRICATION WORKS ( INDIA ) Designation : QAQC / WELDING INSPECTOR NOVEMBER 2010 to DECEMBER 2012 – 2 Years Company Profile FUSION FABRICATION was formed by a group of Engineers who are working in Power ,Water, Oil & Gas Industry. Best in manufacturing Low & High pressure vessel, pipe spools, chemical dosing skids, structural fabrication & Erection. The Job responsibilities are mainly related to piping, piping with equipment & storage tanks, which comprises Welding Inspection, Approval of WPS, Approval of PQR, Approval of welders, Approval of welding consumables, Approval of quality control procedures, Review of NDE results, Review of test packs, and Auditing of welding activities. Responsibilities • Inspection during Fabrication of Piping Spools, Pipe Supports, Structural Bracings, Embed Plate / Insert at Shop & Field. • Inspection of Pre Weld Joint Set-Ups and Post Weld Joint Visuals. Select Welds for NDE. • Surveillance of pipe welding inspection • Approval of welding consumables and auditing of welding activities as per project specifications. • Review NDT and Heat treatment reports • Verify and ensure that all field welds are free from visual defects as per the project specifications. • Determine whether the defective welds are repaired as per the specification. • Check and document the welding heat input periodically, check the condition of the consumables and record their batch Nos. • Ensure the pipes are cleaned inside prior to welding. • Maintain daily inspection reports, notes on welder deficiencies, safety non-compliances and other events pertaining to the work • Identify and document non-conformance, forward the NCR’s to QC engineer for further processing. • Witness the pneumatic test. • Generate all inspection test sheets required by ITP and ensure that all approval signatures are acquired on timely basis. • Liaise with the company QC department on daily inspections and report their concerns to the QC Manager. Page 4 of 7

- 5. CURRICULUM VITAE NATARAJAN SIVASUBRAMANI 04. Employer : BETZ ENGINEERING TECHNOLOGY ZONE (INDIA) Client : TPSC ( THAILAND ) & FNC ( UAE) Designation : THIRD PARTY QA/QC INSPECTOR DECEMBER 2007 to November 2010 – 3 Years Combined Cycle Co-generation power plant project ( Amata city – Thailand ). The responsibilities were visual inspections of welding, clearance of NDE, verification of piping completion and final certification welding clearance in piping test packs. Responsibilities • Supervision and inspection of piping fabrication as per ASME B 31.3. • Fit up clearance for welding. • Monitoring and checking of welding, heat treatment and NDE activities. • Liaison with client inspectors. • Monitoring welder’s performance repair rates and penalty coverage. • Control of welding consumable. • Complete inspection of ISOMETRIC drawings and as built marked to be tested. • Structural fabrication & erection of process engineering utility flow scheme including pipe laying, pipe supports, welding, assembly, designing, hydro test & related test activities for BTIP. • Following HHI procedure & submitting notification as per the site progress. 05. Contract Employer : SUPREME FABRICATOR (subcontractor CVPU) Designation : WELDING FOREMAN PROMOTED TO NDT INSPECTOR OCTOBER 2003 to DECEMBER 2007 – 4 Years CVPU ( A division of Automotive Coach and Component limited ) manufacture of Earth Moving Equipments . Supreme Fabricator is a leading structural fabricator and a registered vendor for CVPU. Job responsibilities were monitoring all aspects of welding and NDT works, visual inspection of welded joints, penetrant and magnetic particle inspection involved for industrial fabrication and erection of ancillary products for Earth Moving Equipment. Responsibilities: • Monitoring all aspects of welding and NDE works with quality surveillance. • Monitoring storage condition and issuance of welding consumables. • Liaison with external inspectors. 06. Employer : SHRI RAM METAL CRAFTS ( INDIA ) Designation : WELDER COMBINED FABRICATOR AUGUST 1999 TO AUGUST 2002 – 3 years Page 5 of 7

- 6. CURRICULUM VITAE NATARAJAN SIVASUBRAMANI Responsibilities: • Structural fabrication & erection , welding, • To make Pipe fabrication schedule and expediting fabrication progress as per the schedule by guiding site supervisor and foreman. • Complete inspection of ISOMETRIC & Engineering drawings and related dimensional check. • To verify the drawing for the material cross check and regularity follow up the material delivery at site. • Supervising the Welders and fitters to attain monthly production targets • Inspect and submit everyday activities reports to the Team Leader. Passport Detail Passport Number : G4912876 Place of Issue : CHENNAI Date of Issue : 14 September 2007 Date of Expiry : 13 September 2017 Personal Detail Father Name : K. NATARAJAN Mother Name : N. PAPPUAMMAL Date of birth & Age : 06th December 1982 & 32 Years Religion : Hindu by birth Nationality : Indian by geographic structure SHORT TERM GOAL : Will upgrade the professional education on periodic intervals to attain API & ISO certification. LONGTERM GOAL: Will attain the “NOBEL PRIZE” in the field of my loveable profession. Professional Reference: 1) Mr.TAREK BECHWATI WHEATSTONE PROJECT LNG- Modules – Project Package Manager ( EVT-JV) Tel: +86 535 345 7853 Mobile: +86 1856 2233 643 Email: tarek.bechwati@entrepose.com & tarek.bechwati@entrepose- projects.com 2) Mr. Ramaswamy Selvaraju Page 6 of 7

- 7. CURRICULUM VITAE NATARAJAN SIVASUBRAMANI QA/QC Manager EVT-JV LNG & Condensate Tanks / Wheatstone LNG Plant Project Tel: +61 861 458989 Mobile: +61 407899518 & +91 9894329886 Email: SRamasamy@evtjv.com.au 3) Mr. JIA HONGLEI Project Manager , PJOE EVT- Wheatstone LNG Modules Fabrication Tel: +86 535 3735 300 Mobile: +86 139 5350 8575 Email: jiahonglei@pjoe.com.cn Page 7 of 7