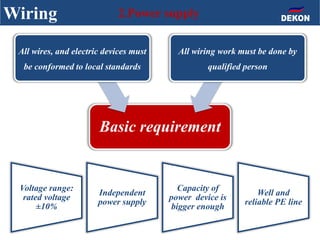

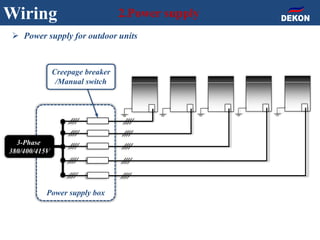

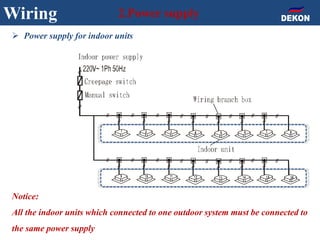

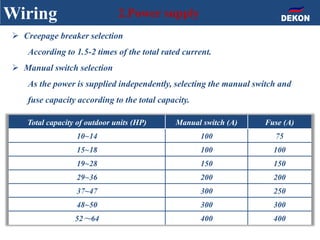

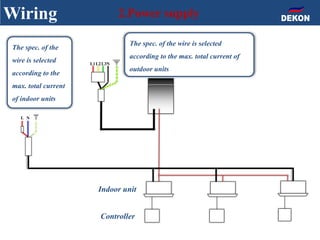

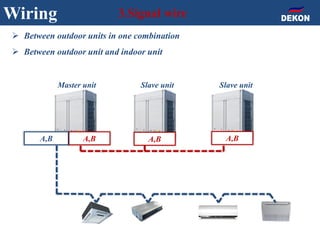

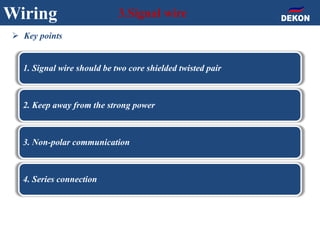

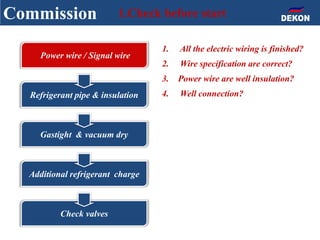

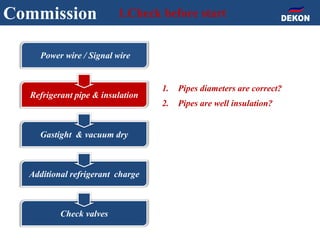

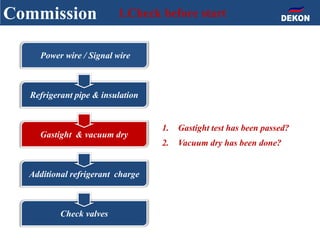

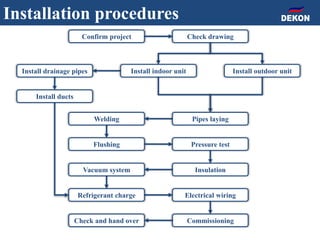

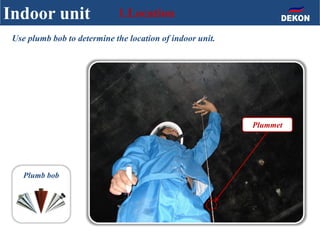

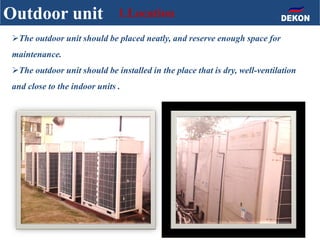

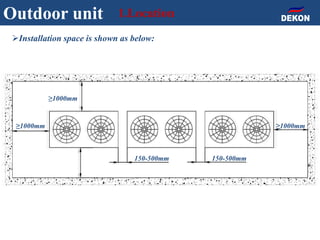

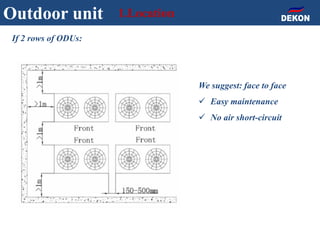

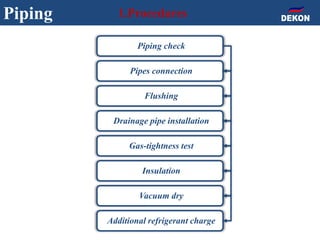

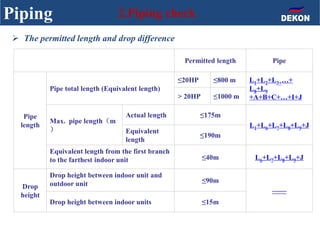

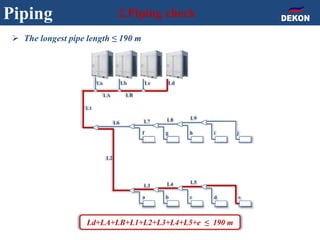

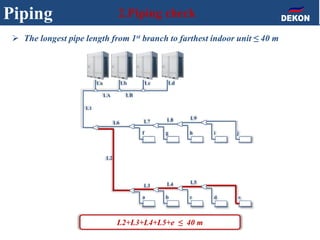

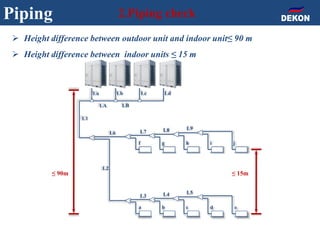

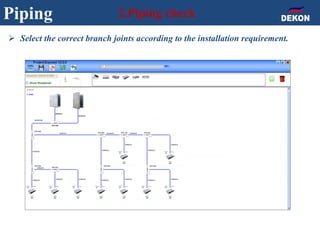

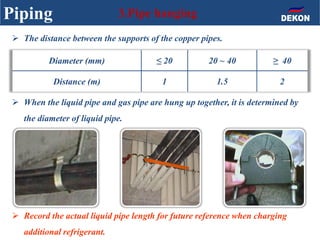

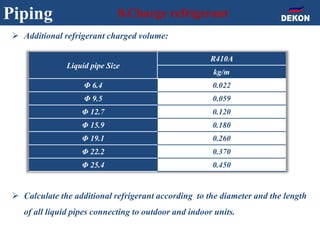

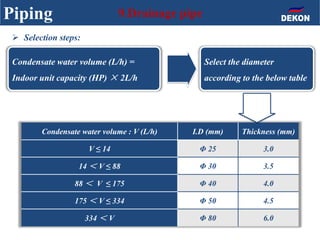

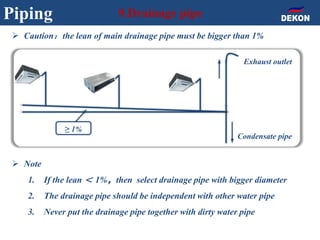

The document provides detailed installation instructions for DC inverter VRF systems, covering procedures for indoor and outdoor unit installation, piping, electrical wiring, and drainage systems. Key steps include proper placement for maintenance, ensuring gas-tightness, and setting up electrical wiring in compliance with regulations. The document emphasizes careful practices in each stage to prevent future issues and enhance system performance.

![Wiring 1.Address setting

Indoor address setting by Remote controller

Indoor unit address

NO.

Methold

Press [Sleep] button 8 times within 5

seconds to enter into the interface of

remote parameter change;

Select “parameter NO.” as “1” to enter

the indoor unit addressing mode;

set “Indoor unit address NO.” as

required on site;

press “sending button” to send order;

When hearing buzzer once, it indicates

successful setting](https://image.slidesharecdn.com/dcinvertervrfinstallationinstruction-170819022834/85/Dc-inverter-vrf-installation-instructions-and-Tips-66-320.jpg)