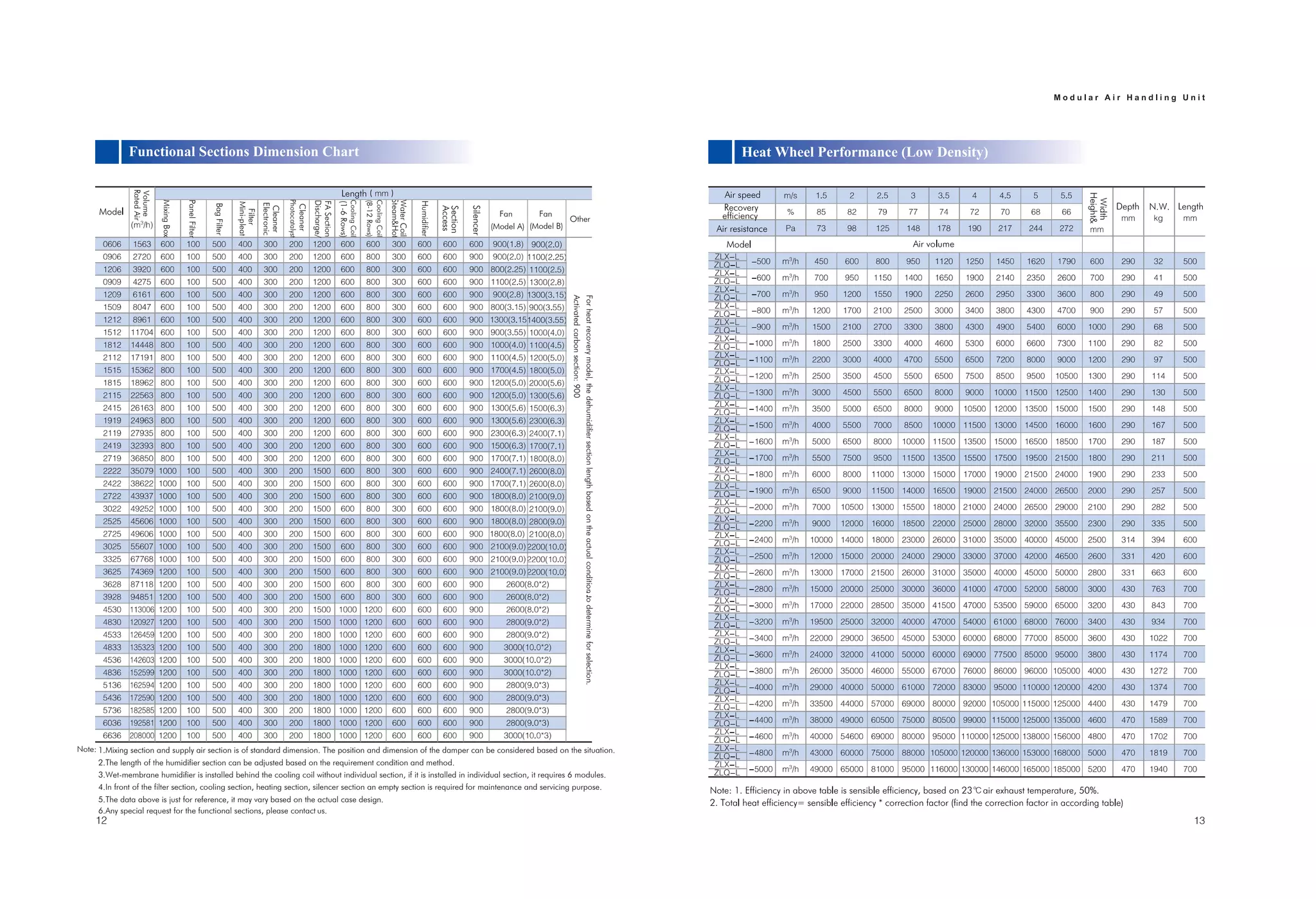

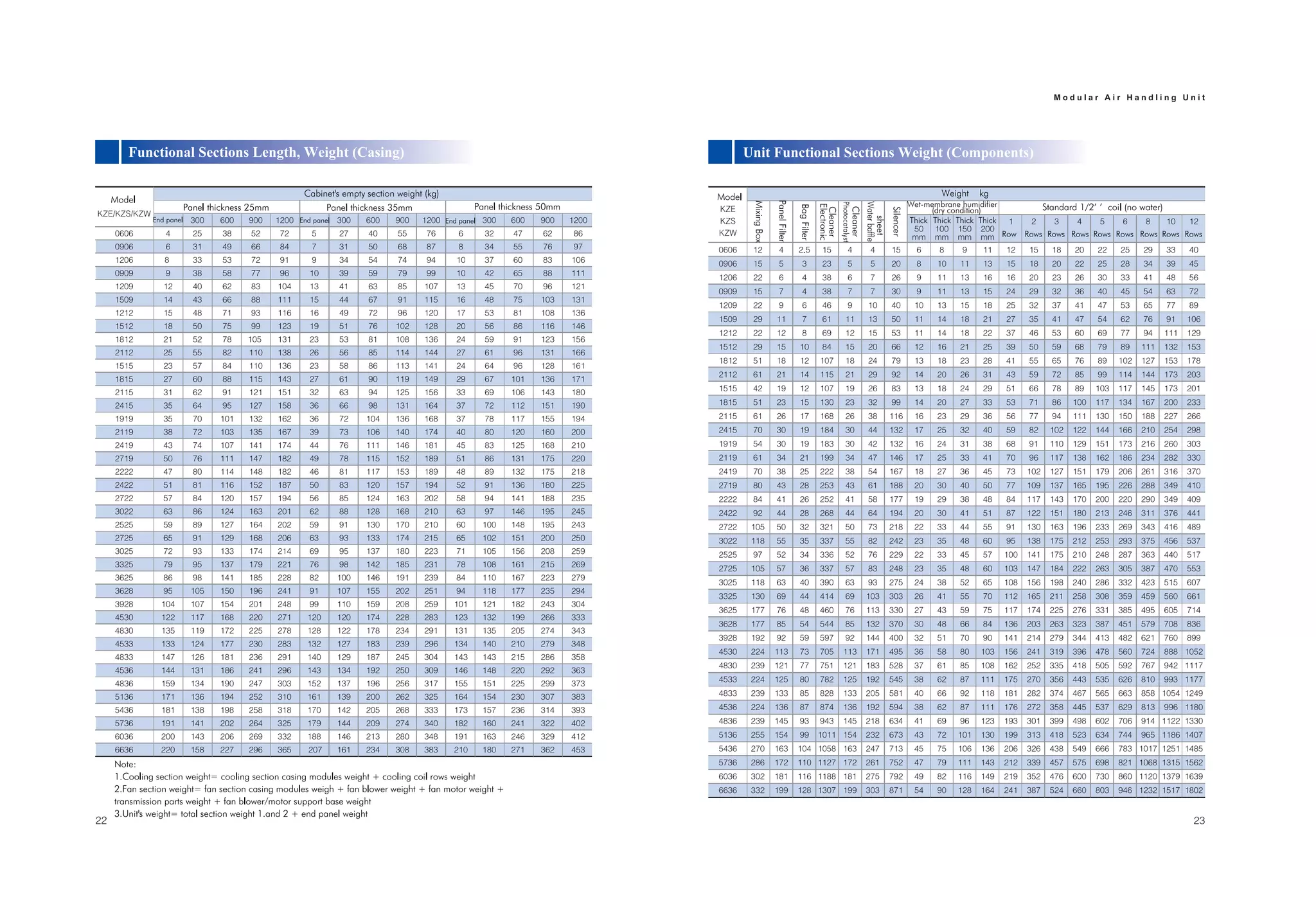

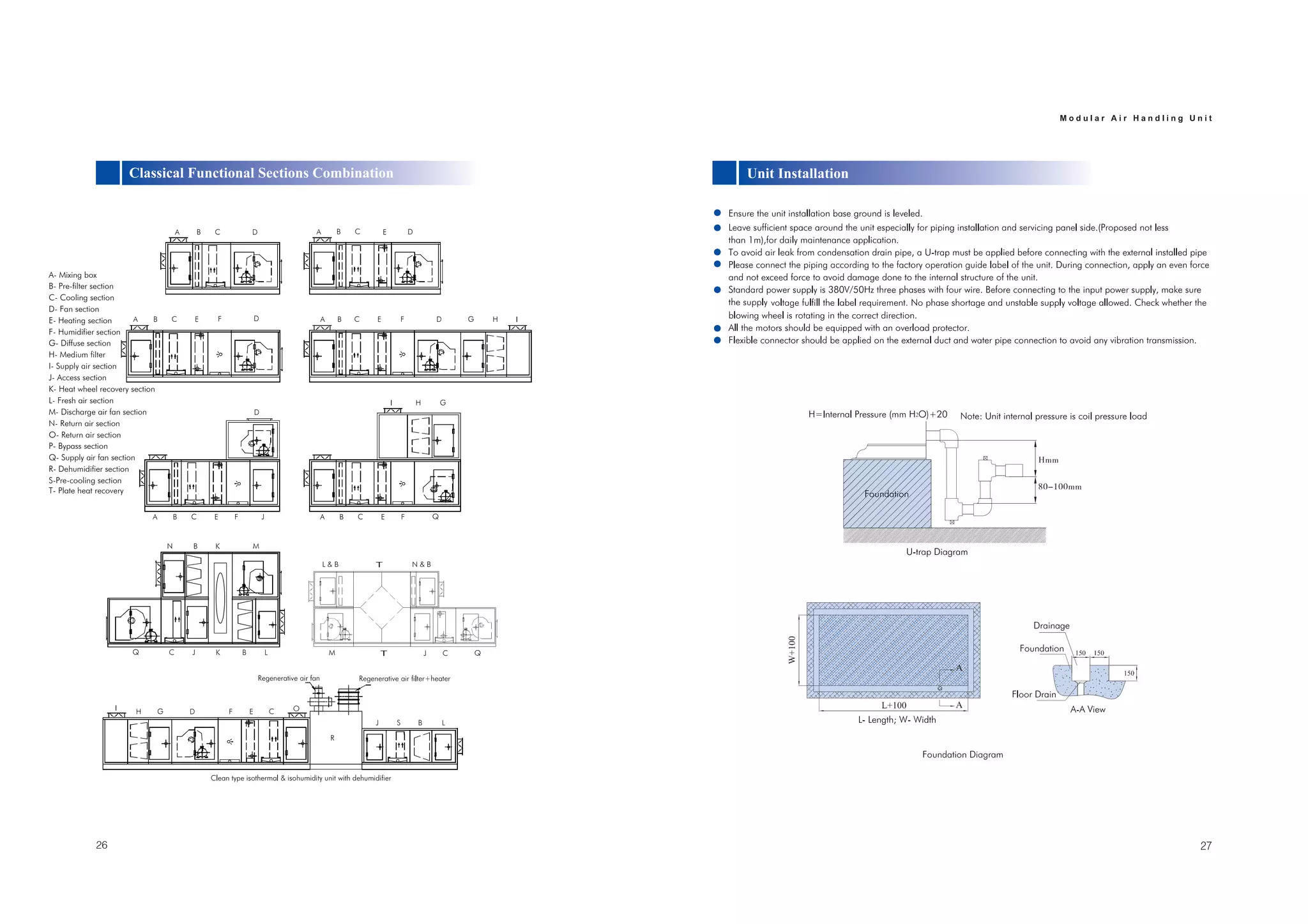

The document outlines specifications and installation considerations for a comprehensive HVAC system, detailing various components such as mixing boxes, filters, cooling and heating sections, and humidifier requirements. It highlights the importance of ensuring adequate dimensions for maintenance access and notes the flexibility of certain section lengths based on specific needs. Additionally, it underscores the necessity for proper interlocking between components such as the humidifier and fan motor in the control design.