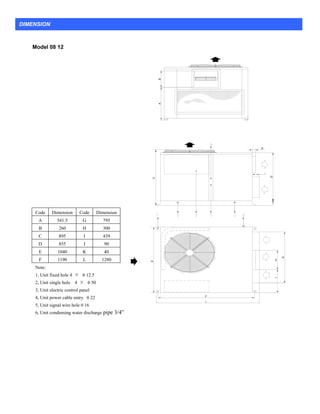

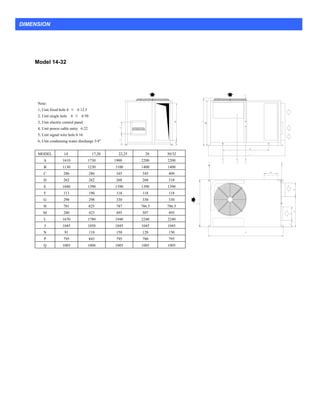

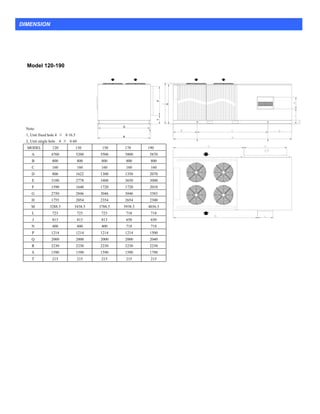

This document provides technical specifications for rooftop packaged air conditioning units with nominal cooling capacities ranging from 8.9 kW to 105.1 kW. It includes key performance data for each model such as cooling/heating capacities, power consumption, current draw, efficiency ratings, component details, dimensions, sound levels and other specifications. The units utilize R410a refrigerant and have centrifugal fans, direct or belt driven depending on size. Control systems include microprocessor controllers and thermal expansion valves.