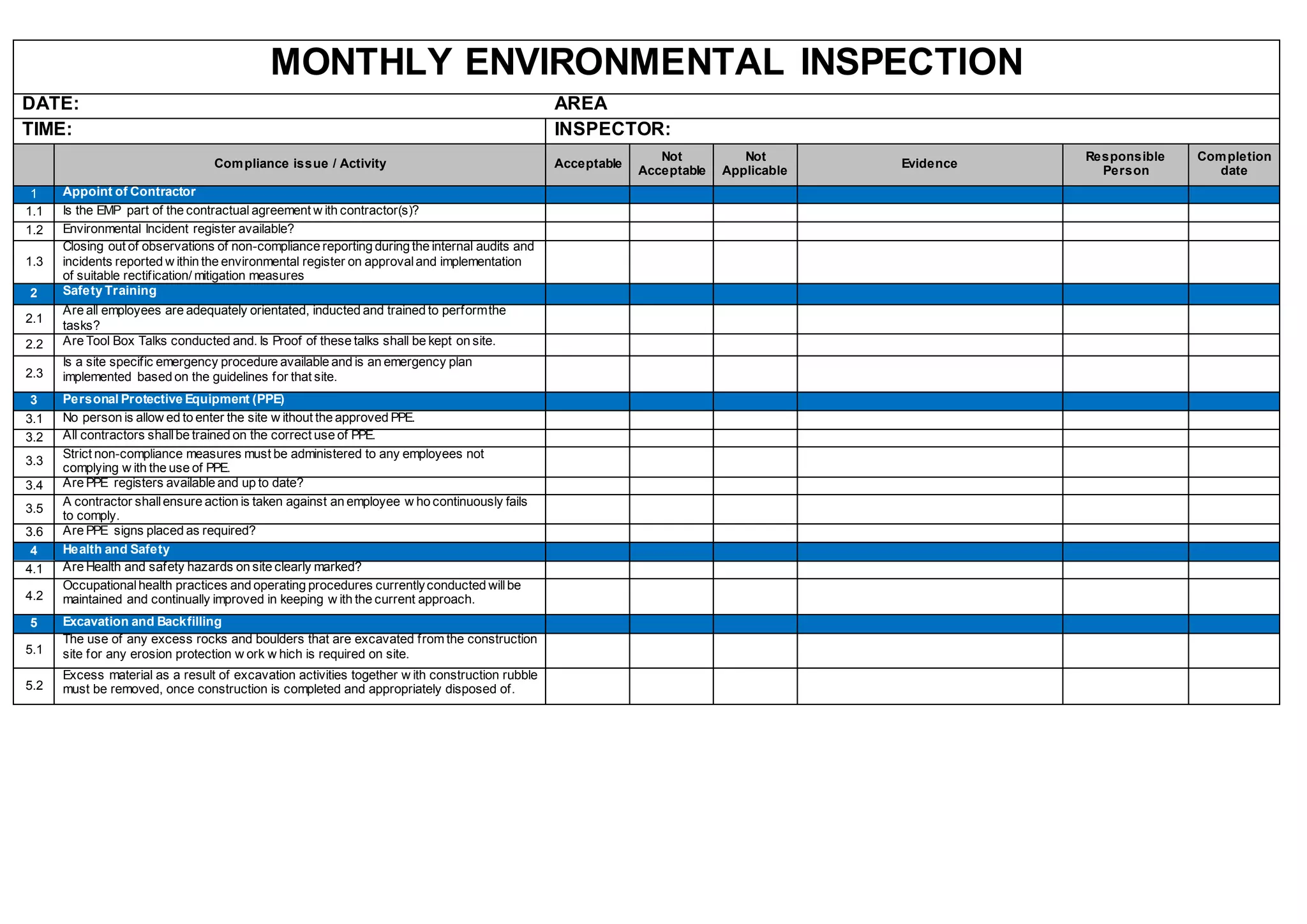

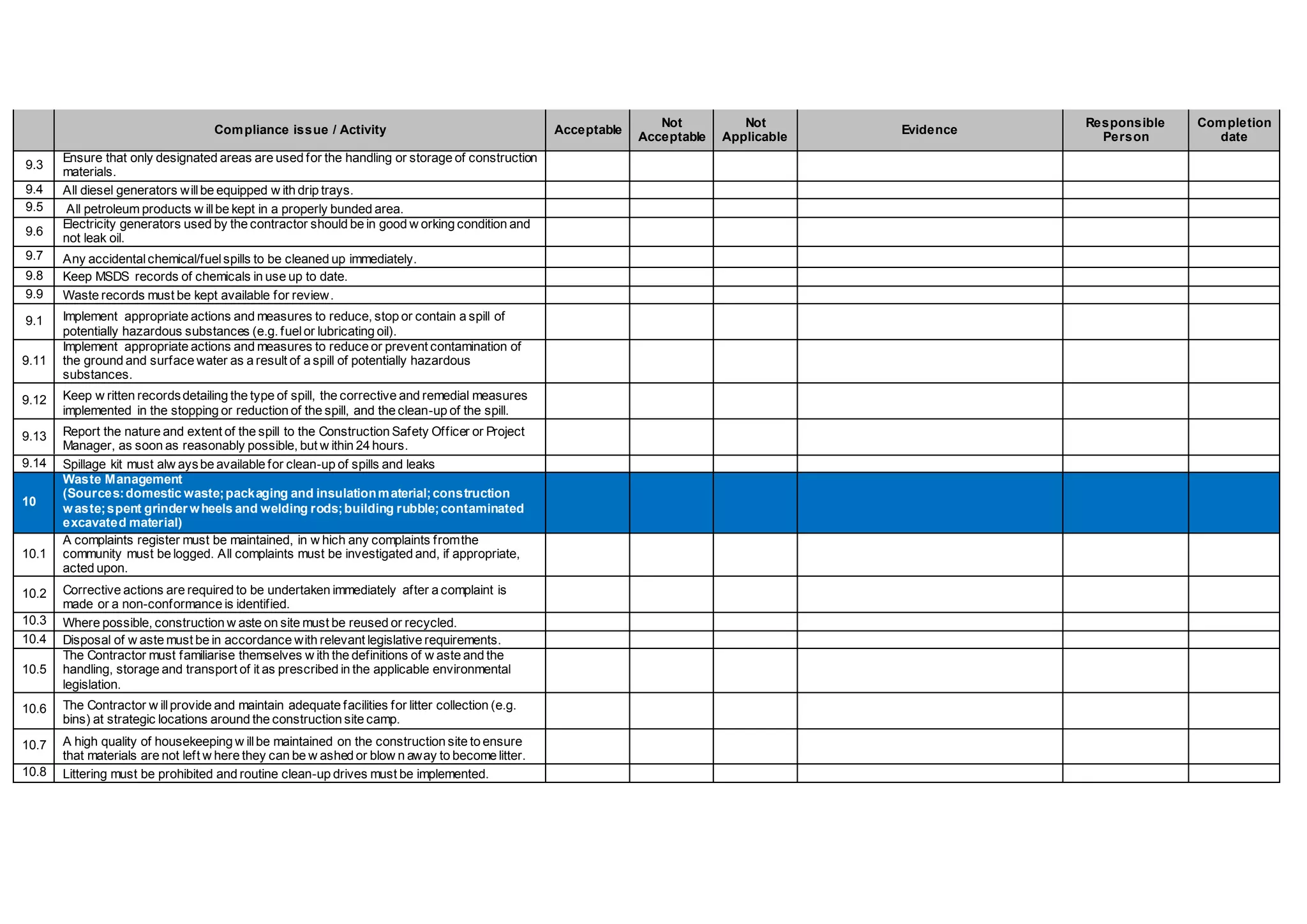

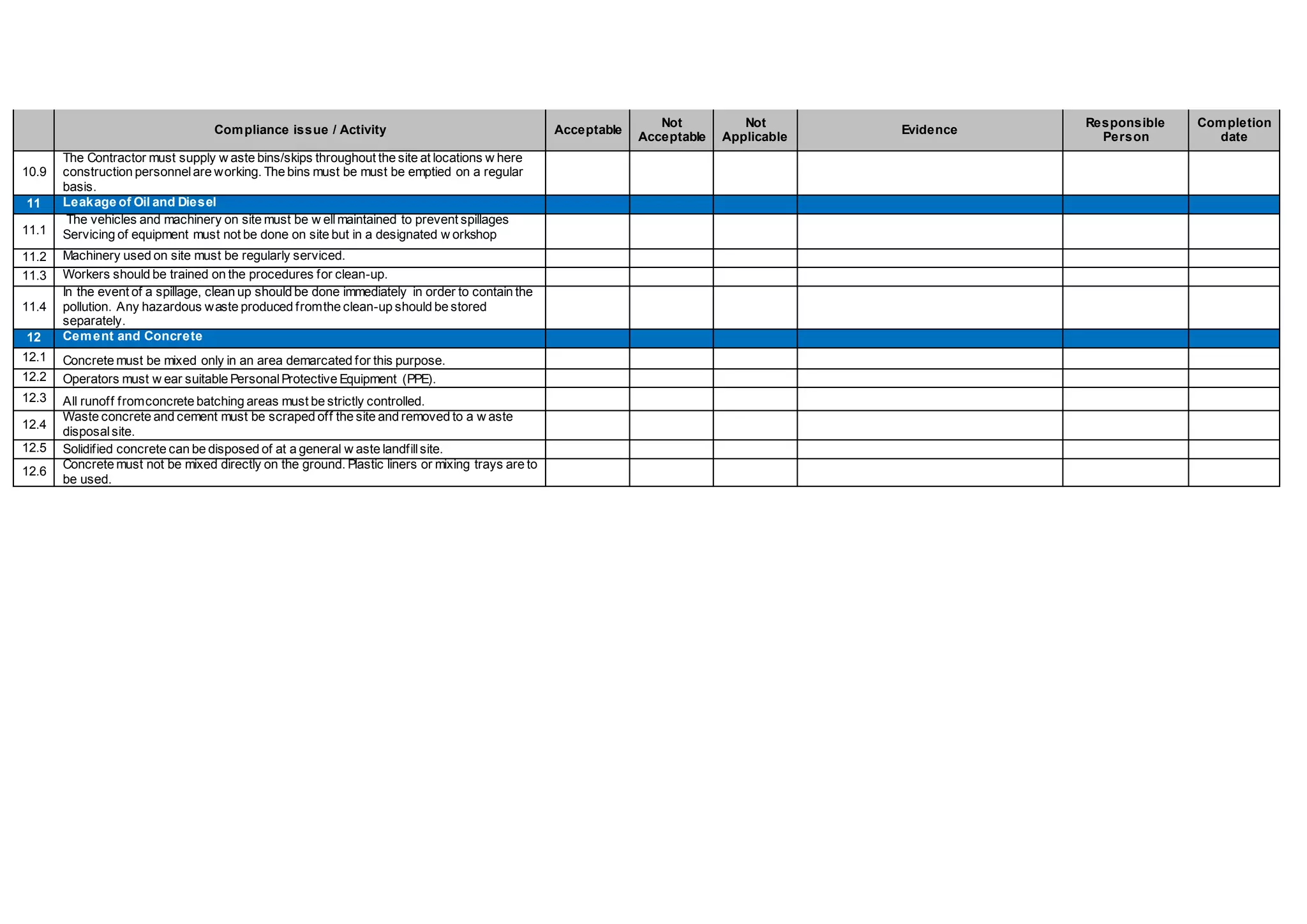

This document outlines the requirements for a monthly environmental inspection at a construction site. It lists 12 compliance issues that are to be checked, including appointing contractors, safety training, personal protective equipment, health and safety, excavation and backfilling, dust control, water management, noise, storage and handling of hazardous substances, and waste management. For each compliance issue, the inspector notes whether the activity is acceptable or not, and includes evidence and details any responsible persons and completion dates for corrective actions. The goal of the inspection is to ensure all construction activities comply with environmental regulations and best practices.