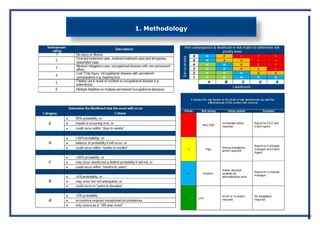

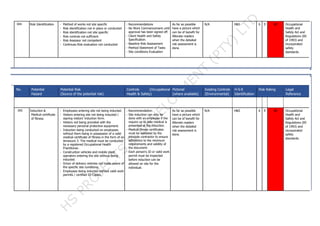

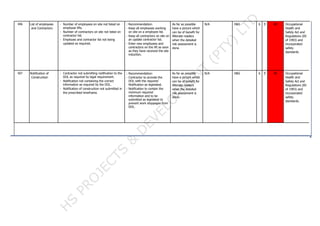

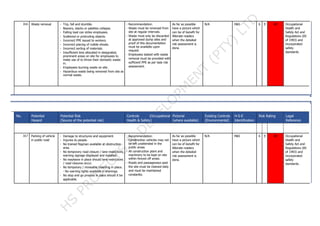

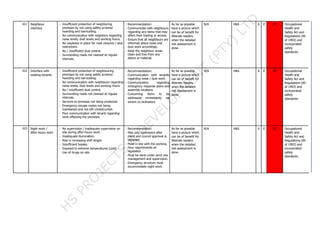

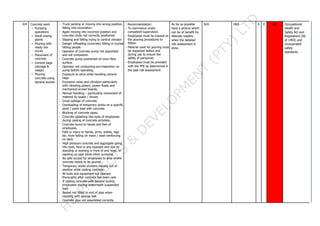

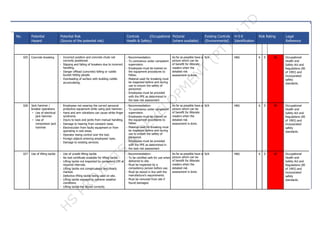

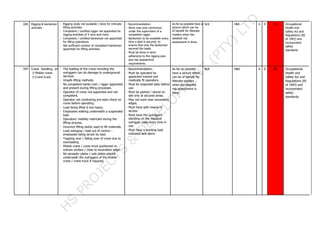

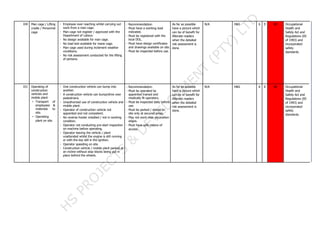

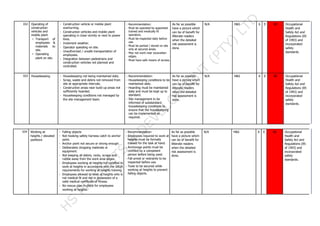

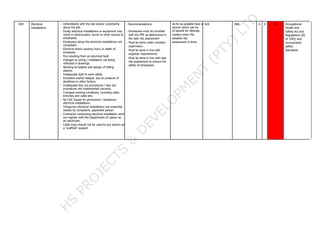

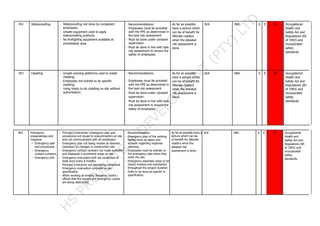

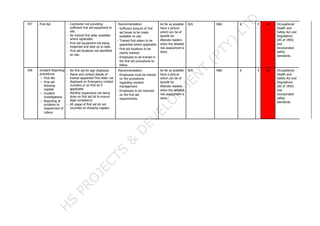

This baseline risk assessment document outlines potential hazards, risks, controls, and legal references for a construction project. It identifies 8 categories of hazards: file approval, legal appointments, required documentation, risk identification, inductions and medical certificates, employee and contractor lists, notification of construction, and client and designer duties. For each hazard, it provides recommendations for controls to reduce risks and refers to relevant sections of the Occupational Health and Safety Act. The assessment will be used to inform a more detailed risk assessment by the principal contractor.