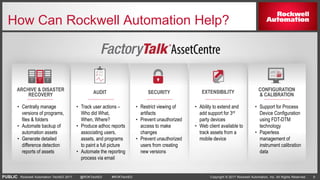

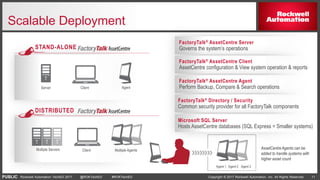

The document provides an overview of FactoryTalk® AssetCentre, highlighting its capabilities in asset management, change control, and disaster recovery. It showcases customer success stories, detailing how various companies improved operational efficiency and reduced downtime through the deployment of this software. Additionally, it emphasizes the importance of managing automation assets and securing user access to mitigate risks and enhance overall productivity.