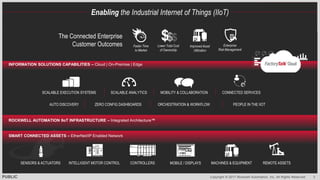

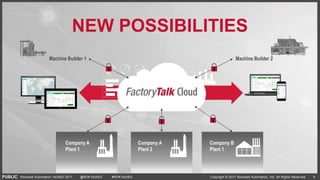

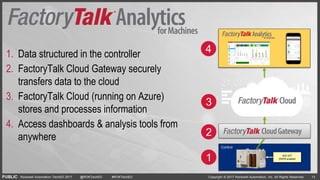

The document outlines Rockwell Automation's strategies for machine builders in the context of the Industrial Internet of Things (IIoT), emphasizing the importance of real-time data analytics, remote monitoring, and differentiation in machine capabilities. It highlights the challenges faced by machine builders, including meeting performance expectations, effective after-sales service, and understanding machine performance post-deployment. Additionally, it discusses the evolution of relationships between original equipment manufacturers (OEMs) and end-users, positioning the connected enterprise as crucial for improved productivity and asset utilization.