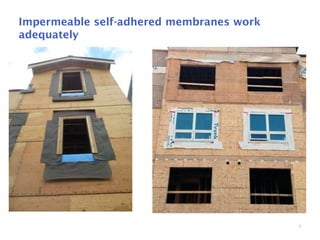

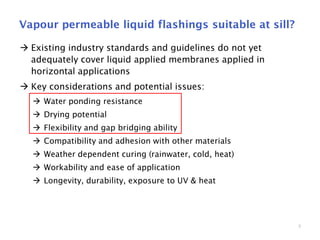

The document discusses testing done to evaluate whether liquid membrane flashings are suitable for use as window sill pan flashings. It describes tests done to assess the long-term water ponding resistance, drying potential, and gap bridging ability of different liquid and self-adhered membrane products. The results showed that while some liquid membrane chemistries were acceptable, thicker applications were needed for proper gap bridging. Overall, permeable and impermeable self-adhered membranes performed better than liquid membranes as sill flashings. No discernible drying benefit was found for liquid membranes over impermeable self-adhered options. New test standards may be needed to better evaluate liquid membrane flashing performance.