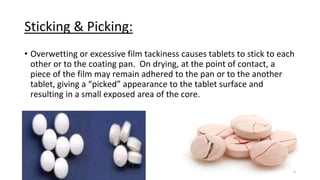

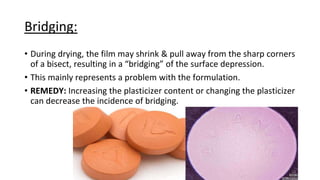

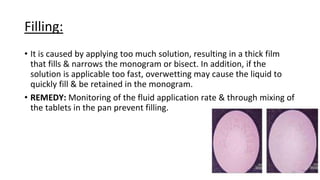

This document discusses common defects that can occur during the tablet coating process, including sticking and picking caused by overwetting, roughness from rapid drying of spray droplets, and orange peel effects from inadequate spreading of the coating solution. Other defects covered are bridging around tablet edges, filling of indentations, blistering from too rapid drying, hazing or dullness from high processing temperatures, color variation from improper mixing or ingredient migration, and cracking from internal stresses exceeding the film's tensile strength. Remedies for each defect aim to optimize the coating formulation, application process, or drying conditions.