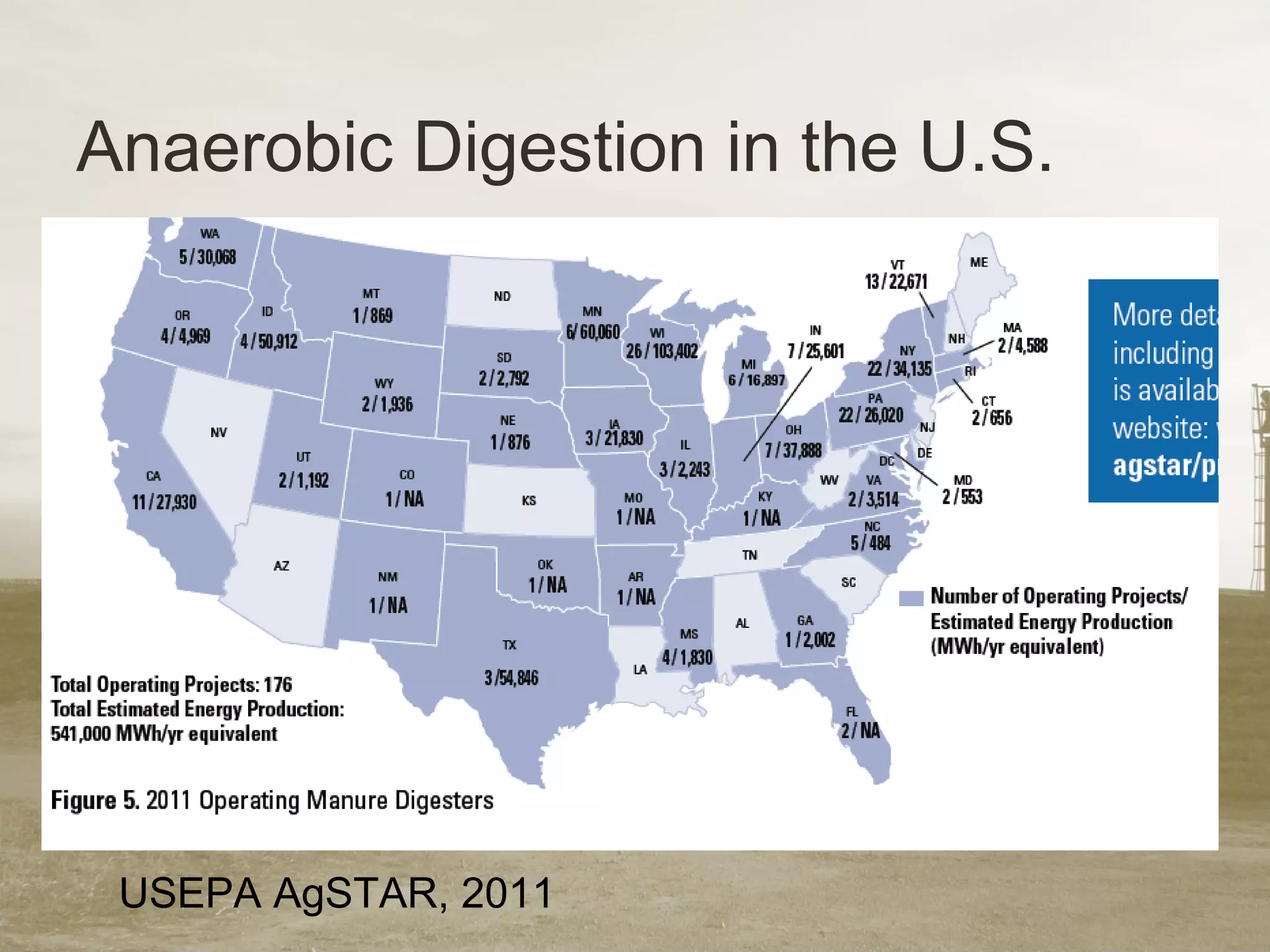

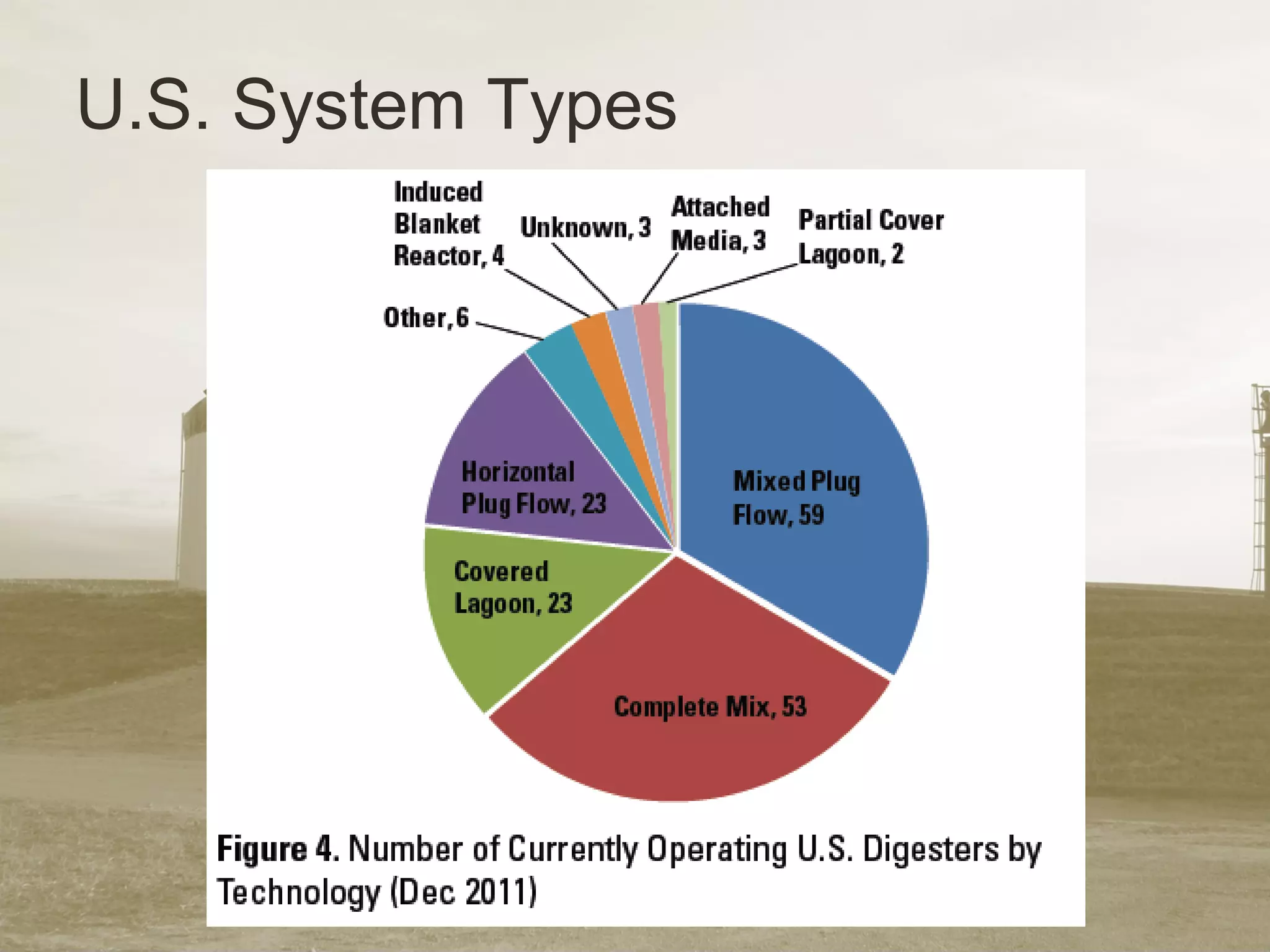

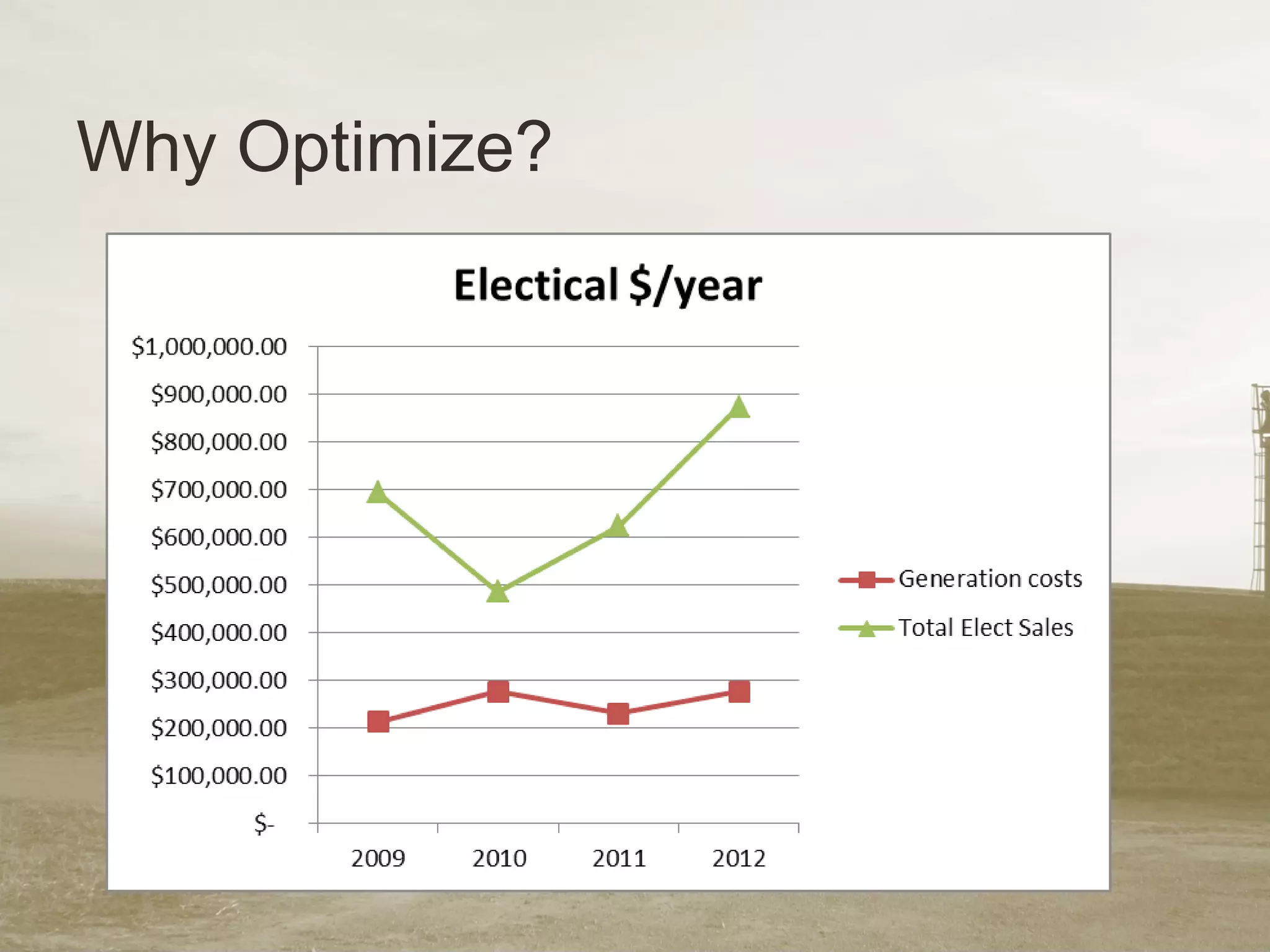

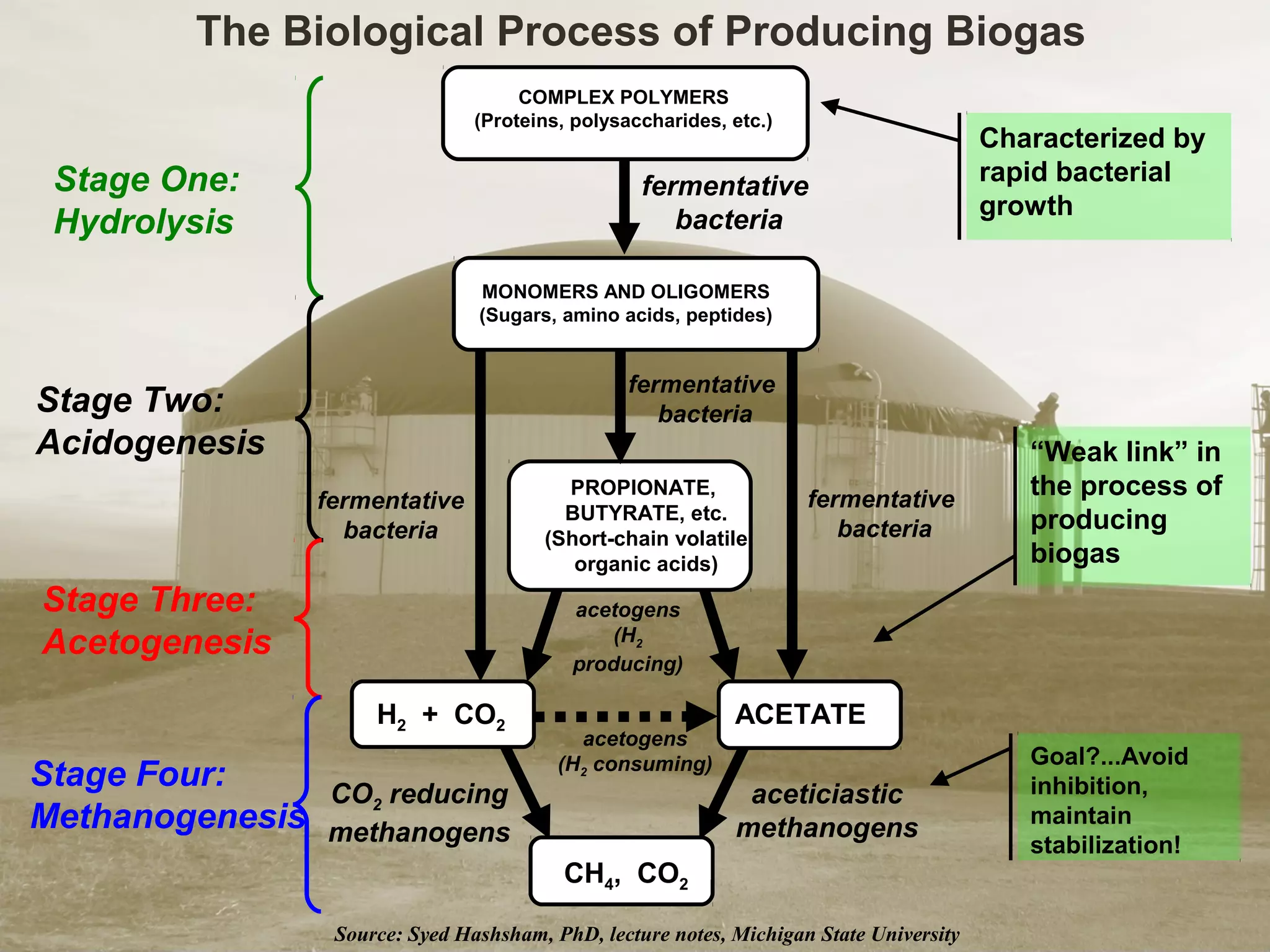

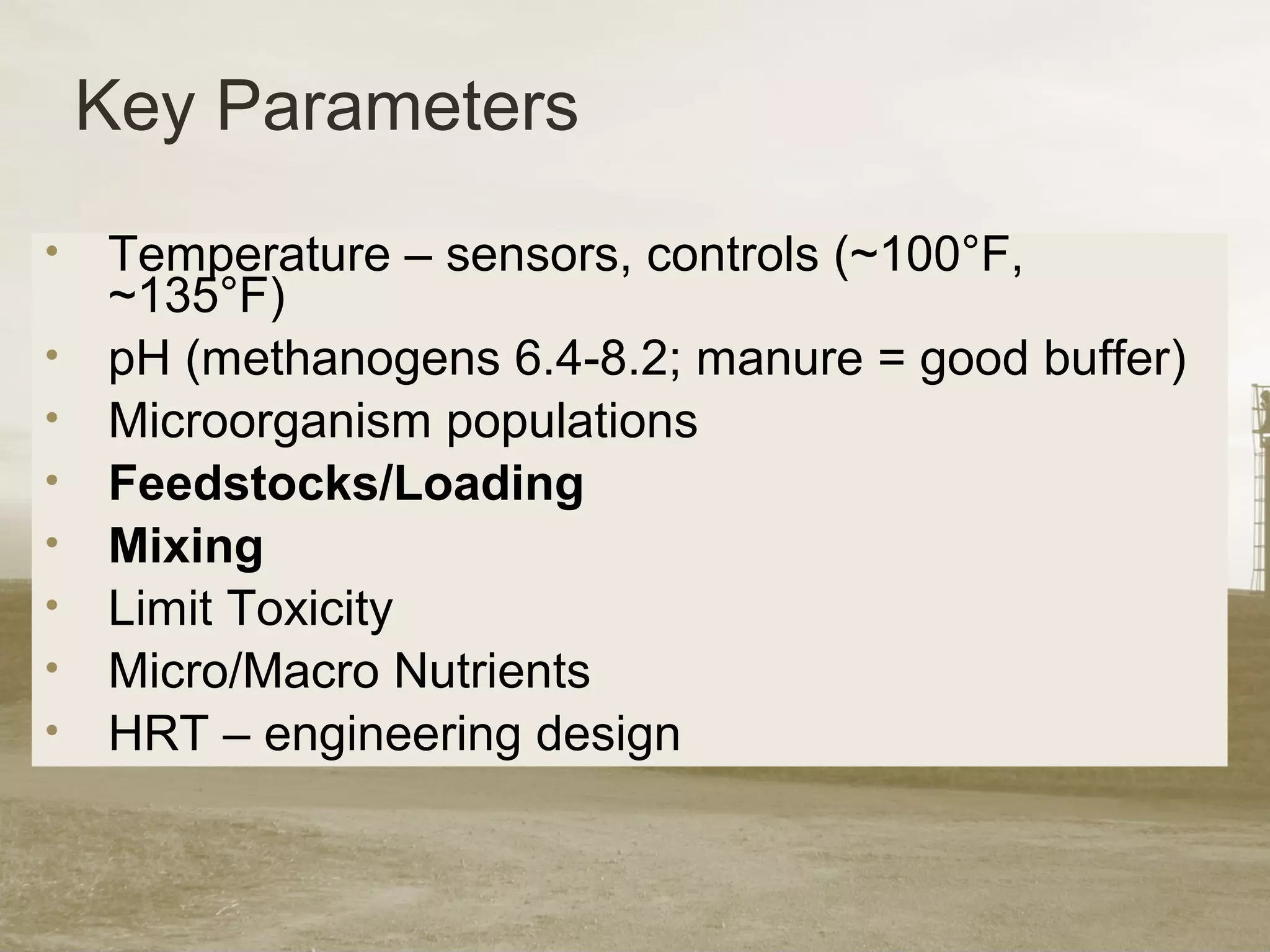

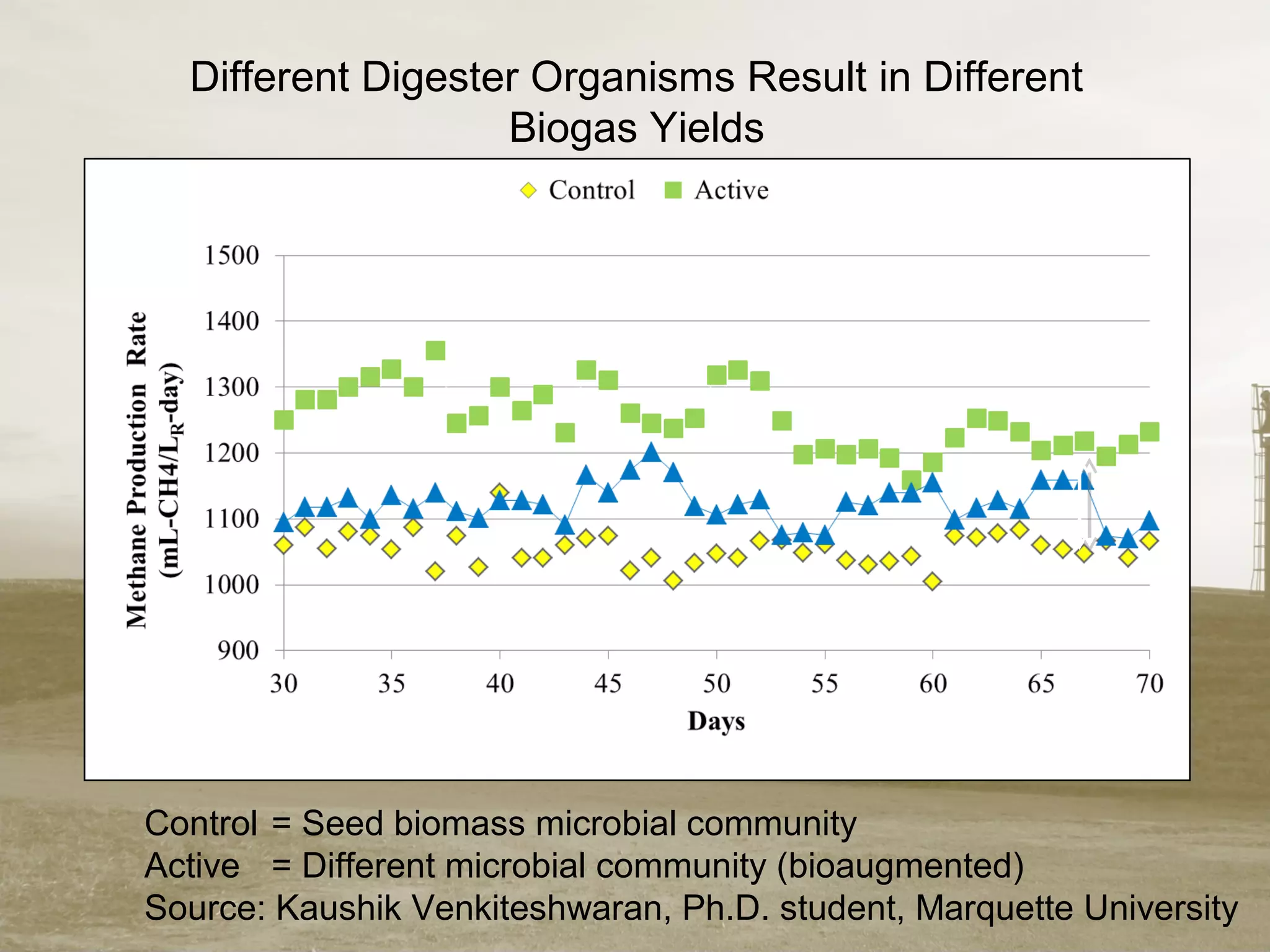

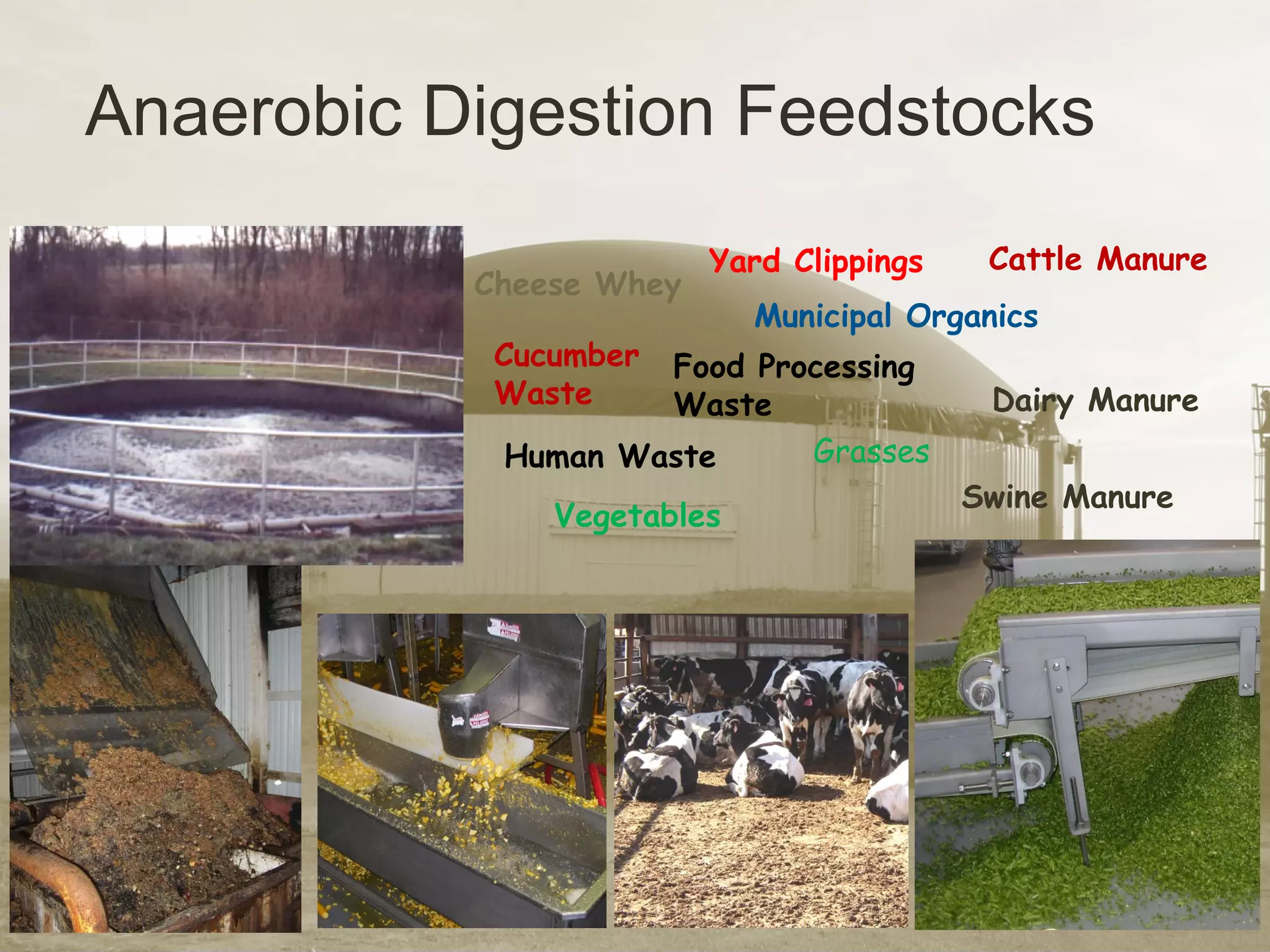

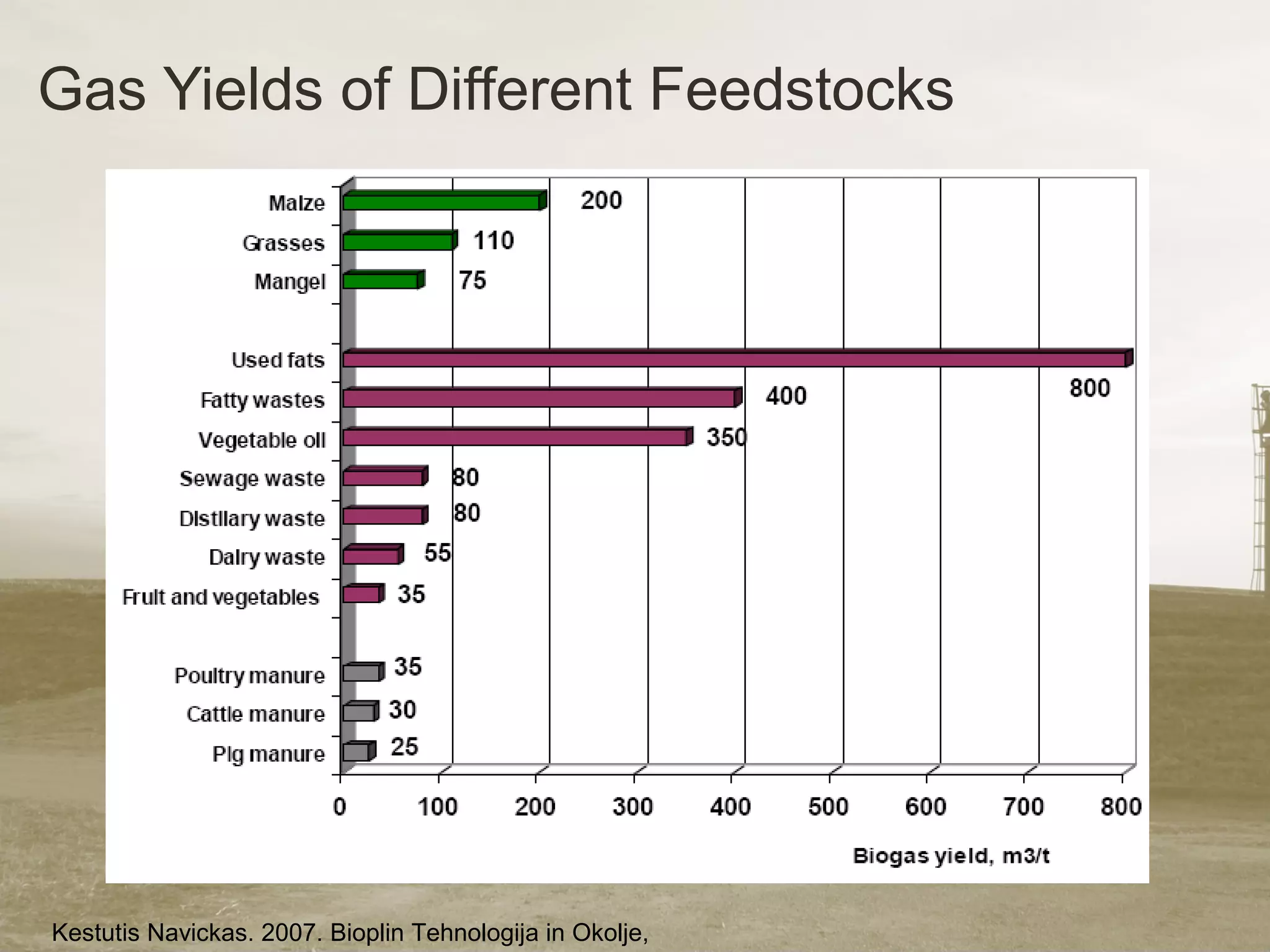

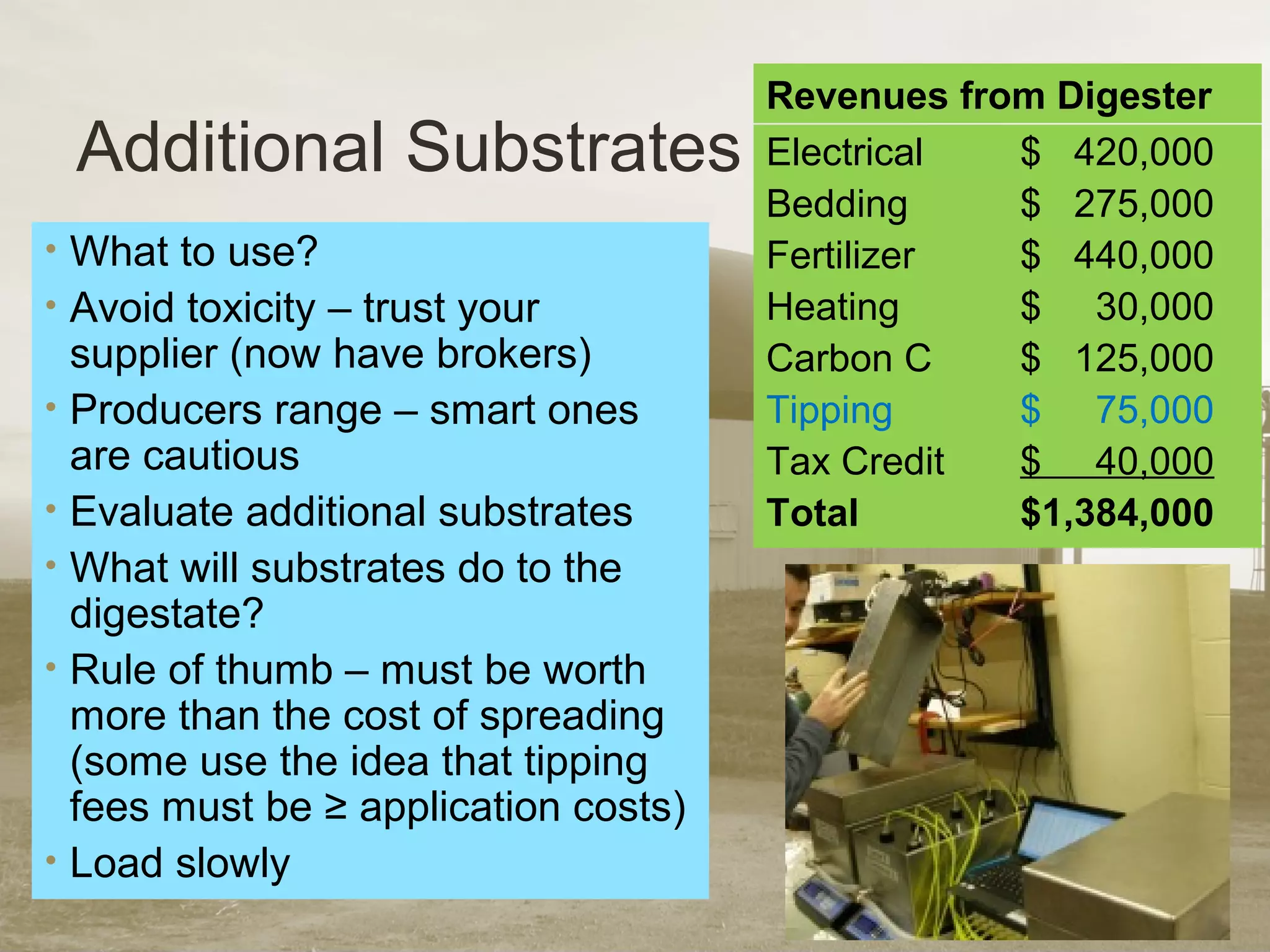

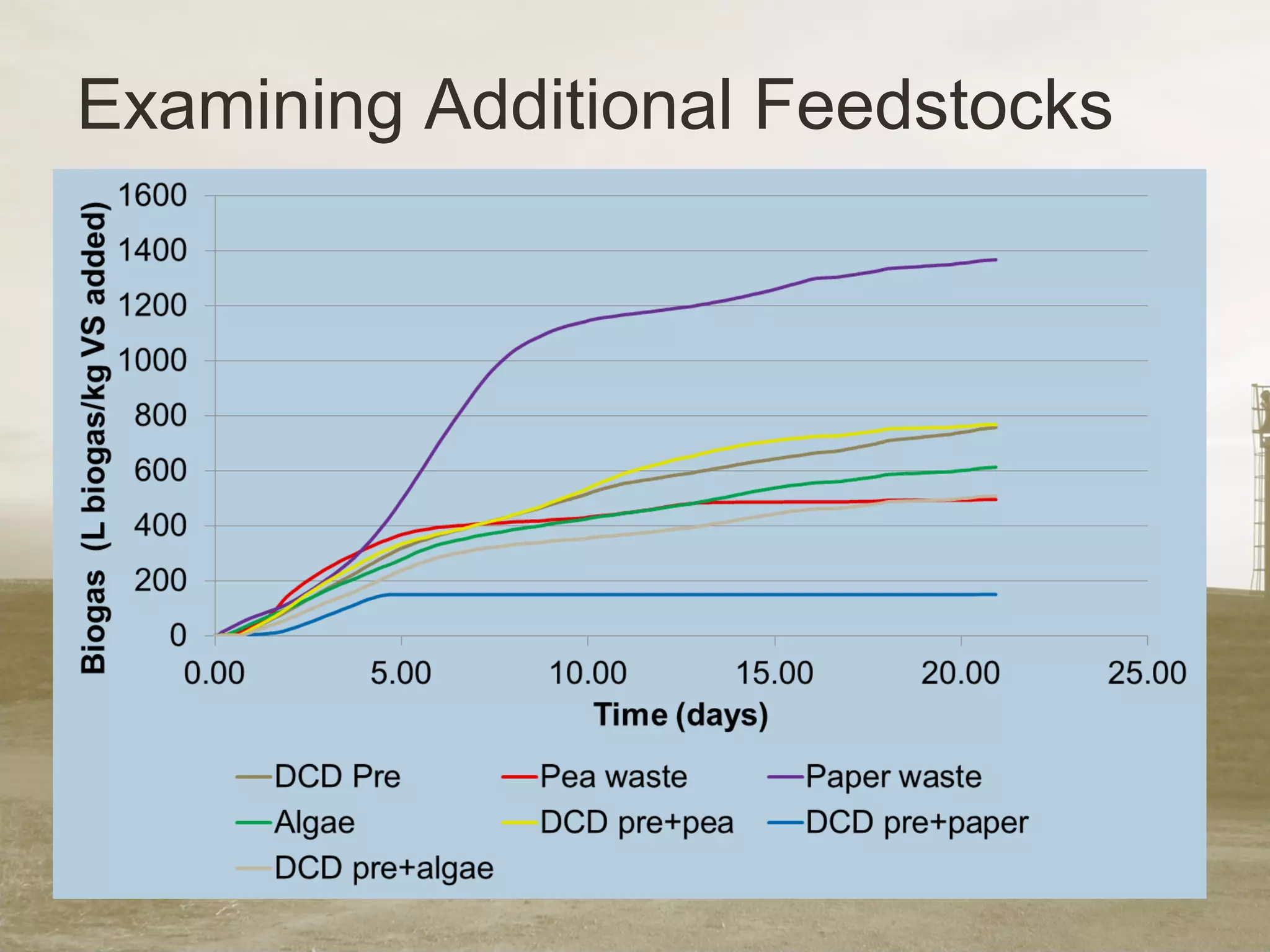

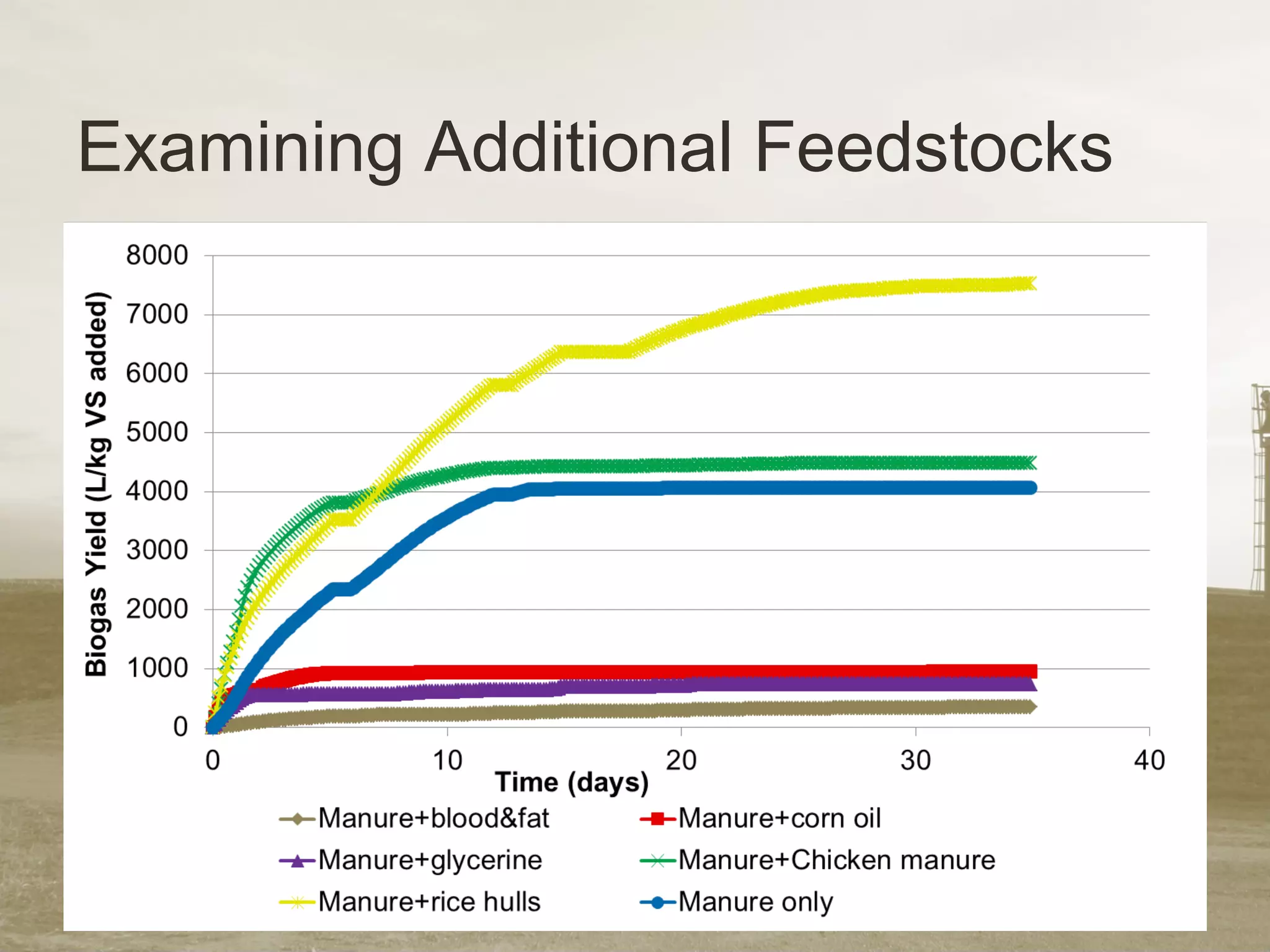

The document discusses the optimization of anaerobic digesters, emphasizing their benefits such as energy independence, reduced greenhouse gases, and potential revenue streams. It outlines the anaerobic digestion process, critical parameters for optimal performance, the importance of feedstock evaluation, and lessons learned from case studies. Key takeaways include that digesters require careful management, mixing is vital yet variable, and operators must understand the system for effective optimization.