The document discusses the SAE-AISI designation system for classifying steel compositions. It provides details on:

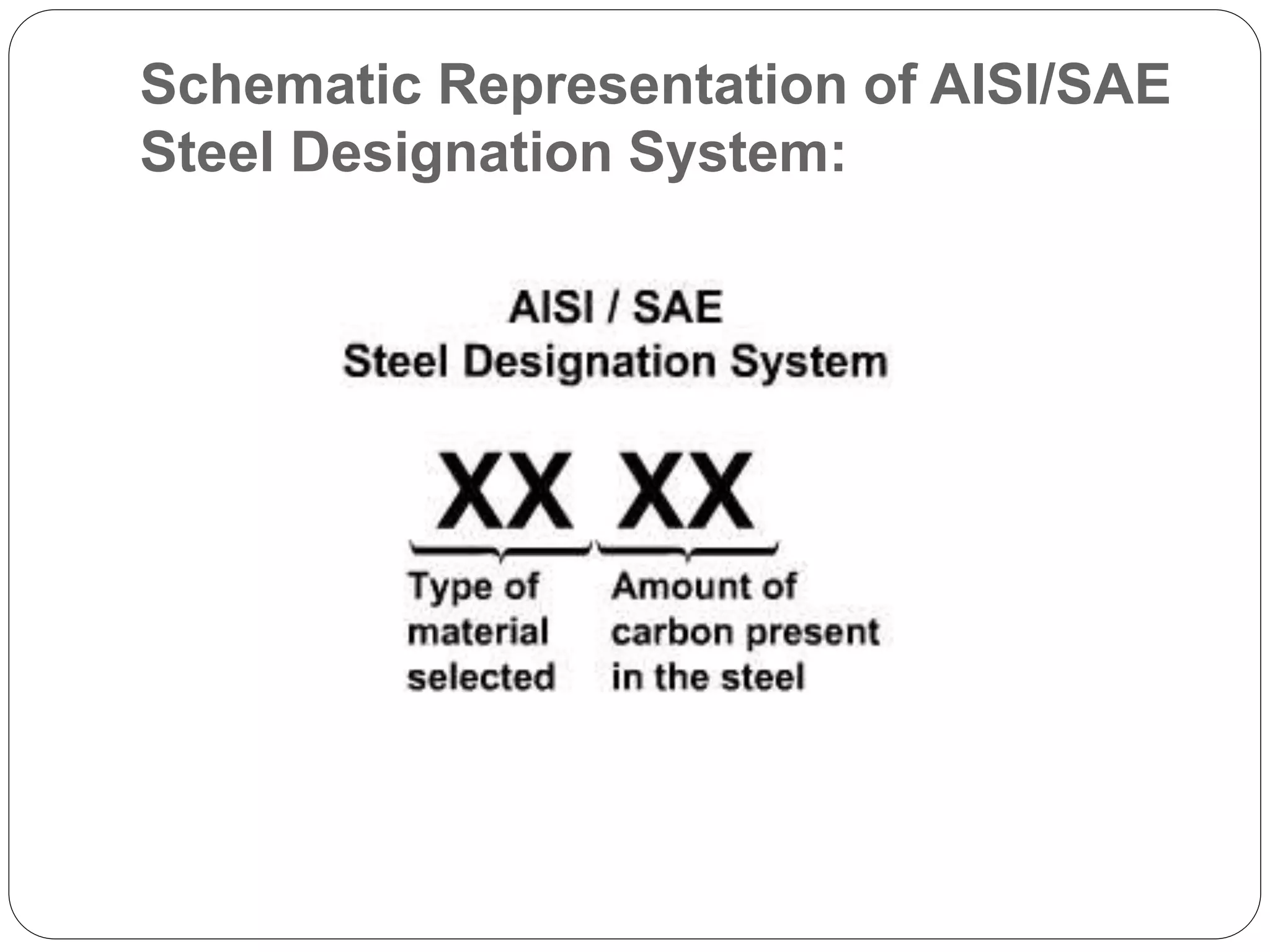

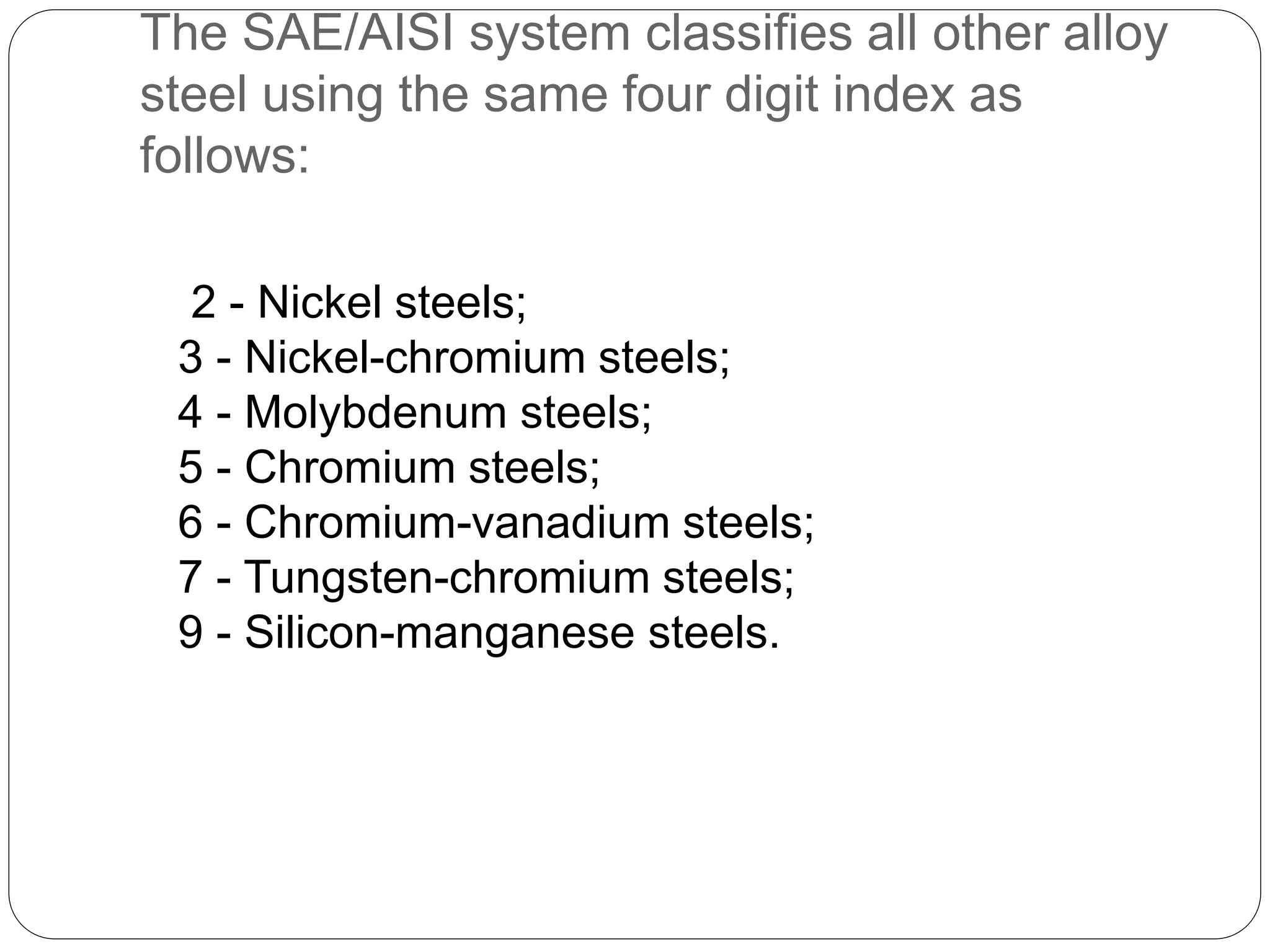

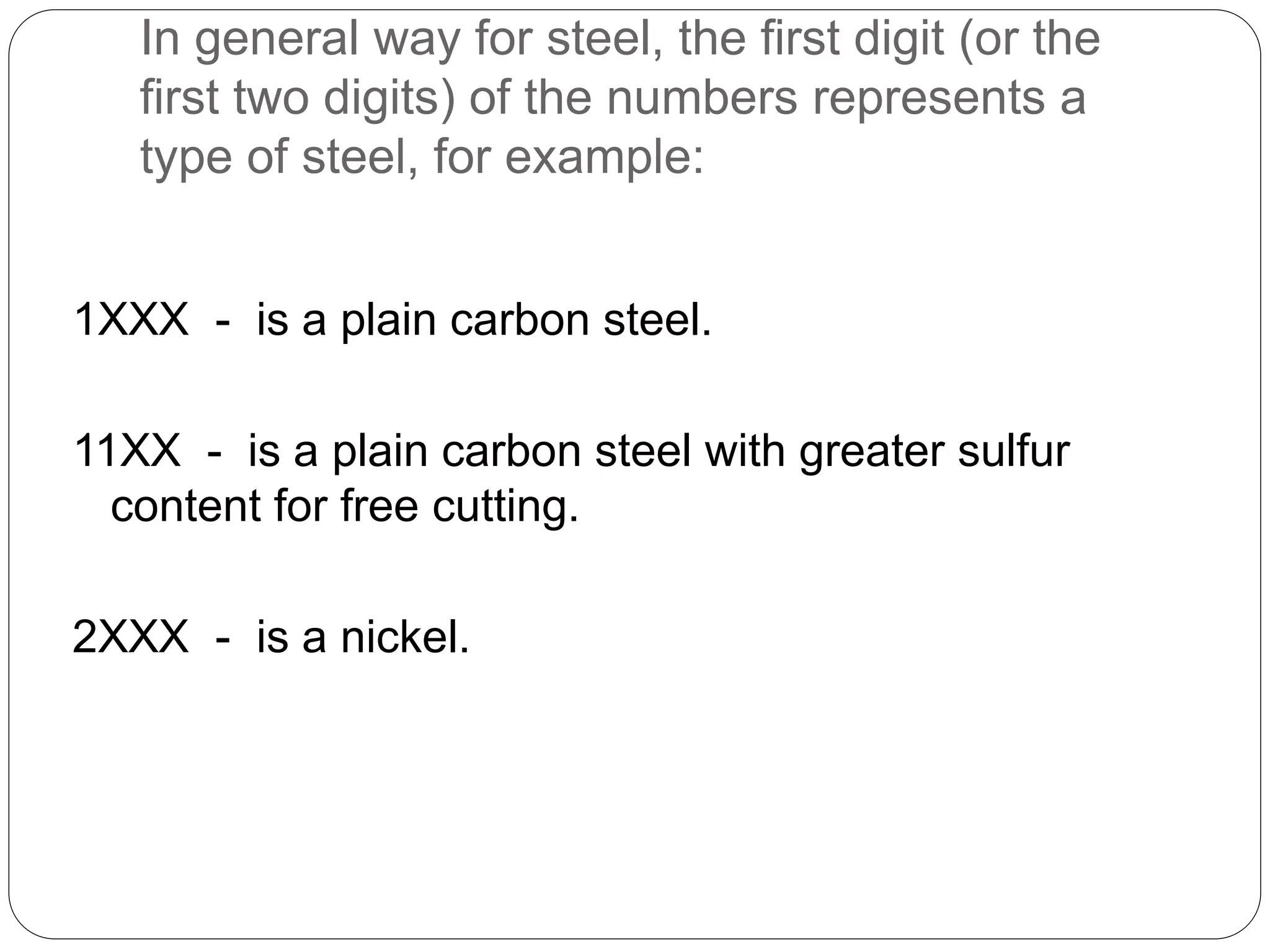

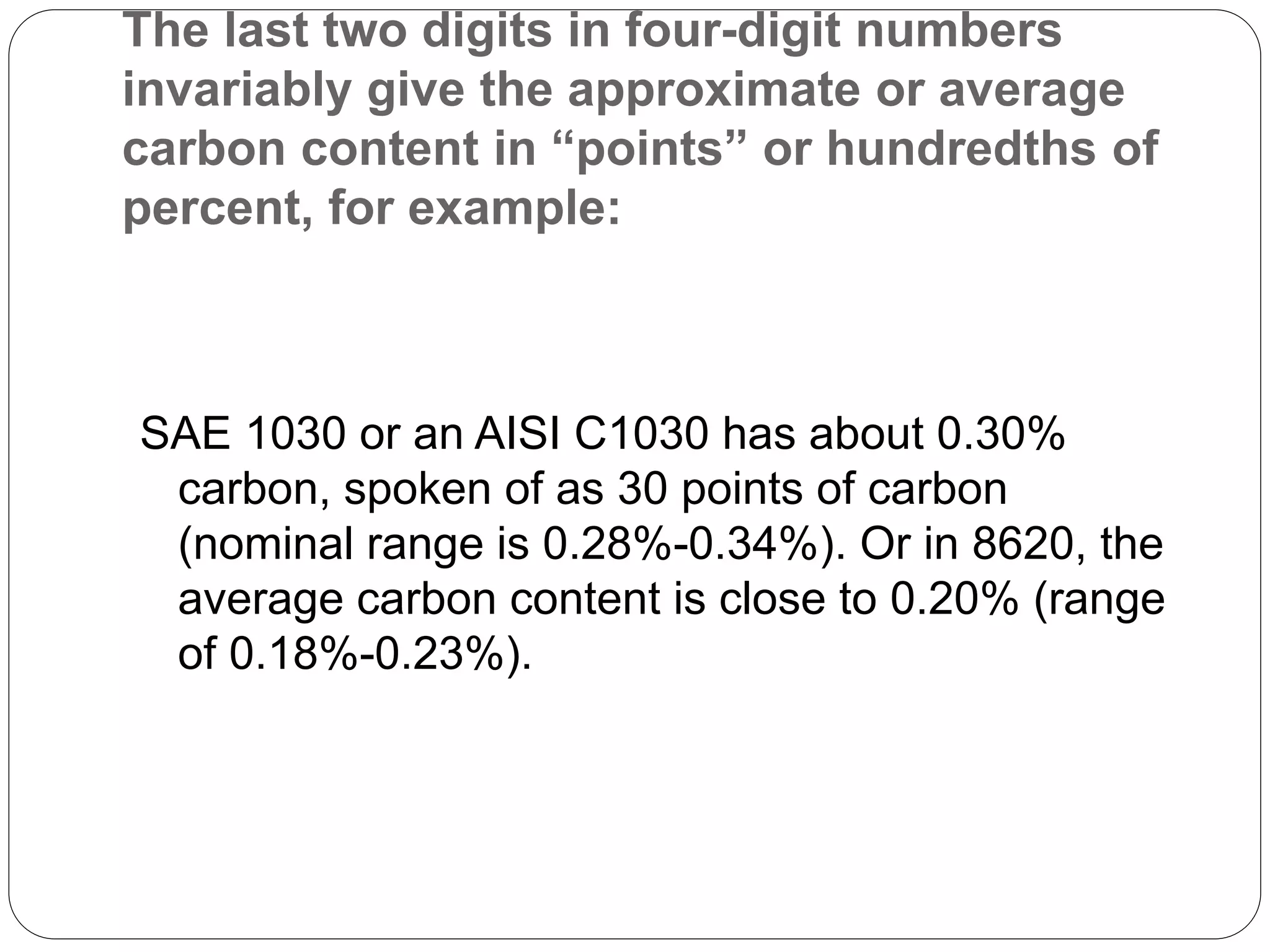

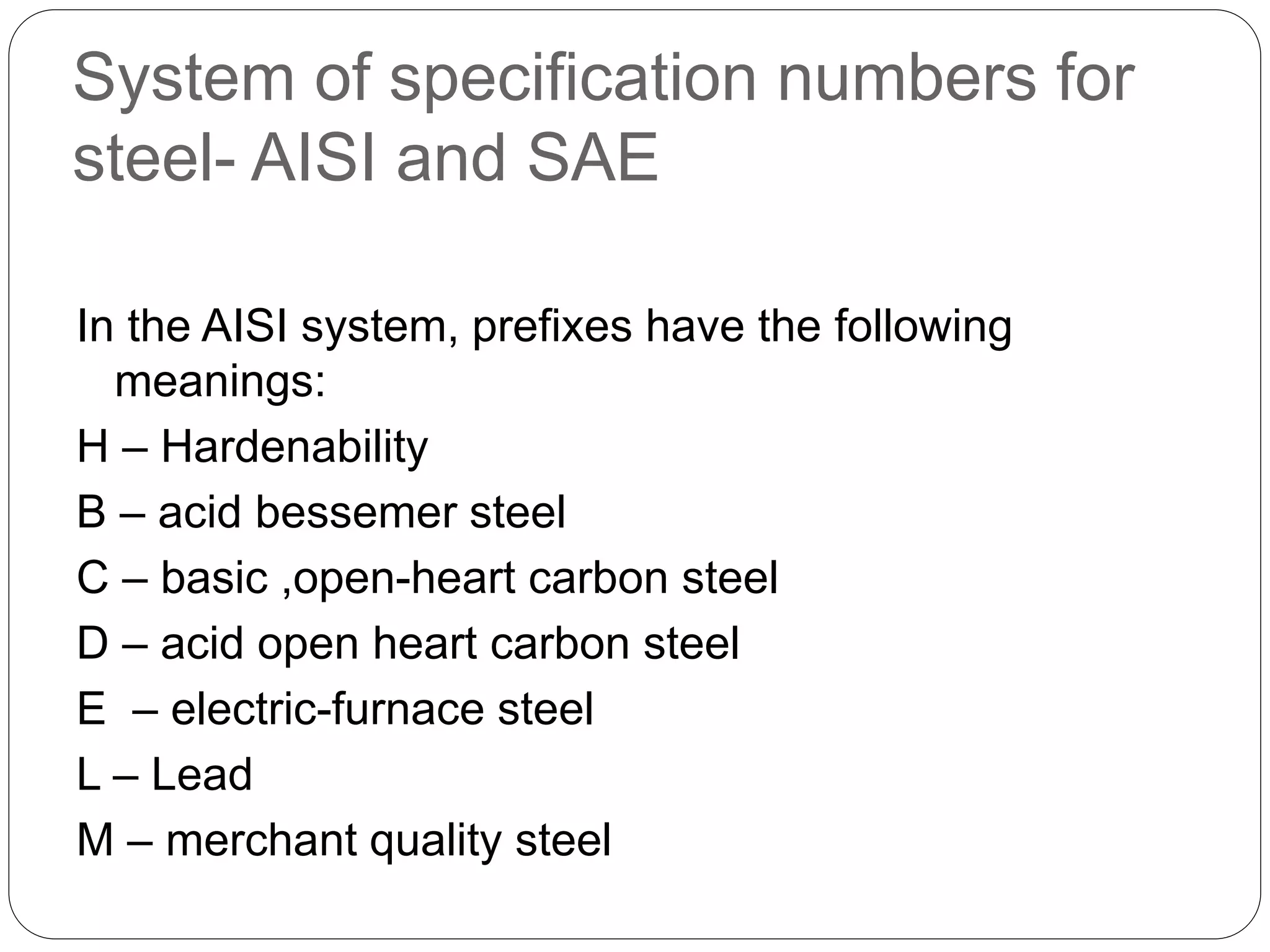

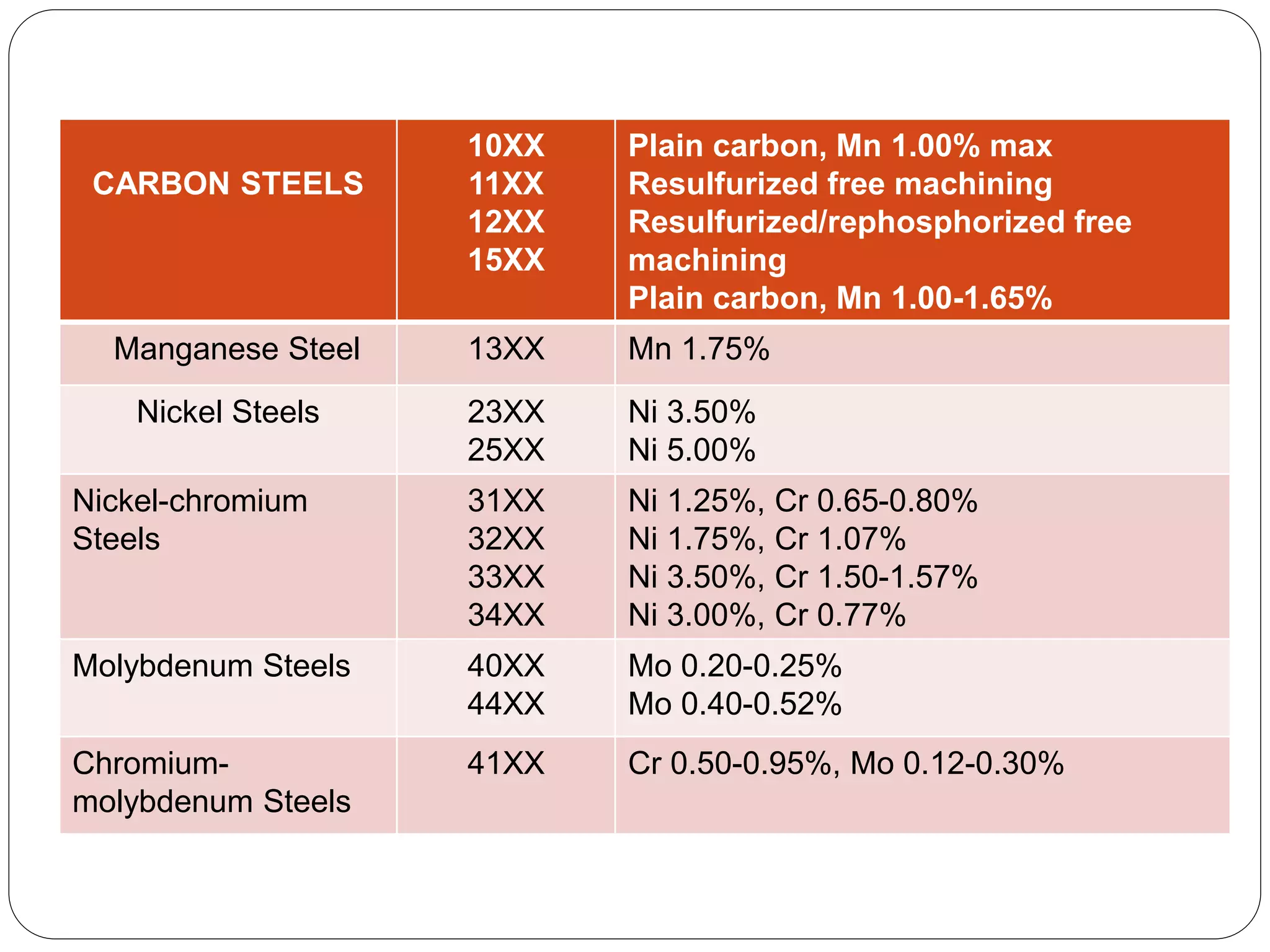

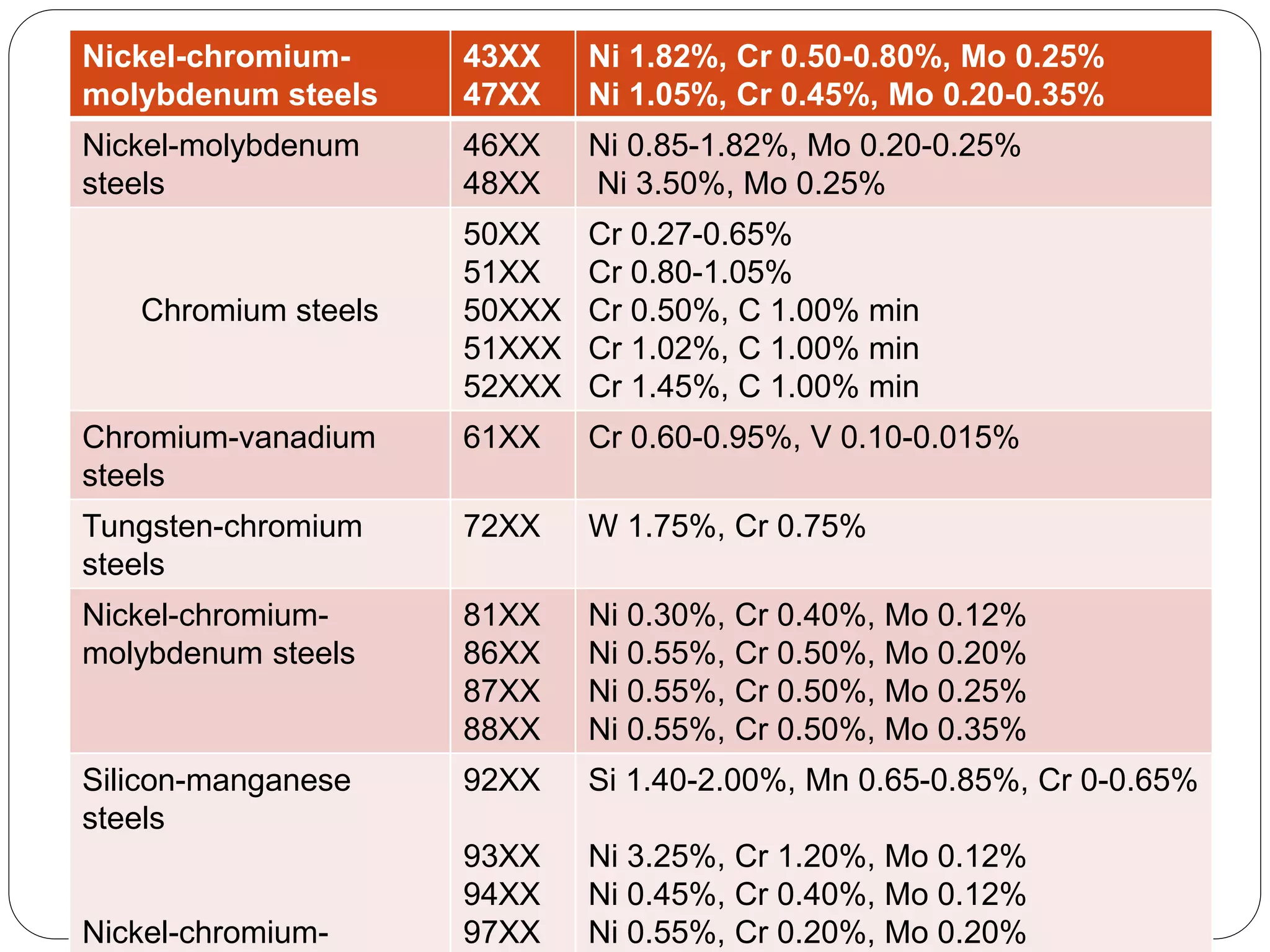

- The SAE and AISI systems use a numerical code, typically 4 digits, to specify steel grades based on chemical composition, most notably carbon content.

- The first digit(s) indicate the steel type (e.g. carbon, alloy) and the last two digits indicate average carbon percentage.

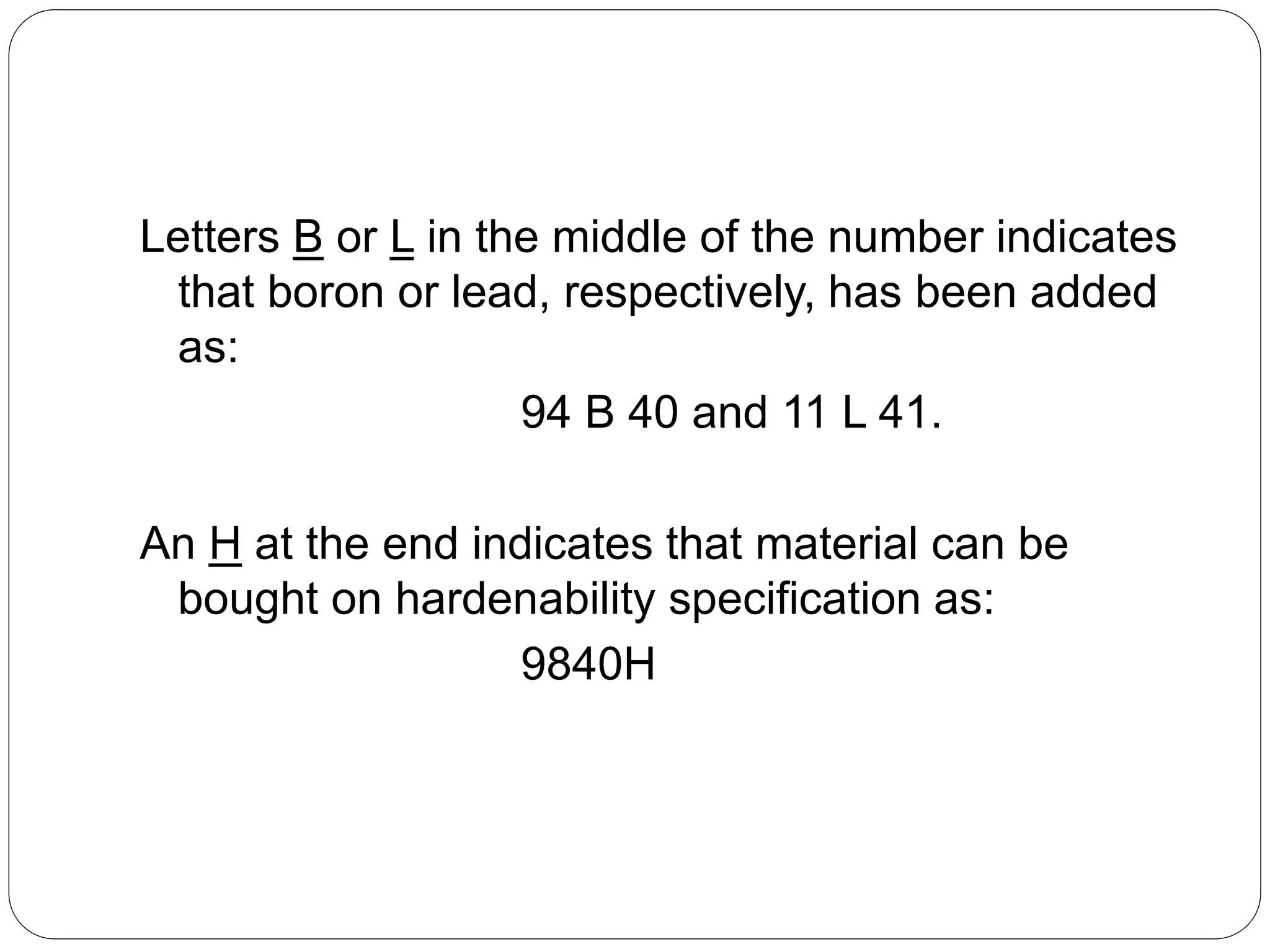

- Prefixes in the AISI system provide additional information on manufacturing method or alloying elements.

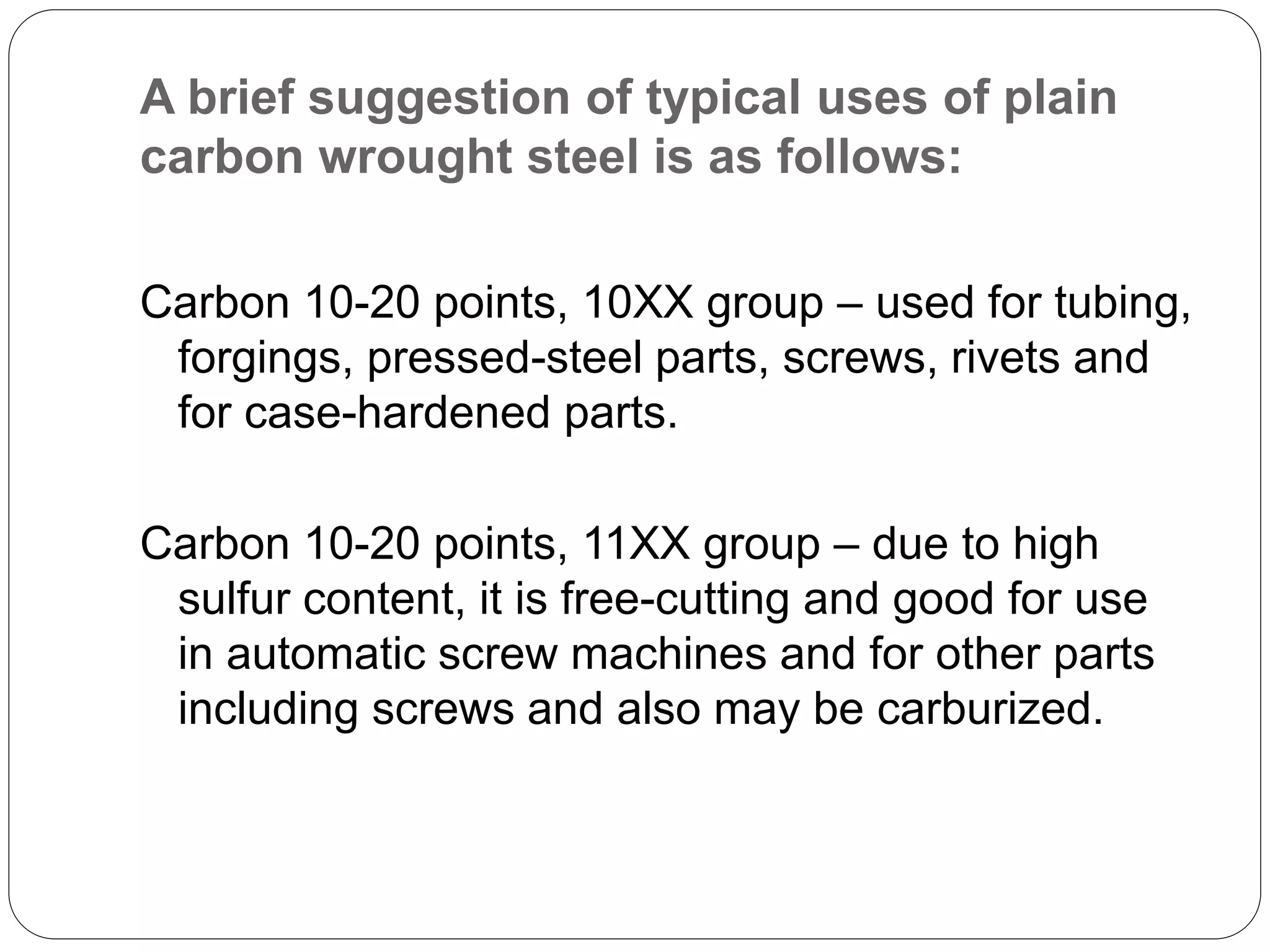

- Various steel types are designated by their chemical compositions and typical applications are outlined.