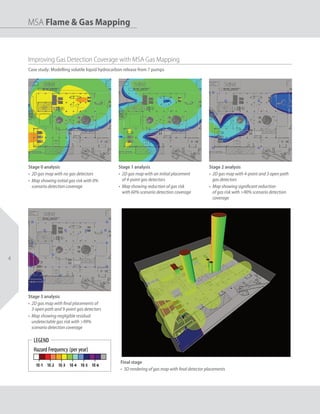

MSA Flame & Gas Mapping provides solutions for evaluating and reducing flame and gas risks in process facilities by optimally positioning detection systems. It employs systematic methods that go beyond traditional approaches to assess risks associated with different gas releases and environmental conditions. The process culminates in a comprehensive mapping report that includes detector placements, coverage assessments, and residual risk evaluations.