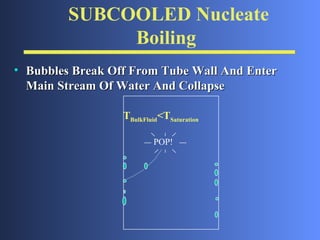

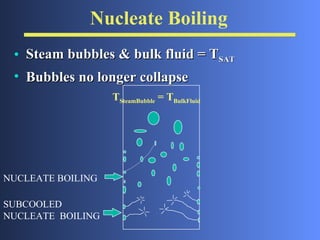

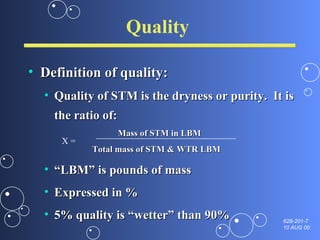

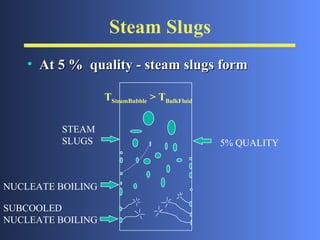

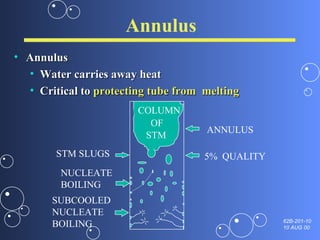

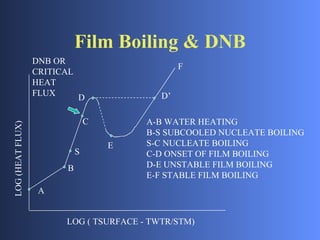

This document summarizes key concepts in basic steam engineering related to nucleate boiling in boilers. It describes the process of nucleate boiling and how variations in circulation can lead to temporary changes in water level known as shrink and swell. Key terms are defined, such as subcooled nucleate boiling, quality, annulus formation, thermal driving head, head losses, and boiler end points including the end point of circulation. Causes and limits of natural circulation in boilers are also covered.