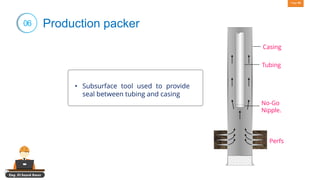

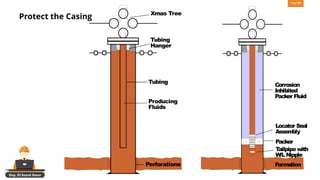

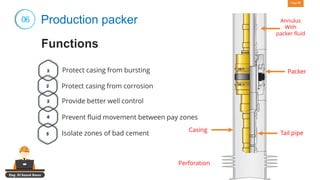

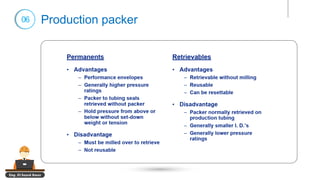

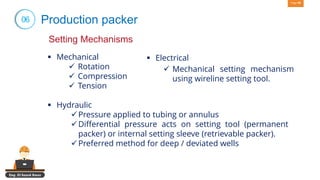

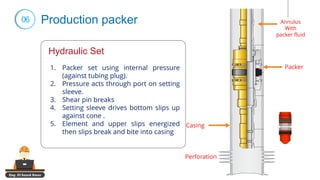

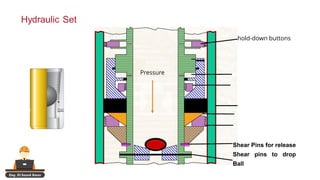

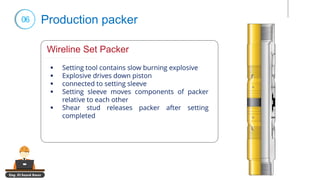

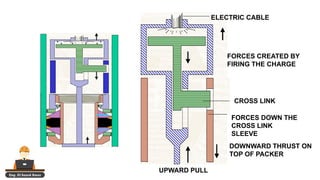

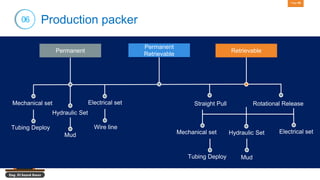

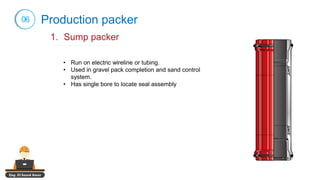

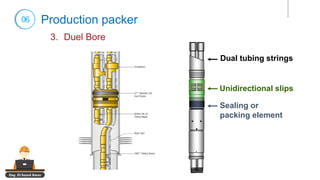

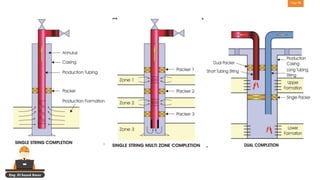

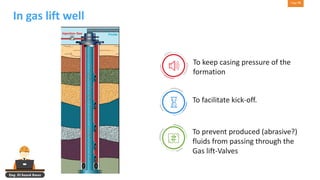

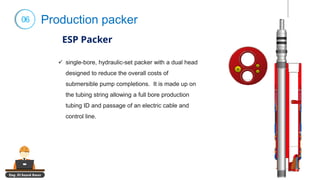

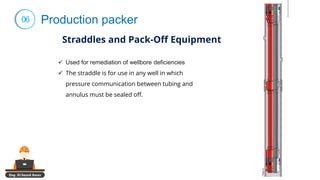

Eng. El Sayed Amer, a senior process and production engineer with a degree in petroleum and natural gas engineering, has extensive experience in well drilling and completion, including work at Suez Oil Co and Weatherford Drilling. The document details the functions and types of production packers, including their setting mechanisms and advantages associated with various designs like retrievable and permanent packers. Additionally, it outlines their applications in well isolation and production management within oil and gas operations.