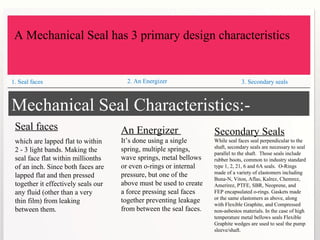

Mechanical seals have become essential in various industries, including refineries and wastewater plants, due to their effectiveness in reducing environmental contamination. They consist of seal faces, an energizer, and secondary seals, which prevent leakage in fluid pumps and have largely replaced traditional braided packing. As environmental concerns grow globally, the use of mechanical seals is expected to increase further, providing customized solutions for different industrial applications.