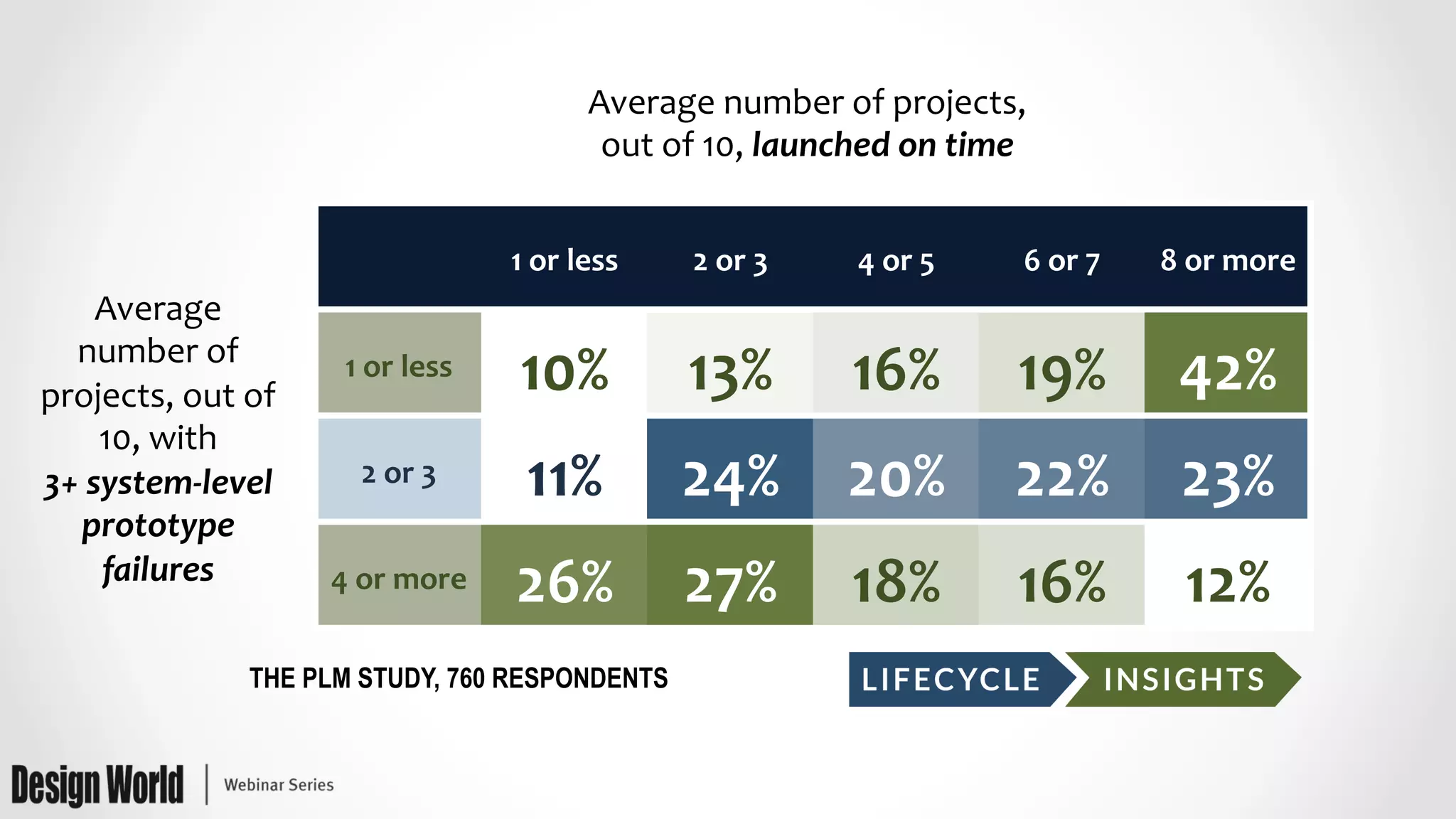

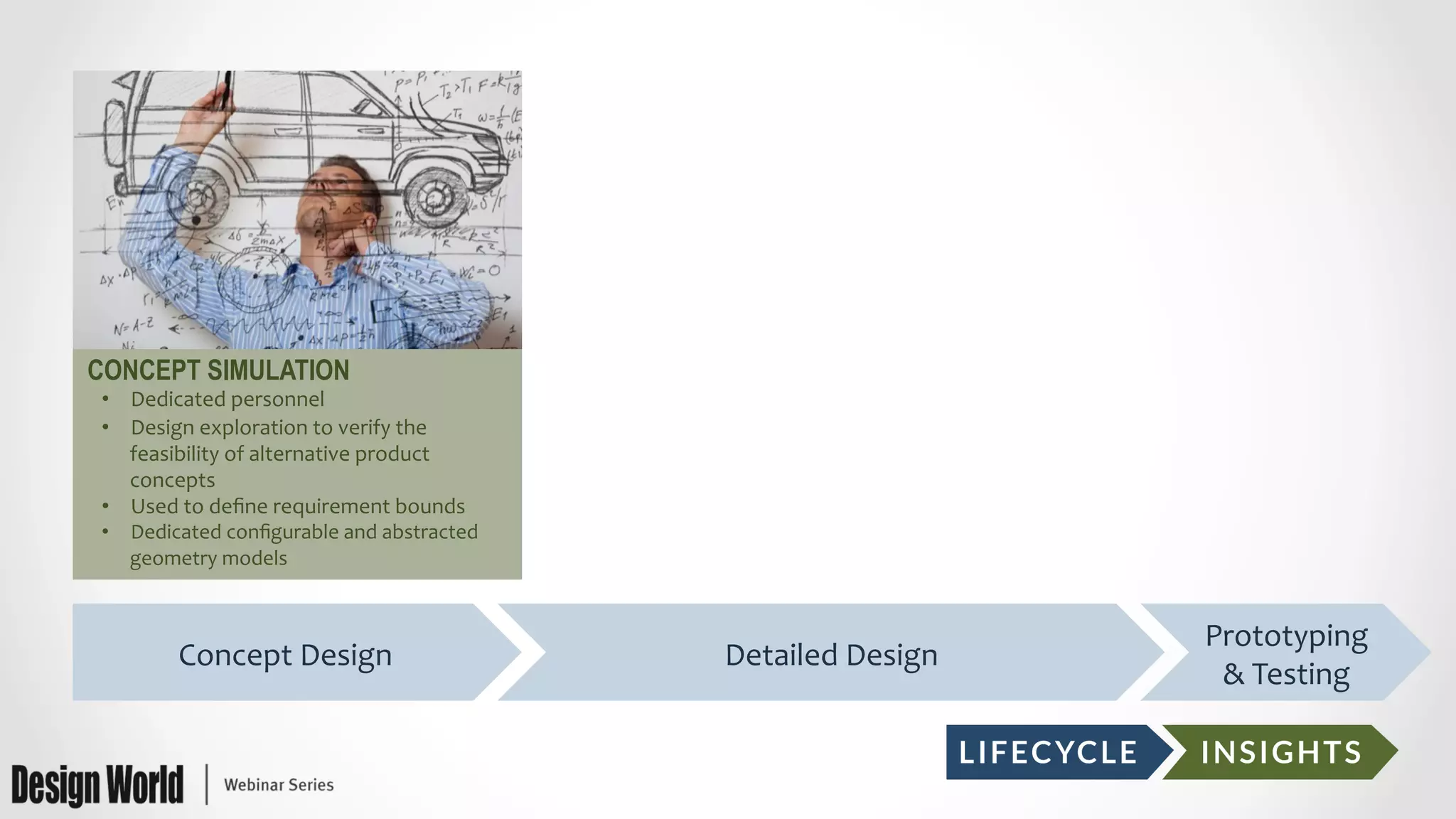

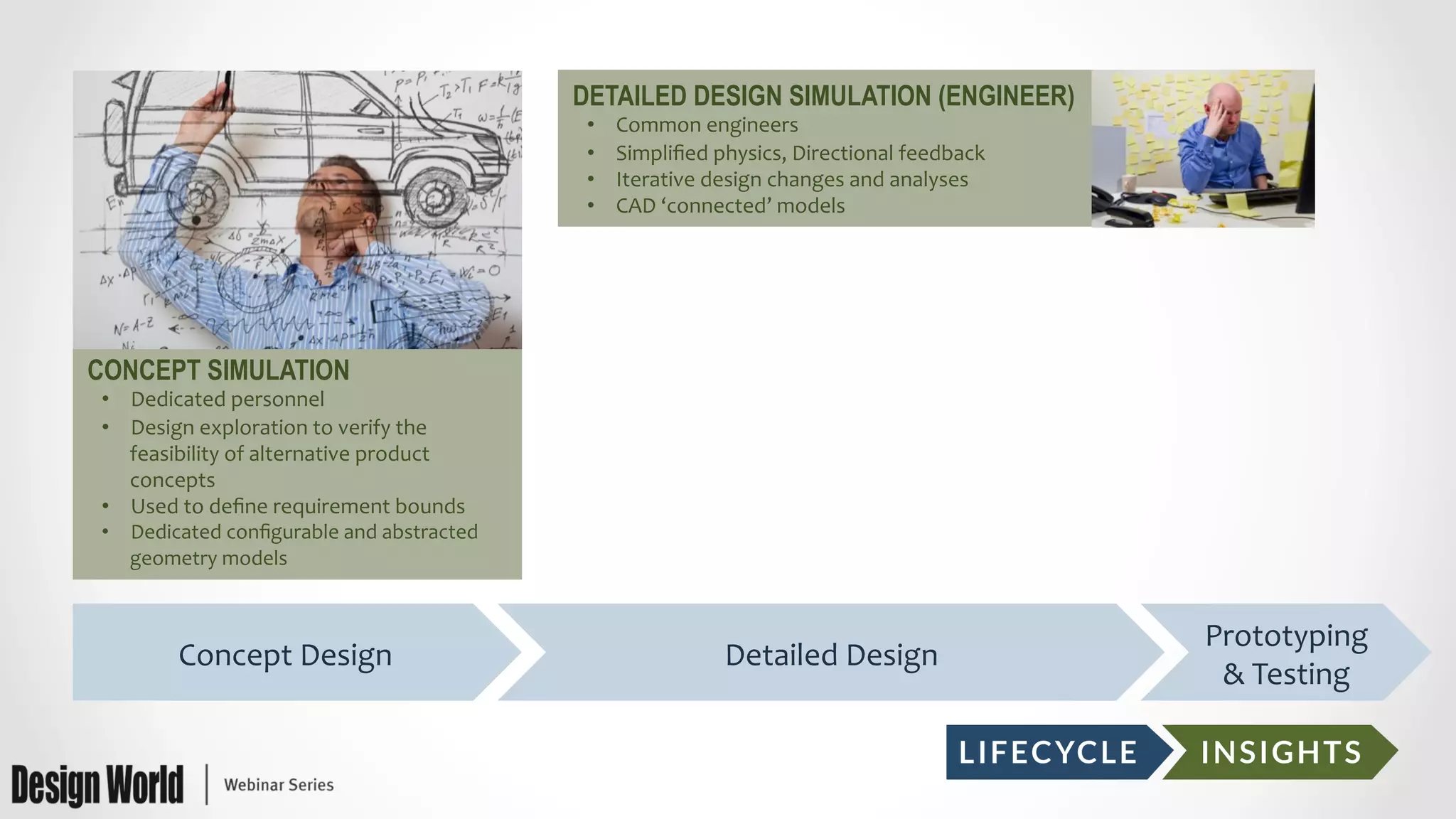

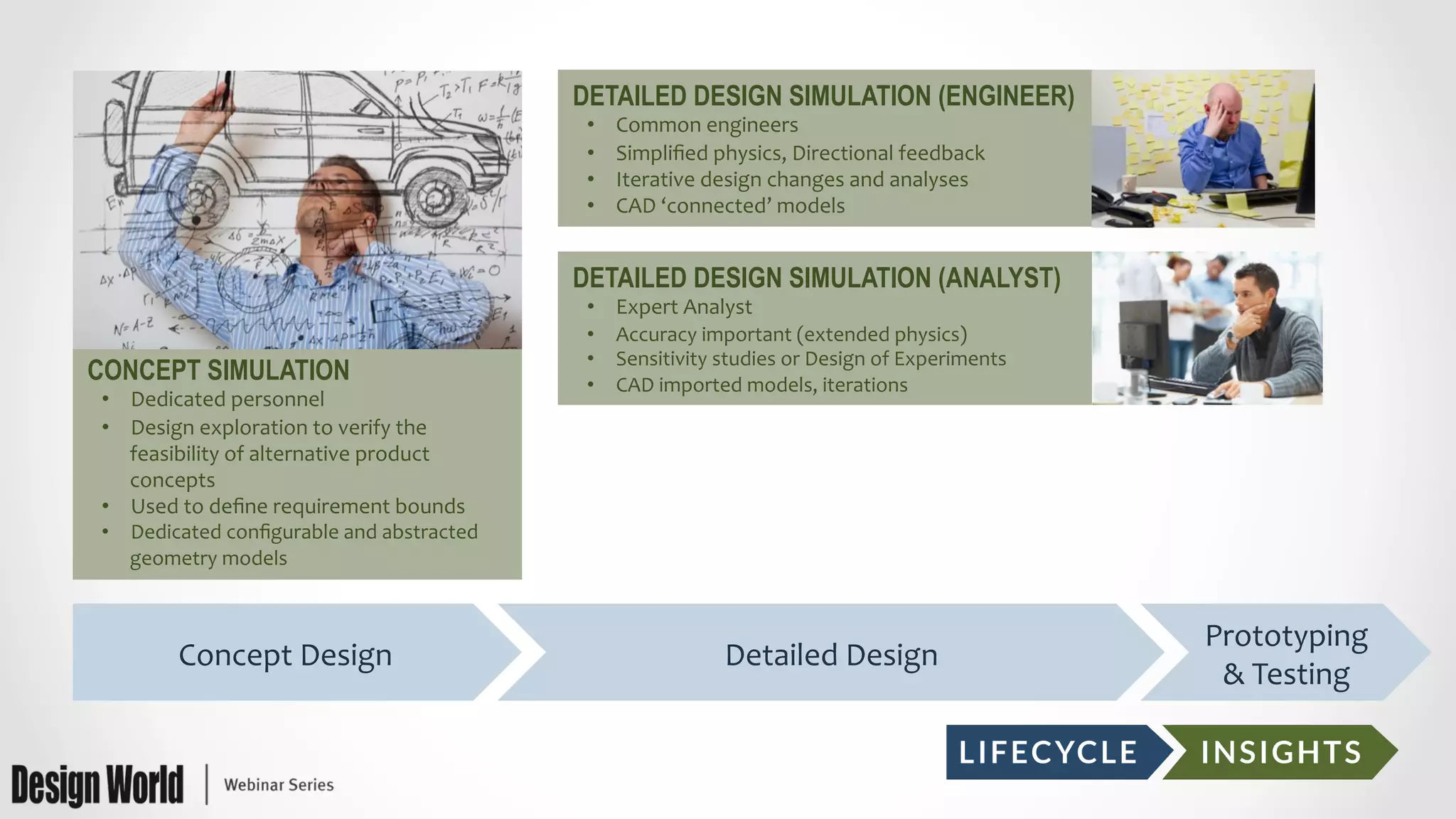

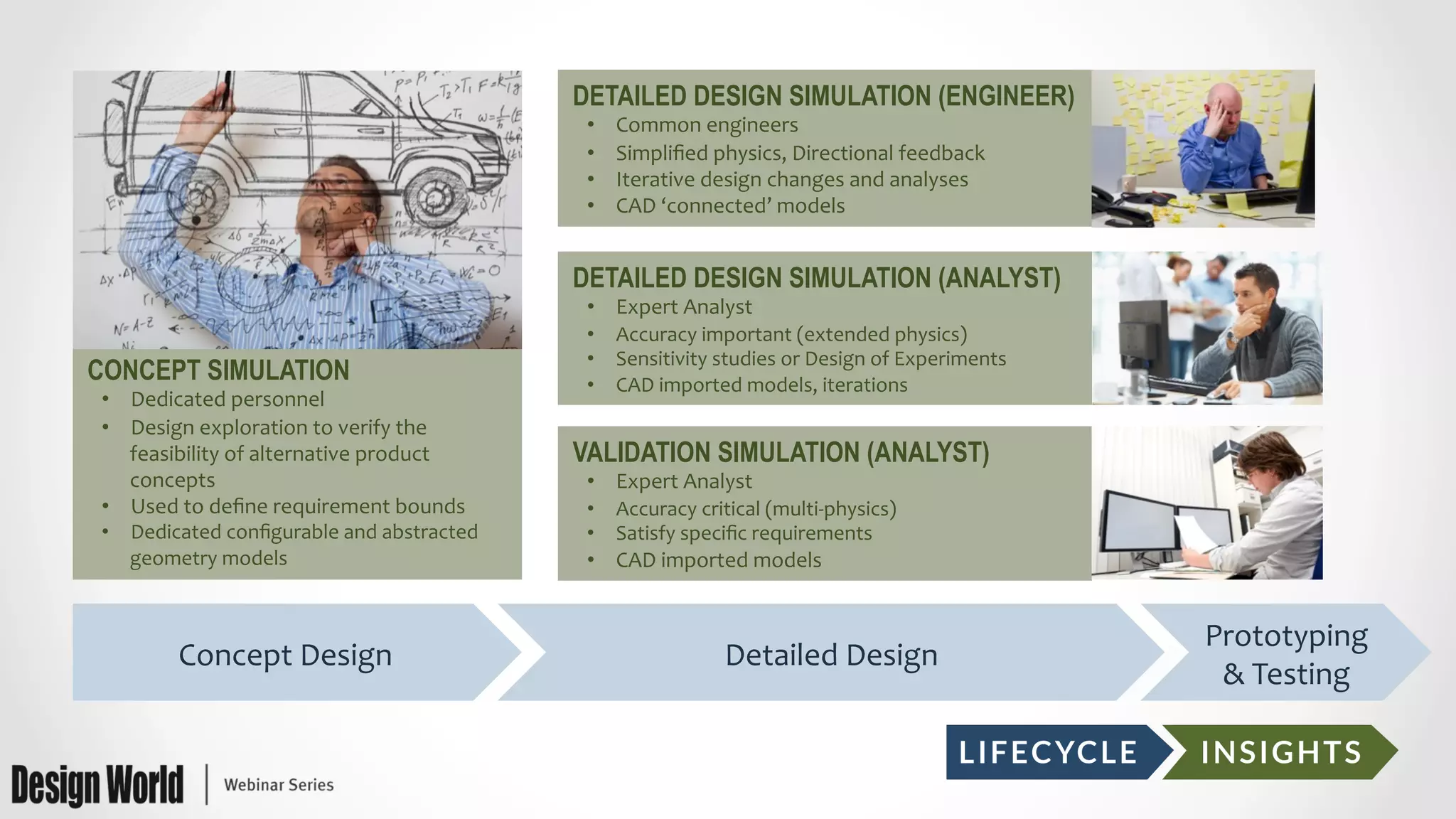

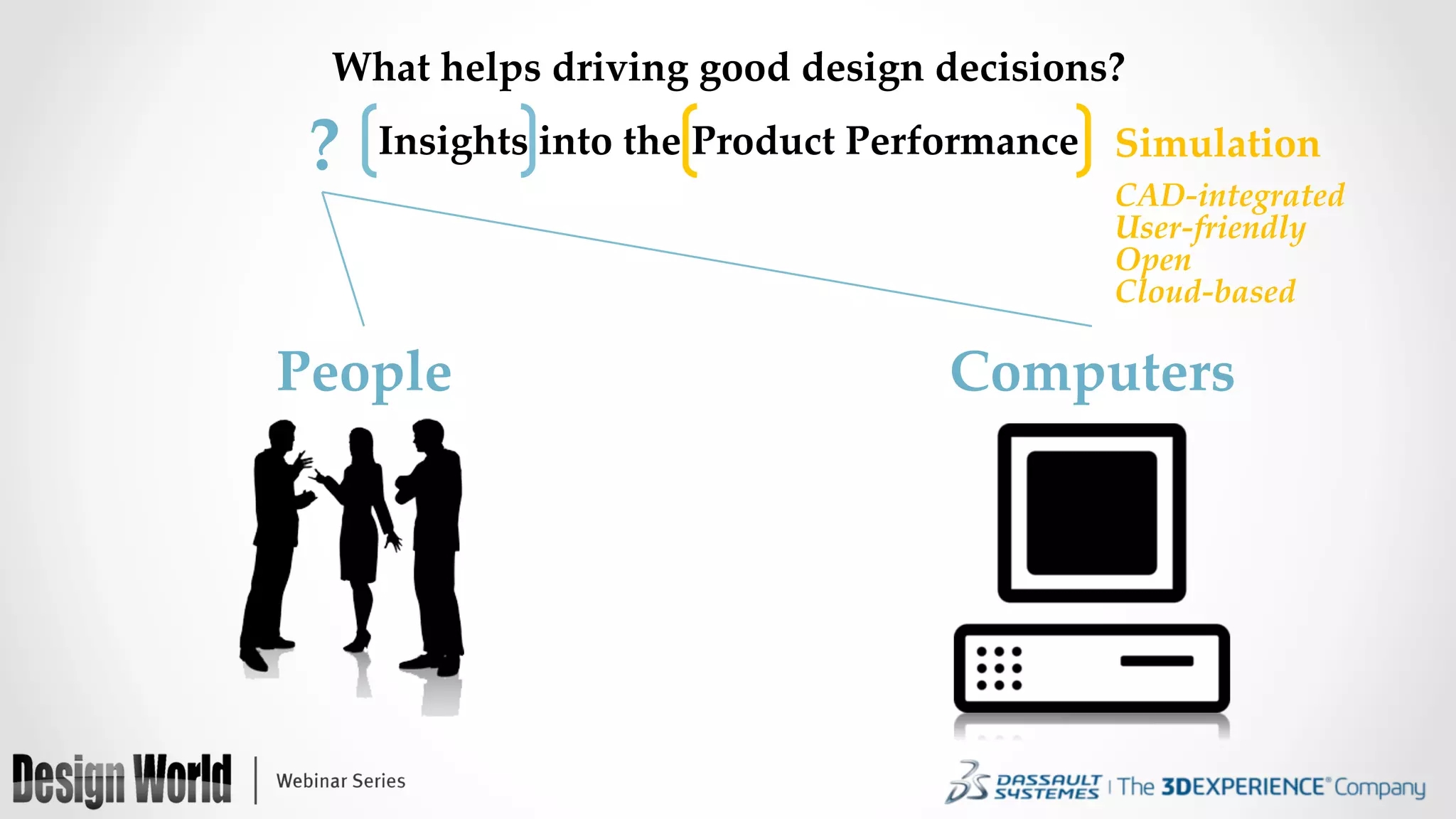

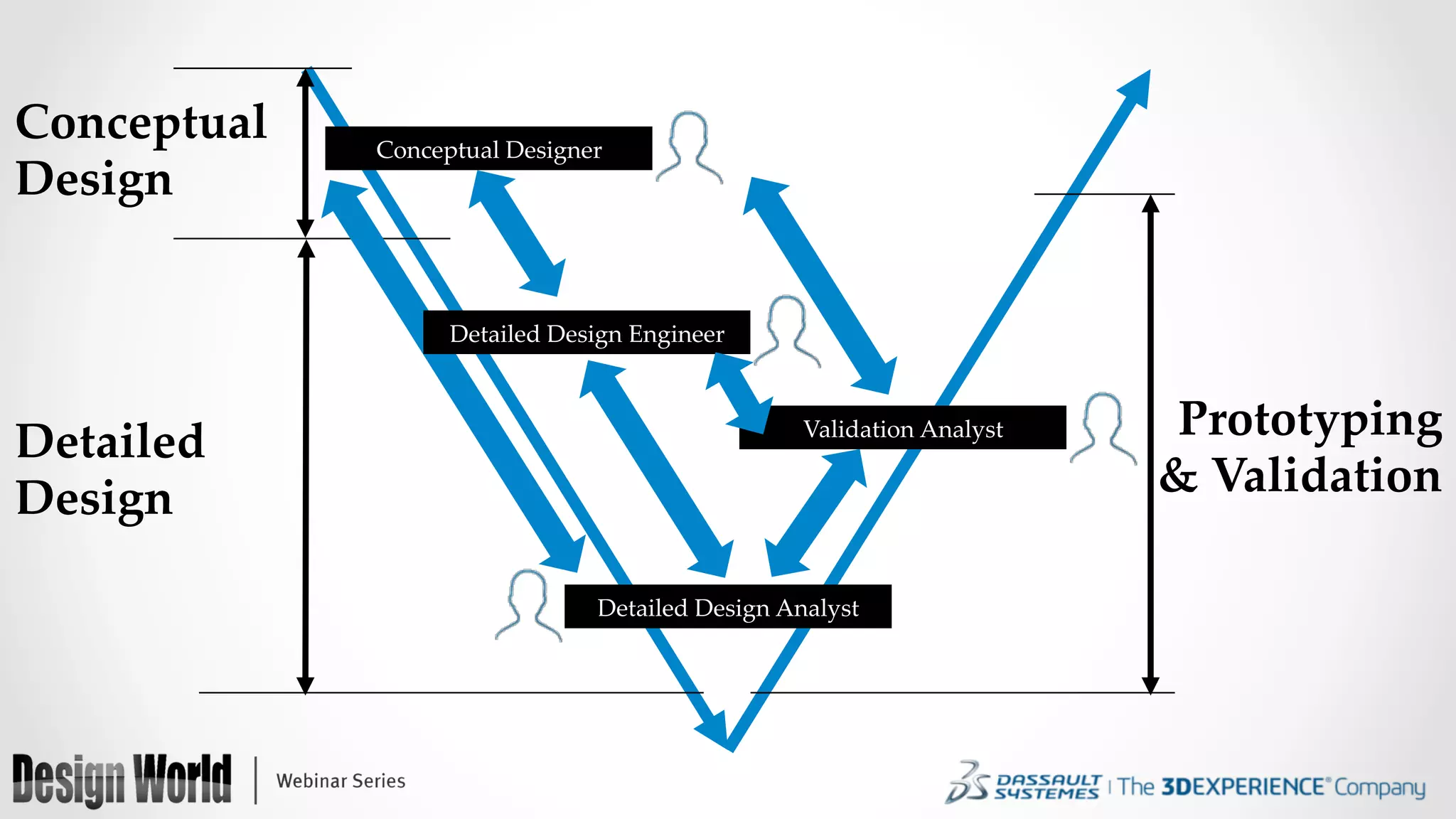

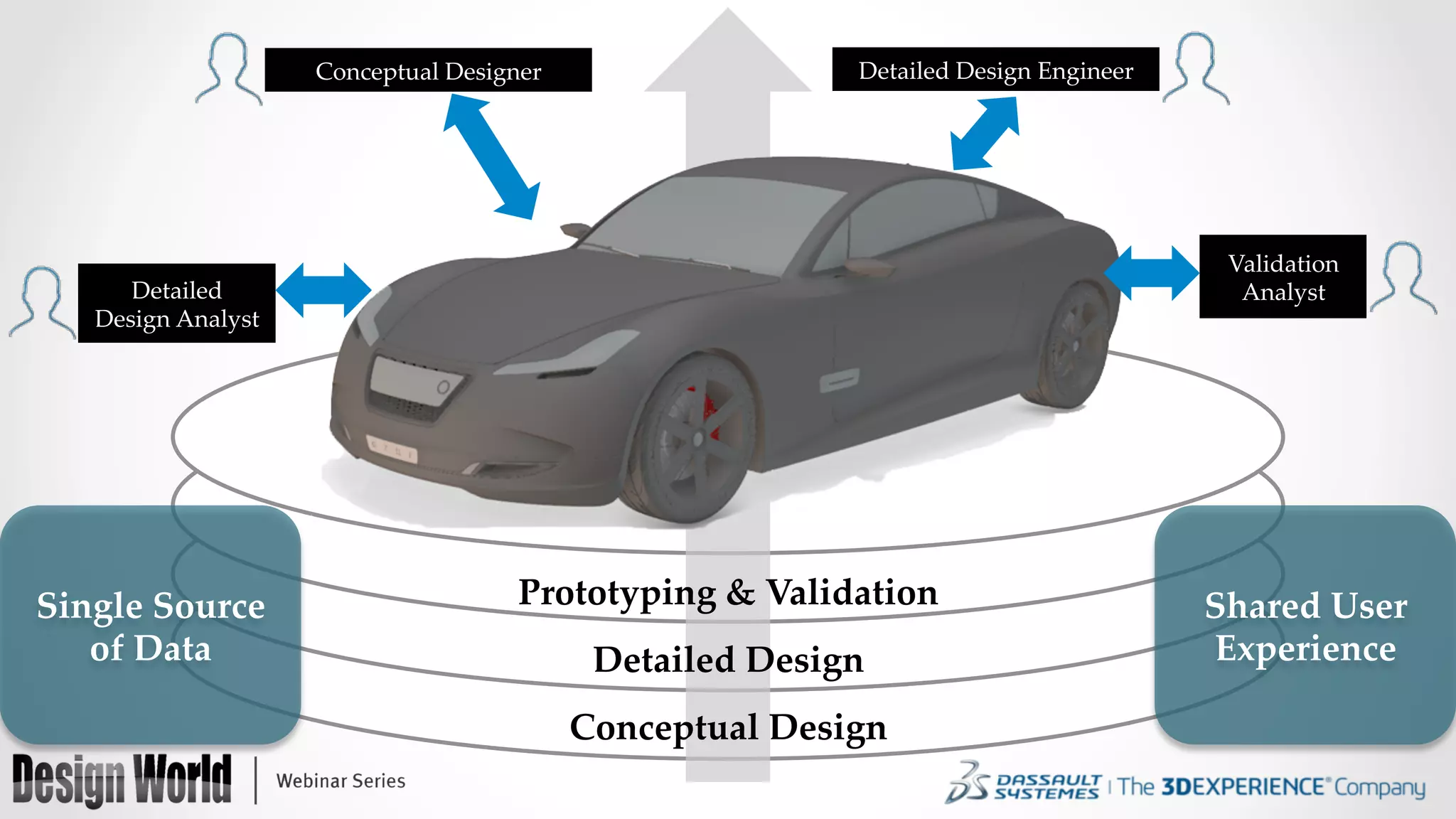

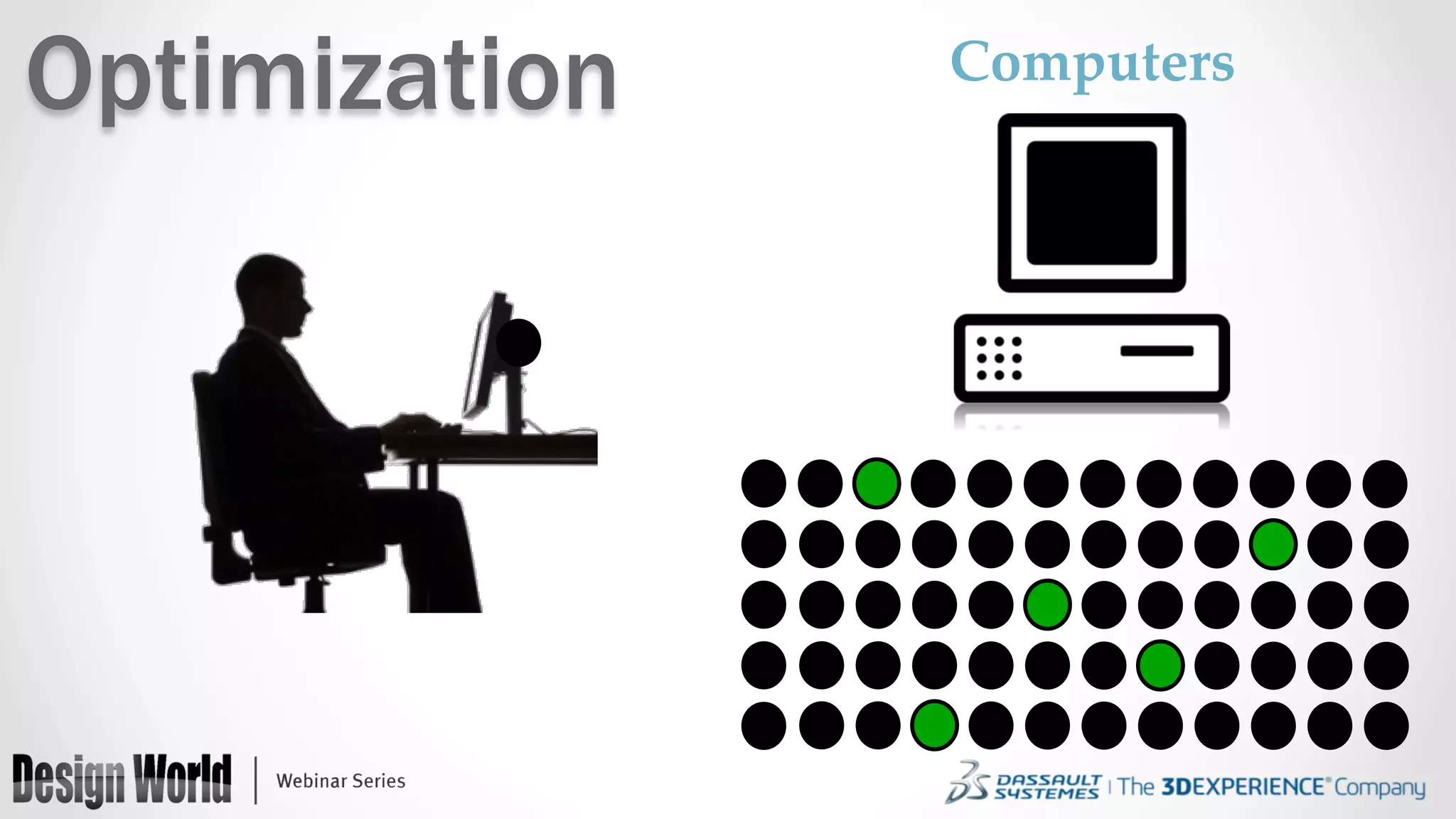

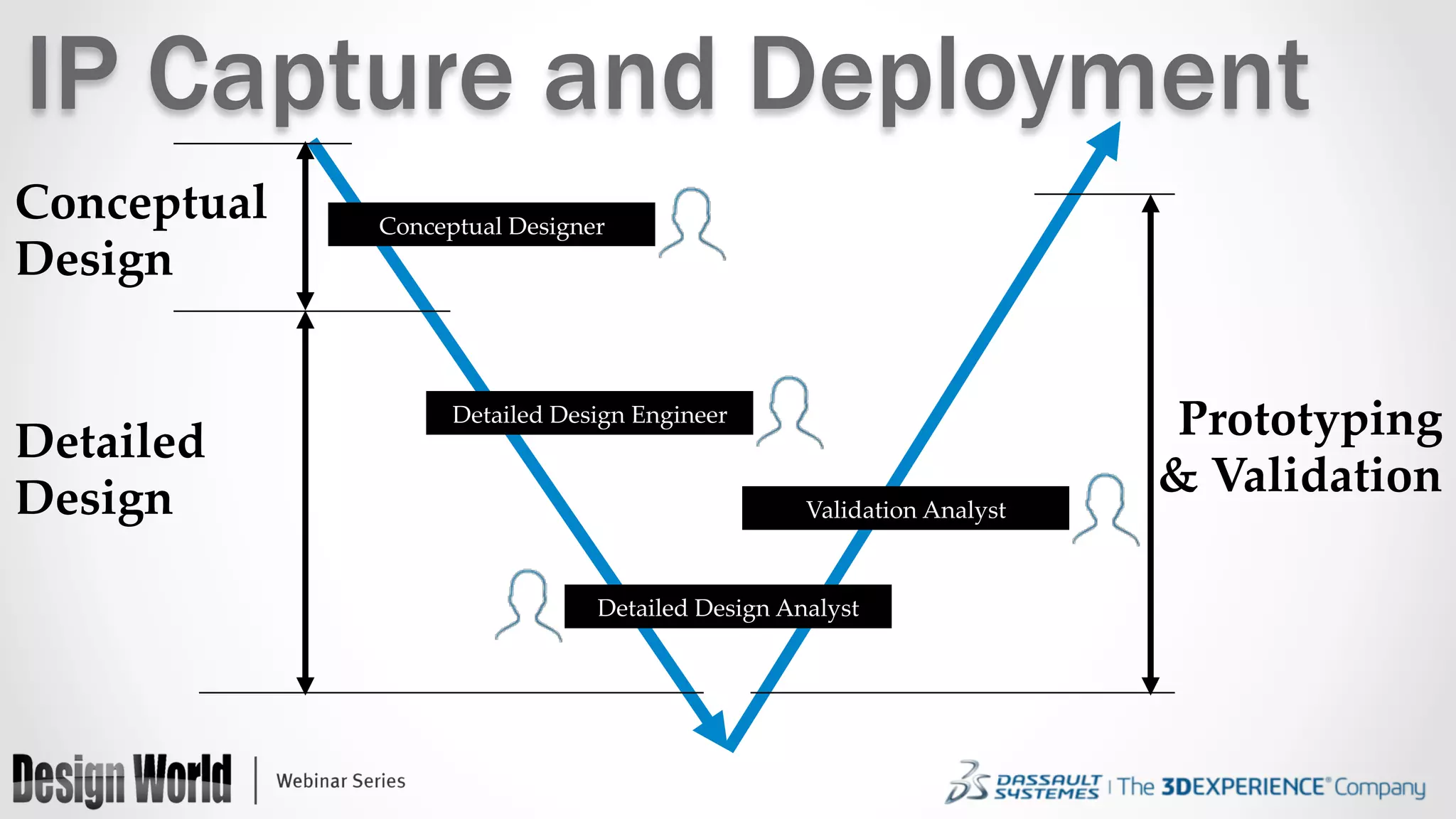

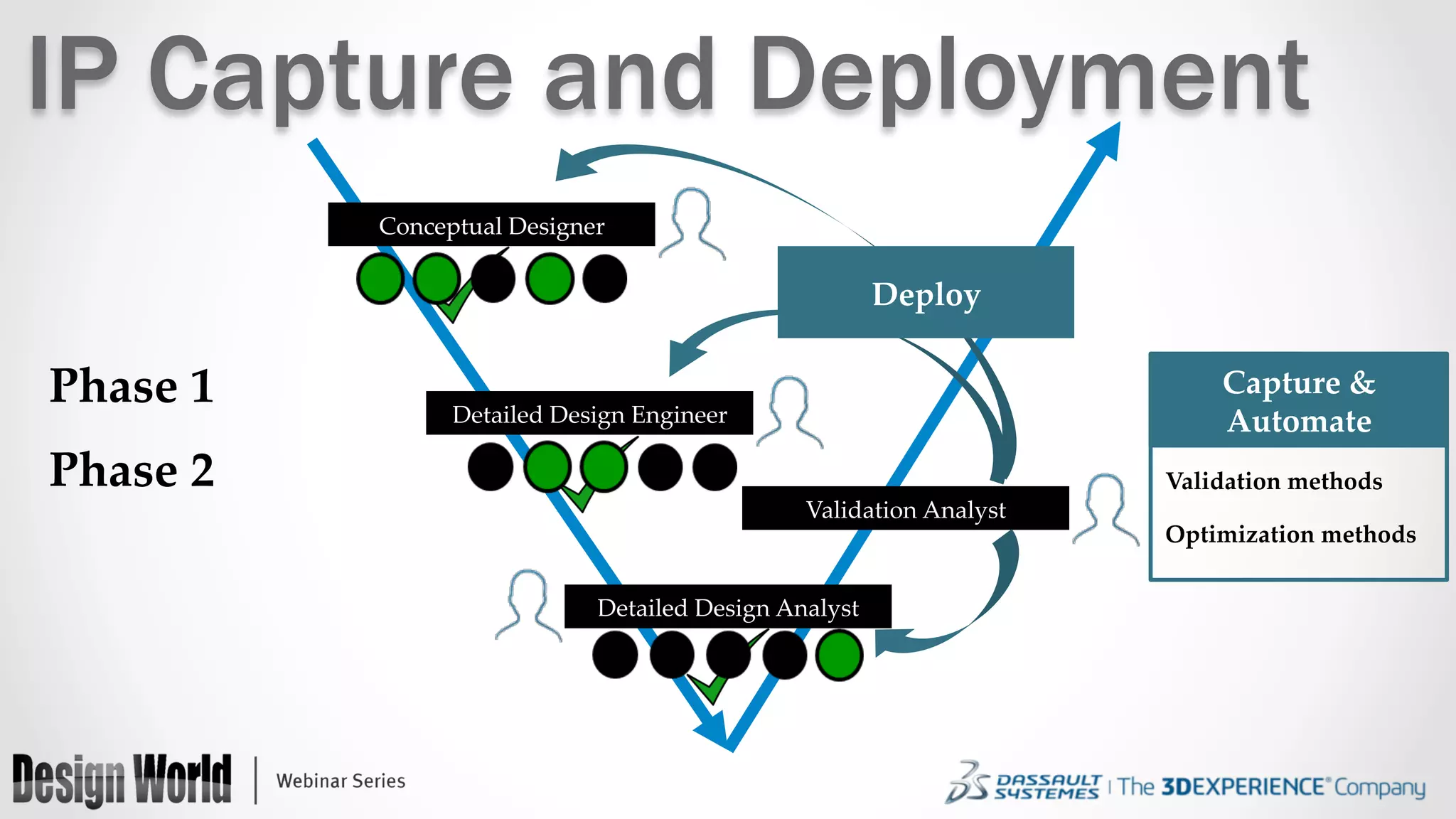

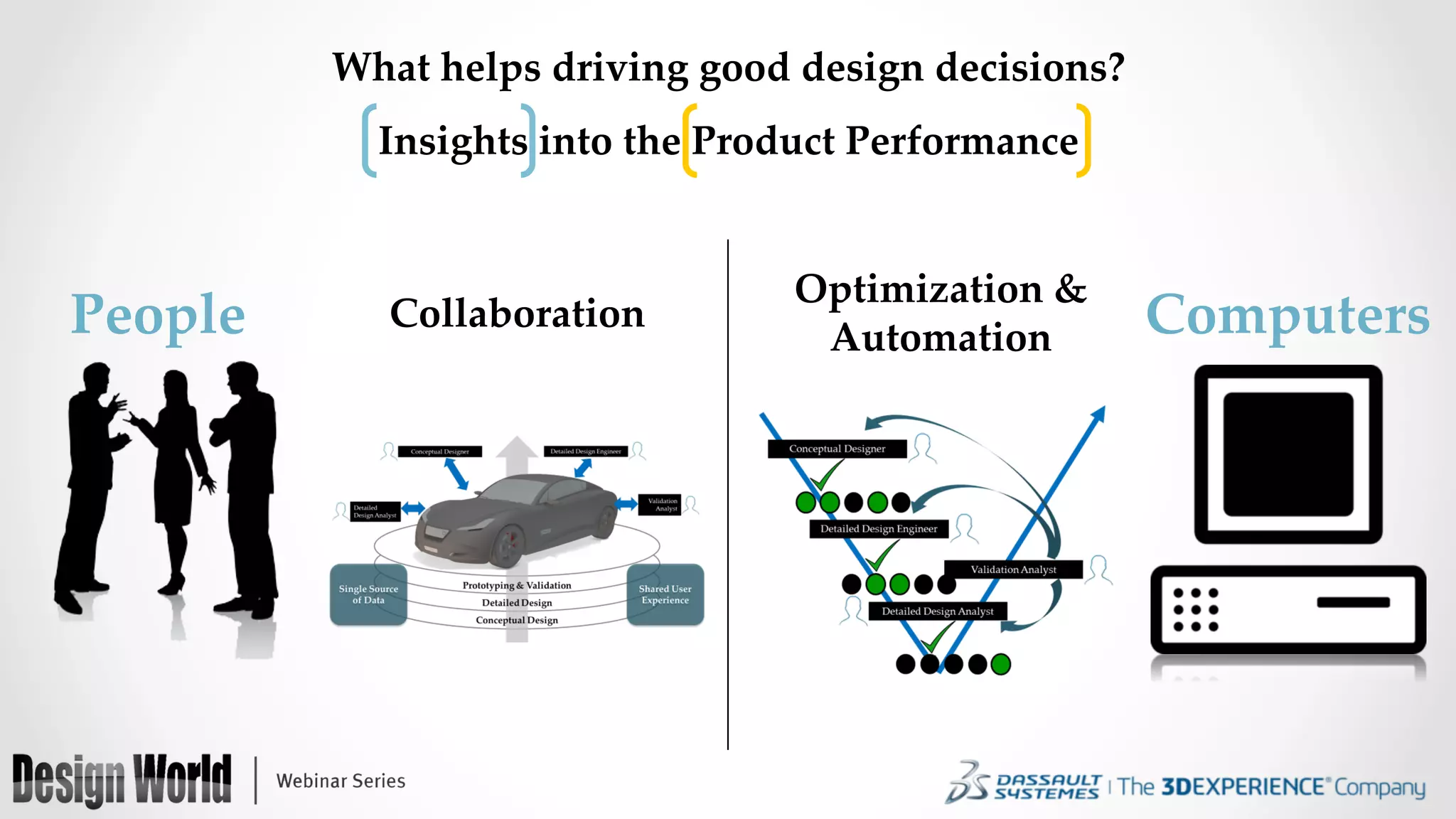

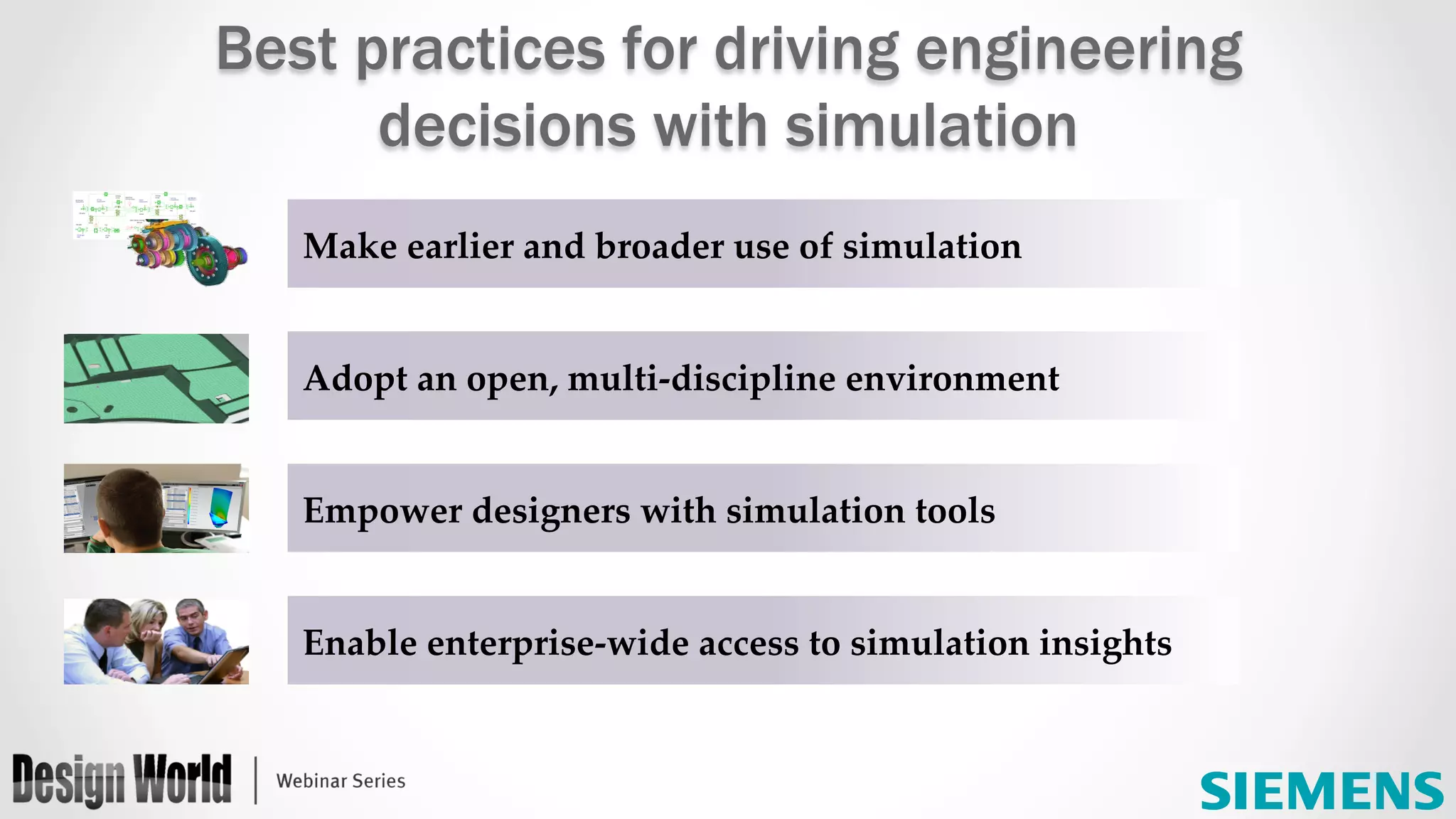

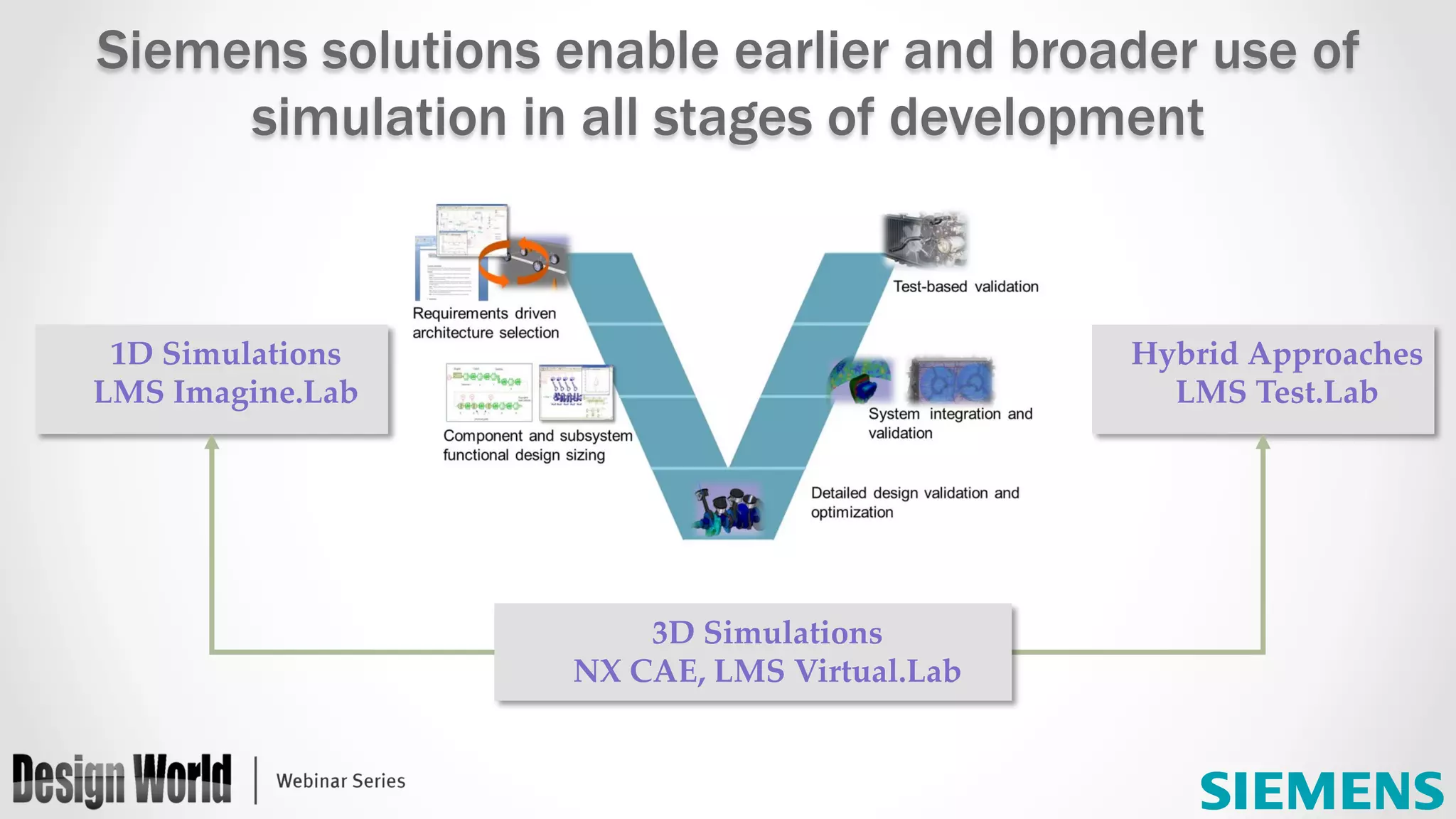

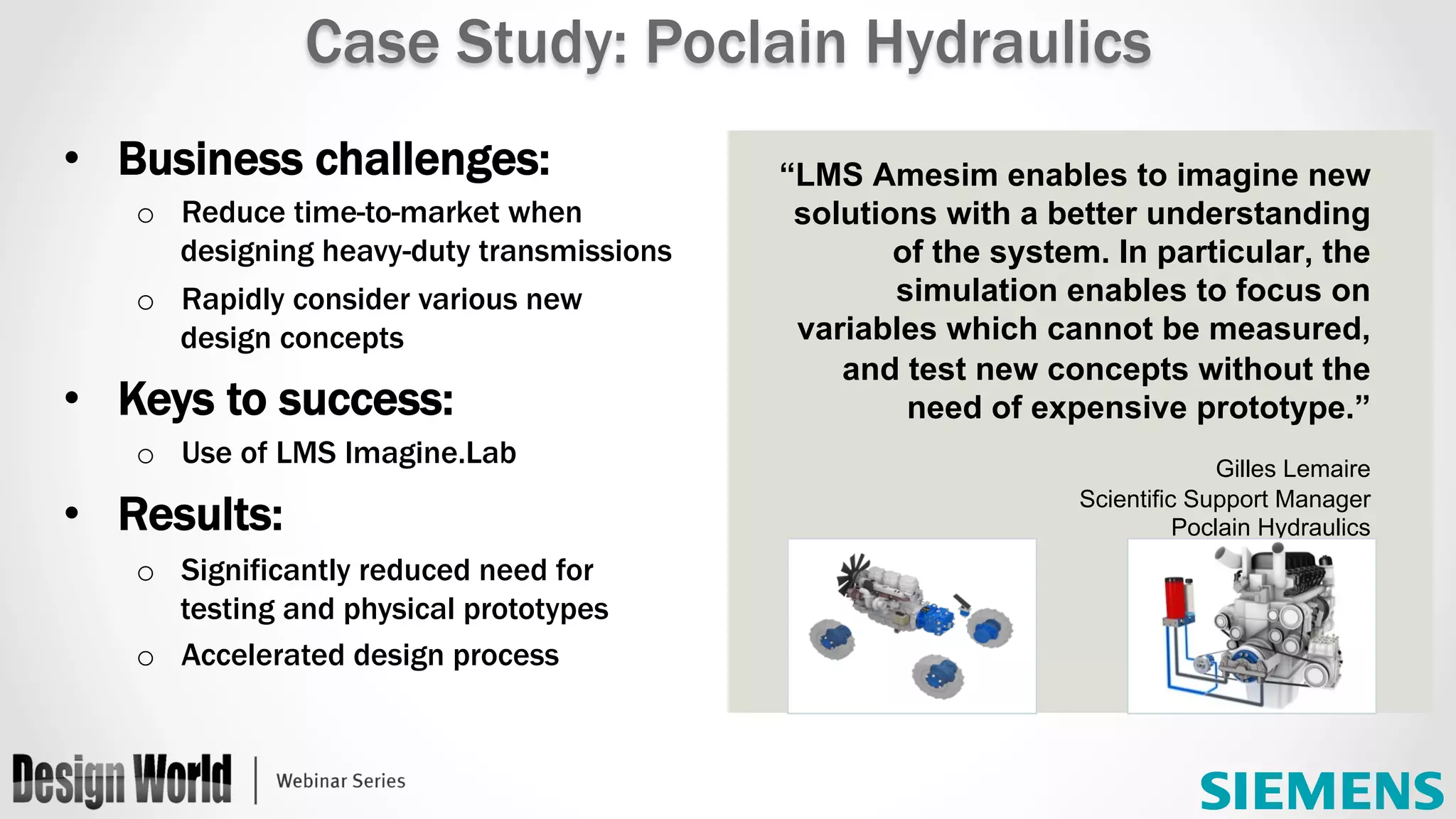

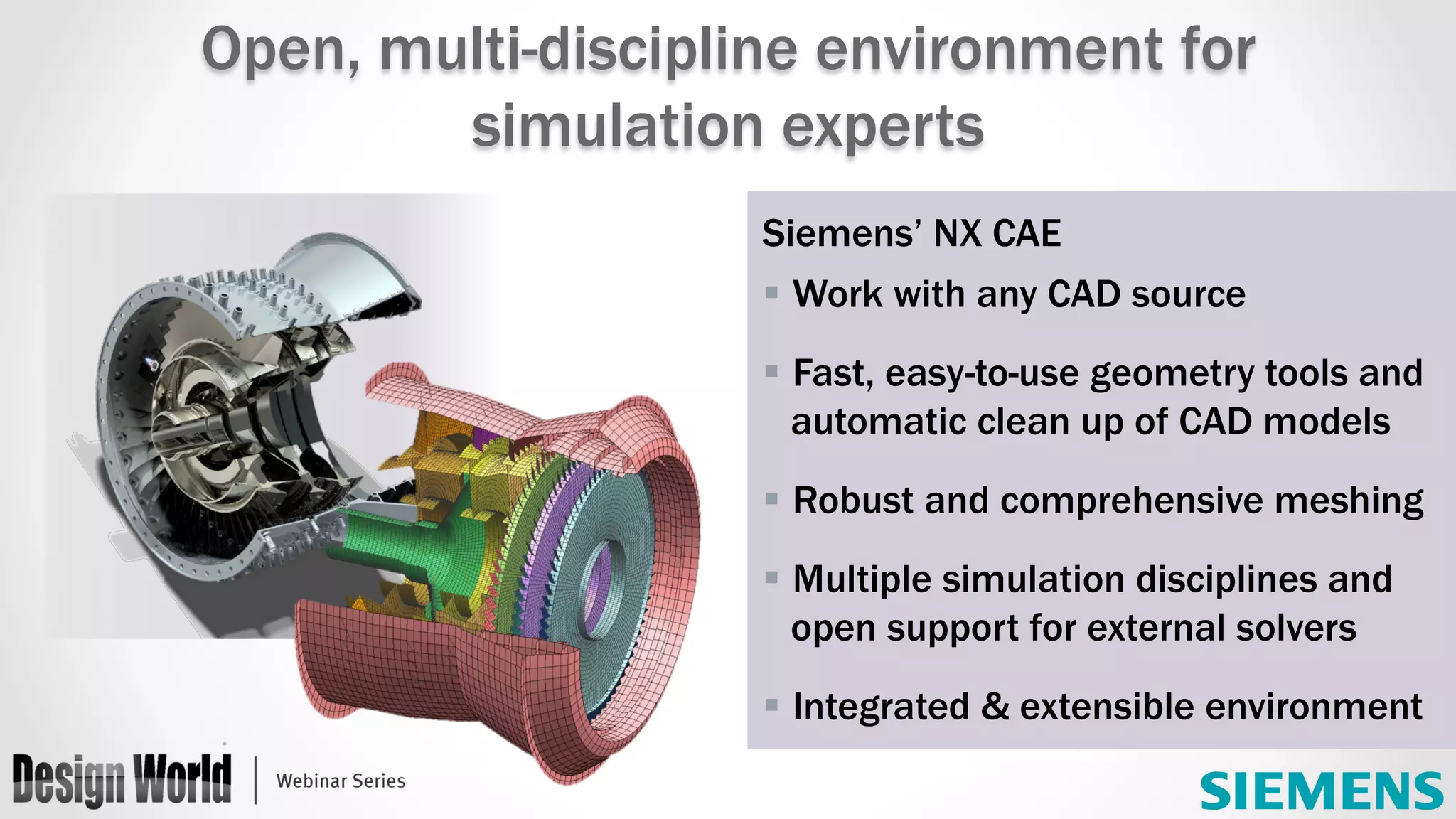

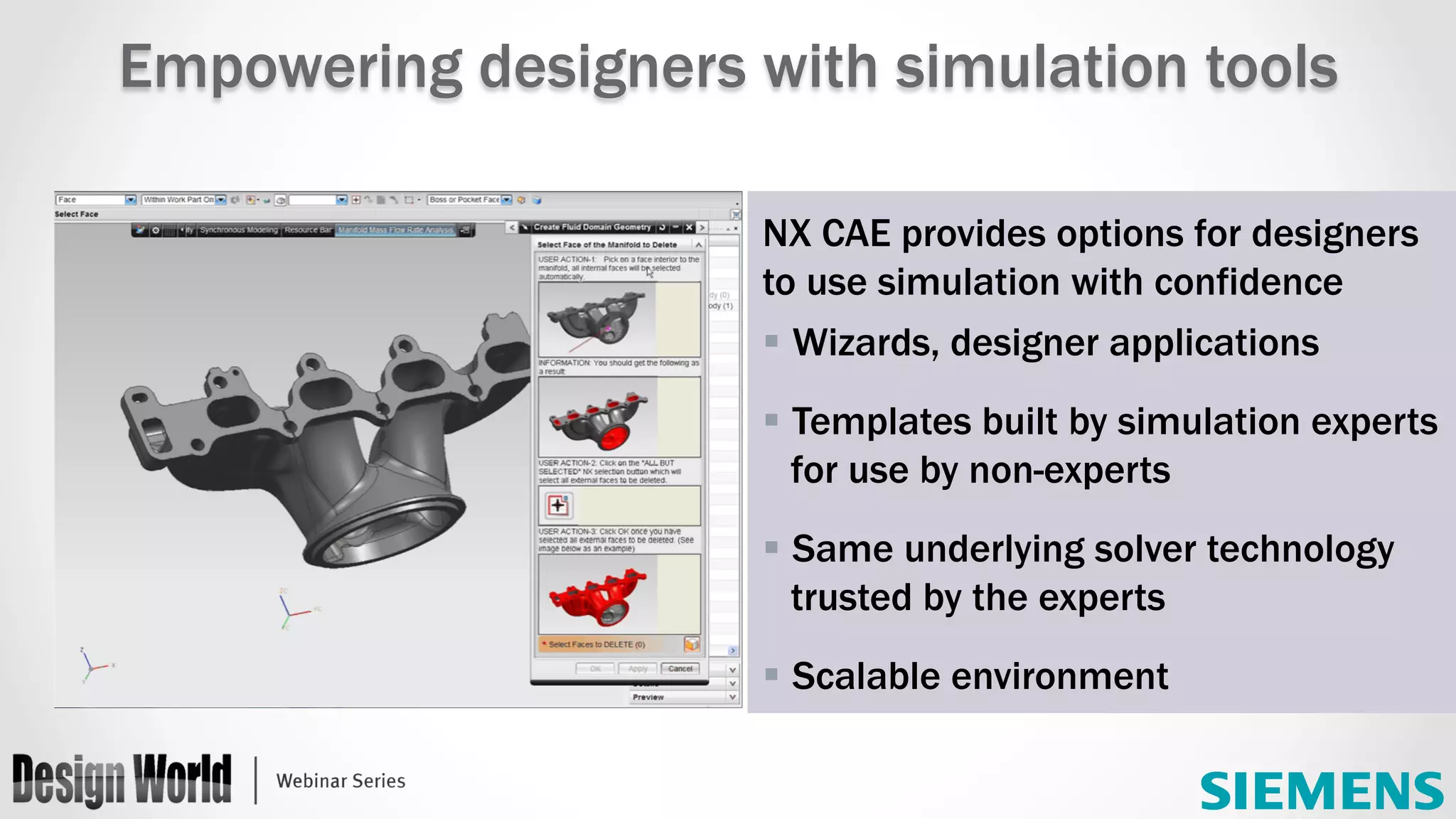

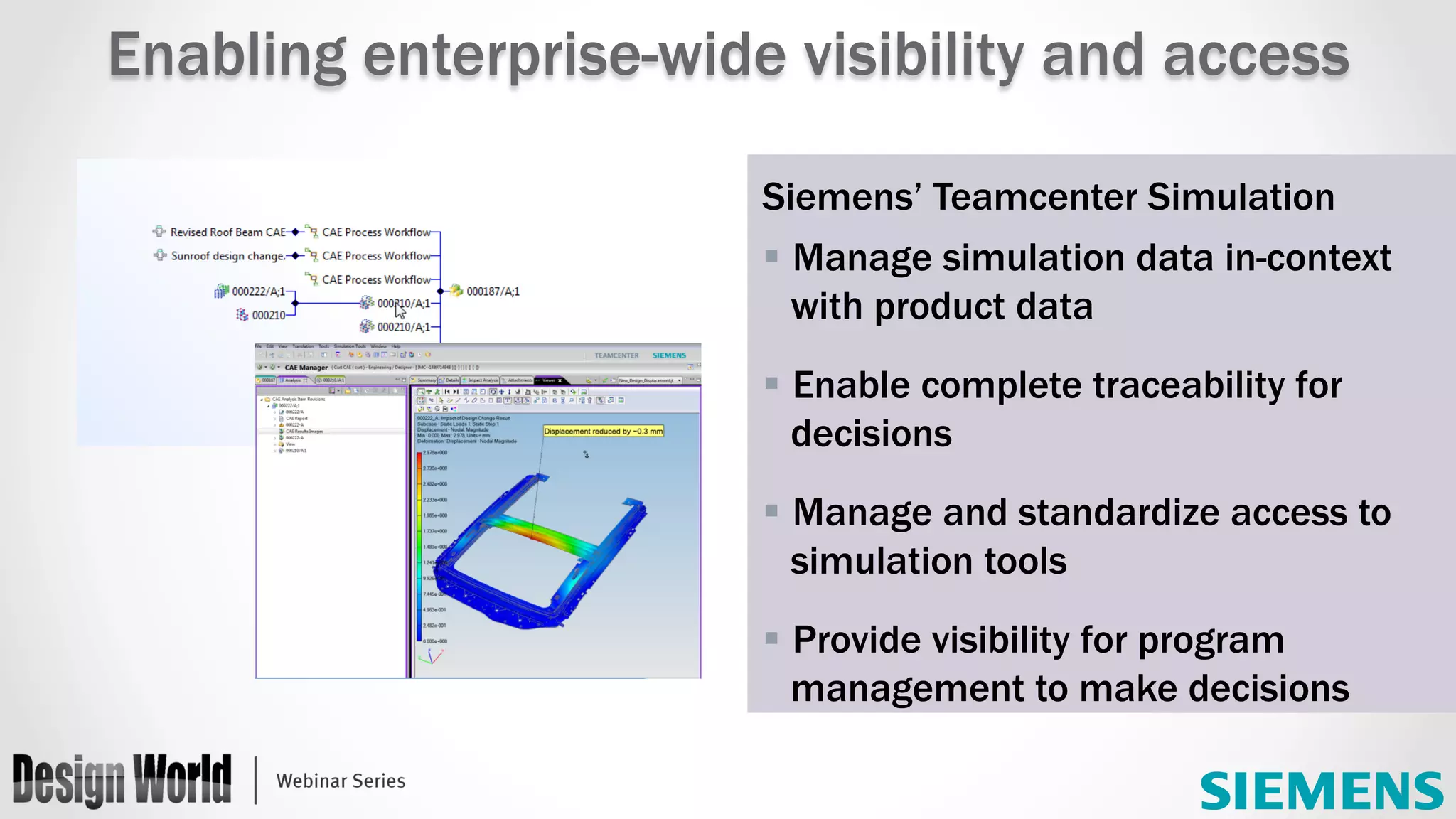

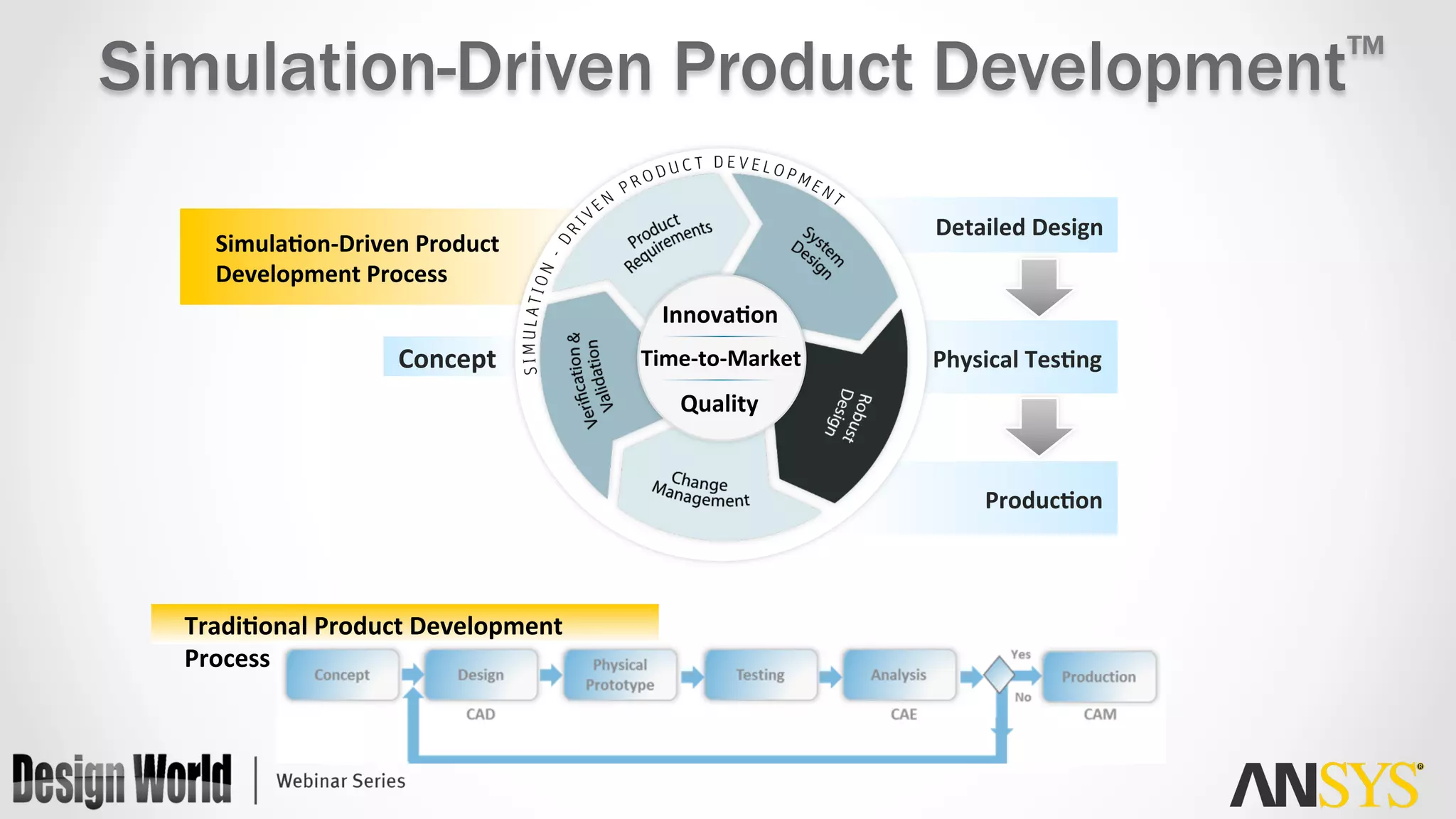

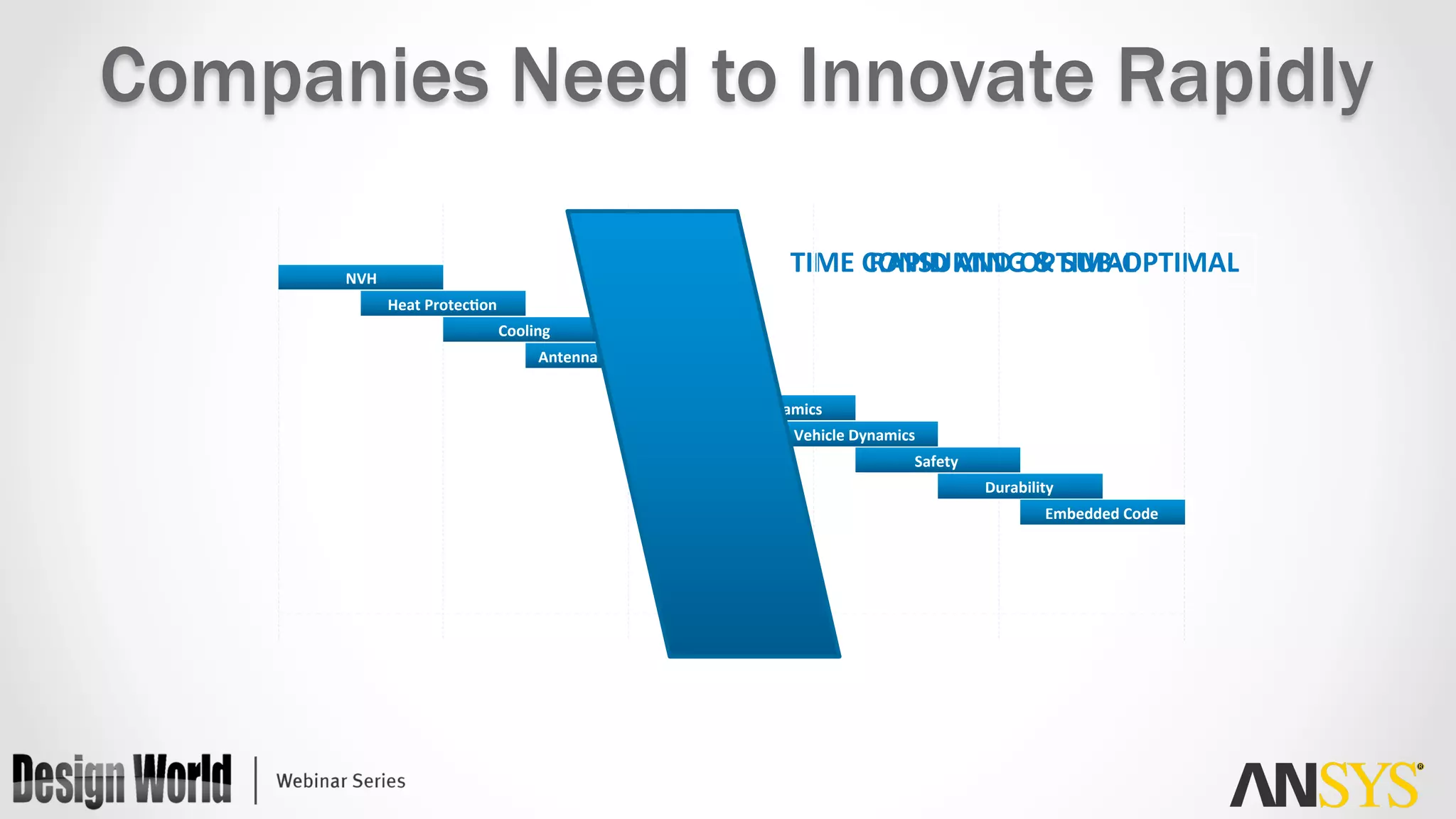

The document outlines best practices for using simulation to drive engineering design decisions, emphasizing earlier and broader adoption of simulation tools in an open, multi-disciplinary environment. It includes case studies demonstrating successful implementations that reduced time-to-market and improved design processes through integrated design and analysis. Key strategies discussed involve empowering designers, utilizing CAD-integrated simulation tools, and managing simulation data effectively within product development workflows.