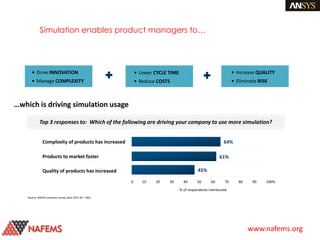

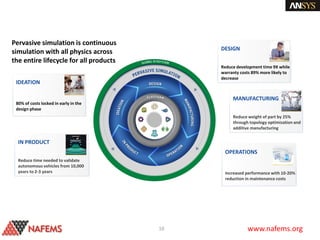

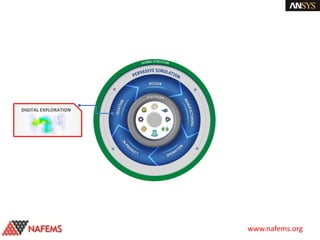

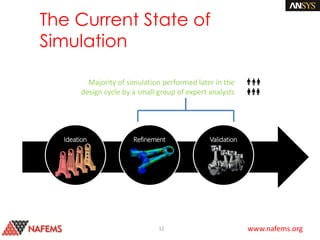

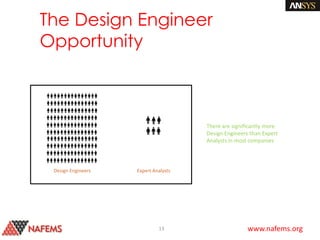

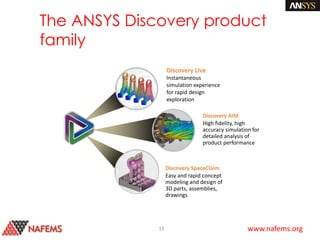

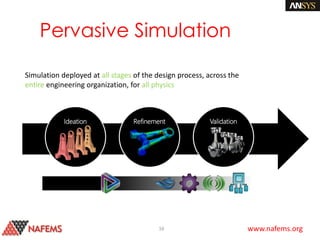

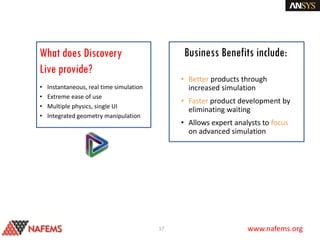

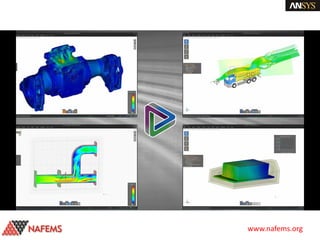

This document discusses ANSYS and its product offerings for simulation. It summarizes that ANSYS is the largest independent simulation software company, with over 45,000 customers worldwide. It also introduces its Discovery product family, which aims to make simulation easier to use and more accessible earlier in the design process. This includes Discovery Live for rapid design exploration through instantaneous real-time simulation, and Discovery AIM for detailed analysis. The goal is to enable "pervasive simulation" across the entire design lifecycle.