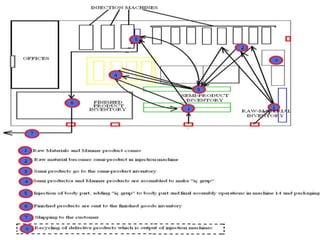

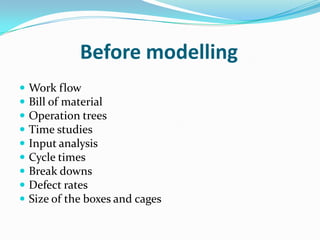

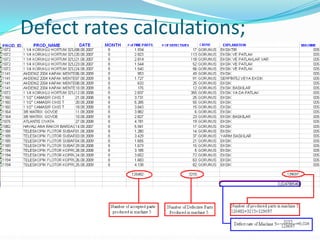

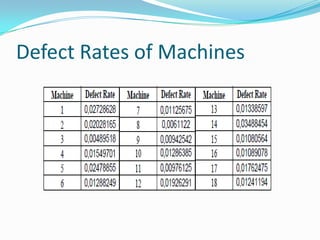

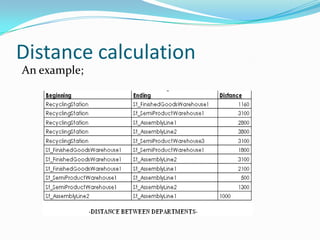

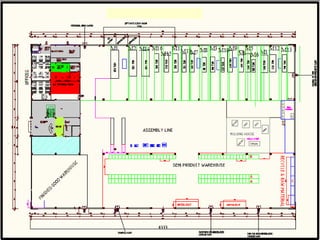

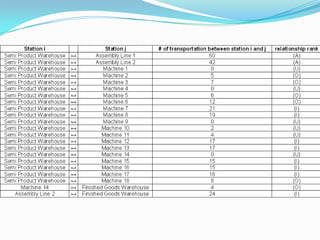

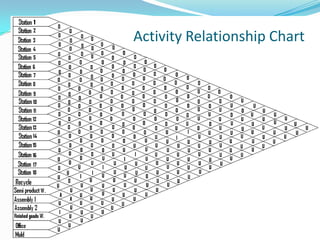

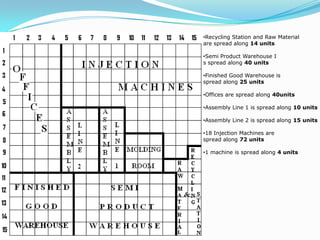

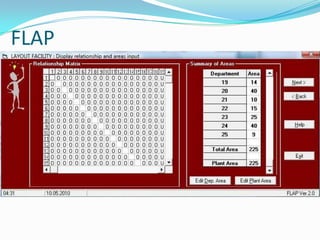

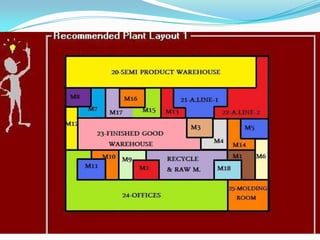

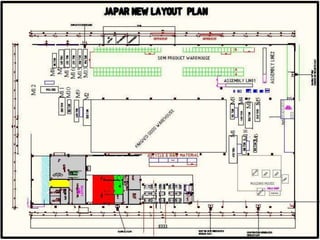

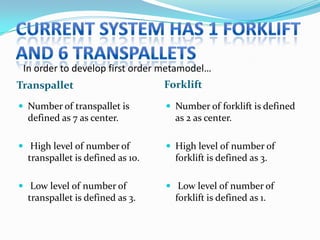

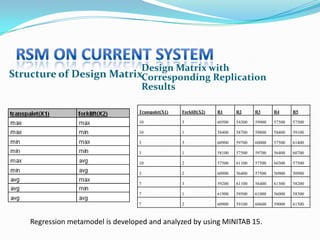

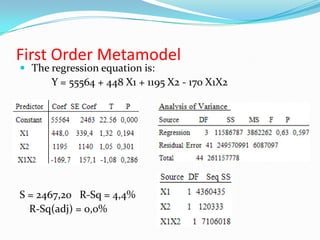

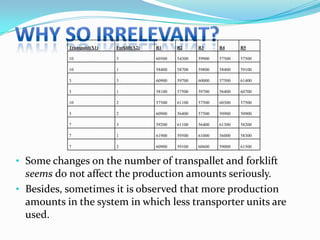

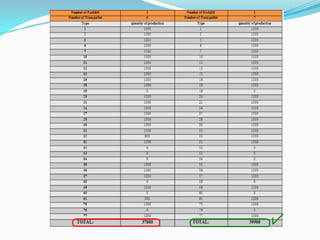

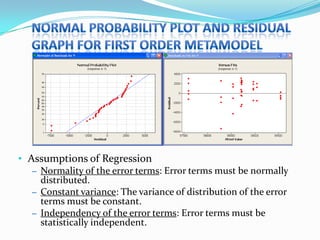

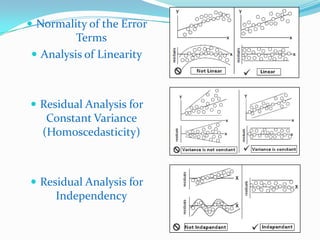

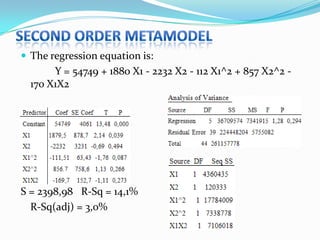

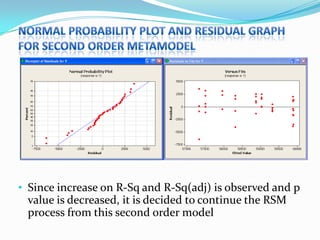

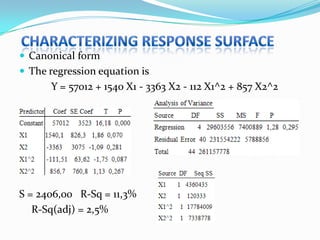

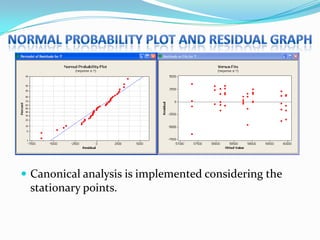

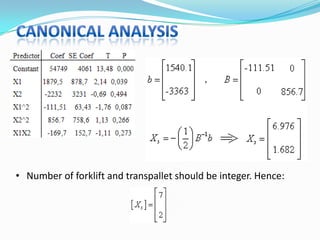

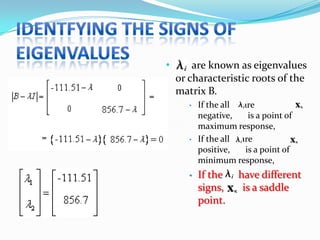

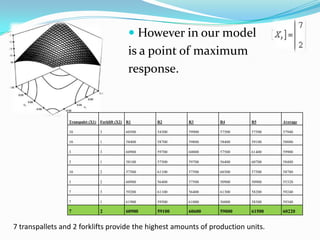

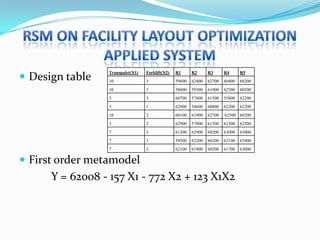

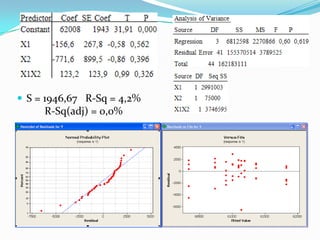

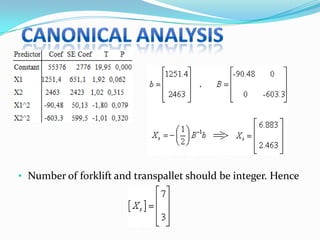

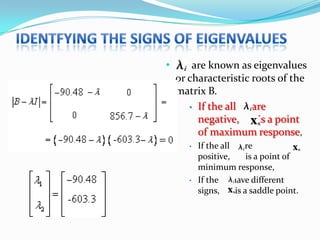

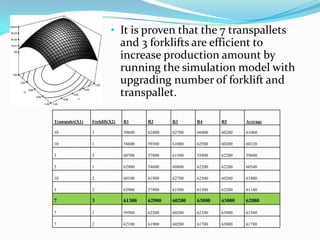

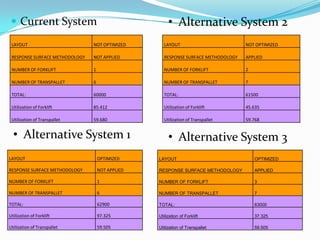

The document discusses a plastic manufacturing facility that produces items like toilet components. It outlines work to optimize the facility layout and logistics. Response surface methodology was used to determine the optimal number of forklifts and transpallet vehicles needed. Simulation results found that 7 transpallet vehicles and 2 forklifts provided the highest production output. Alternative systems were also analyzed.