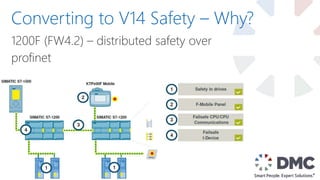

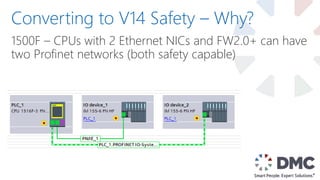

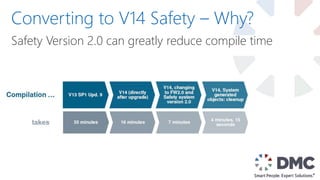

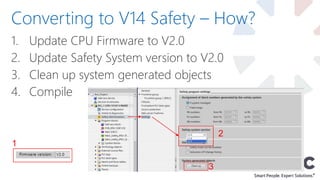

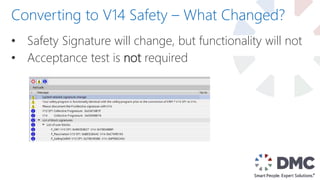

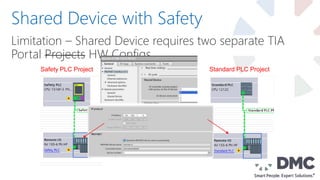

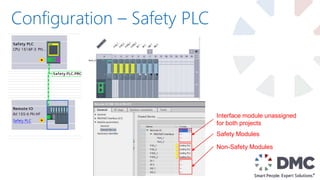

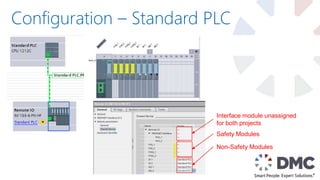

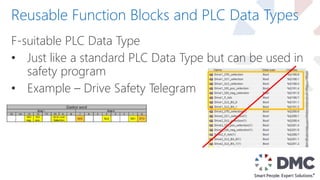

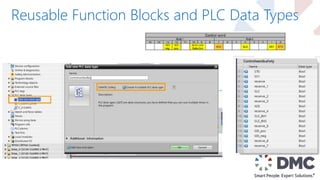

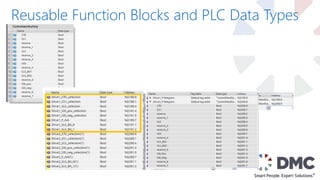

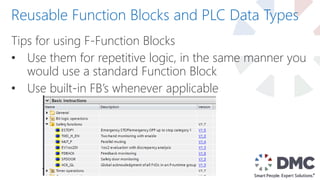

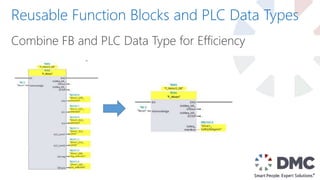

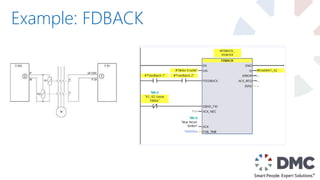

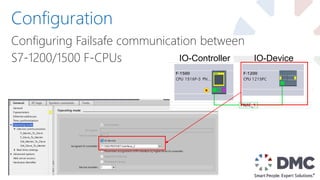

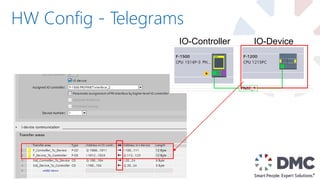

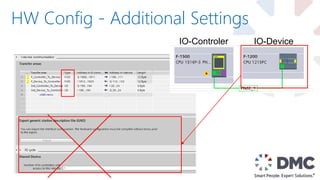

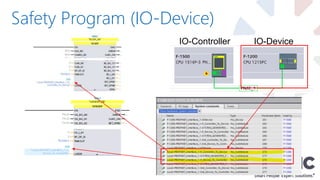

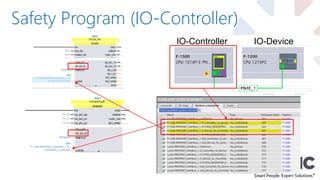

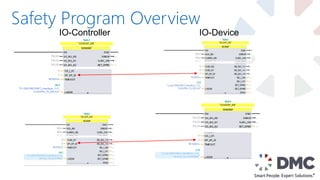

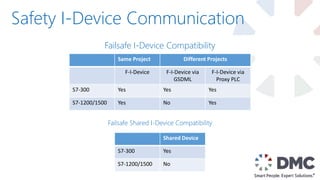

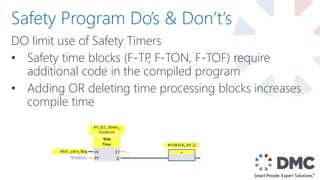

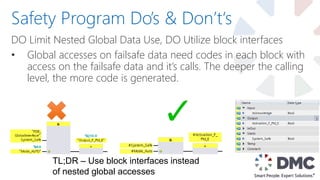

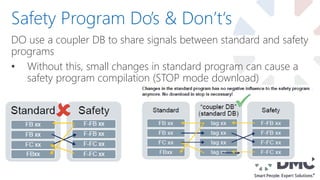

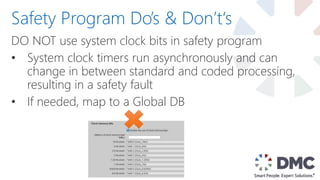

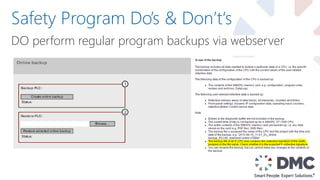

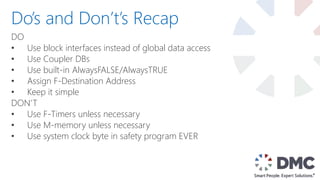

The document presents five tips for using TIA Portal V14 to reduce safety development time, focusing on aspects such as converting to version 14 safety, shared device configurations, and reusable function blocks. It highlights the benefits of updating to safety version 2.0, which improves compile times and comparison capabilities. Additionally, it outlines best practices and pitfalls in safety program development to enhance efficiency and safety compliance.