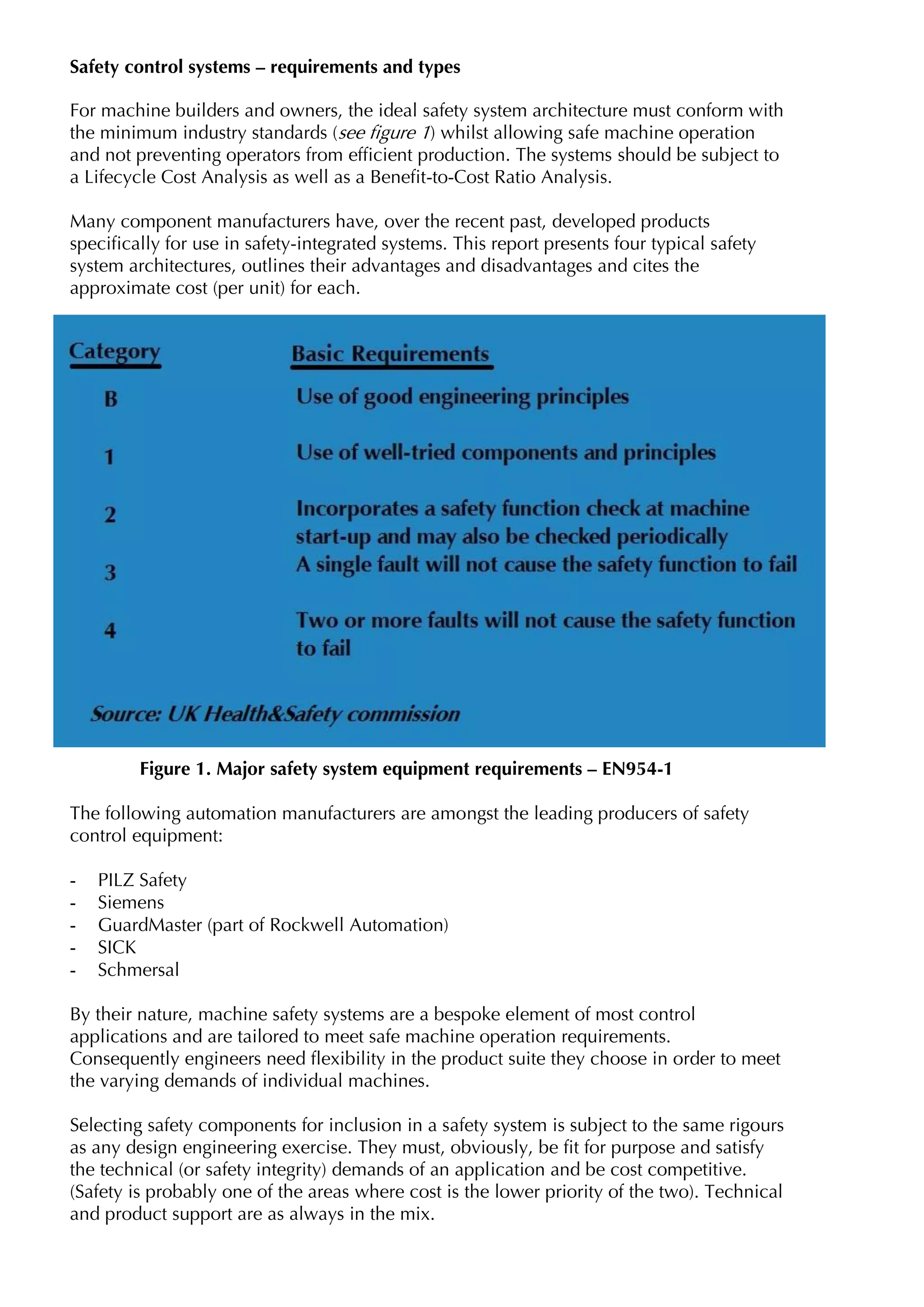

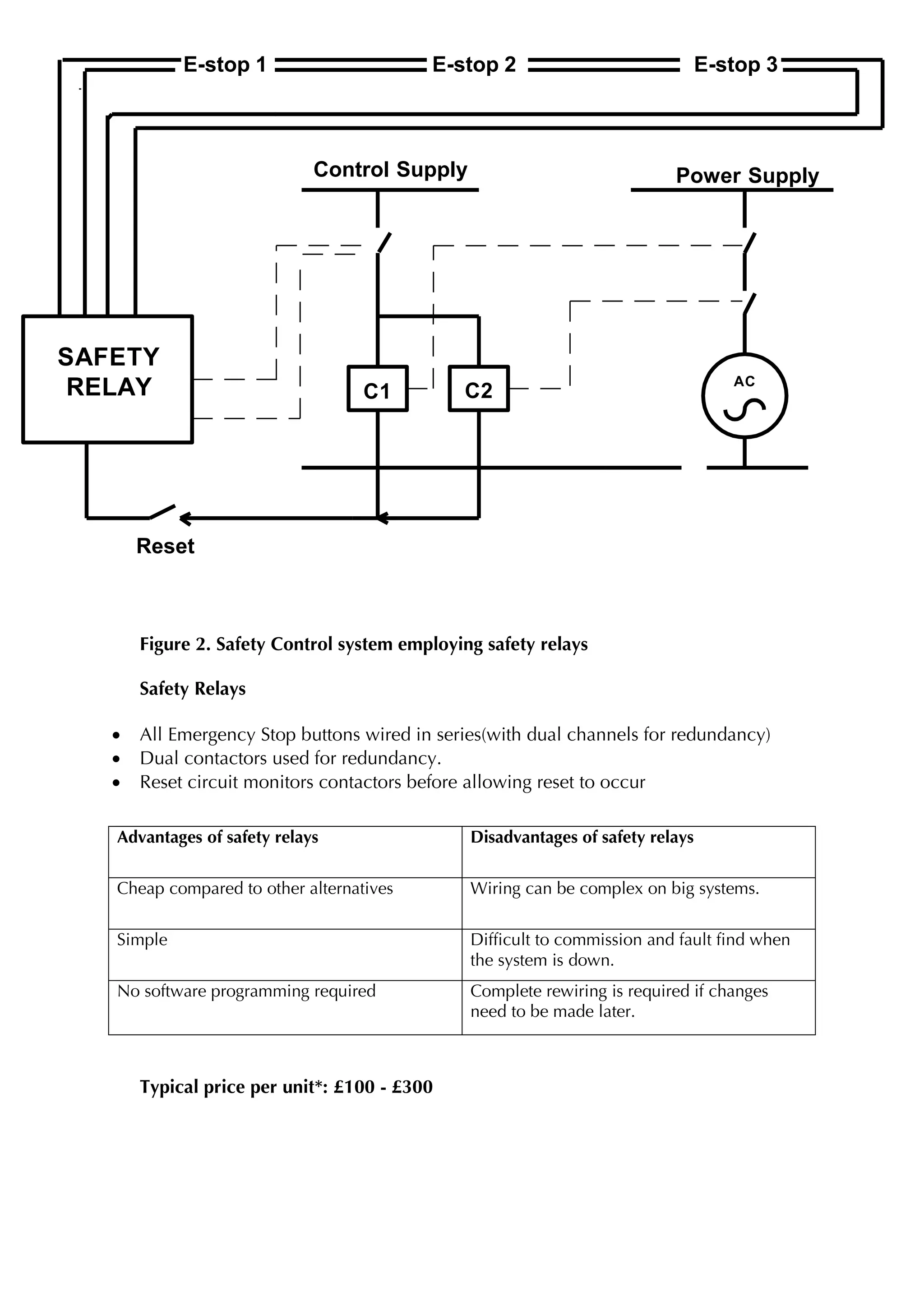

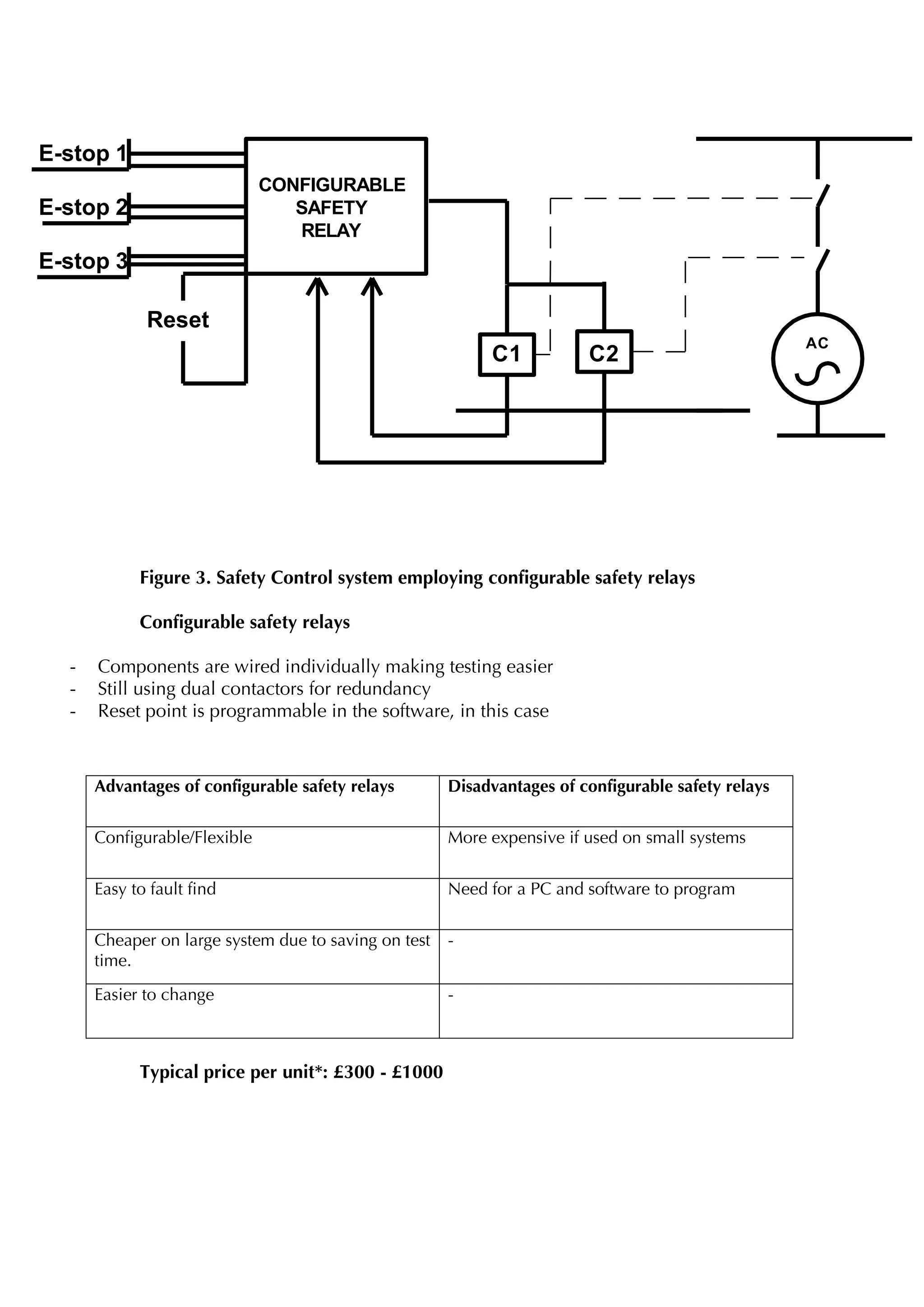

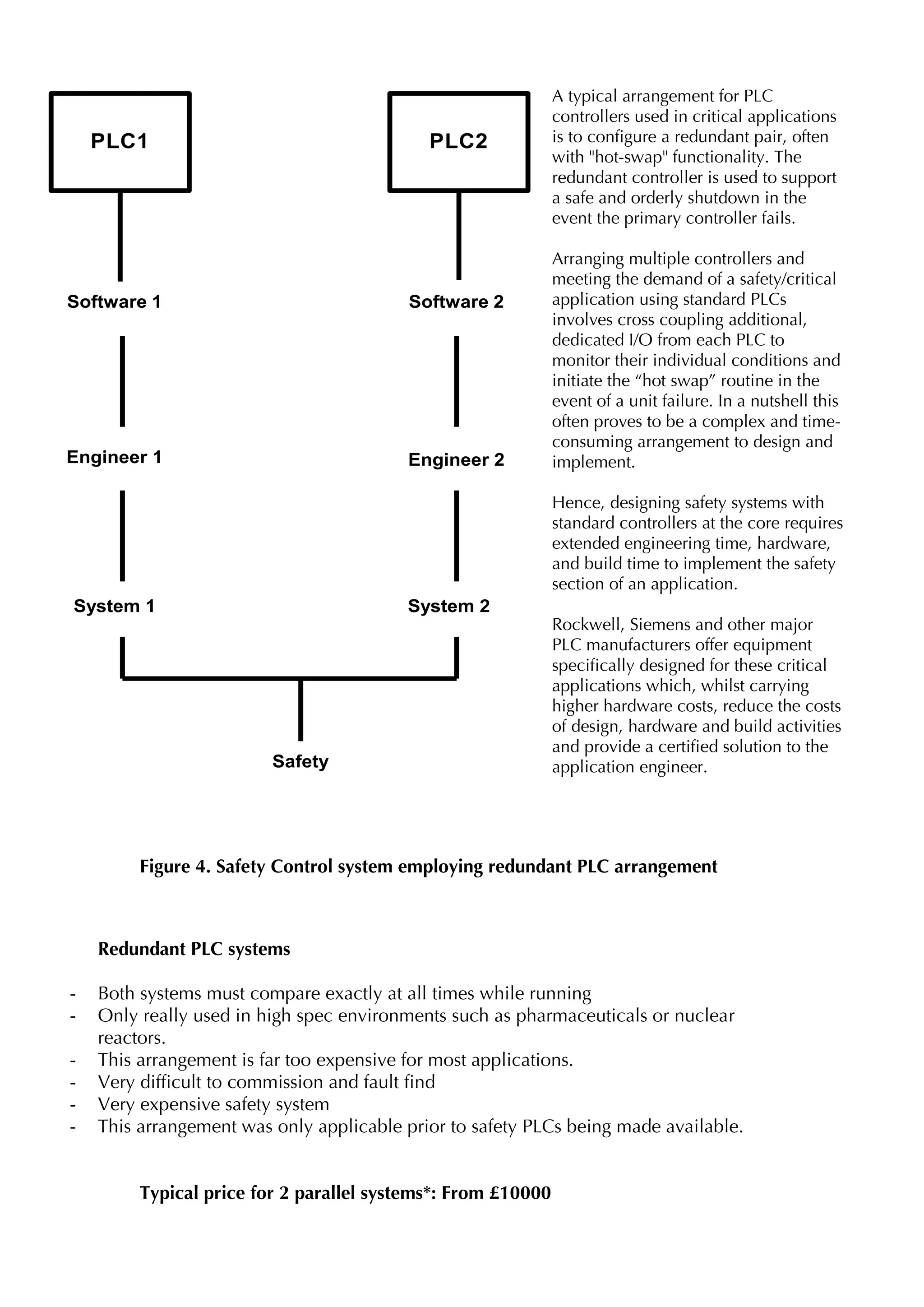

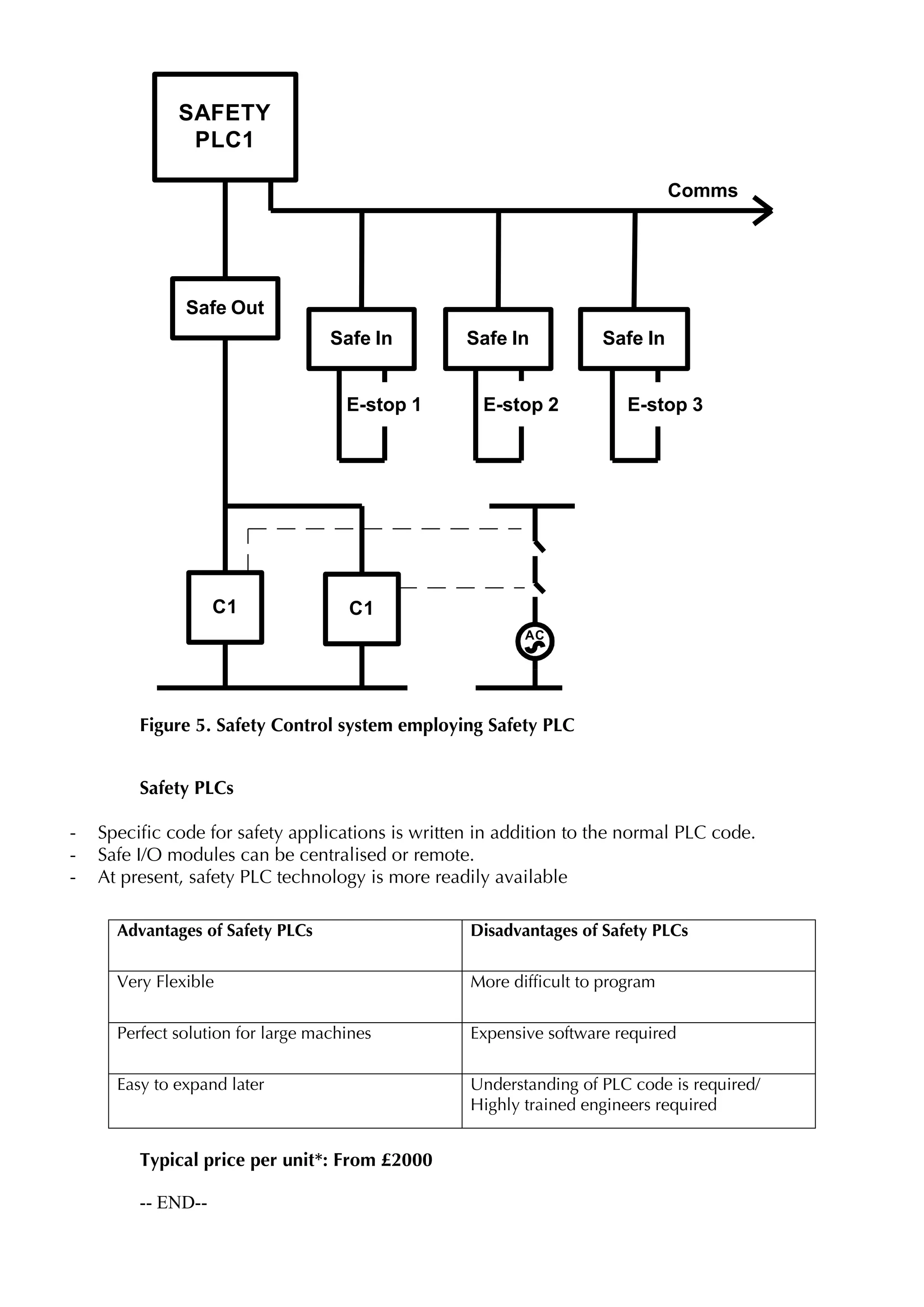

The document discusses the importance of reliable safety control systems in the industrial automation sector, highlighting the risks associated with workplace accidents and major injuries. It reviews various types of safety system architectures, their cost implications, and the trade-offs between safety and efficiency for machine builders and owners. Key safety control technologies include safety relays, configurable safety relays, redundant PLCs, and safety PLCs, each with distinct advantages and disadvantages.