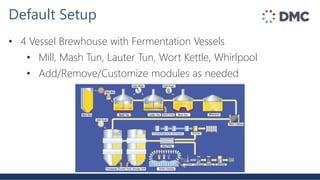

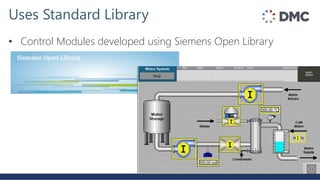

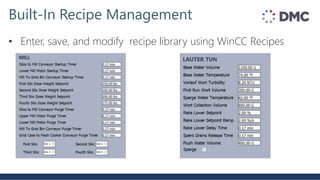

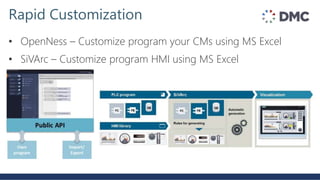

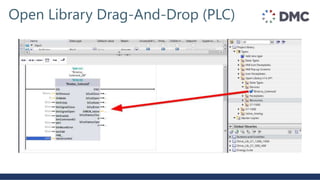

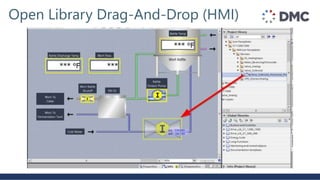

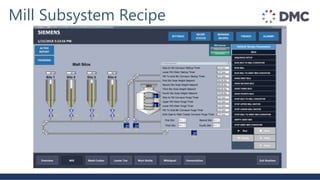

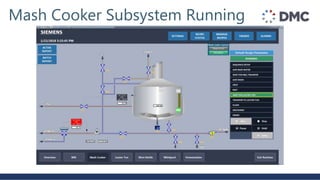

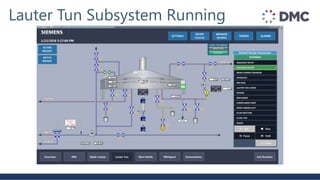

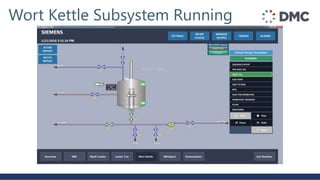

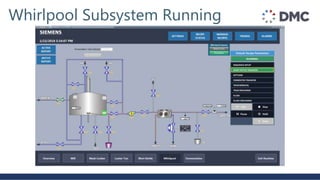

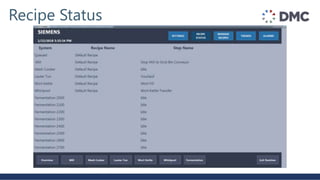

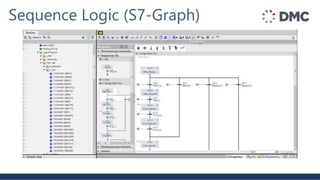

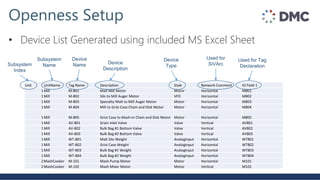

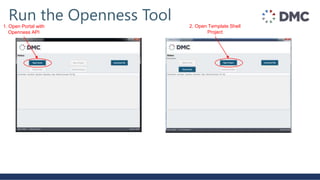

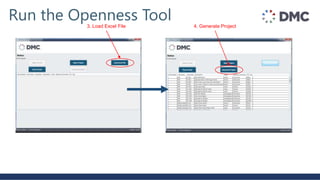

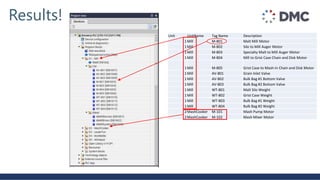

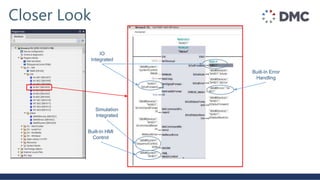

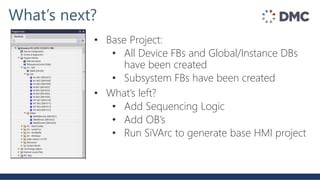

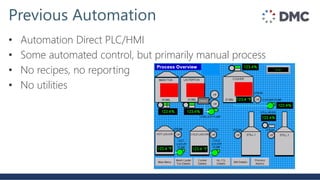

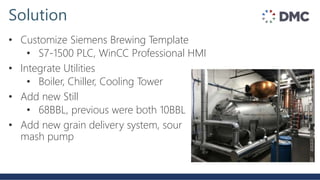

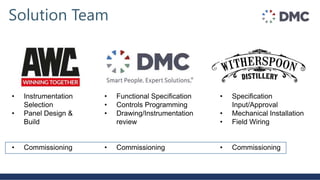

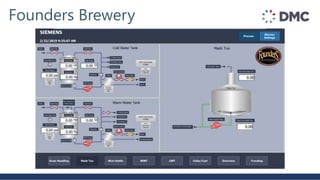

The document outlines a presentation on rapid brewery and distillery automation by Ryan Landwehr from DMC, Inc. It introduces the Siemens brewing template, which is open-source and customizable for craft brewers, detailing its components, benefits, and successful case studies, including Witherspoon Distillery. The presentation emphasizes the ease of use, scalability, and support provided through Siemens and partners, showcasing a live demo of the automation systems.