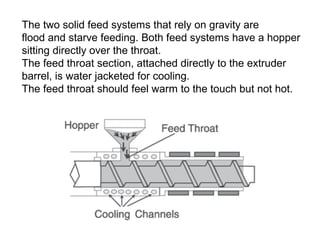

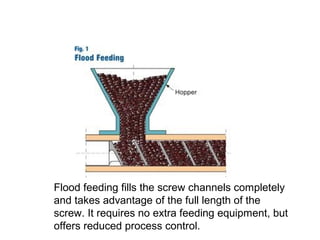

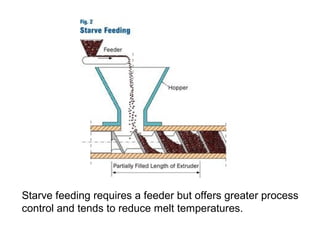

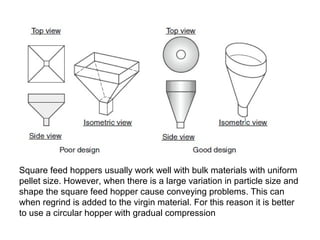

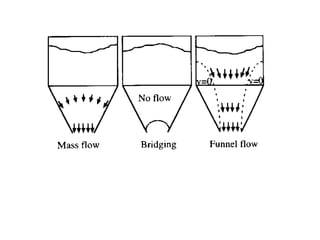

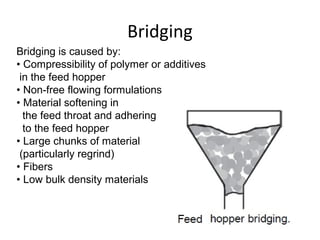

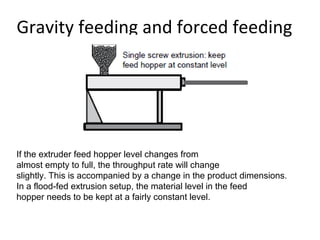

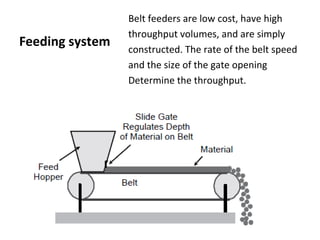

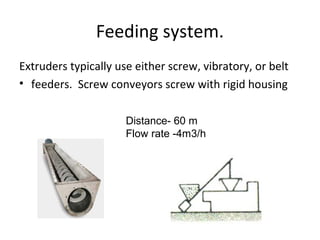

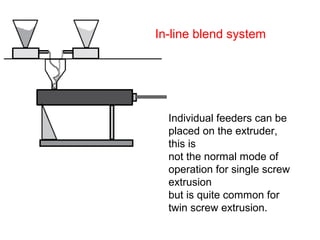

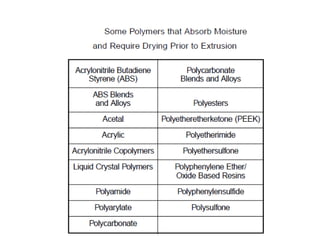

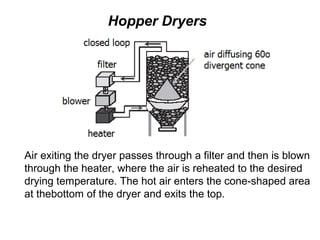

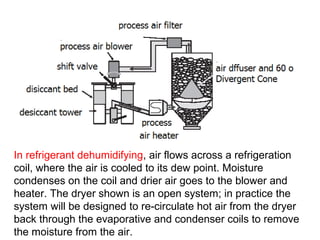

This document discusses auxiliary equipment used in extrusion processes, including various feeding systems, potential problems that can occur during feeding (e.g., bridging, funneling, selective entrapment), and solutions to address those problems (e.g., using a circular rather than square hopper). It also describes different types of feeding equipment like screw conveyors and belt feeders. Finally, it covers drying equipment like ovens and hopper dryers that are used to reduce the moisture content of hygroscopic polymers before extrusion.