TRANSPORTATION_ENGINEERING_M3.pdf

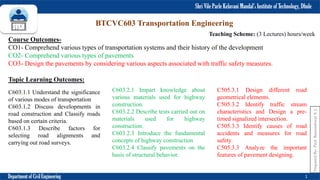

- 1. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 1 Prepared By- Prof. Basweshwar S. J. BTCVC603 Transportation Engineering Teaching Scheme: (3 Lectures) hours/week Course Outcomes- CO1- Comprehend various types of transportation systems and their history of the development CO2- Comprehend various types of pavements CO3- Design the pavements by considering various aspects associated with traffic safety measures. Topic Learning Outcomes: C603.2.1 Impart knowledge about various materials used for highway construction. C603.2.2 Describe tests carried out on materials used for highway construction. C603.2.3 Introduce the fundamental concepts of highway construction C603.2.4 Classify pavements on the basis of structural behavior. C505.3.1 Design different road geometrical elements. C505.3.2 Identify traffic stream characteristics and Design a pre- timed signalized intersection. C505.3.3 Identify causes of road accidents and measures for road safety. C505.3.3 Analyze the important features of pavement designing. C603.1.1 Understand the significance of various modes of transportation C603.1.2 Discuss developments in road construction and Classify roads based on certain criteria. C603.1.3 Describe factors for selecting road alignments and carrying out road surveys.

- 2. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 2 Prepared By- Prof. Basweshwar S. J. Module 3: (8 Lectures) Highway Materials: Soil – relevant properties, Various tests, Aggregates – strength, hardness, toughness, soundness, durability, shape, specific gravity, water absorption, Bituminous materials – Bitumen, Tar, and Asphalt – various properties, Design of Bituminous paving mixes-Marshall stability test Module 4: Traffic Engineering (8 Lectures) Traffic Characteristics, Speed, Journey Time and Delays, Vehicle Volume Counts, Origin and Destination Studies, Analysis and Interpretation of Survey Data, Traffic Operations, Design of Signals and Rotary intersections, Parking Space Design,Highway Lighting, Planning and Administration, Road Markings, Signs Road Accidents and Safety:Classification, Causes, Mitigation and Control Measures, Aspects of Safety in Usage of Roads, Type and Design of anti- crash barriers, Introduction to Intelligent Transport Systems (ITS). Module 5: Pavement Design (8 Lectures) Basic Principles, Methods for Different Types of Pavements, Design of flexible pavement using IRC: 37- 2012, Design of rigid pavement using IRC: 58-2011 Other modes of Transport Introduction to Railways, Airways, Waterways, Pipeline Transportation, Classification, Requirements, Comparative Studies

- 3. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 3 Prepared By- Prof. Basweshwar S. J. 3.1 Highway Materials: Soil – relevant properties The soil as Roads subgrade has the following function: 1. Soil is an essential component in road construction which is used as subgrade material. 2. It acts as an integral part of the road pavement. 3. It ensures the stability and durability of the road under adverse conditions. 4. It facilitates proper drainage for rainwater percolating through the road pavement.

- 4. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 4 Prepared By- Prof. Basweshwar S. J. Properties of Soil as a Road Material The properties of soil as a road material are as follows: 1. The soil subgrade should remain stable in adverse condition. 2. It should have permanent strength. 3. It should be incompressible. 4. It should have proper drainage properties to evade excessive retention of moisture. 5. It should be easily compatible which ensures higher dry density (dry density of soil) and strength under particular type and amount of compaction. 6. It should have minimum variation in volume under adverse conditions of weather and groundwater. The minimum change in volume will ensure minimum variation in differential strength and differential expansion.

- 5. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 5 Prepared By- Prof. Basweshwar S. J. 3.1.1 Highway Materials: Soil –Various tests • Types of soil tests for a road construction project require the site investigation to be carried out to understand the soil profile. • For road construction works, the properties of soil at the subgrade level are required. • The common soil test for road construction includes classification of soil, particle size distribution, moisture content determination, specific gravity, liquid limit, and plastic limit tests. • Moisture content, particle size, and specific gravity tests on soils are used for the calculation of soil properties such as degree of saturation. • The soil tests can be laboratory tests or in-situ tests. • Laboratory tests should be carried out on every sample taken for the determination of particle size and moisture content.

- 6. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 6 Prepared By- Prof. Basweshwar S. J. 3.1.1 Highway Materials: Soil –Various tests Types of Soil Tests for Road Construction Following are the various types of soil tests for pavement construction: 3.1.1.1 In-situ Moisture Content • The moisture content of the soil test is carried out in the laboratory. • It is expressed as the percentage of water in the soil to its dry mass. • The moisture content in soil signifies the various properties of soil such as compaction, permeability, particle size, etc. 3.1.1.2 Specific gravity of soil • The specific gravity of soil is the ratio of the weight of soil in the air of a given volume at a standard temperature to the weight in air of an equal volume of distilled water at the same stated temperature. • This test is also carried out in the laboratory.

- 7. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 7 Prepared By- Prof. Basweshwar S. J. Following are the various types of soil tests for pavement construction: 3.1.1.3 Particle Size Distribution (By wet sieving & pipette method) • This test determines the particle size distribution of soil from the coarse sand size down to fine clay size. • The data from the particle size distribution test is used to determine the suitability of soil for road construction, airfield, etc. • This test can also be used to predict soil water movement although permeability tests are more generally used. 3.1.1.4 Compaction test - Proctor test • This soil compaction test also called as Proctor test is used for the determination of the mass of dry soil per cubic meter when the soil is compacted over a range of moisture contents, giving the maximum dry density at optimum moisture content. • Thus this test provides the compaction characteristics of different soils with change in moisture content. • This is achieved by the densification of soil by reducing the air voids.

- 8. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 8 Prepared By- Prof. Basweshwar S. J. Following are the various types of soil tests for pavement construction: 3.1.1.5 California Bearing Ratio (CBR) Test • California Bearing Ratio test is conducted in the laboratory. • This test provides the load penetration resistance of the soil. • CBR value is obtained by measuring the relationship between force and penetration when a cylindrical plunger is made to penetrate the soil at a standard rate. • The CBR test is used for the evaluation of the subgrade strength of roads and pavements. • The CBR value obtained by this test is used with the empirical curves to determine the thickness of pavement and its component layers. • This is the most widely used method for the design of flexible pavement. • Even though the provision of subsoil drains reduces the effect of water on the subgrade, fully soaked CBR tests shall be considered to be appropriate for road construction projects.

- 9. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 9 Prepared By- Prof. Basweshwar S. J. Following are the various types of soil tests for pavement construction: 3.1.1.5 California Bearing Ratio (CBR) Test The following points should be taken care of while soil testing for road construction: • Sampling and Testing: • Sampling of soil for tests in laboratory or in-situ is to be carefully done by an experienced engineer. • The requirement for the various mass/volume of soil at different points of a road project shall be followed as per the specification and standard codes. • Test Data Logging: • Logging of all the soil sample and test data shall be done by trained staff who has the knowledge of soil properties and tests results. • Testing Frequency: • The testing frequency of soil shall be as per input from Engineer. • The decision on the testing frequency is usually taken on the basis of results obtained from the previous tests.

- 10. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 10 Prepared By- Prof. Basweshwar S. J. 3.1.2 Highway Materials: Aggregates – strength, hardness, toughness, soundness, durability, shape, specific gravity, water absorption, • Aggregate is a collective term for the mineral materials such as sand, gravel, and crushed stone that are used with a binding medium (such as water, bitumen, Portland cement, lime, etc.) to form compound materials (such as bituminous concrete and Portland cement concrete). • By volume, aggregate generally accounts for 92 to 96 percent of Bituminous concrete and about 70 to 80 percent of Portland cement concrete. • Aggregate is also used for base and sub-base courses for both flexible and rigid pavements. • Aggregates can either be natural or manufactured. • Natural aggregates are generally extracted from larger rock formations through an open excavation (quarry). • Extracted rock is typically reduced to usable sizes by mechanical crushing. • Manufactured aggregate is often a bye product of other manufacturing industries.

- 11. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 11 Prepared By- Prof. Basweshwar S. J. 3.1.2 Highway Materials: Aggregates – strength, hardness, toughness, soundness, durability, shape, specific gravity, water absorption, Desirable properties 3.1.2.1 Strength • The aggregates used in top layers are subjected to (i) Stress action due to traffic wheel load, (ii) Wear and tear, (iii) crushing. • For a high quality pavement, the aggregates should posses high resistance to crushing, and to withstand the stresses due to traffic wheel load. 3.1.2.2 Hardness • The aggregates used in the surface course are subjected to constant rubbing or abrasion due to moving traffic. • The aggregates should be hard enough to resist the abrasive action caused by the movements of traffic. • The abrasive action is severe when steel tyred vehicles moves over the aggregates exposed at the top surface.

- 12. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 12 Prepared By- Prof. Basweshwar S. J. 3.1.2 Highway Materials: Aggregates – strength, hardness, toughness, soundness, durability, shape, specific gravity, water absorption, Desirable properties 3.1.2.3 Toughness • Resistance of the aggregates to impact is termed as toughness. • Aggregates used in the pavement should be able to resist the effect caused by the jumping of the steel tyred wheels from one particle to another at different levels causes severe impact on the aggregates. 3.1.2.4 Shape of aggregates • Aggregates which happen to fall in a particular size range may have rounded, cubical, angular, flaky or elongated particles. • It is evident that the flaky and elongated particles will have less strength and durability when compared with cubical, angular or rounded particles of the same aggregate. • Hence too flaky and too much elongated aggregates should be avoided as far as possible.

- 13. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 13 Prepared By- Prof. Basweshwar S. J. 3.1.2 Highway Materials: Aggregates – strength, hardness, toughness, soundness, durability, shape, specific gravity, water absorption, Desirable properties 3.1.2.5 Adhesion with bitumen • The aggregates used in bituminous pavements should have less affinity with water when compared with bituminous materials, otherwise the bituminous coating on the aggregate will be stripped off in presence of water. 3.1.2.6 Durability • The property of aggregates to withstand adverse action of weather is called soundness. • The aggregates are subjected to the physical and chemical action of rain and bottom water, impurities there-in and that of atmosphere, hence it is desirable that the road aggregates used in the construction should be sound enough to withstand the weathering action. 3.1.2.7 Freedom from deleterious particles • Specifications for aggregates used in bituminous mixes usually require the aggregates to be clean, tough and durable in nature and free from excess amount of flat or elongated pieces, dust, clay balls and other objectionable material. • Similarly aggregates used in Portland cement concrete mixes must be clean and free from deleterious substances such as clay lumps, chert, silt and other organic impurities.

- 14. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 14 Prepared By- Prof. Basweshwar S. J. 3.1.2 Highway Materials: Aggregates – strength, hardness, toughness, soundness, durability, shape, specific gravity, water absorption, Aggregate tests In order to decide the suitability of the aggregate for use in pavement construction, following tests are carried out: • Crushing test • Abrasion test • Impact test • Soundness test • Shape test • Specific gravity and water absorption test • Bitumen adhesion test

- 15. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 15 Prepared By- Prof. Basweshwar S. J. 3.1.3 Highway Materials: Bituminous materials – Bitumen, Tar, and Asphalt – various properties, Design of Bituminous paving mixes-Marshall stability test 3.1.3.1 What is Asphalt? • The asphalt is a mixture which consists alumina, lime, silica and asphaltic bitumen. • At low temperatures, it is in solid state and at high temperatures it is in liquid state. • Asphalt is produced in two different ways as follows. Natural asphalt Residual asphalt Natural Asphalt • Natural asphalt is obtained directly from the nature especially from the two resources lakes and rocks. • The lake asphalt contains 40 to 70 % of pure bitumen which is boiled in tank and water content evaporates and impurities are separated. • The final product is called as asphalt which can be used for laying roads etc. • Rock asphalt contains 10 to 15% of pure bitumen and calcareous matter. These rocks are crushed and heated and consolidates by sudden cooling. This asphalt is used for paving tiles etc.

- 16. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 16 Prepared By- Prof. Basweshwar S. J. 3.1.3 Highway Materials: Bituminous materials – Bitumen, Tar, and Asphalt – various properties, Design of Bituminous paving mixes-Marshall stability test What is Asphalt? • The asphalt is a mixture which consists alumina, lime, silica and asphaltic bitumen. • At low temperatures, it is in solid state and at high temperatures it is in liquid state. • Asphalt is produced in two different ways as follows. Natural asphalt Residual asphalt Residual Asphalt • Residual asphalt is obtained artificially by the distillation of crude petroleum oil with asphaltic base.

- 17. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 17 Prepared By- Prof. Basweshwar S. J. 3.1.3 Highway Materials: Bituminous materials – Bitumen, Tar, and Asphalt – various properties, Design of Bituminous paving mixes-Marshall stability test Forms of Asphalt The available forms of asphalt are: Cutback Asphalt • Cutback asphalt is in liquid state. • Asphalt is dissolved in a volatile solvent to get this cutback asphalt. • It is used for manufacturing bituminous paint, repairing roofs etc. Asphalt Emulsion • Asphaltic emulsion is obtained by adding 50 to 60% water to the asphalt in presence of 1% emulsifying agent. • The emulsifying agent forms waterproof film when water evaporates. • So, it can be used in cold conditions. Asphalt Cement • Natural asphalt is subjected to high pressure air under high temperature to get asphalt cement. • Asphalt cement is plastic in nature and it is used for flooring, roofing, water proofing material etc. Mastic Asphalt • Mastic asphalt is obtained by heating natural asphalt with sand and mineral fillers. • It is impermeable matter does not contain any voids. • It is in solid state and by heating it can be brought to liquid state. • It is used for damp proofing course.

- 18. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 18 Prepared By- Prof. Basweshwar S. J. 3.1.3 Highway Materials: Bituminous materials – Bitumen, Tar, and Asphalt – various properties, Design of Bituminous paving mixes-Marshall stability test 3.1.3.2 What is Bitumen? • Bitumen is obtained by the partial distillation of crude petroleum. • It is also called as mineral tar and is present in asphalt also. • It contains 87% carbon, 11% hydrogen and 2% oxygen. The forms of bitumen are generally 5 types as follows. • Cutback bitumen • Bitumen emulsion • Plastic bitumen • Blown bitumen • Straight run bitumen

- 19. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 19 Prepared By- Prof. Basweshwar S. J. 3.1.3 Highway Materials: Bituminous materials – Bitumen, Tar, and Asphalt – various properties, Design of Bituminous paving mixes-Marshall stability test Cutback Bitumen • Cutback bitumen is obtained from the distillation of asphaltic bitumen with the addition of coal tar or petroleum. • Cut back bitumen can be used as paint in cold weather conditions. Bitumen Emulsion • Bitumen emulsion is obtained by dissolving very finely divided bitumen in an aqueous medium. • Suitable stabilizing agents are added to this solution. Plastic Bitumen • Plastic bitumen majorly contains inert filler about 40 to 45% and bitumen and thinner is the other material. • It is used as sealing material for leakages, cracks in masonry structures etc. Straight Run Bitumen • Straight run bitumen is obtained by the distillation of bitumen into definite viscosity. • It is also available as rocks. Blown Bitumen • Blown bitumen is special type of bitumen. • It is manufactured by subjecting bitumen to air under heavy pressure at high temperature. • It can be used as damp proofing material, heat insulating material etc.

- 20. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 20 Prepared By- Prof. Basweshwar S. J. 3.1.3 Highway Materials: Bituminous materials – Bitumen, Tar, and Asphalt – various properties, Design of Bituminous paving mixes-Marshall stability test 3.1.3.3 What is Tar? • Tar is a high viscous liquid which contains high amount of carbon content. • It is used for laying surface layer for pavements, preserving wood etc.. Forms of Tar General forms of tar are as follows. • Coal tar • Wood tar • Mineral tar

- 21. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 21 Prepared By- Prof. Basweshwar S. J. 3.1.3 Highway Materials: Bituminous materials – Bitumen, Tar, and Asphalt – various properties, Design of Bituminous paving mixes-Marshall stability test Coal Tar • Coal tar is the by-product obtained during the production of coal gas. • It is used for preserving timber, laying macadam roads etc. • The process consists of coal heated in closed iron vessels and the evaporated gases are collected in tubes. • These tubes are circulated with cooling water. • So, some matter is deposited in these tubes and it is nothing but coal tar. • It is dense and strong-smelling liquid. • It is in black color. Wood Tar • Wood tar is obtained by the distillation of resinous woods like pines etc. • The distillation of resinous wood provides the creosote oil which has very good preservative property. • So, wood tar is well suitable for preserving wood. Mineral Tar • Mineral tar is produced by the exploitation of kerogens. • Kerogens are generally obtained from bituminous shale’s which are nothing but rocks. • Volatile content of mineral tar is very less.

- 22. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 22 Prepared By- Prof. Basweshwar S. J. Comparison Between Asphalt, Bitumen and Tar Properties Property Asphalt Bitumen Tar Color Blackish brown Dark color with slight reddish tinge Deep black State Solid or semi-solid Solid Viscous Liquid Carbon content Low Medium High Water Resistance More More Less Acid resistance More More Less Adhesive power Less More High Setting time Less Less More

- 23. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 23 Prepared By- Prof. Basweshwar S. J. 3.2 Design of Bituminous paving mixes-Marshall stability test • The mix design (wetmix) determines the optimum bitumen content. • This is preceded by the dry mix design. • There are many methods available for mix design which vary in the size of the test specimen, compaction, and other test specifications. Marshall mix design • The Marshall stability and flow test provides the performance prediction measure for the Marshall mix design method. • The stability portion of the test measures the maximum load supported by the test specimen at a loading rate of 50.8 mm/minute. • Load is applied to the specimen till failure, and the maximum load is designated as stability. • During the loading, an attached dial gauge measures the specimen's plastic flow (deformation) due to the loading. • The flow value is recorded in 0.25 mm (0.01 inch) increments at the same time when the maximum load is recorded.

- 24. Shri Vile Parle Kelavani Mandal’s Institute of Technology, Dhule Department of Civil Engineering 24 Prepared By- Prof. Basweshwar S. J.