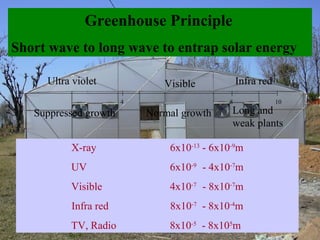

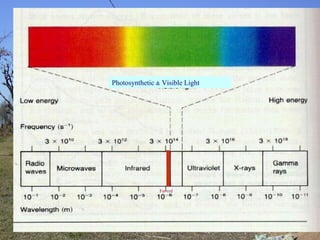

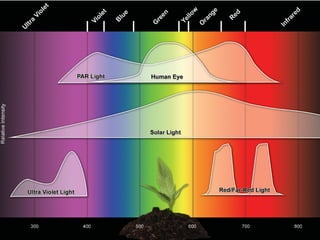

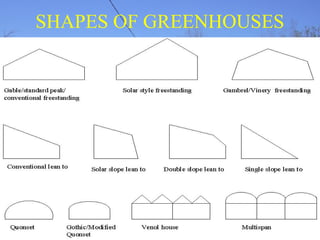

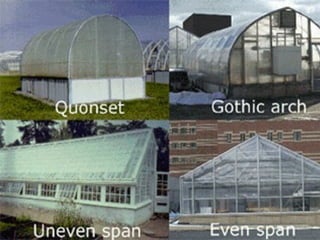

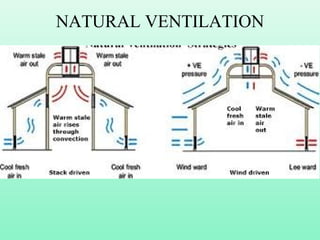

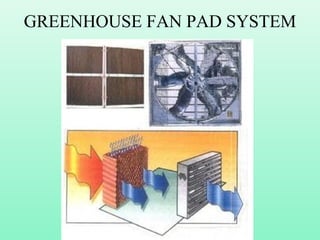

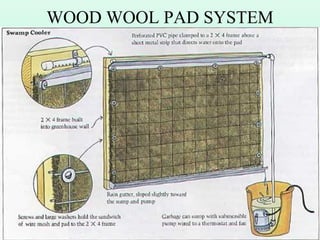

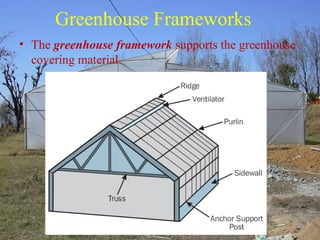

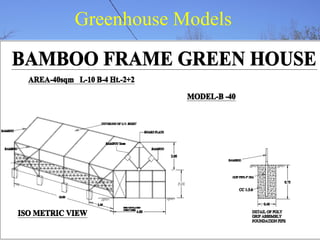

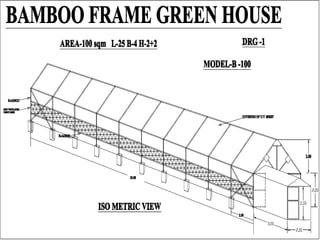

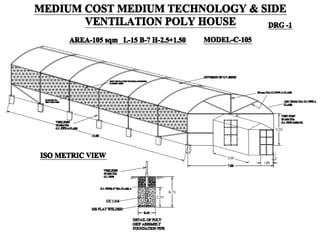

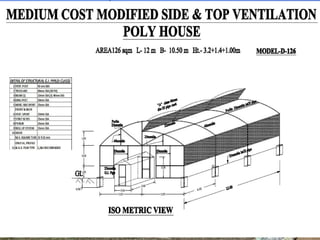

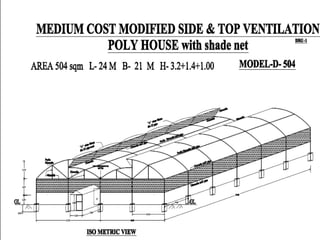

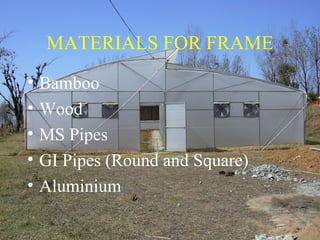

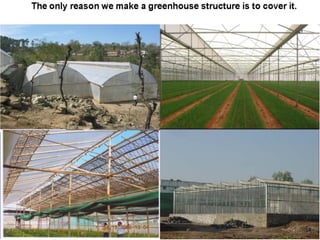

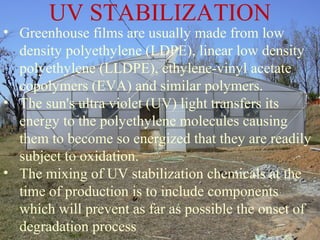

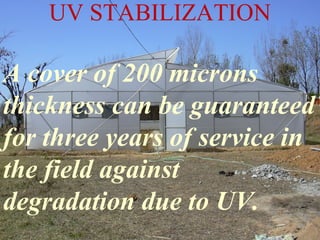

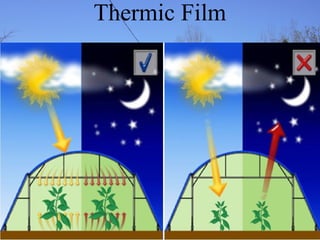

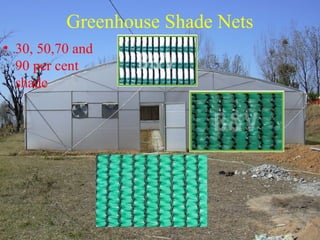

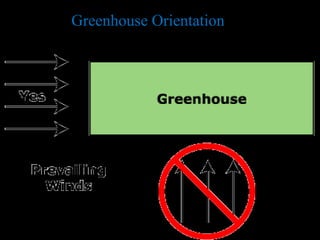

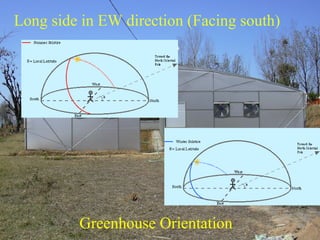

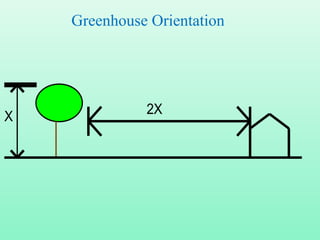

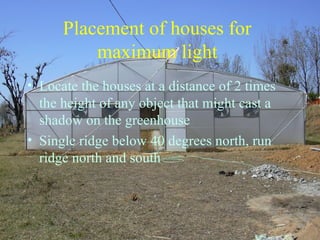

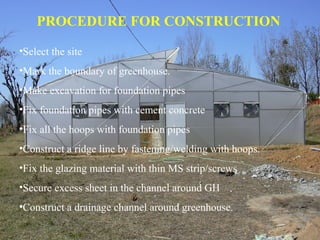

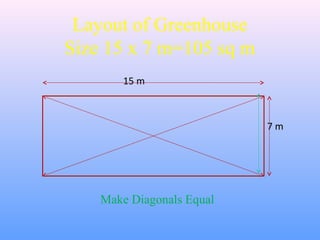

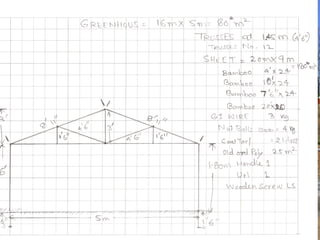

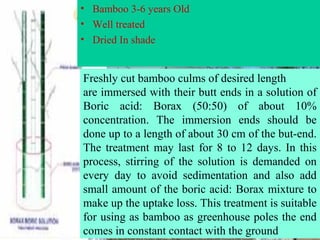

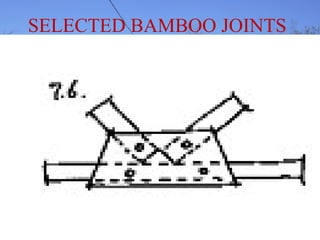

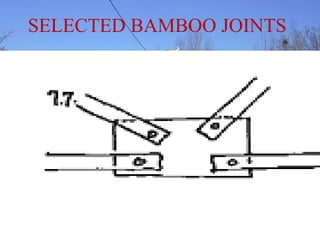

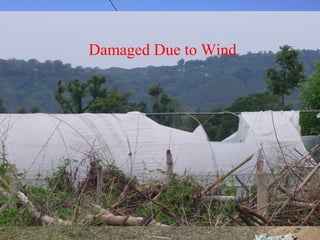

This document provides information on greenhouse types, design, and precautions. It discusses the principles of greenhouses, their uses for growing plants, and classifications based on cost. It describes different greenhouse shapes and frames materials. The document covers natural ventilation systems, glazing materials like glass and polyethylene films, and considerations for soil, water, and seeds. It provides details on greenhouse construction, orientation, sizing, and maintenance.