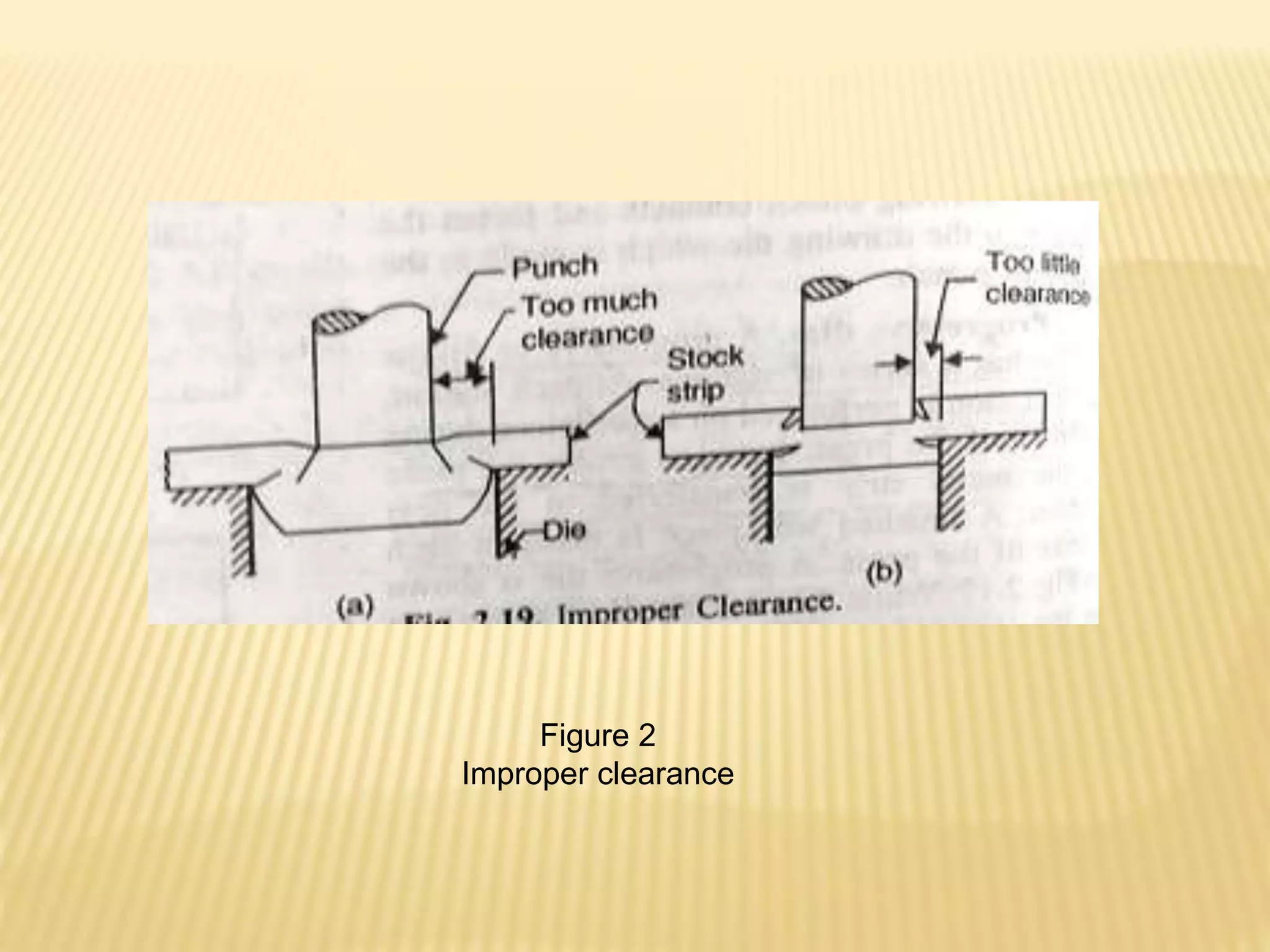

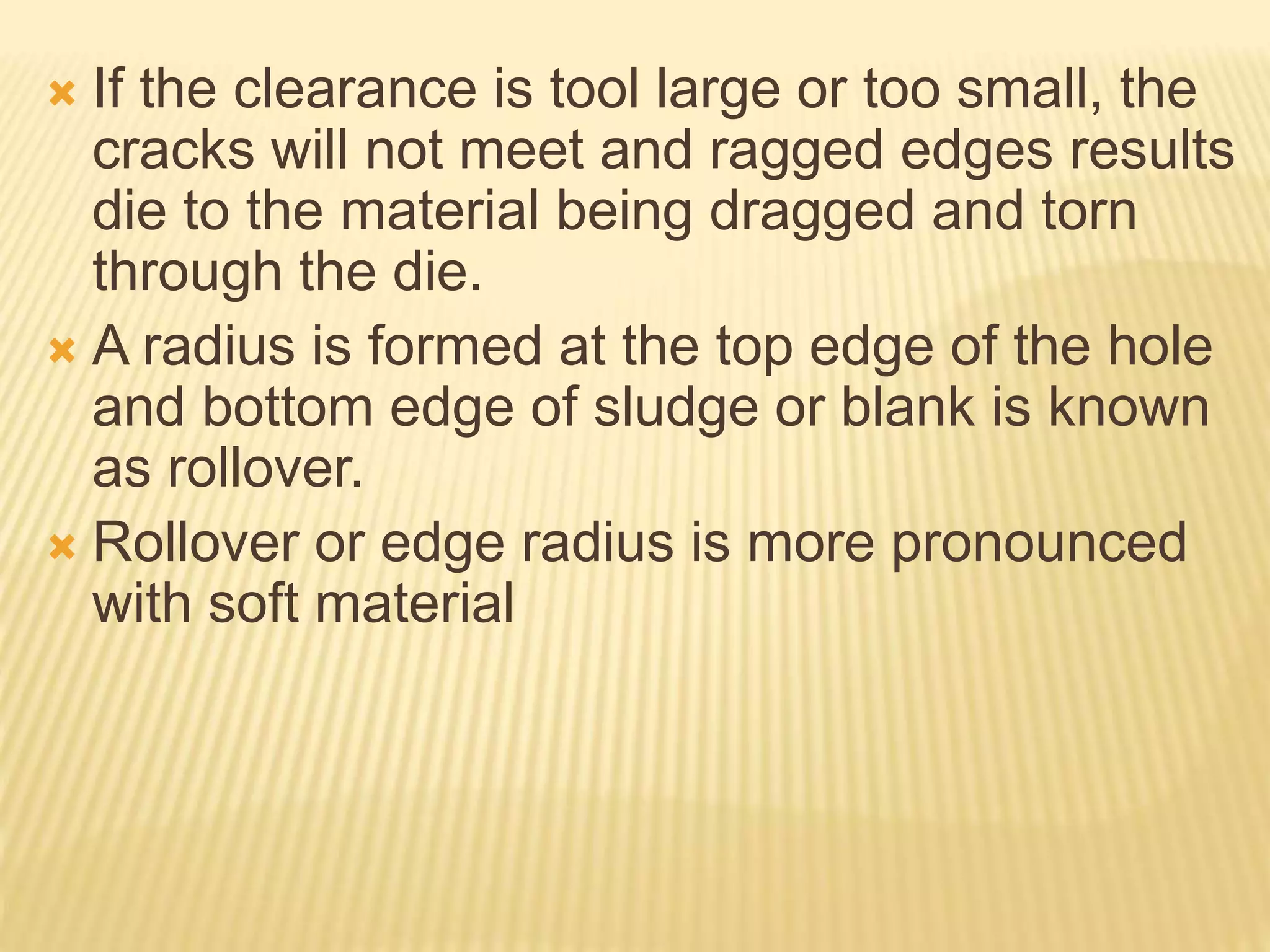

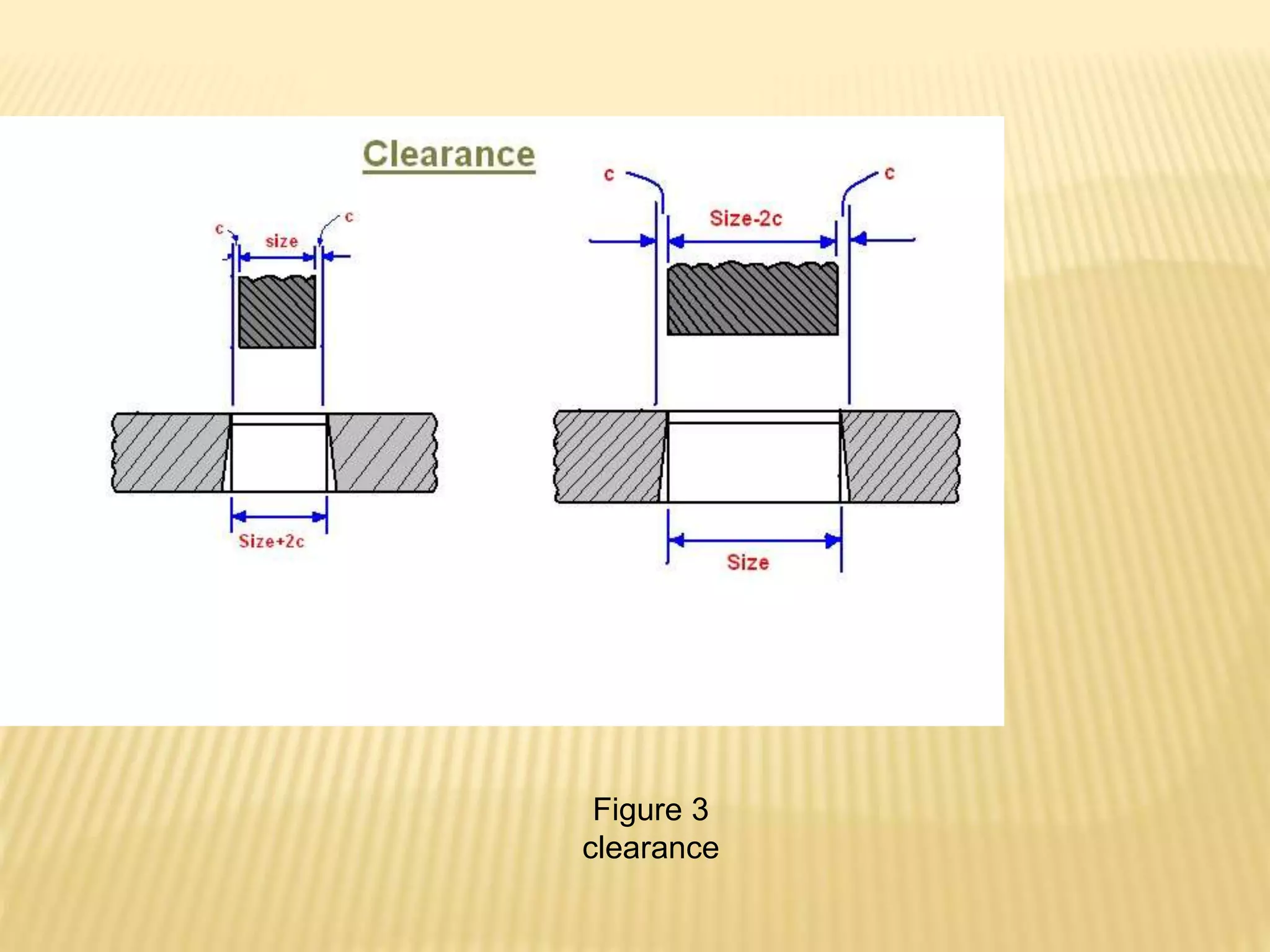

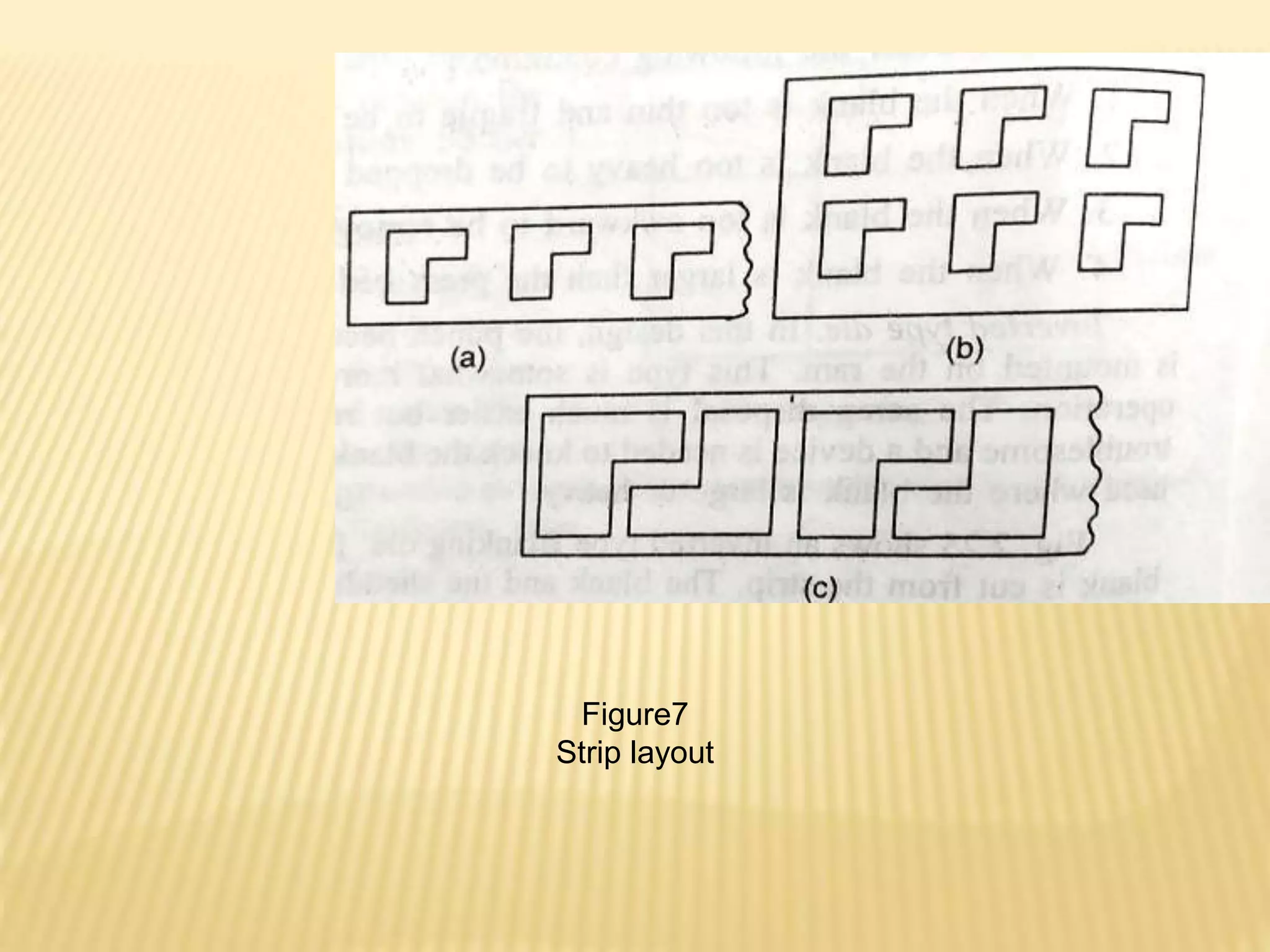

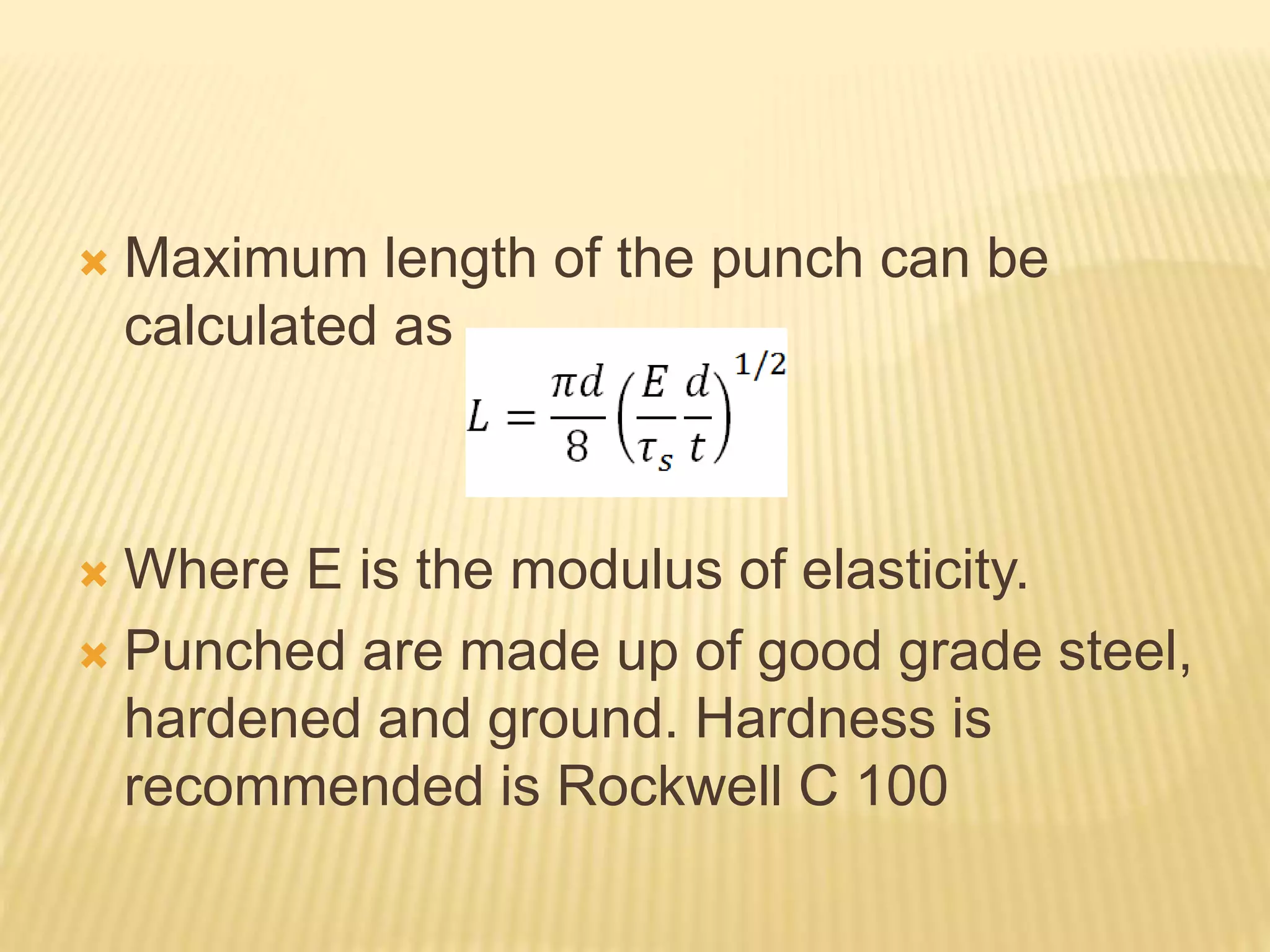

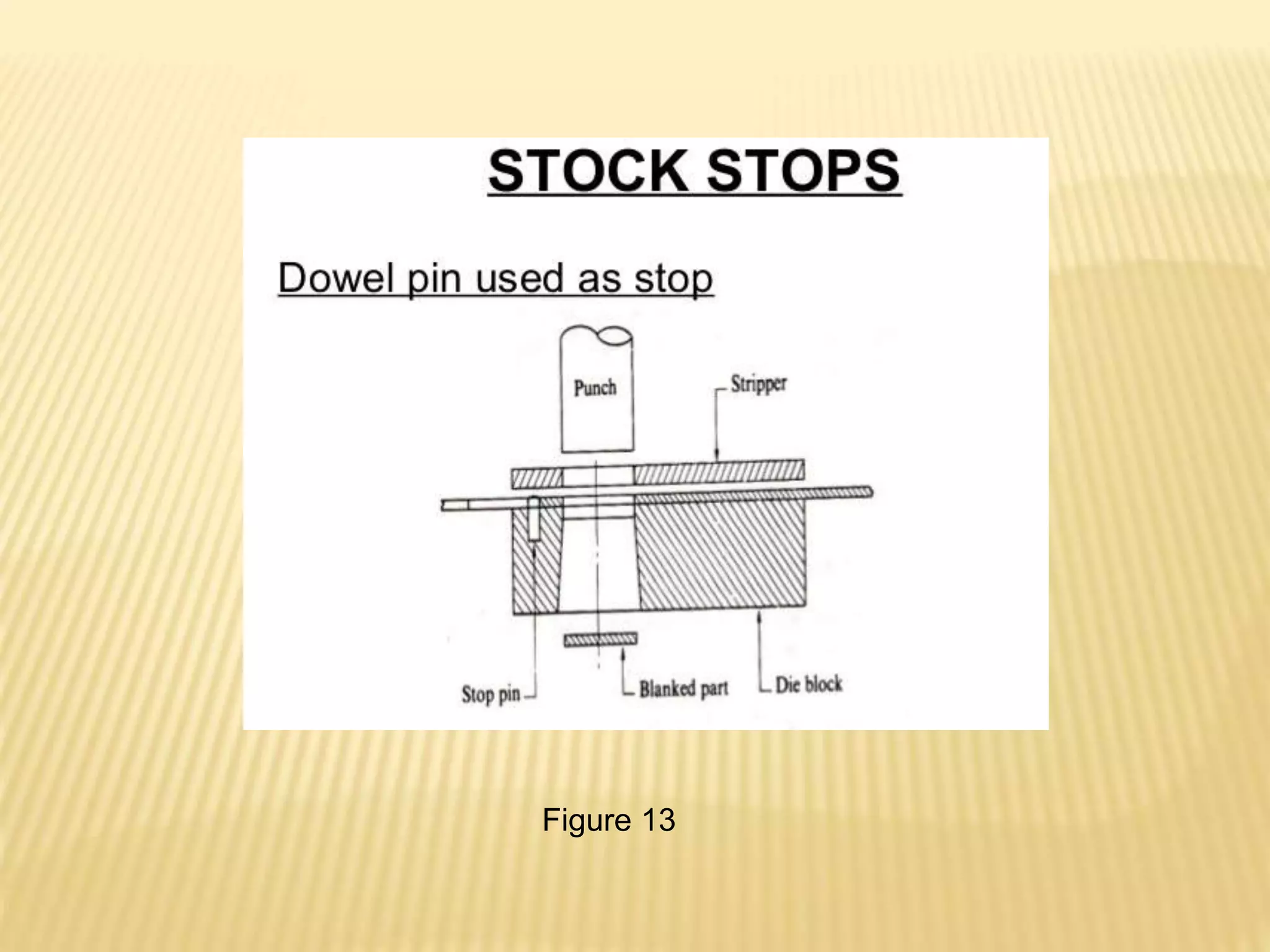

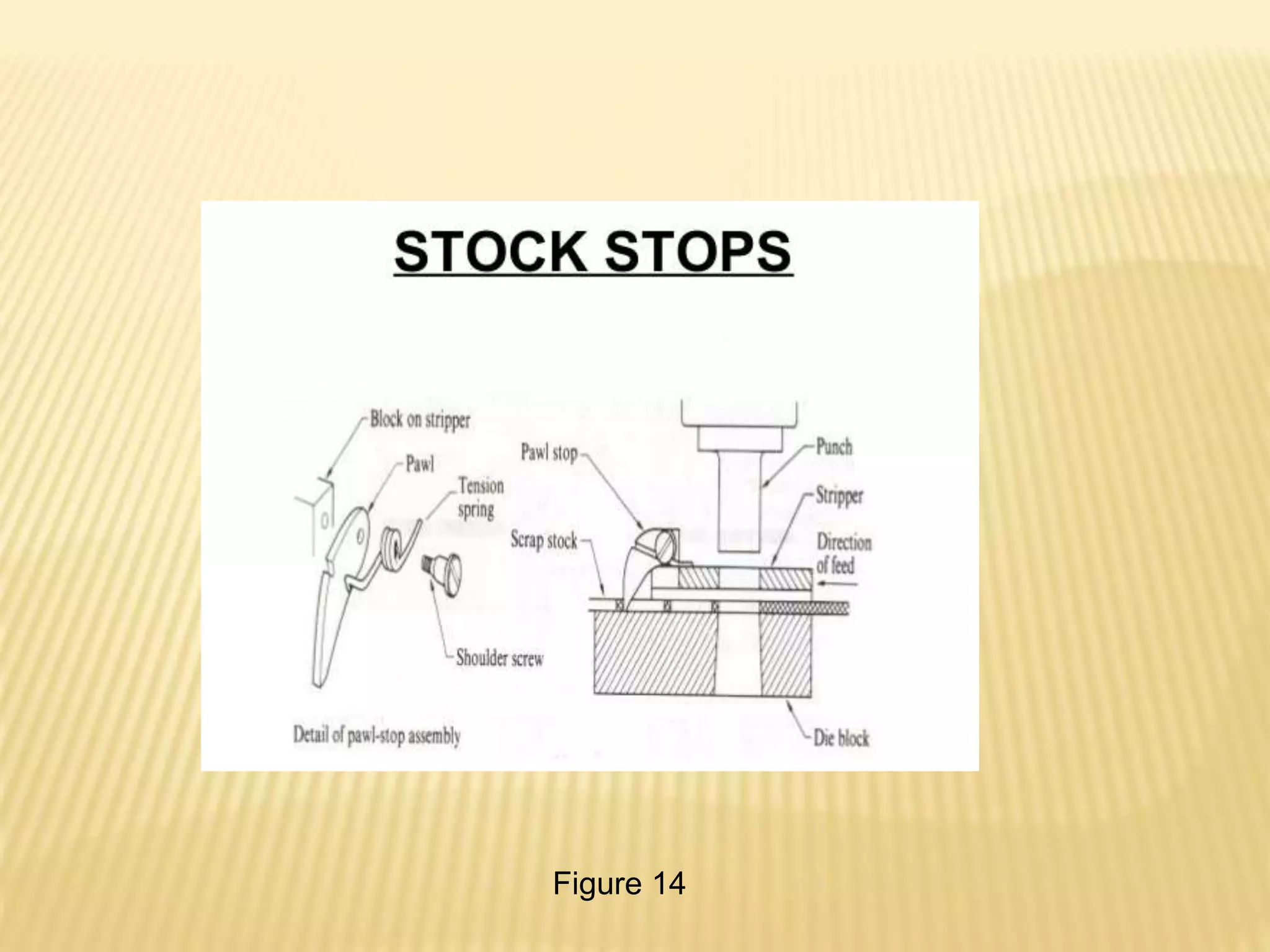

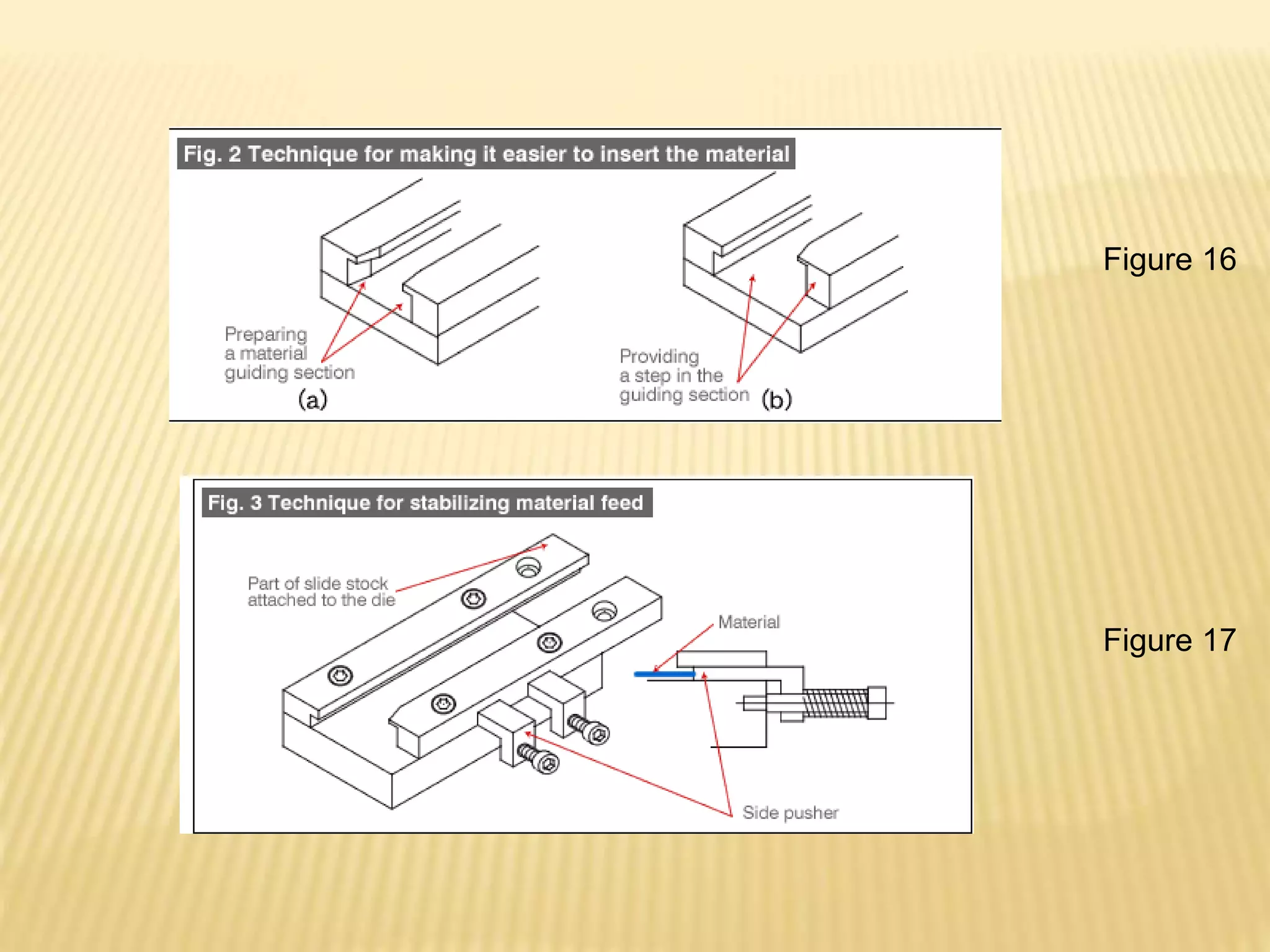

The document discusses the design of punches and dies used in sheet metal cutting operations. It covers topics such as the cutting action in a die, stresses during cutting, clearance between the punch and die, factors that affect minimum hole size, and blanking die design. Key points include that the cutting action is a shearing process, clearance is needed to allow the cut material to be displaced, and minimum hole size depends on the material thickness and properties.