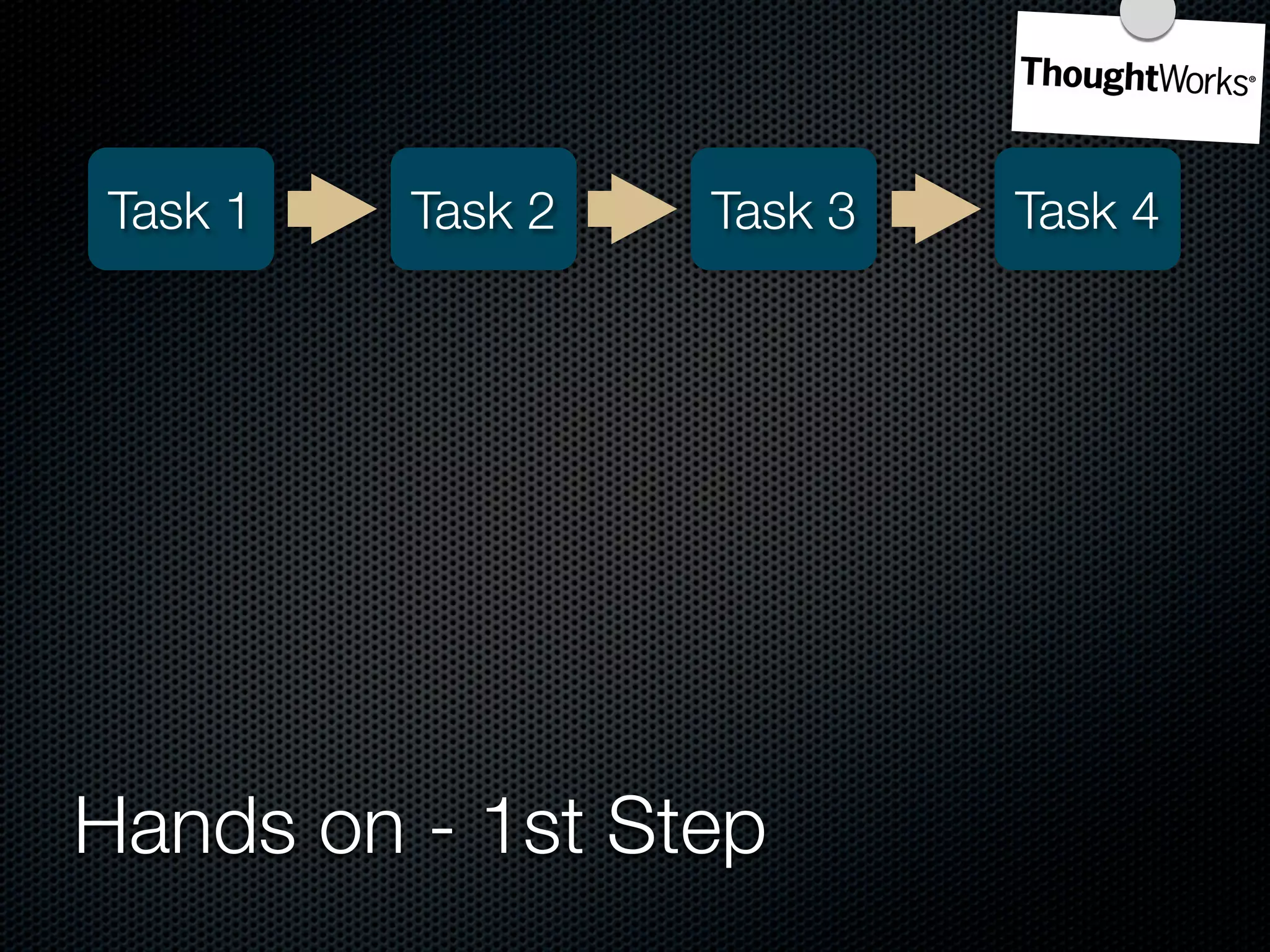

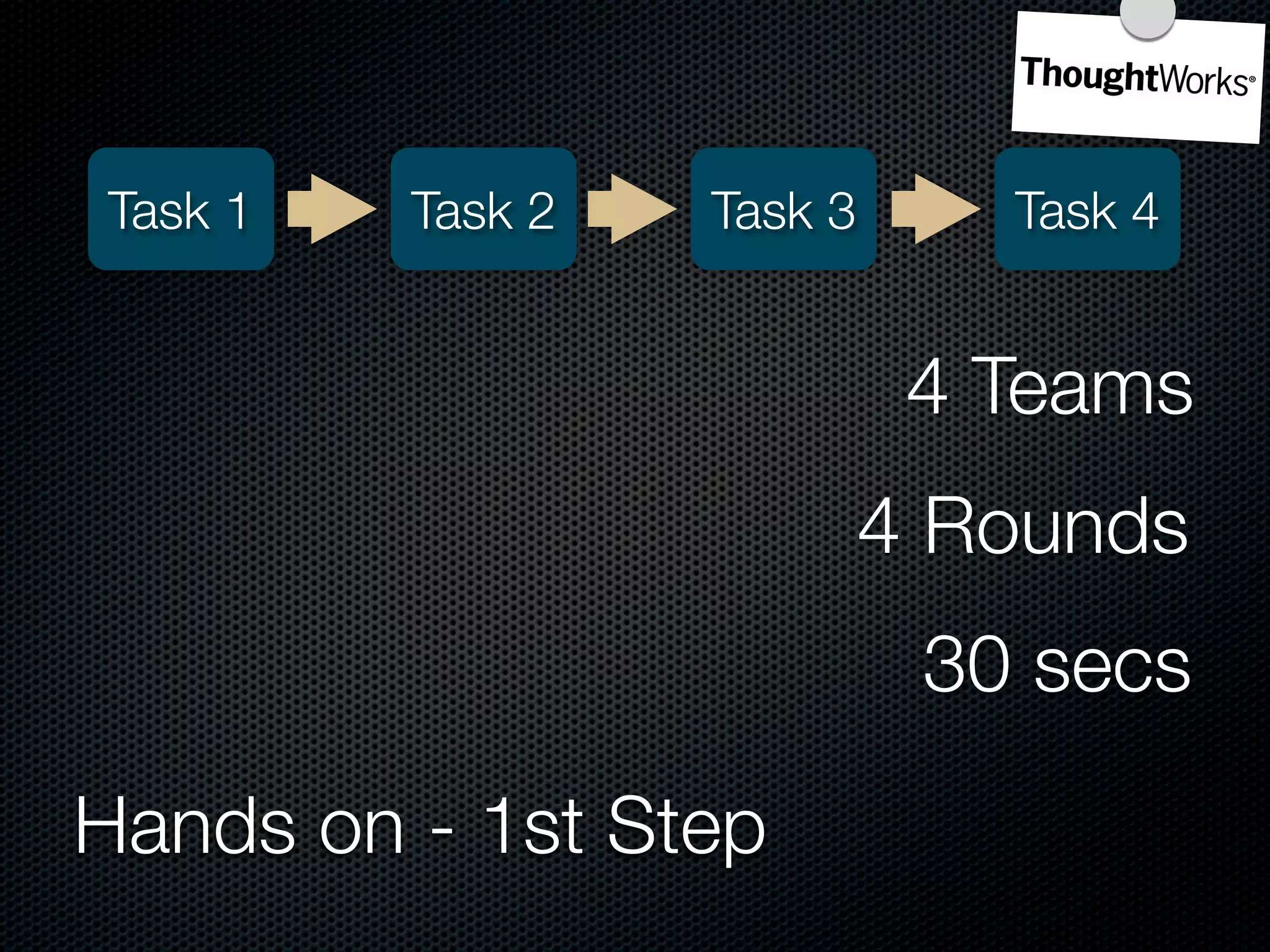

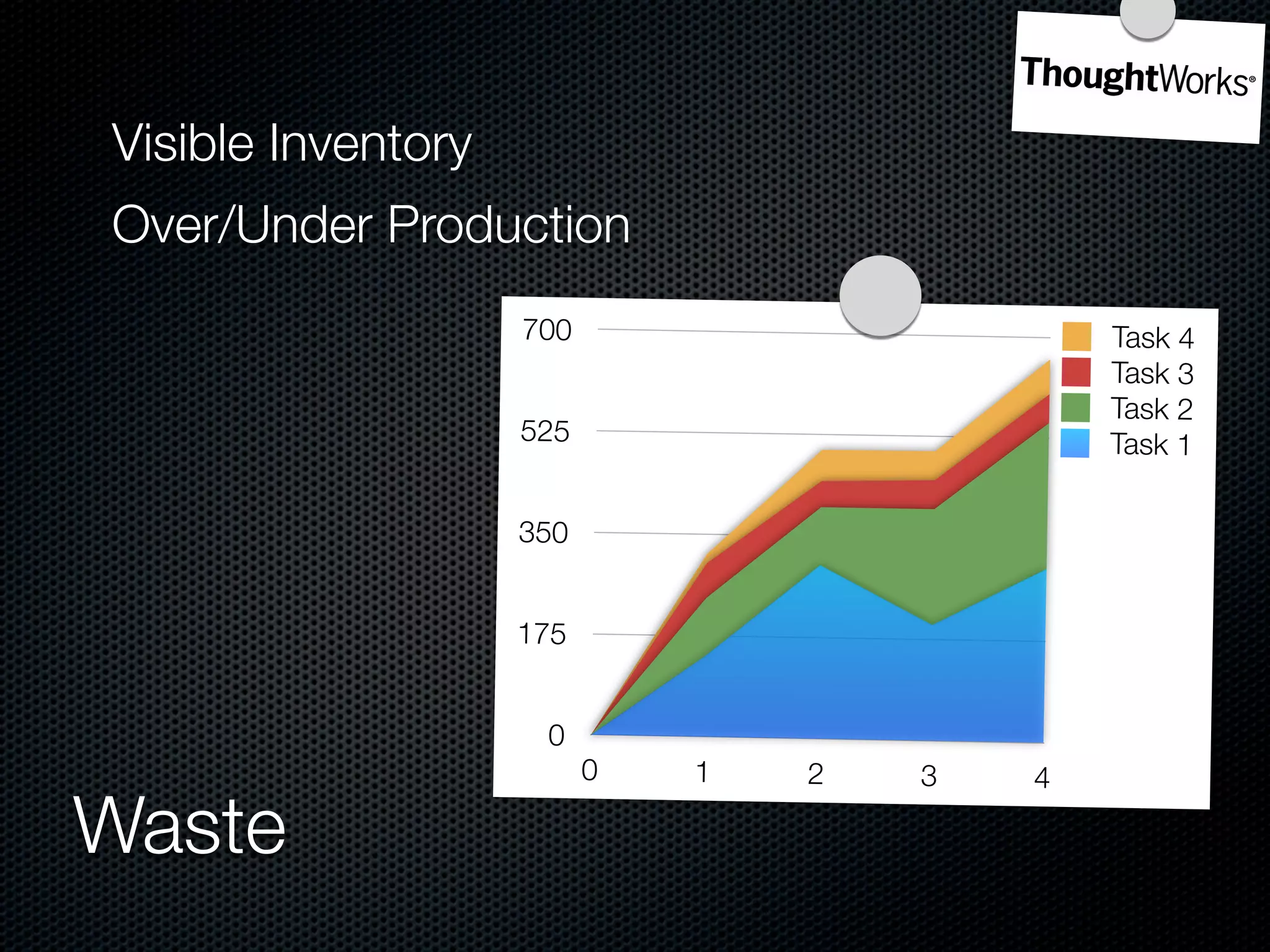

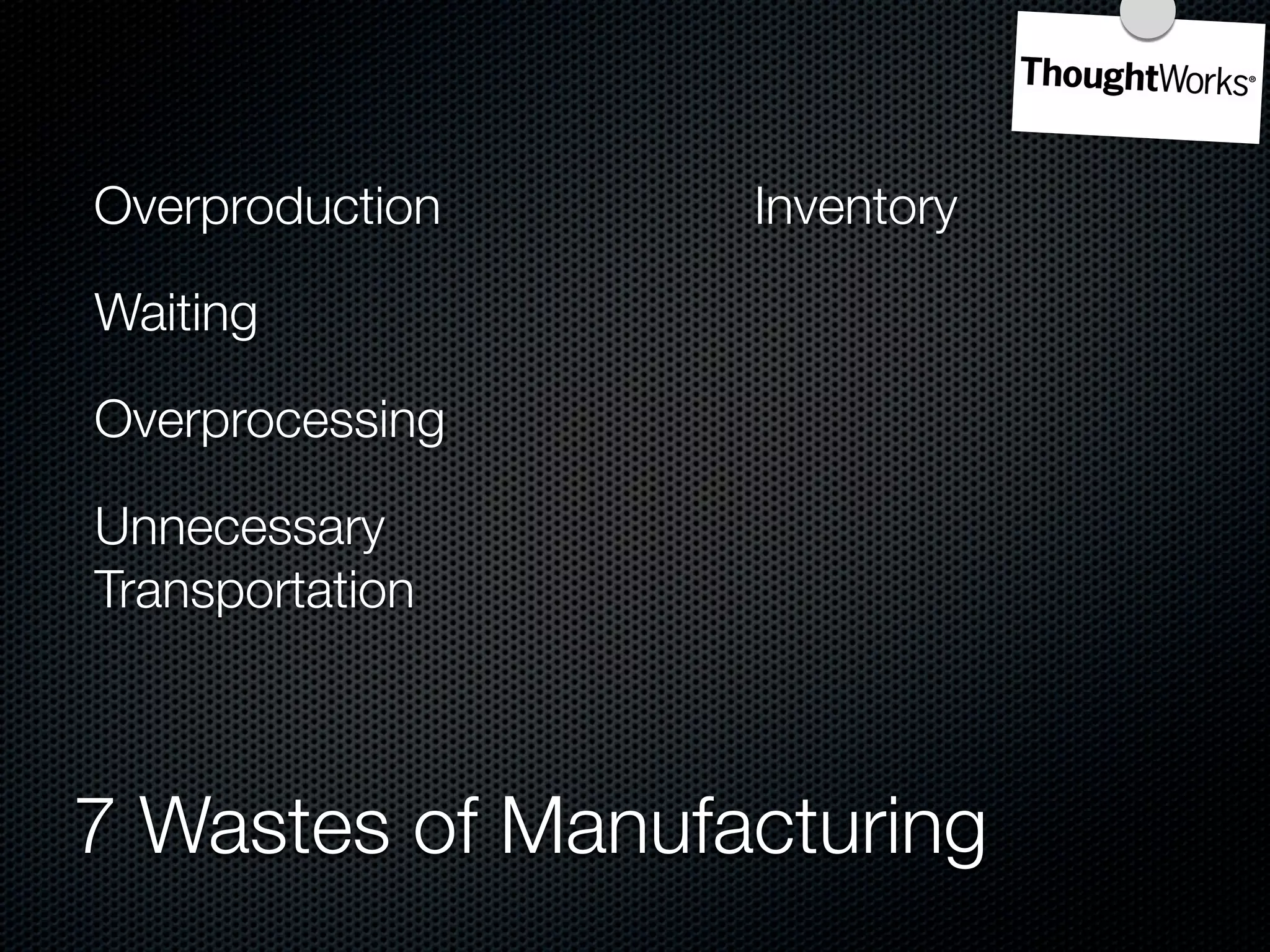

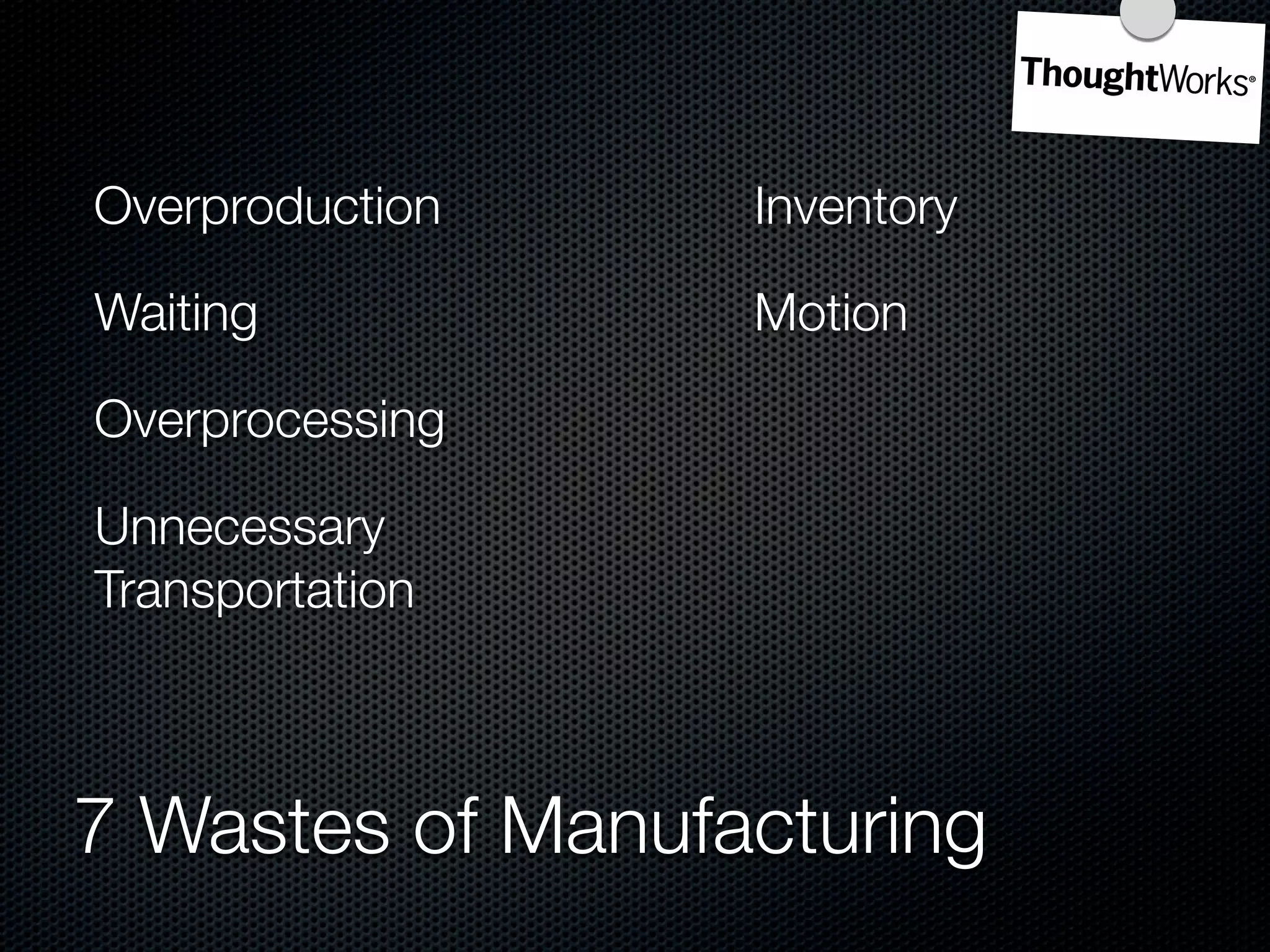

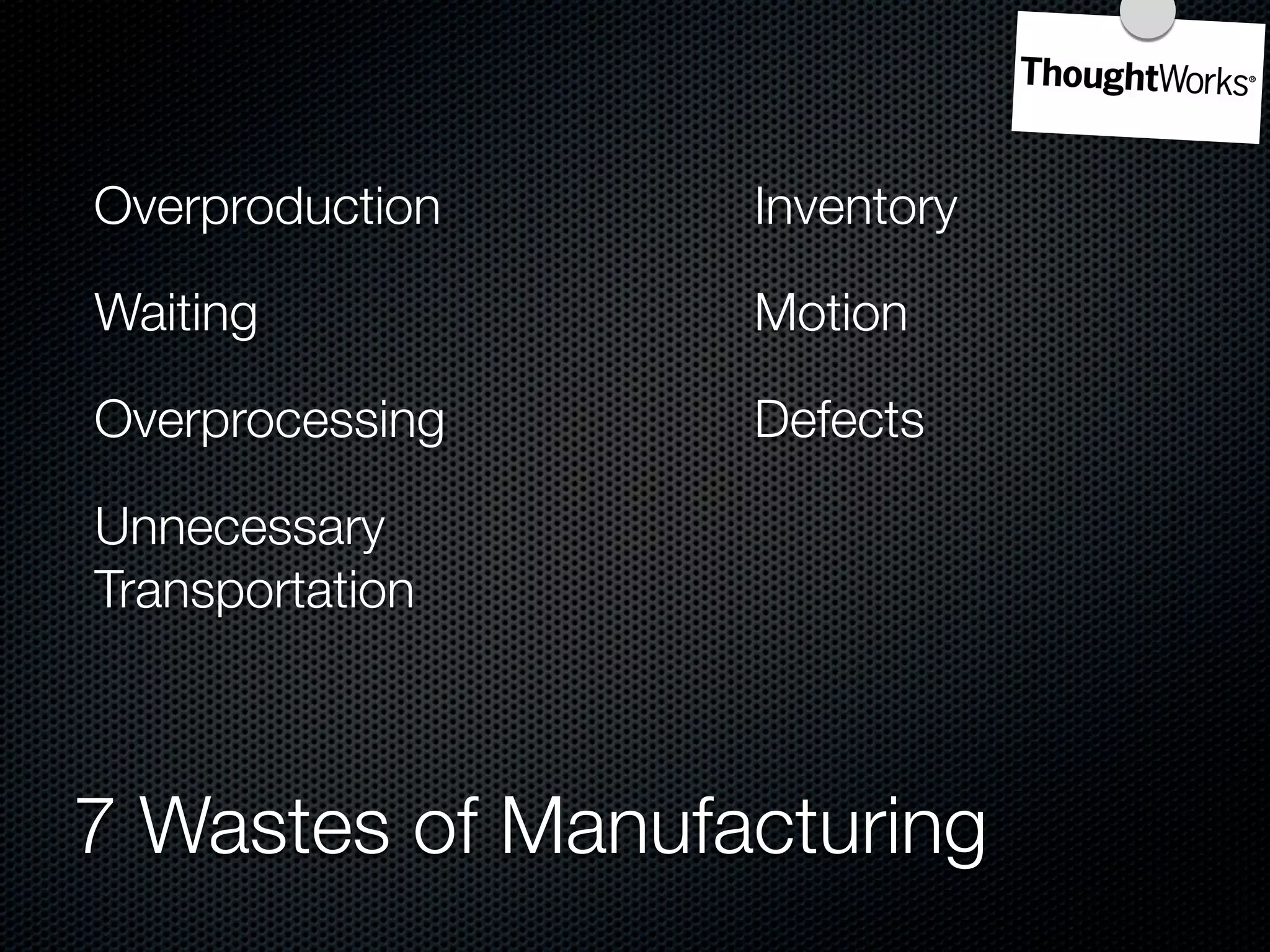

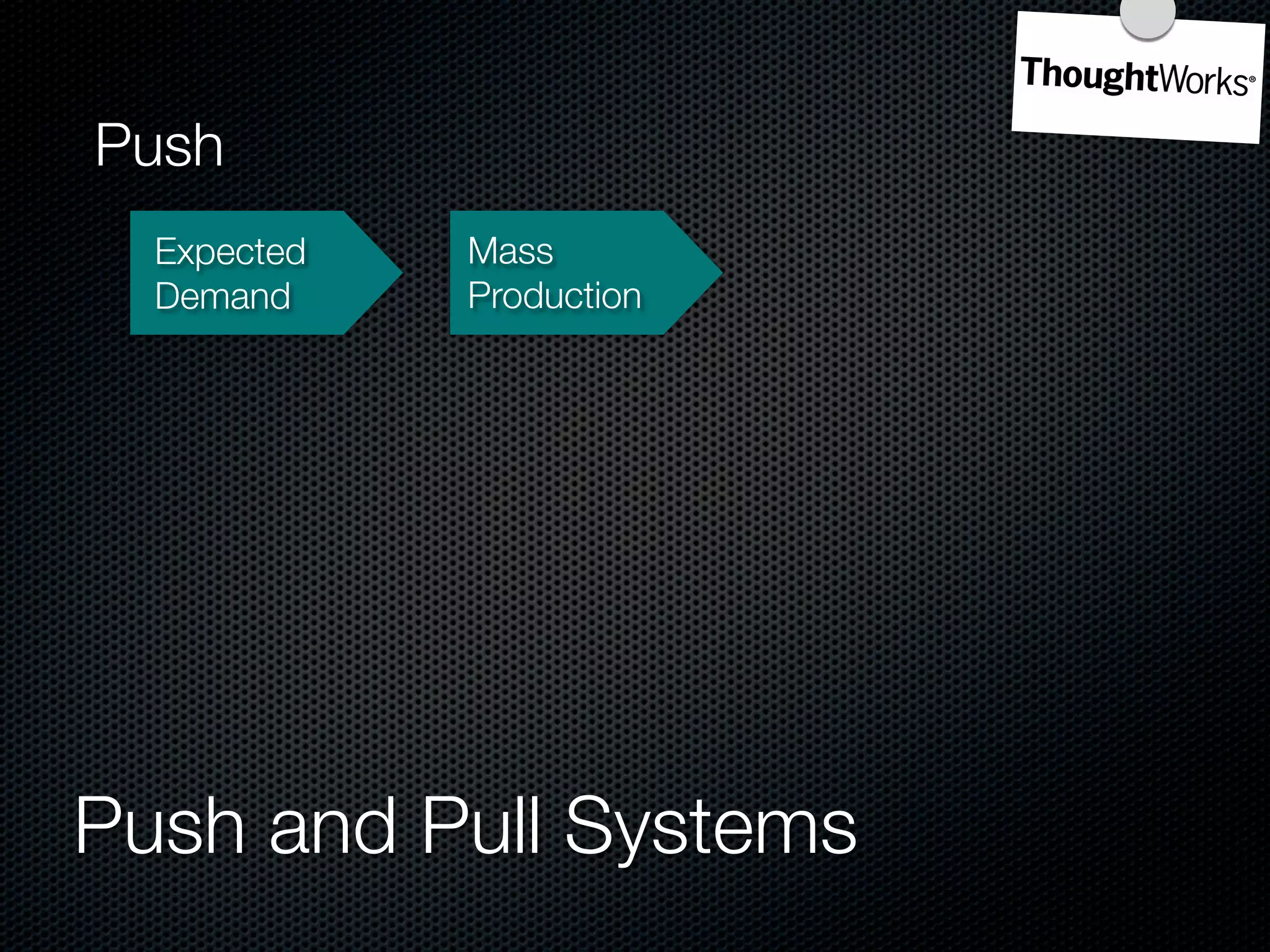

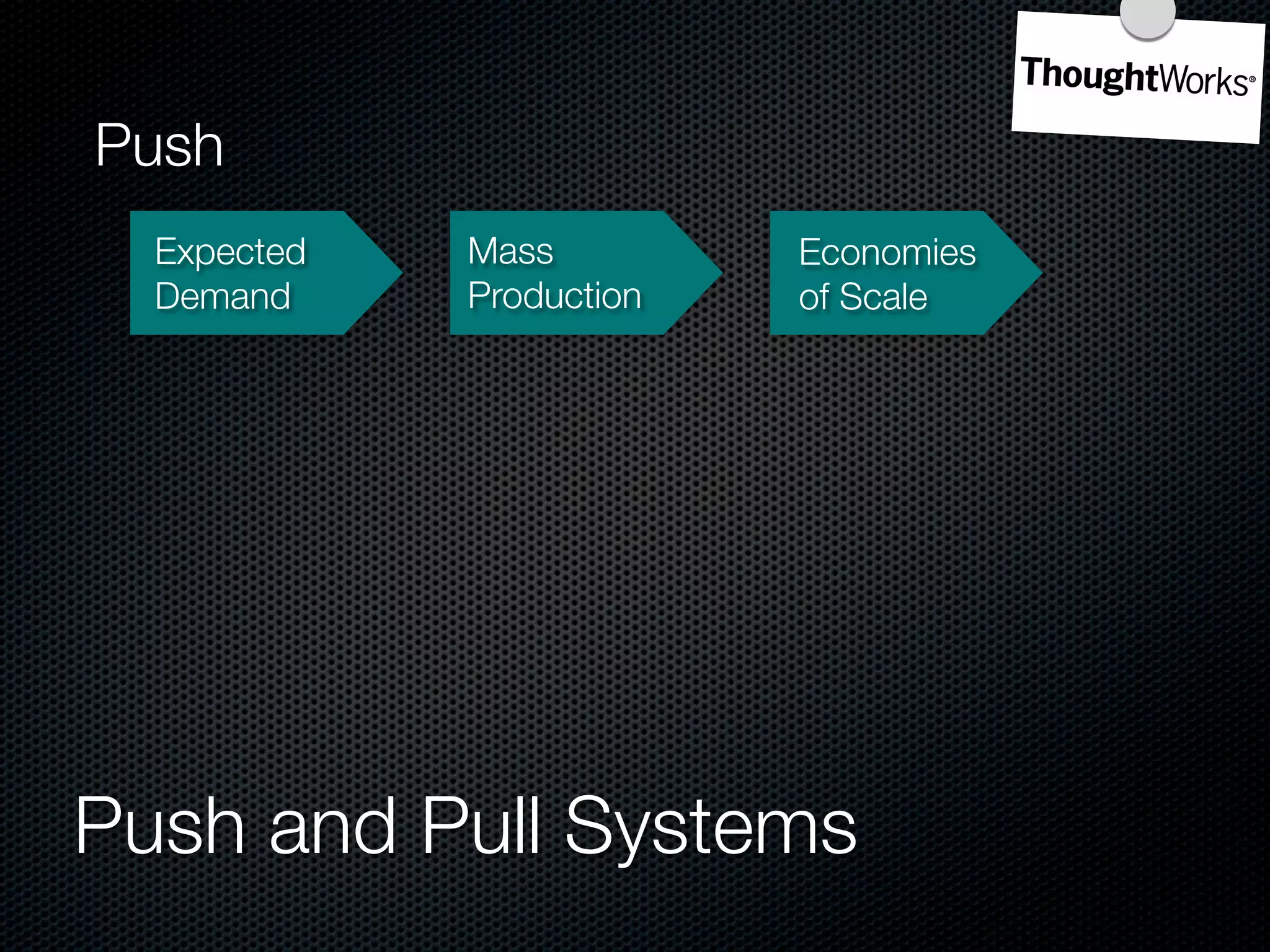

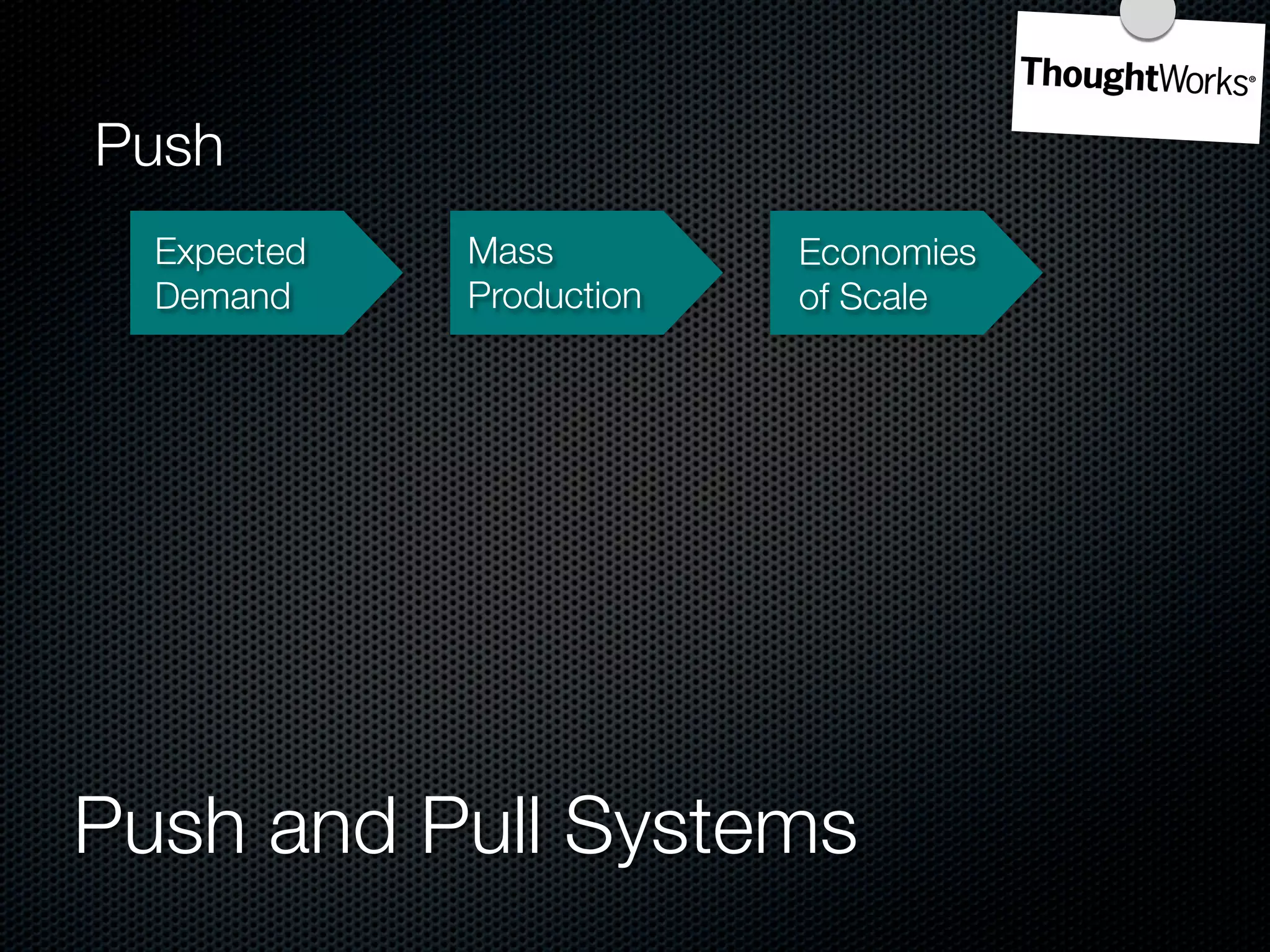

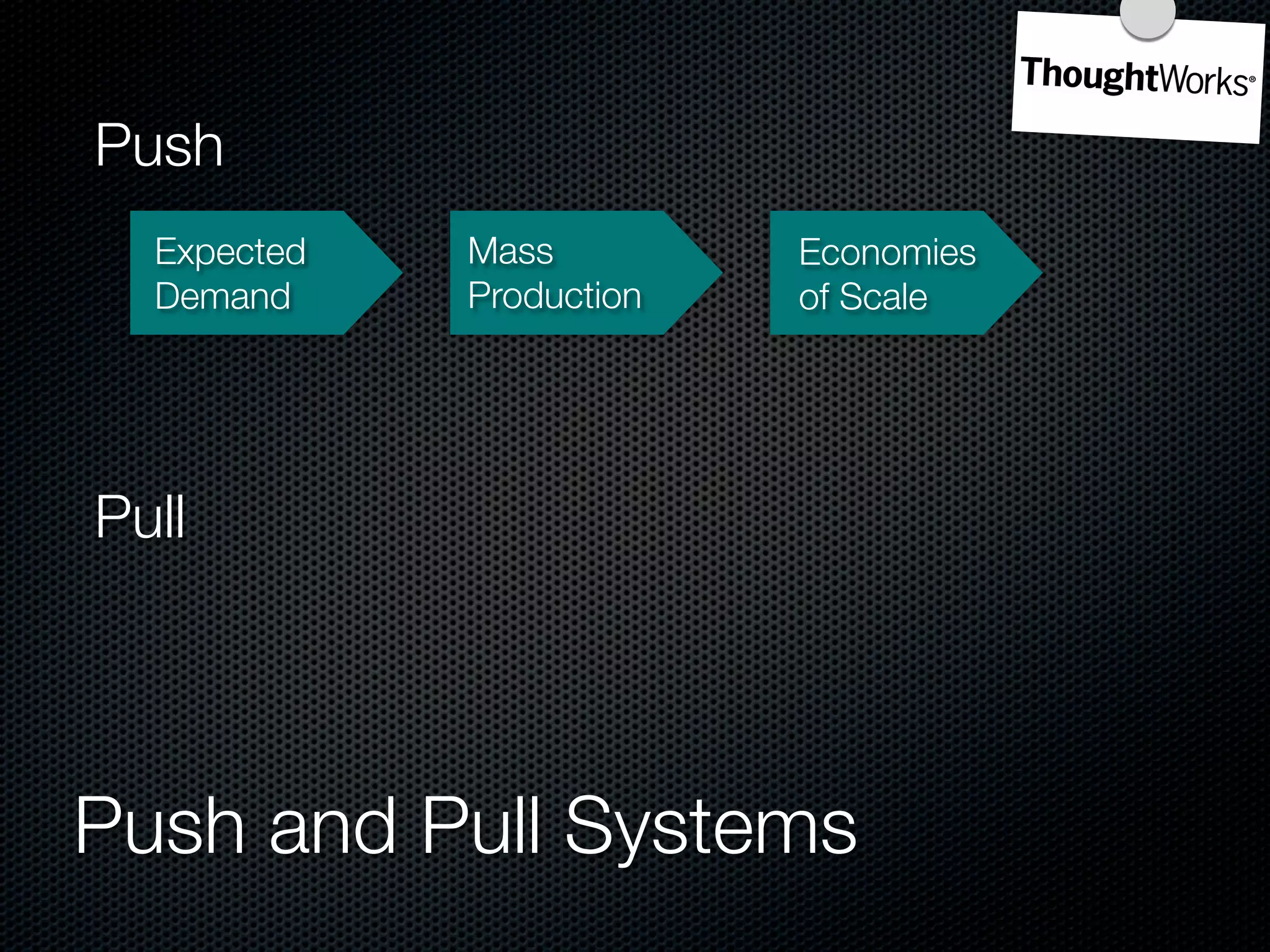

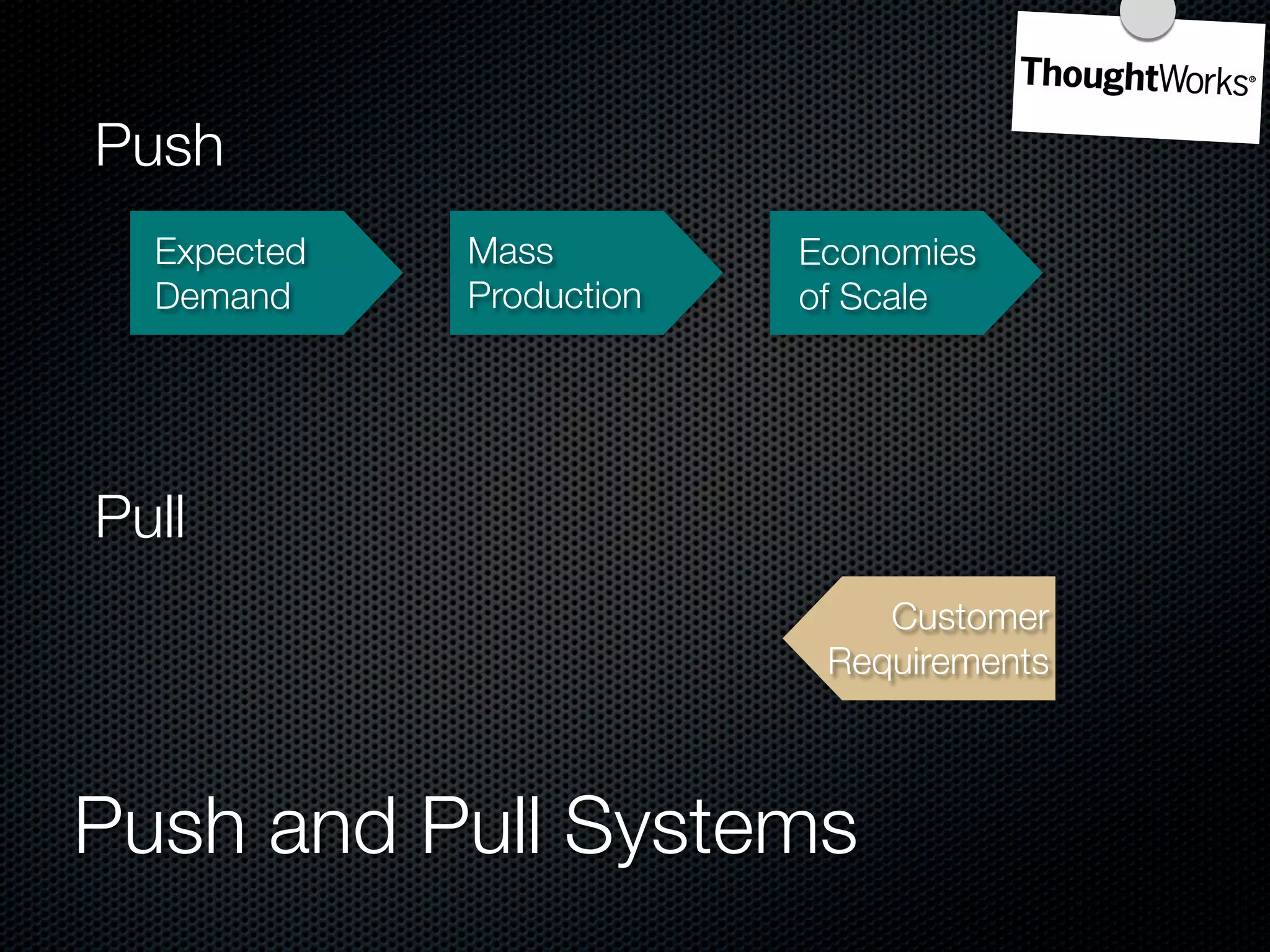

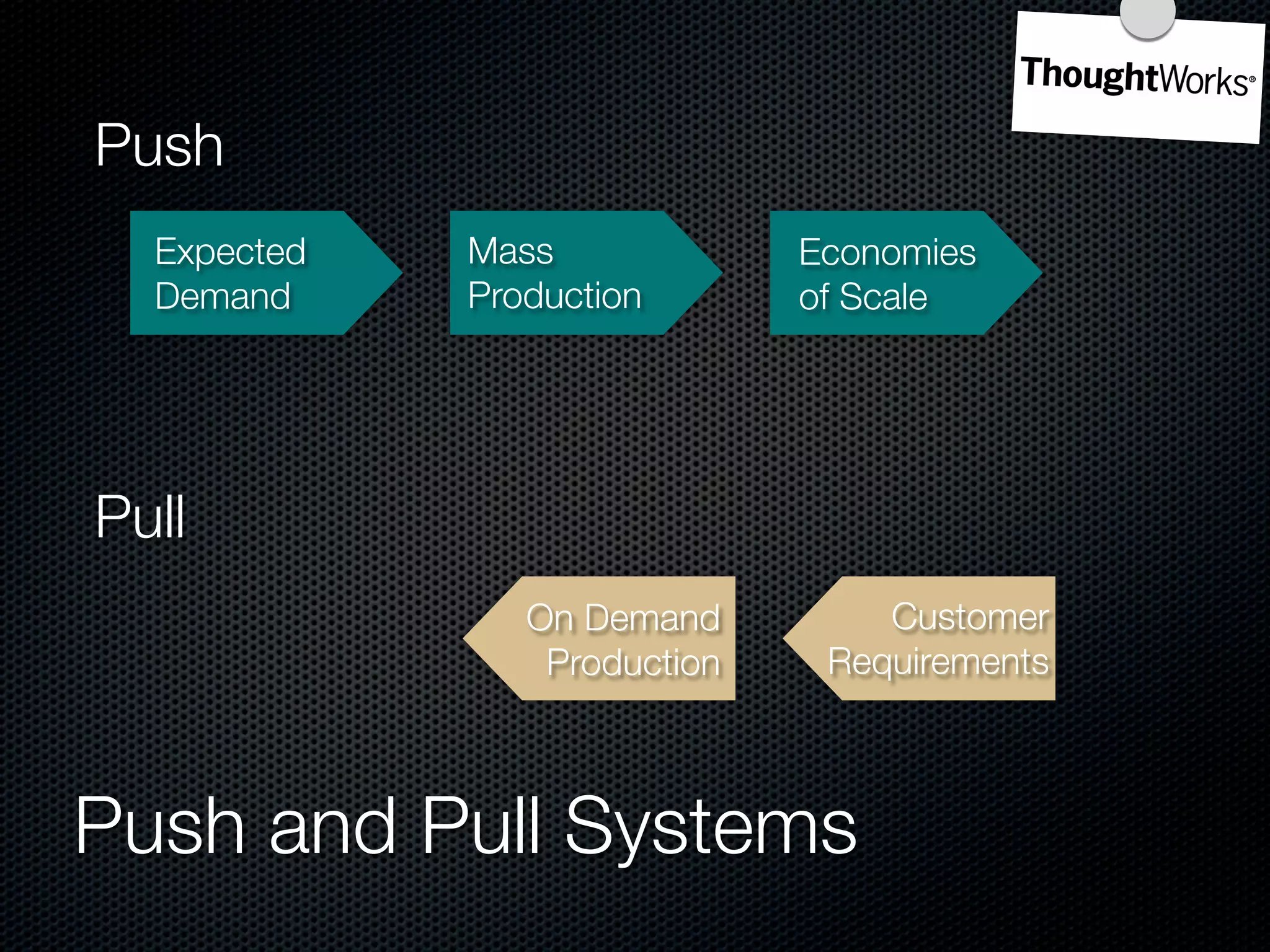

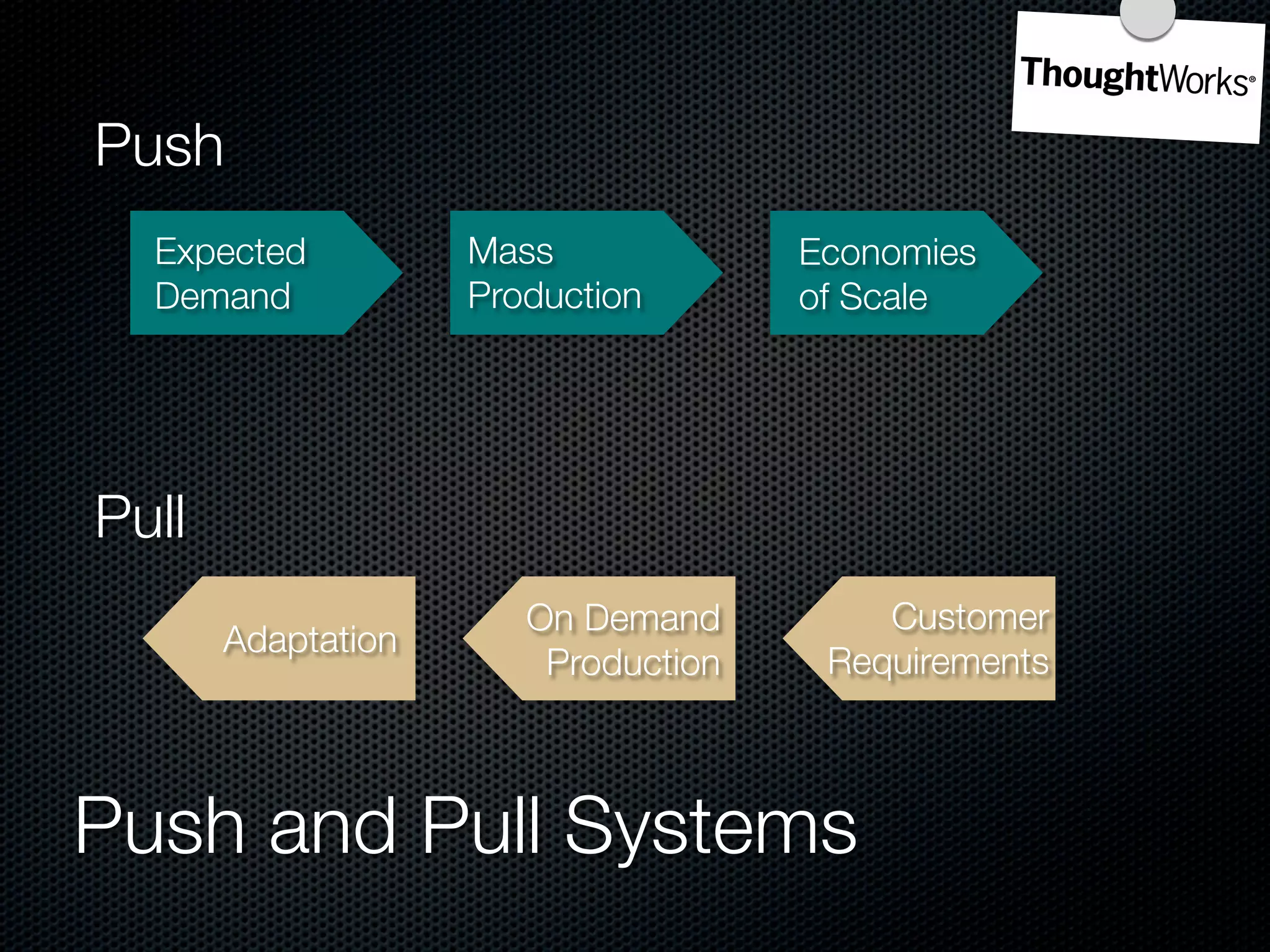

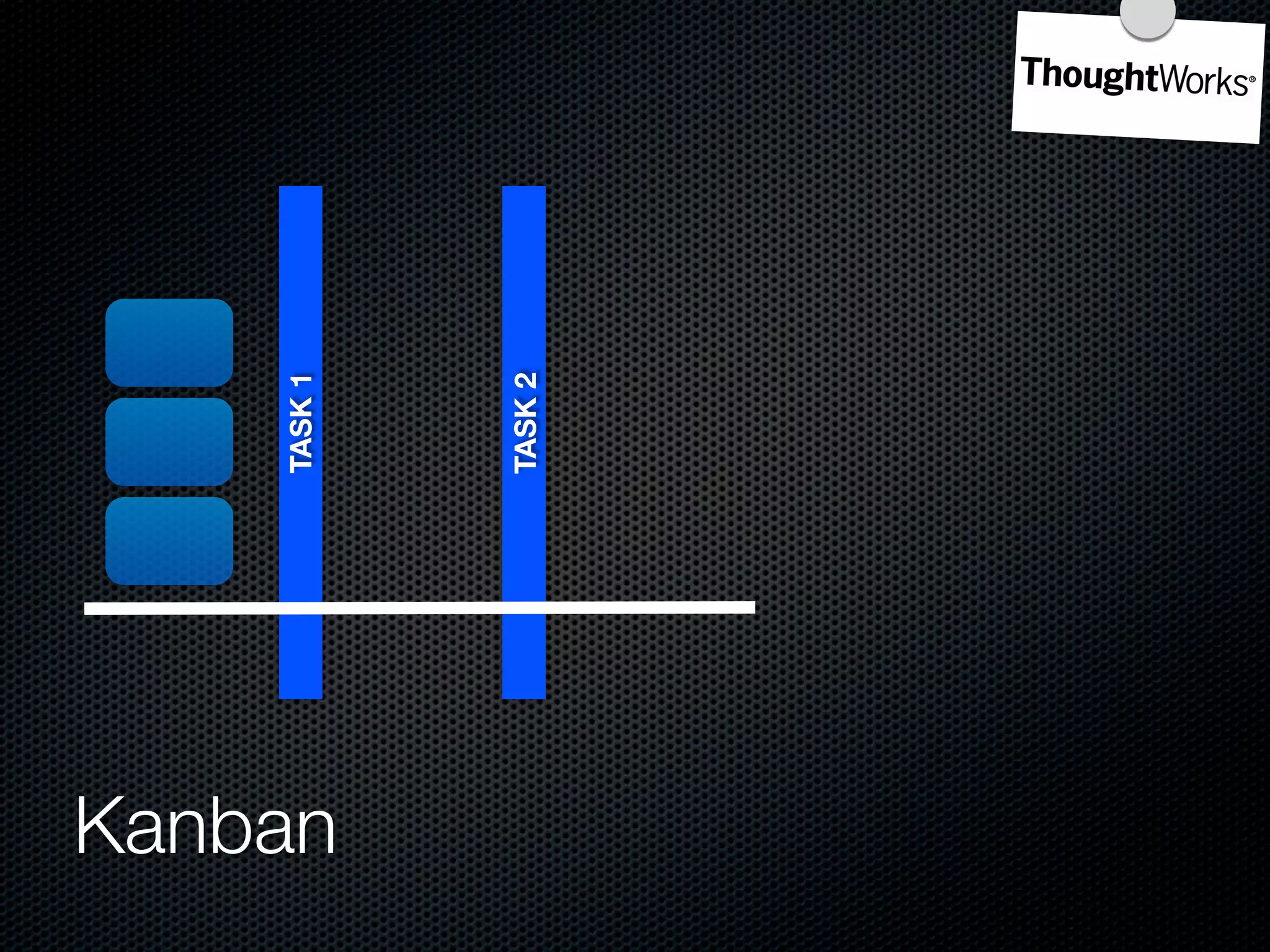

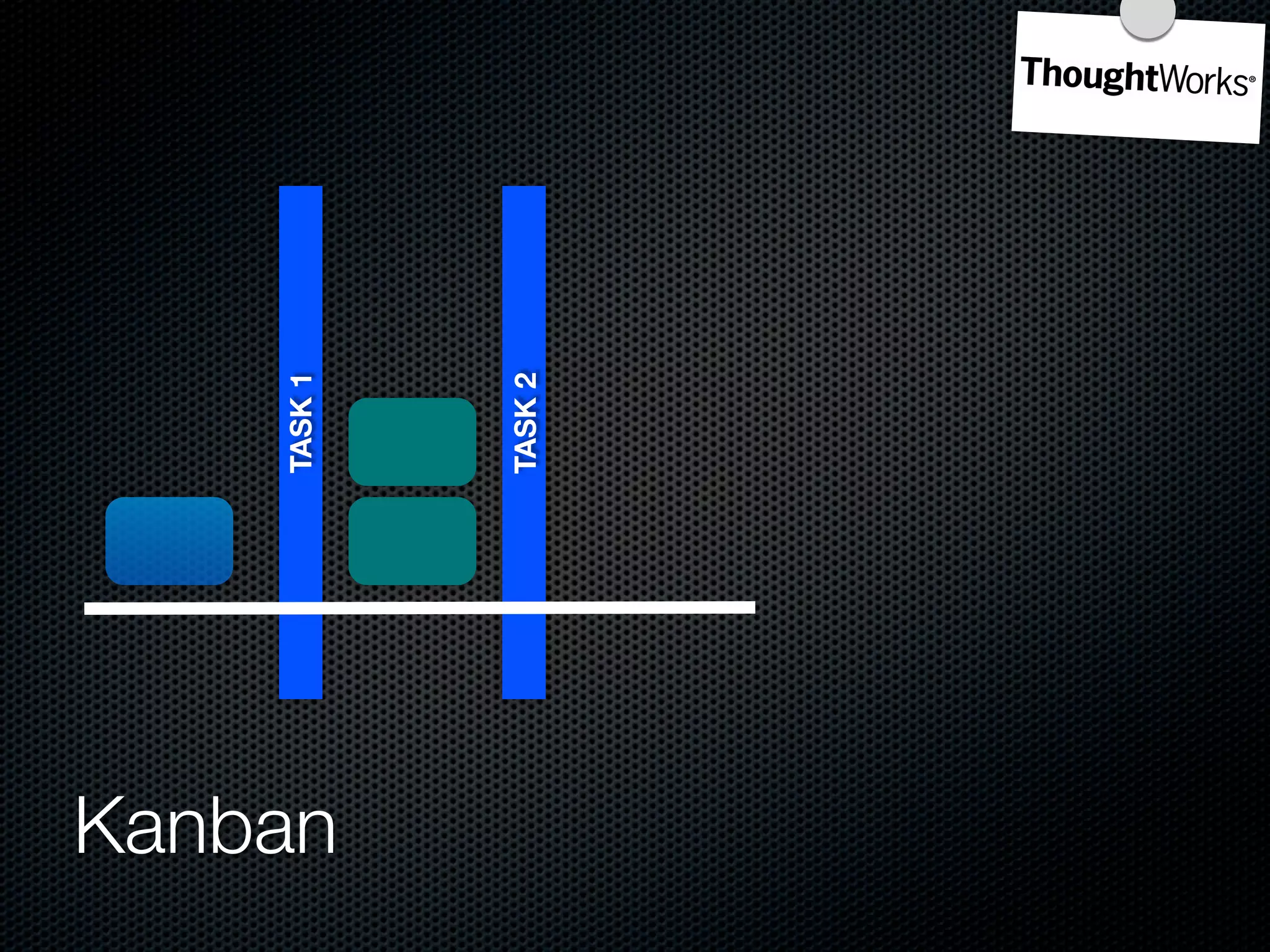

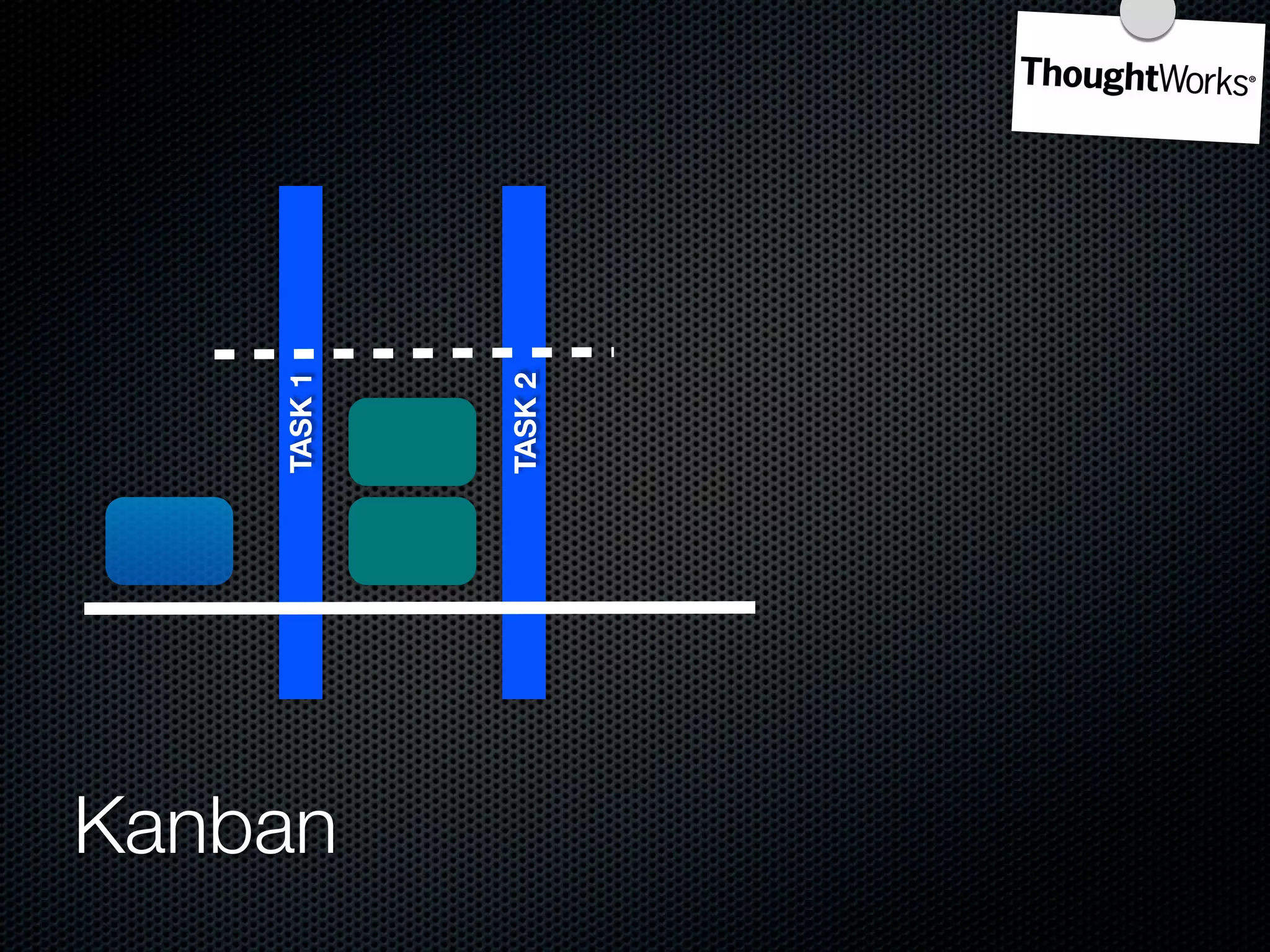

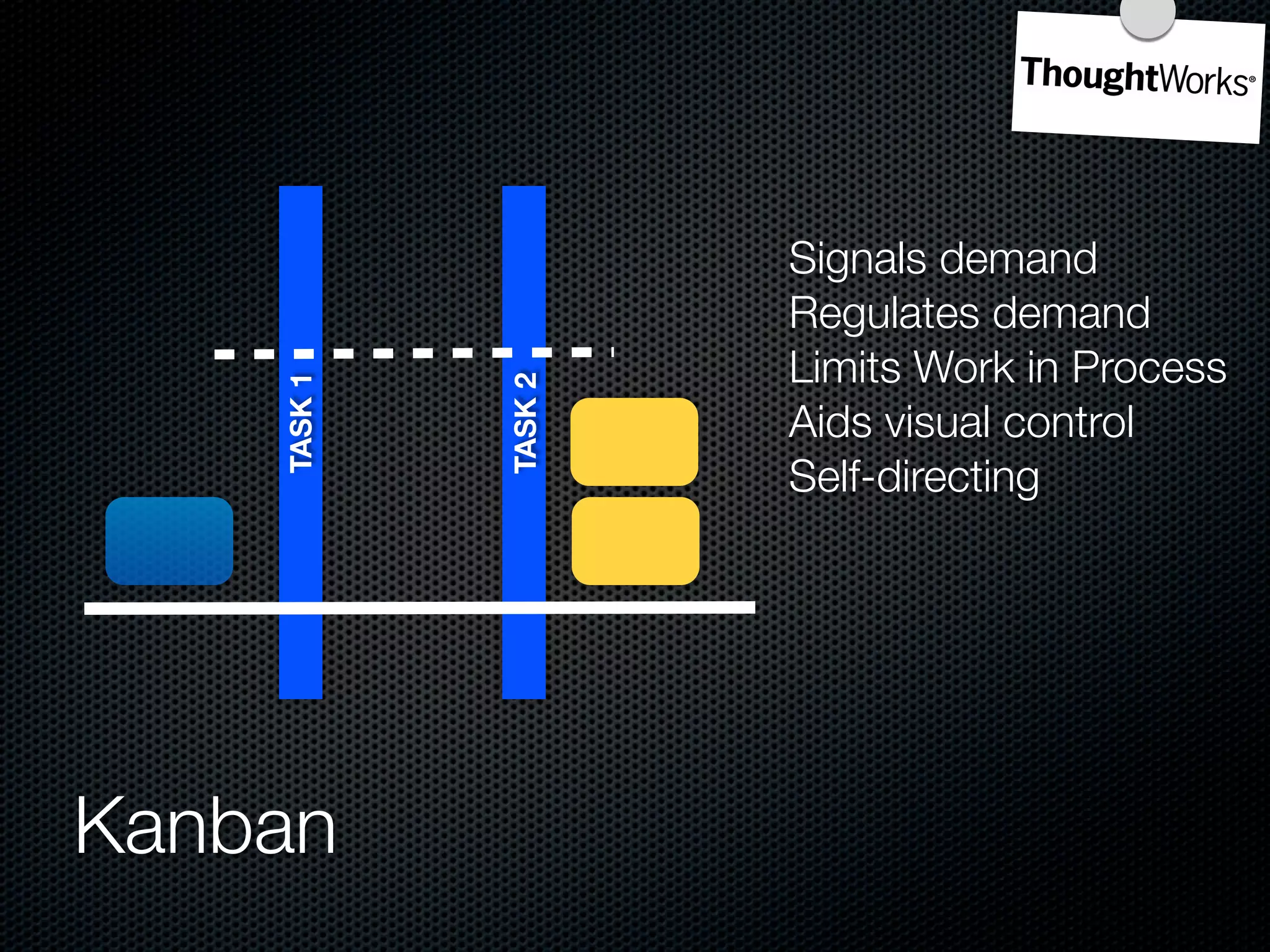

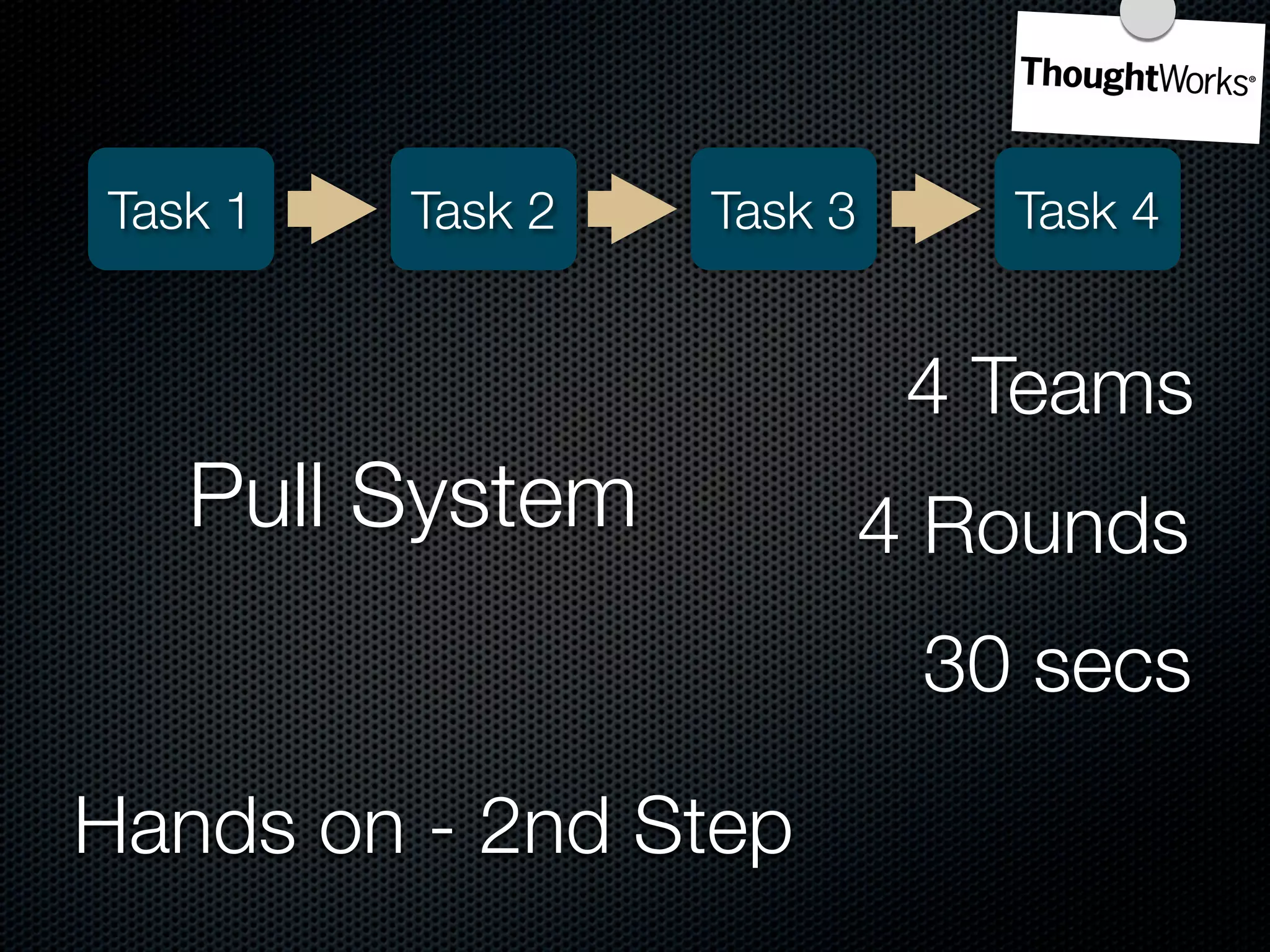

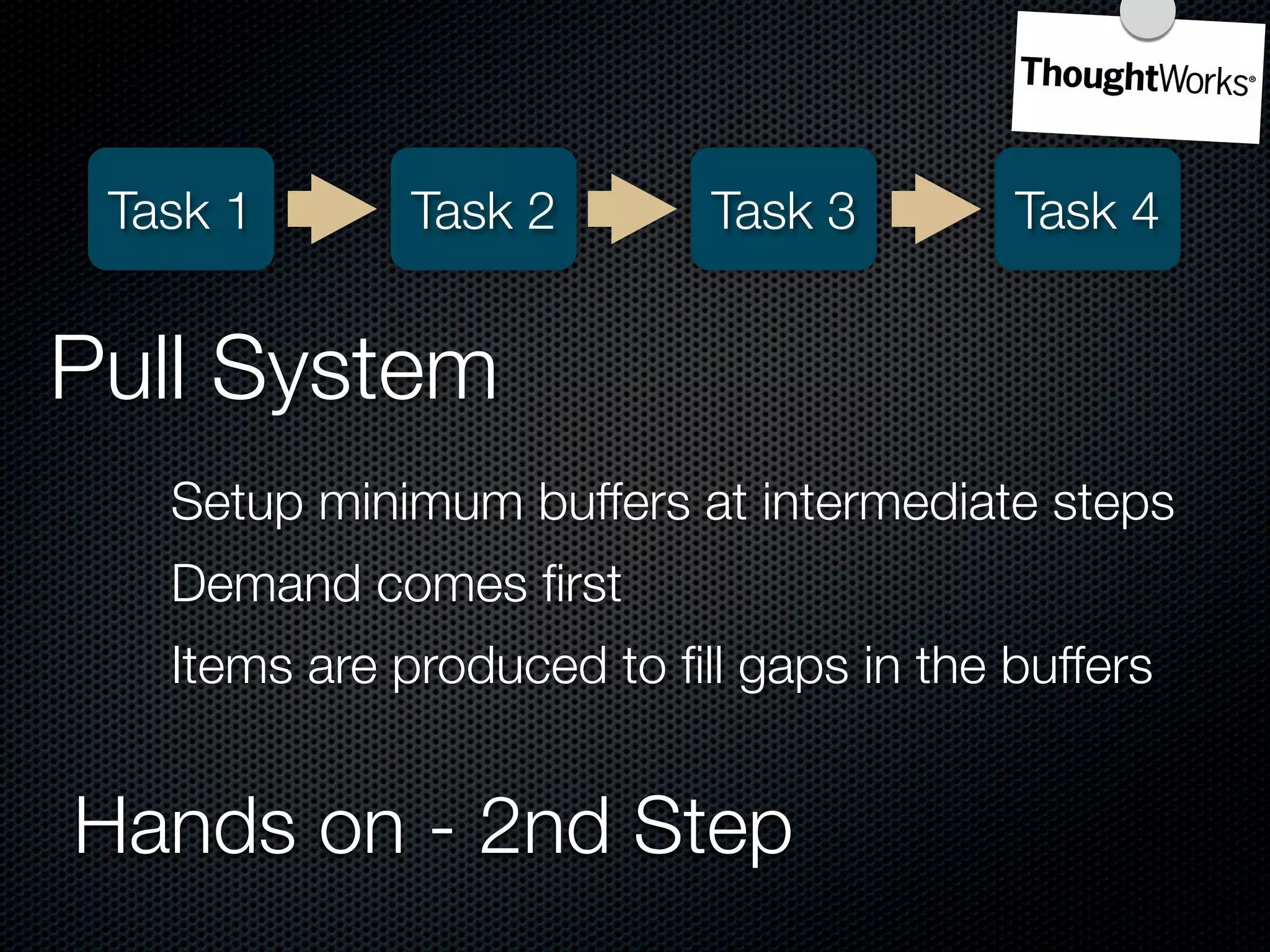

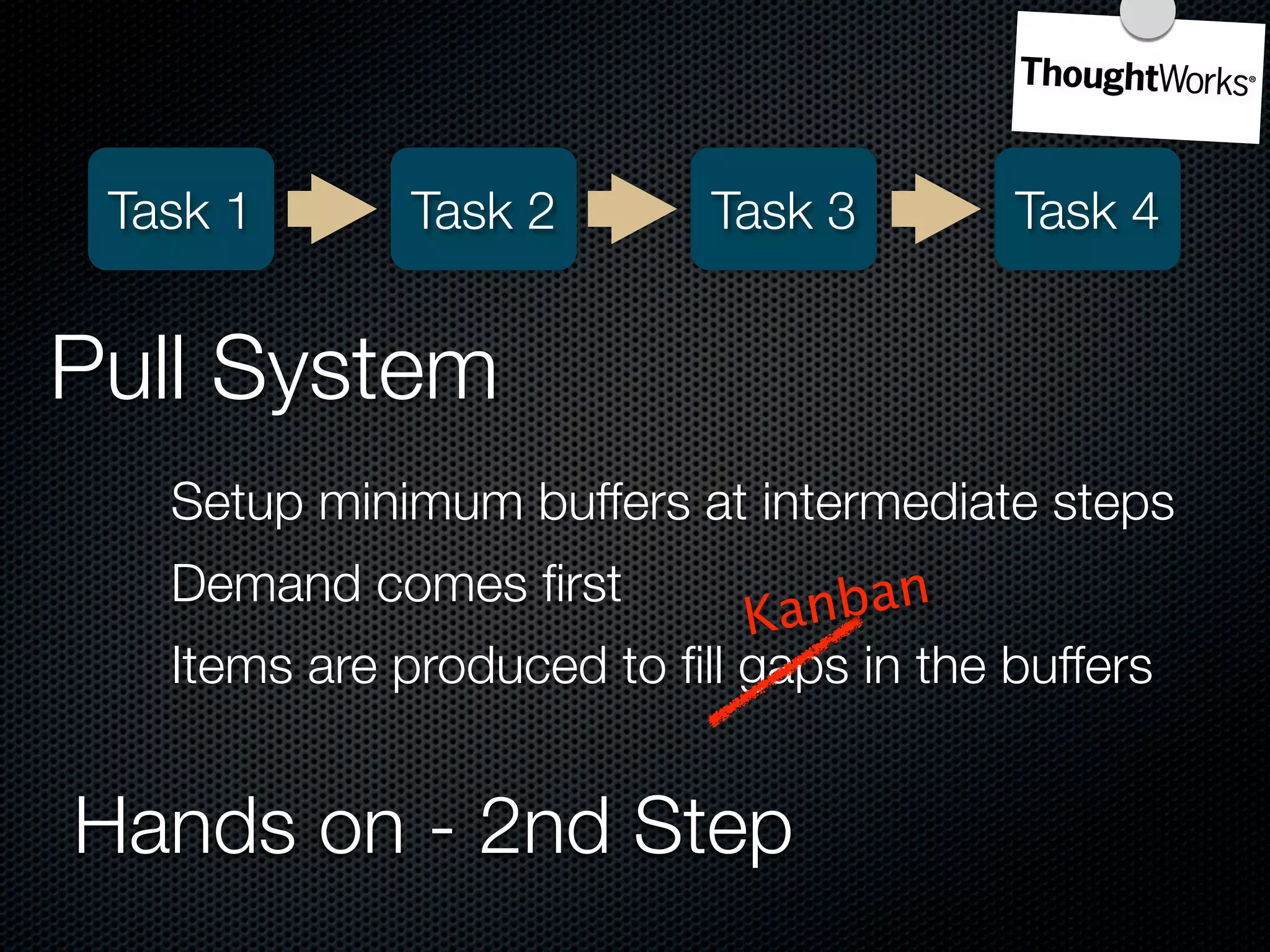

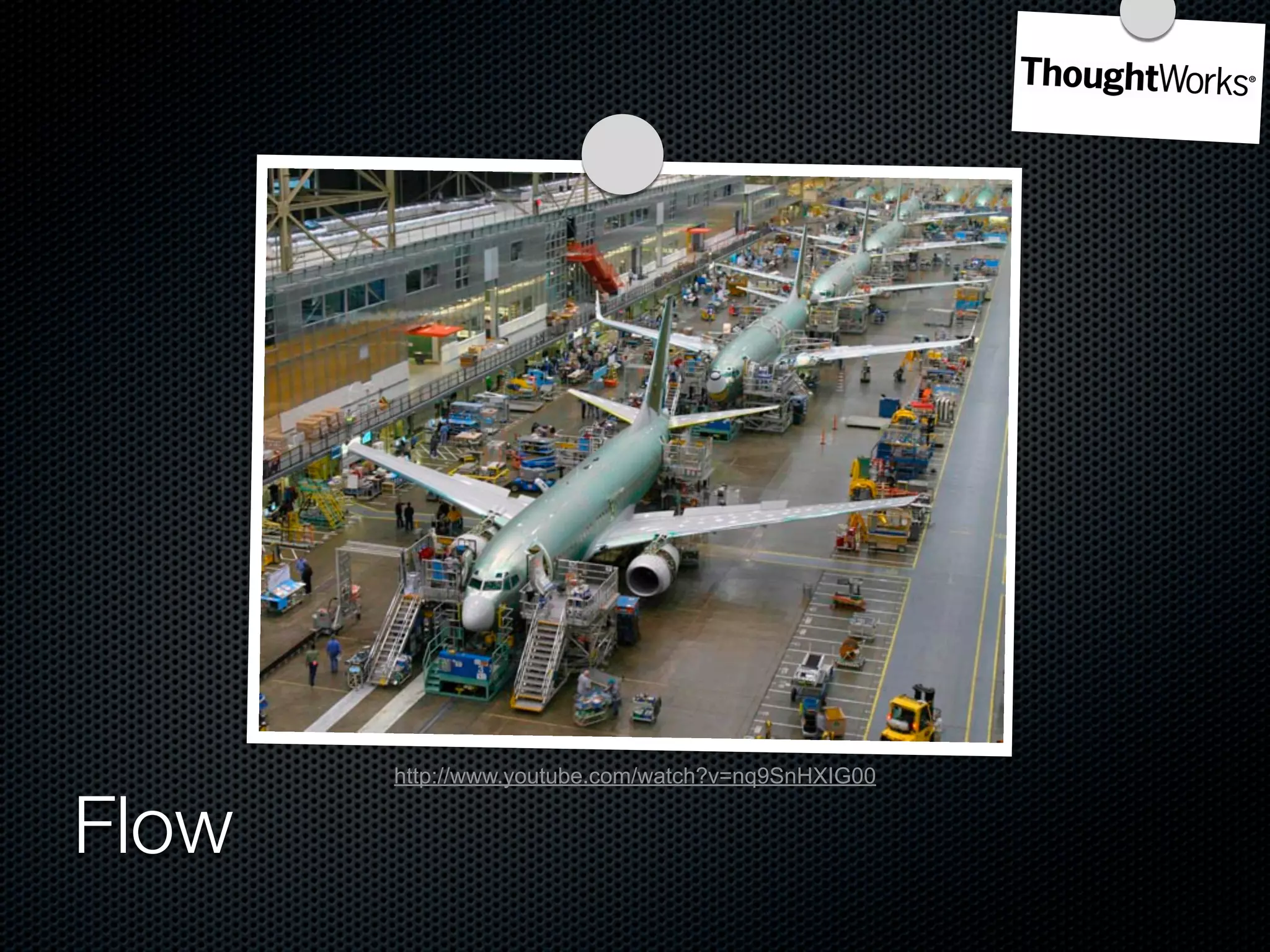

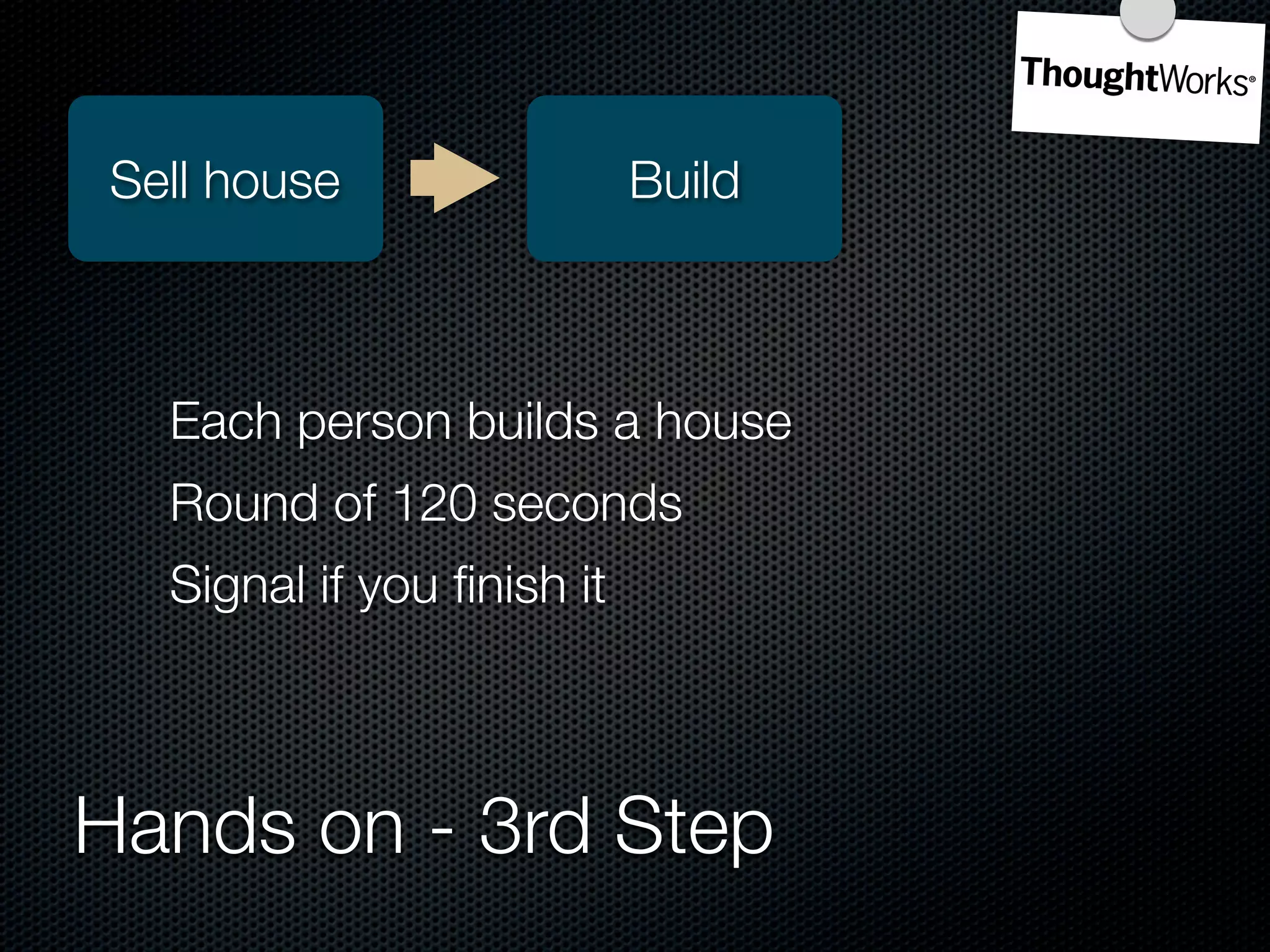

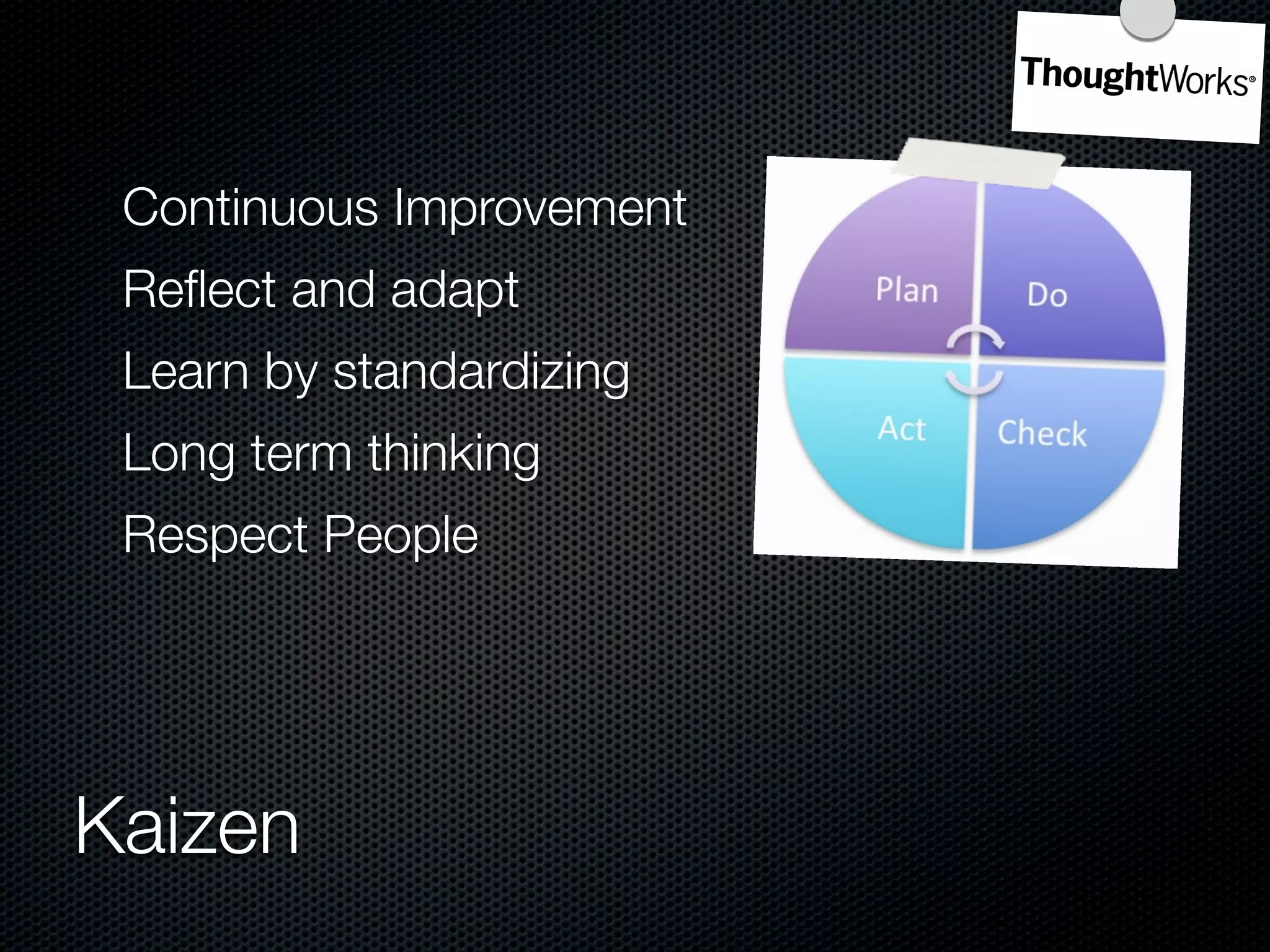

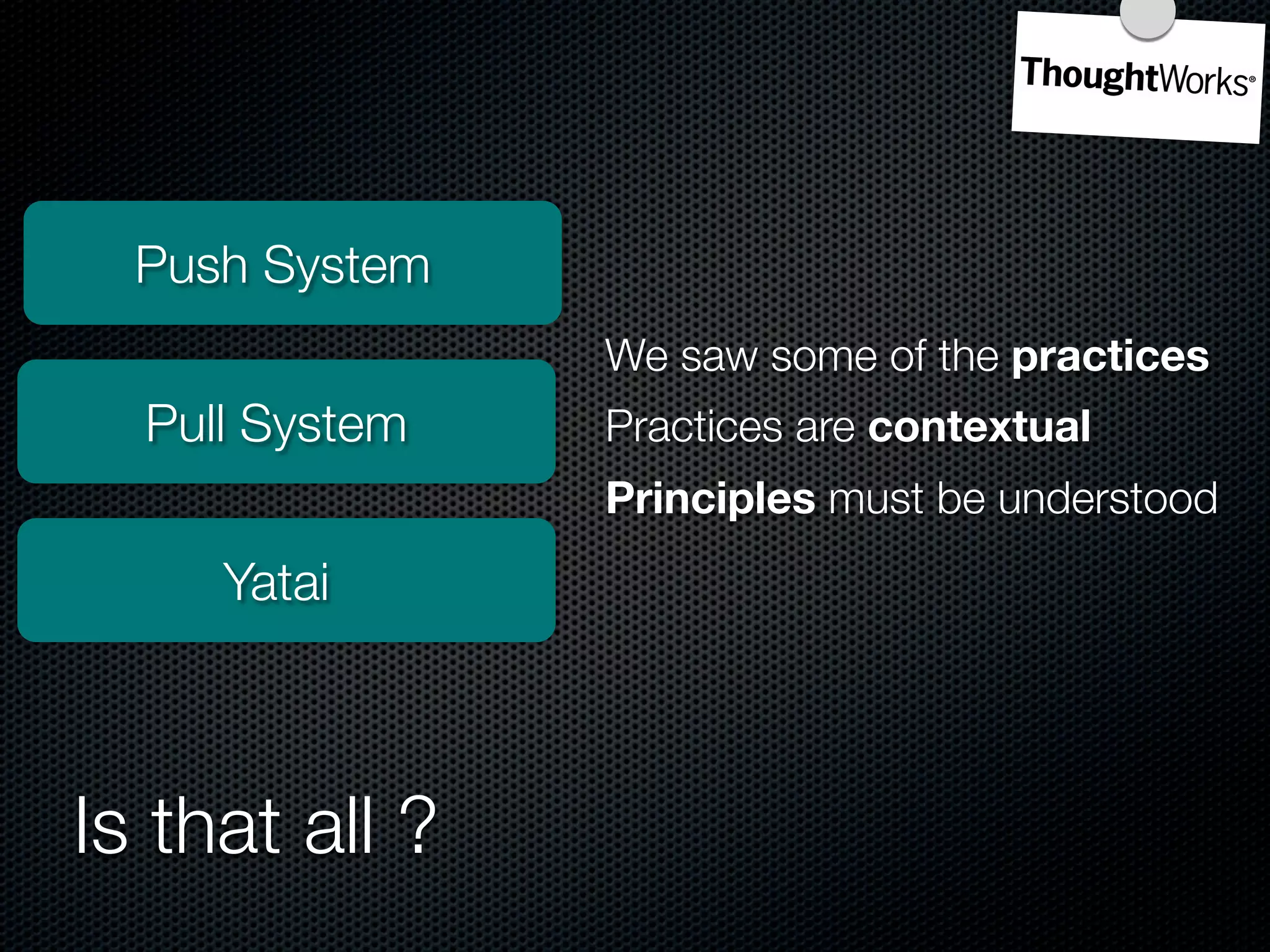

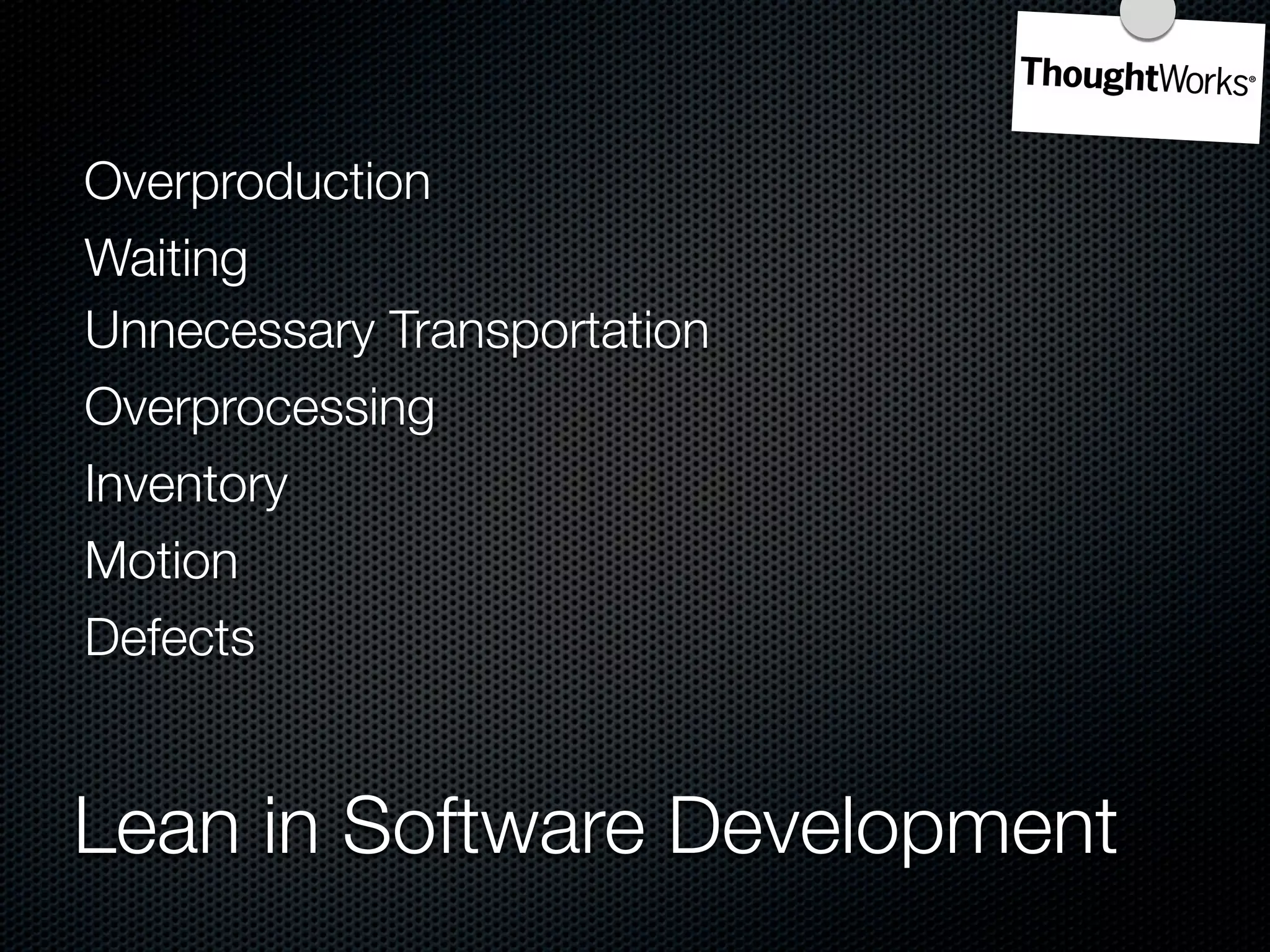

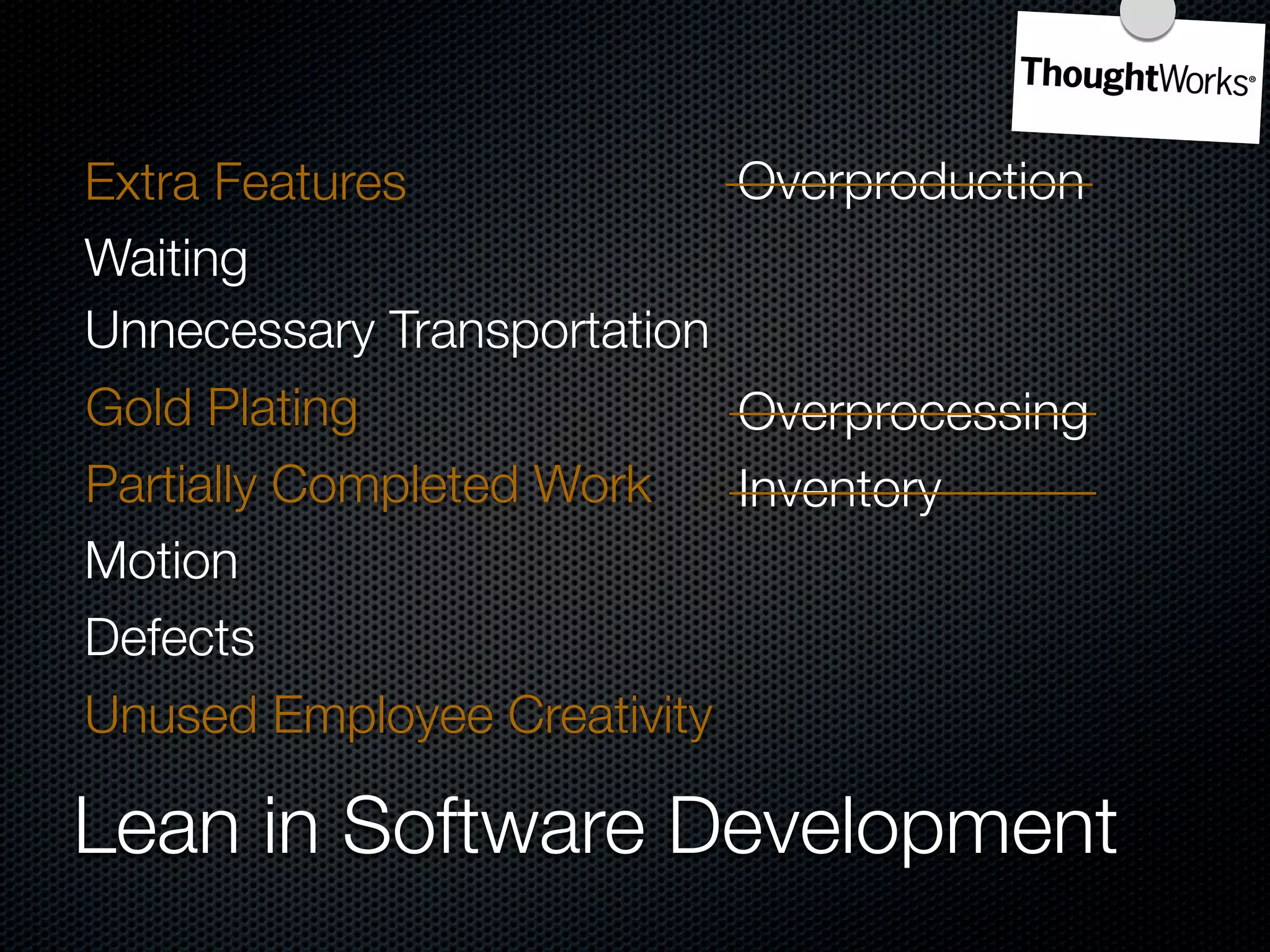

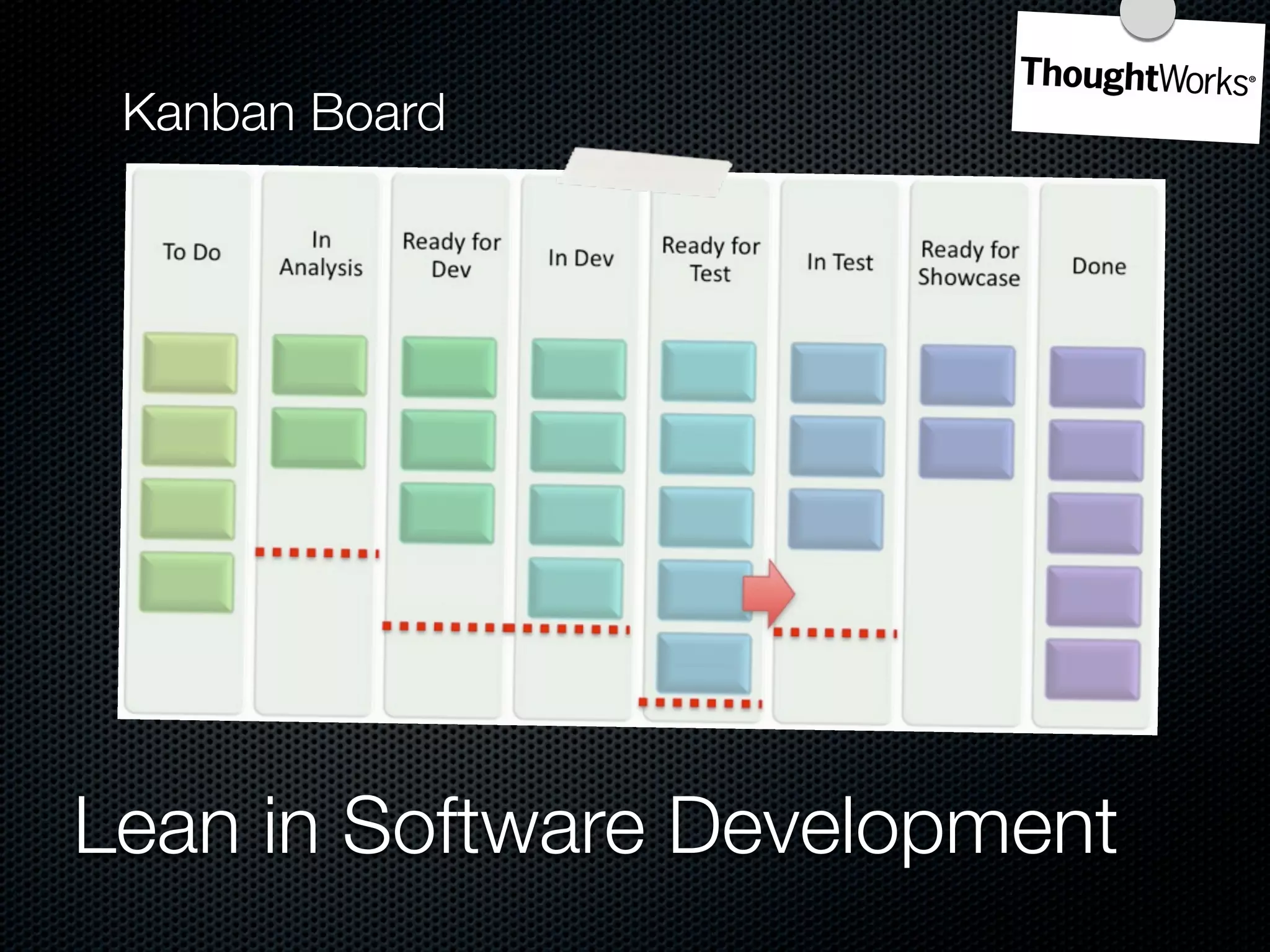

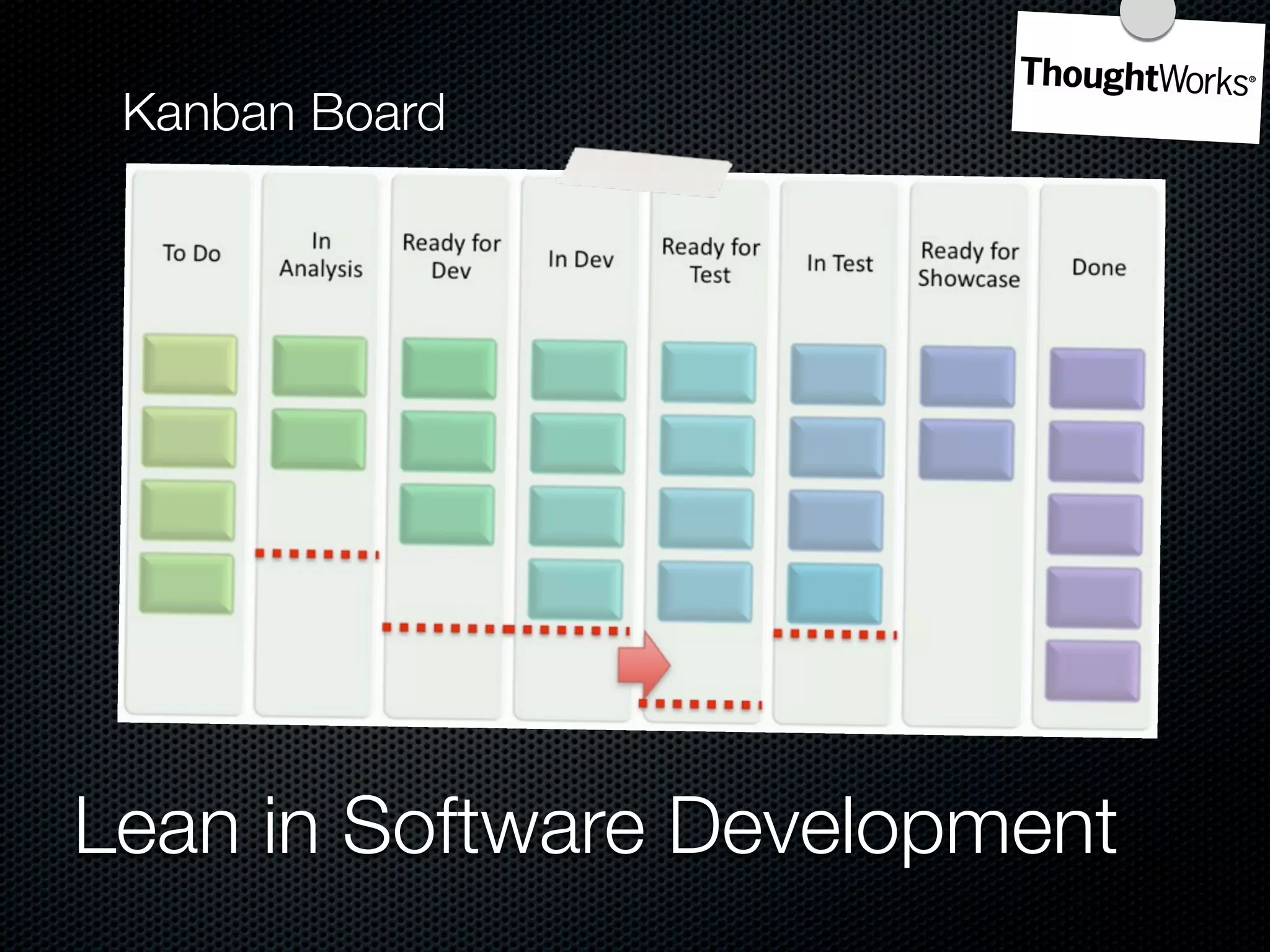

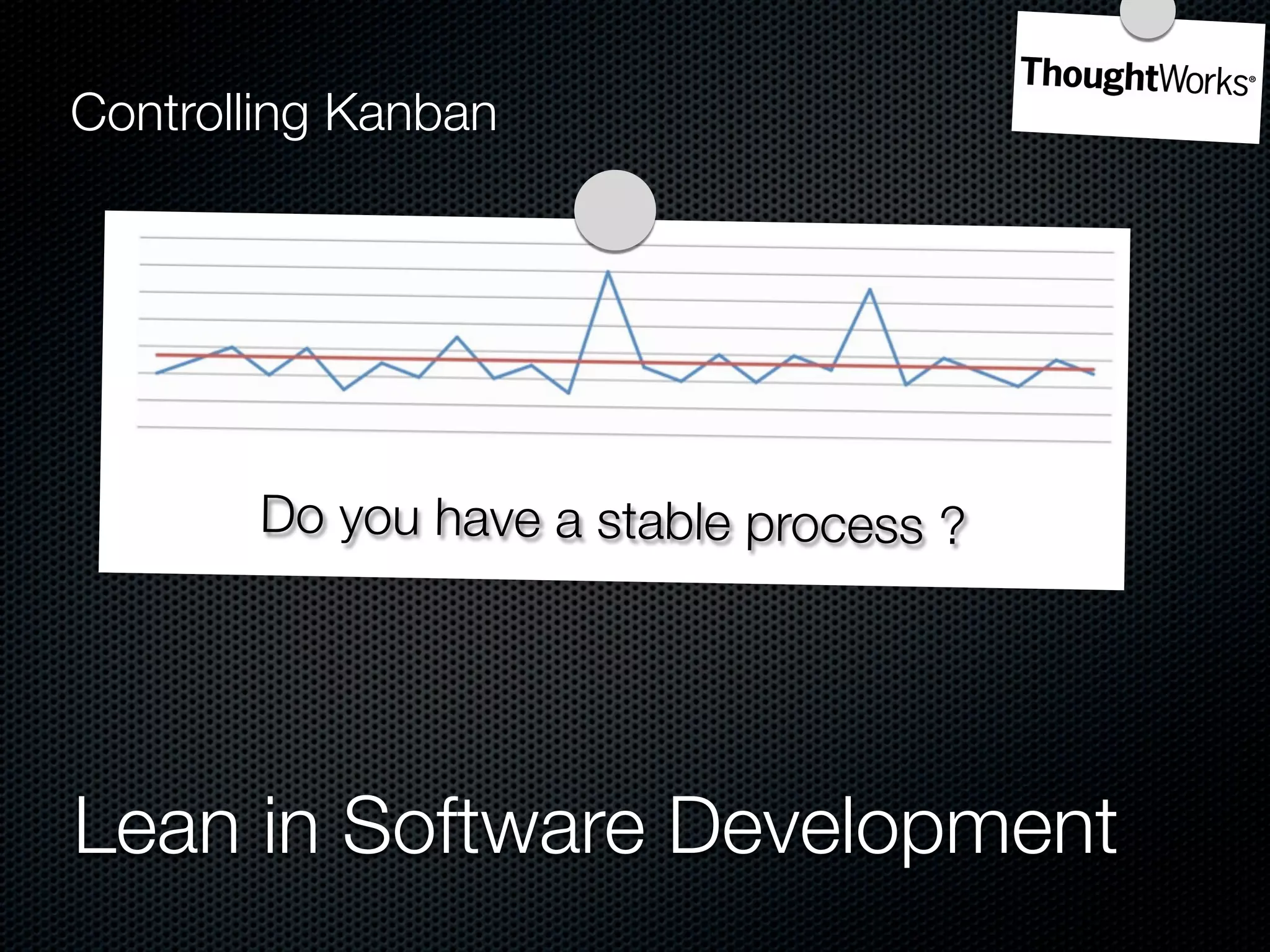

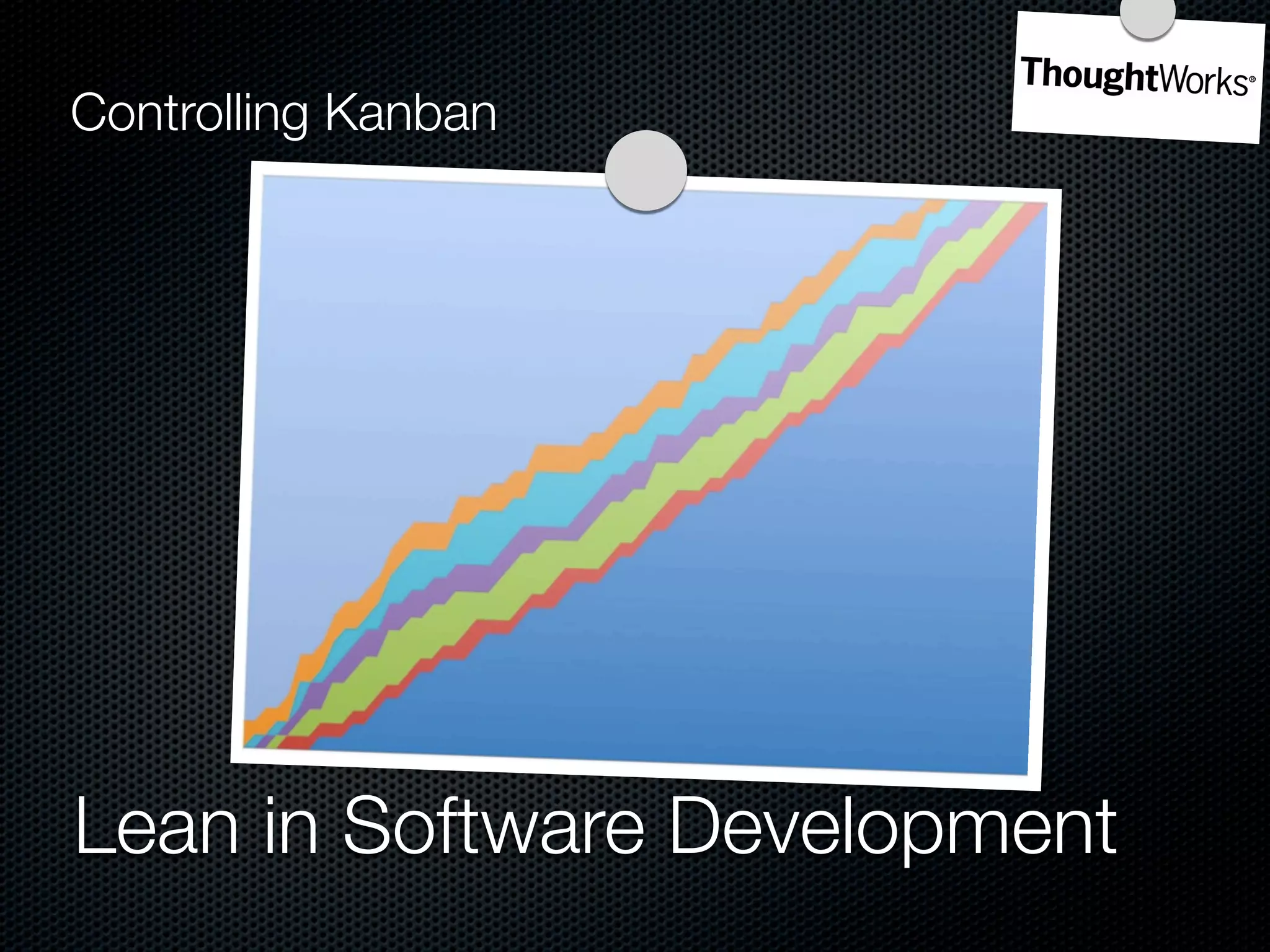

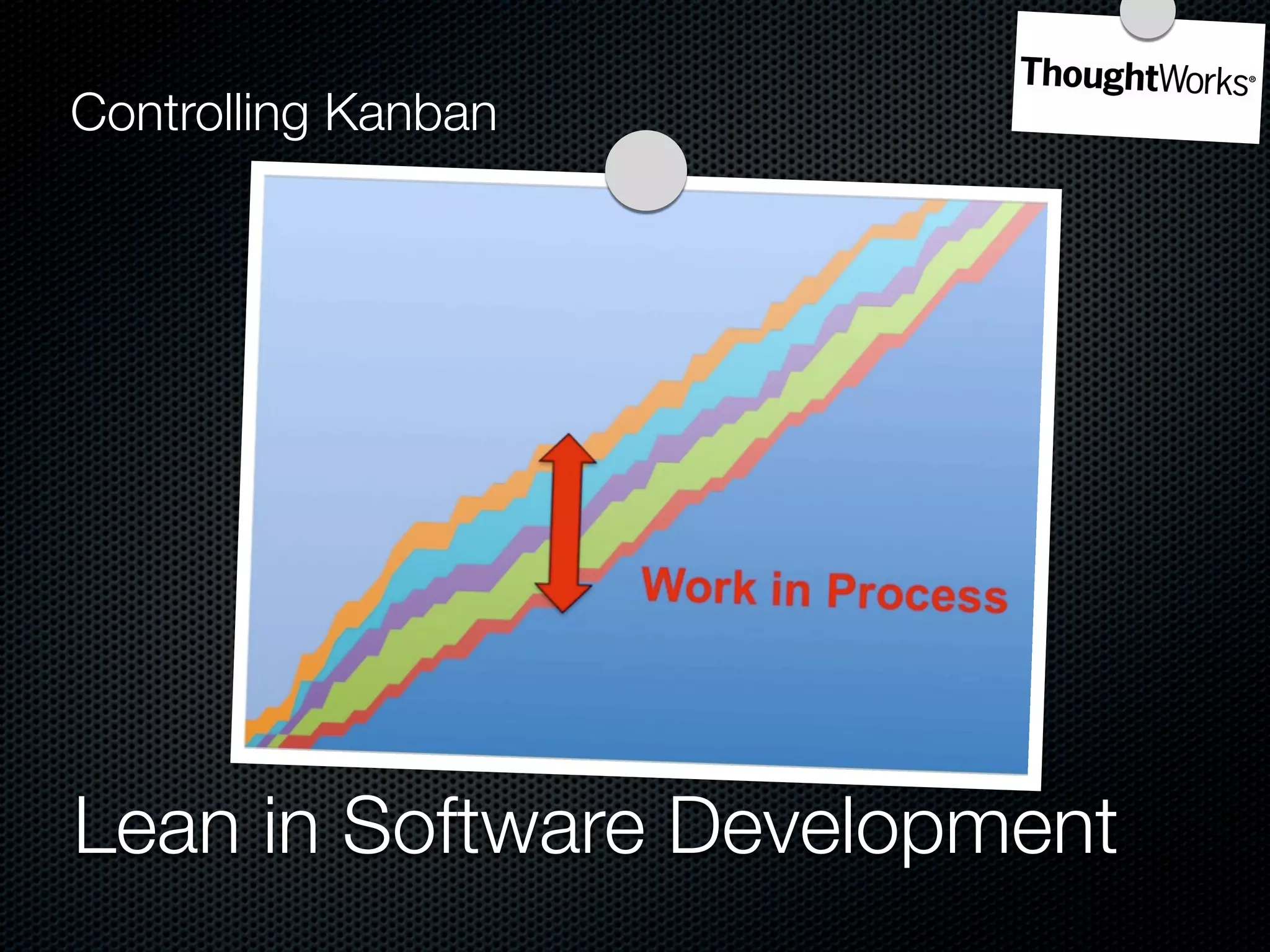

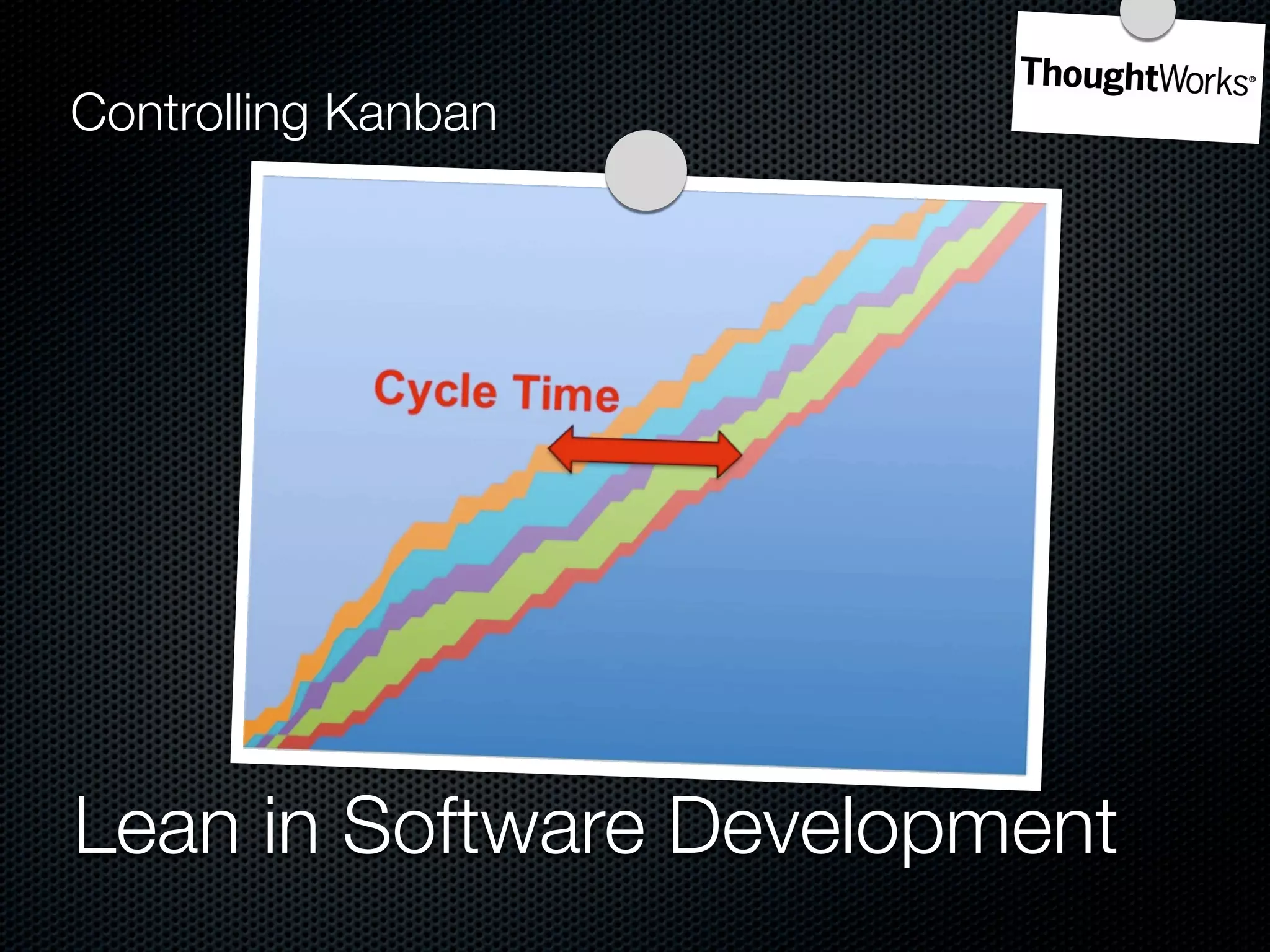

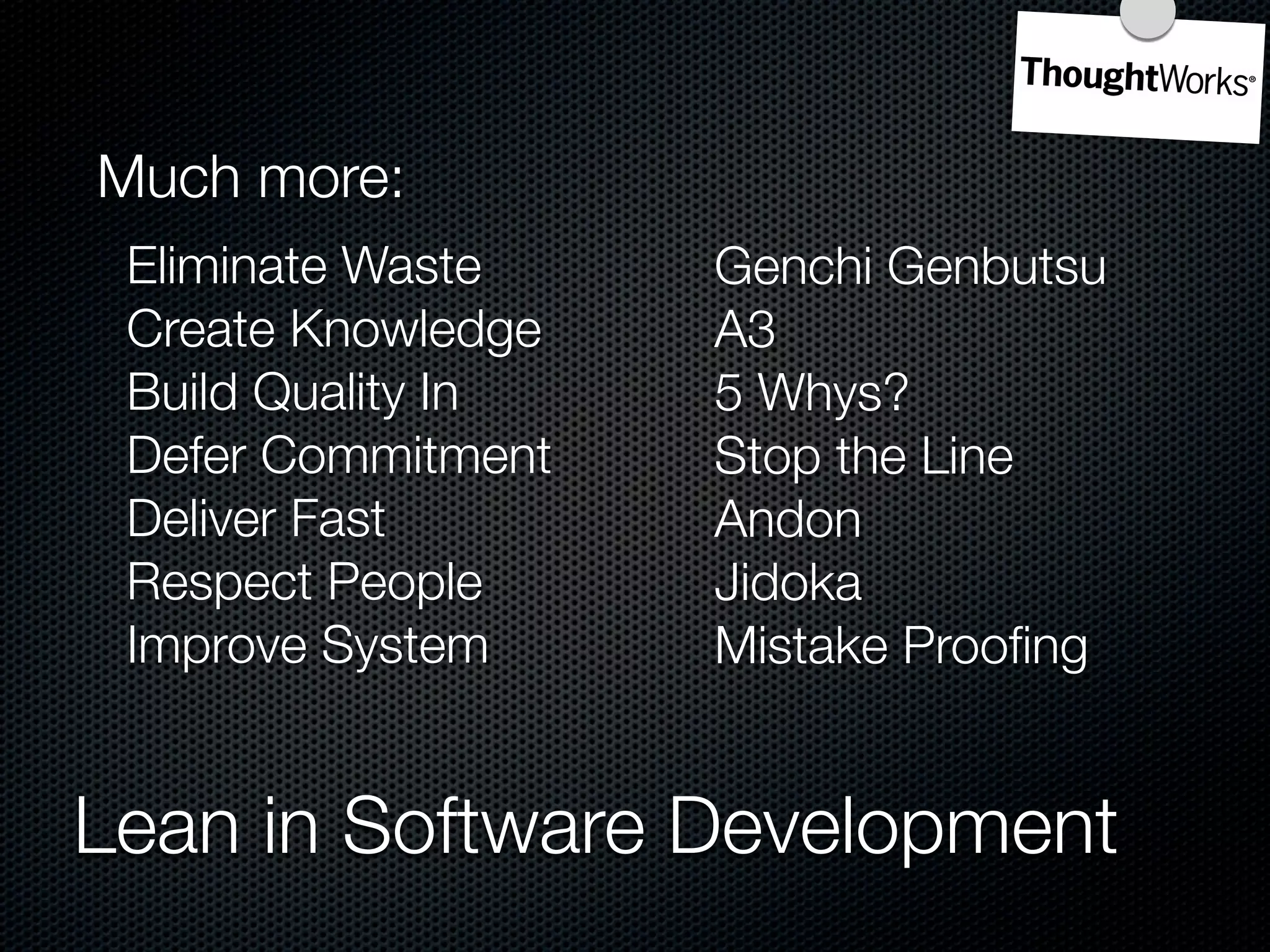

The document describes a workshop on introducing lean principles to software development. It begins with an agenda and introduction to lean concepts. Participants then take part in hands-on exercises simulating production processes to experience issues like waste, uneven workflow, and inflexibility without lean. The exercises demonstrate how lean tools like kanban, pull systems, and multitasking can address these issues and improve flow. The workshop emphasizes that lean is not just tools but a long-term philosophy of continuous improvement respecting people.