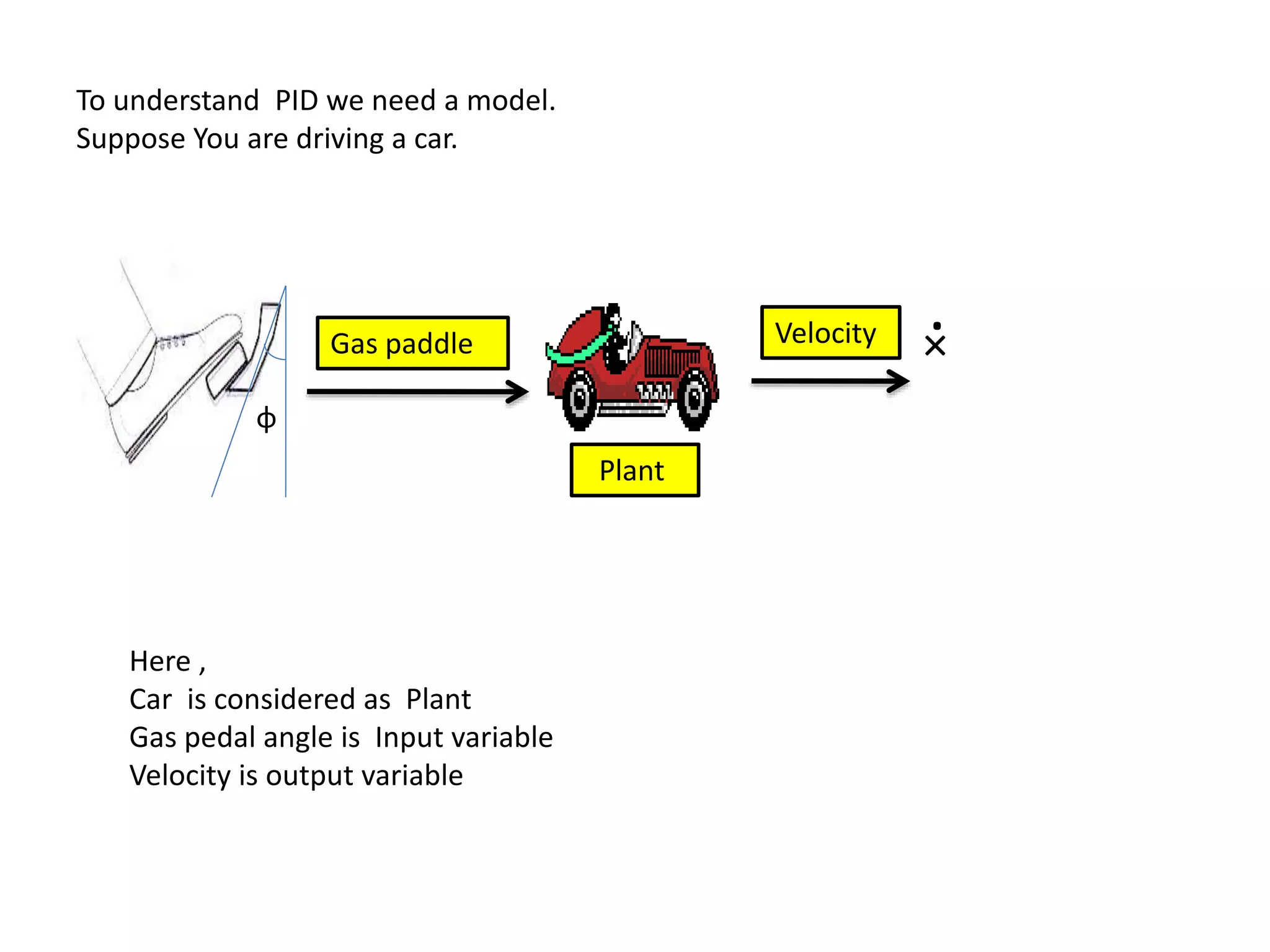

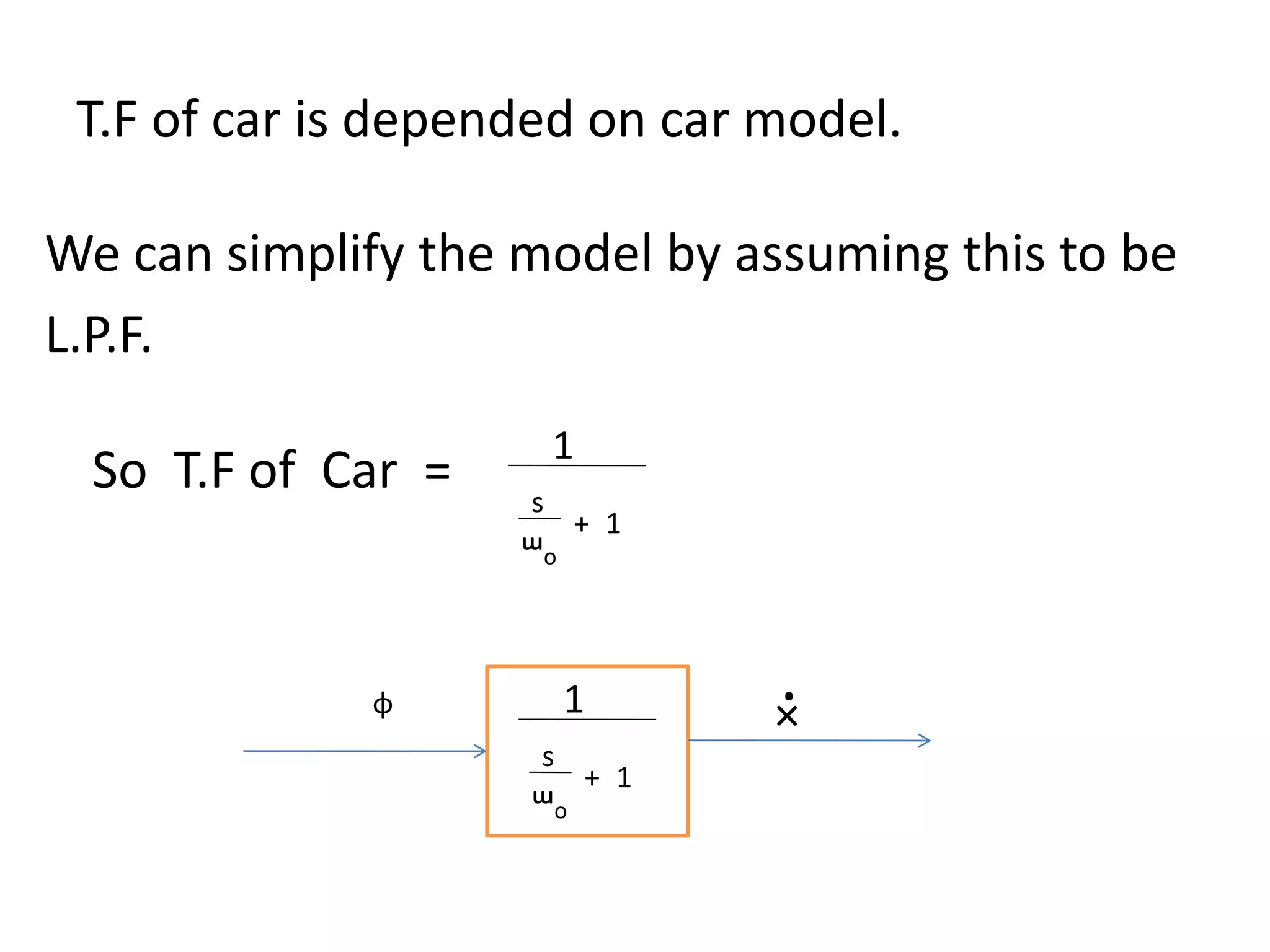

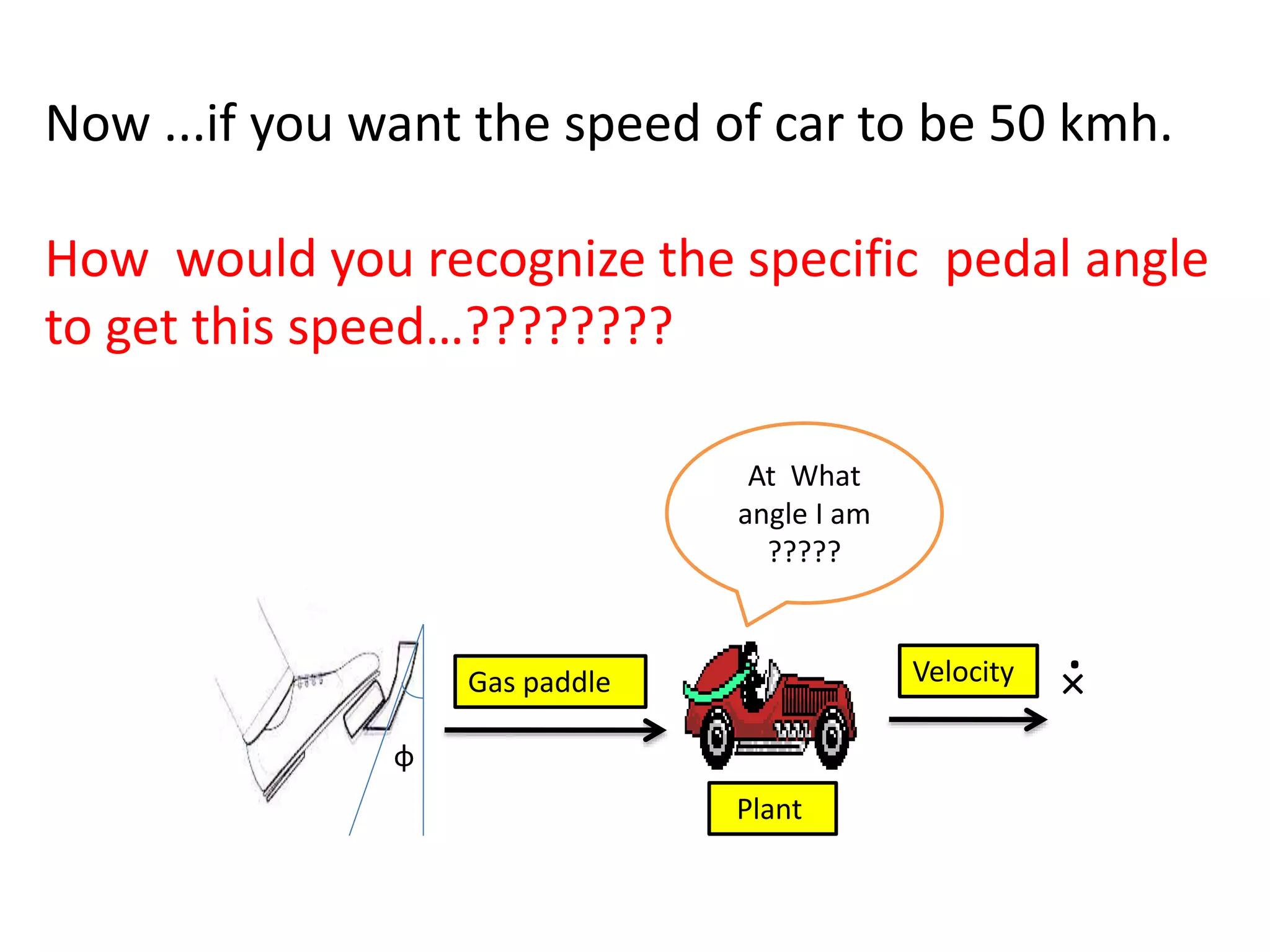

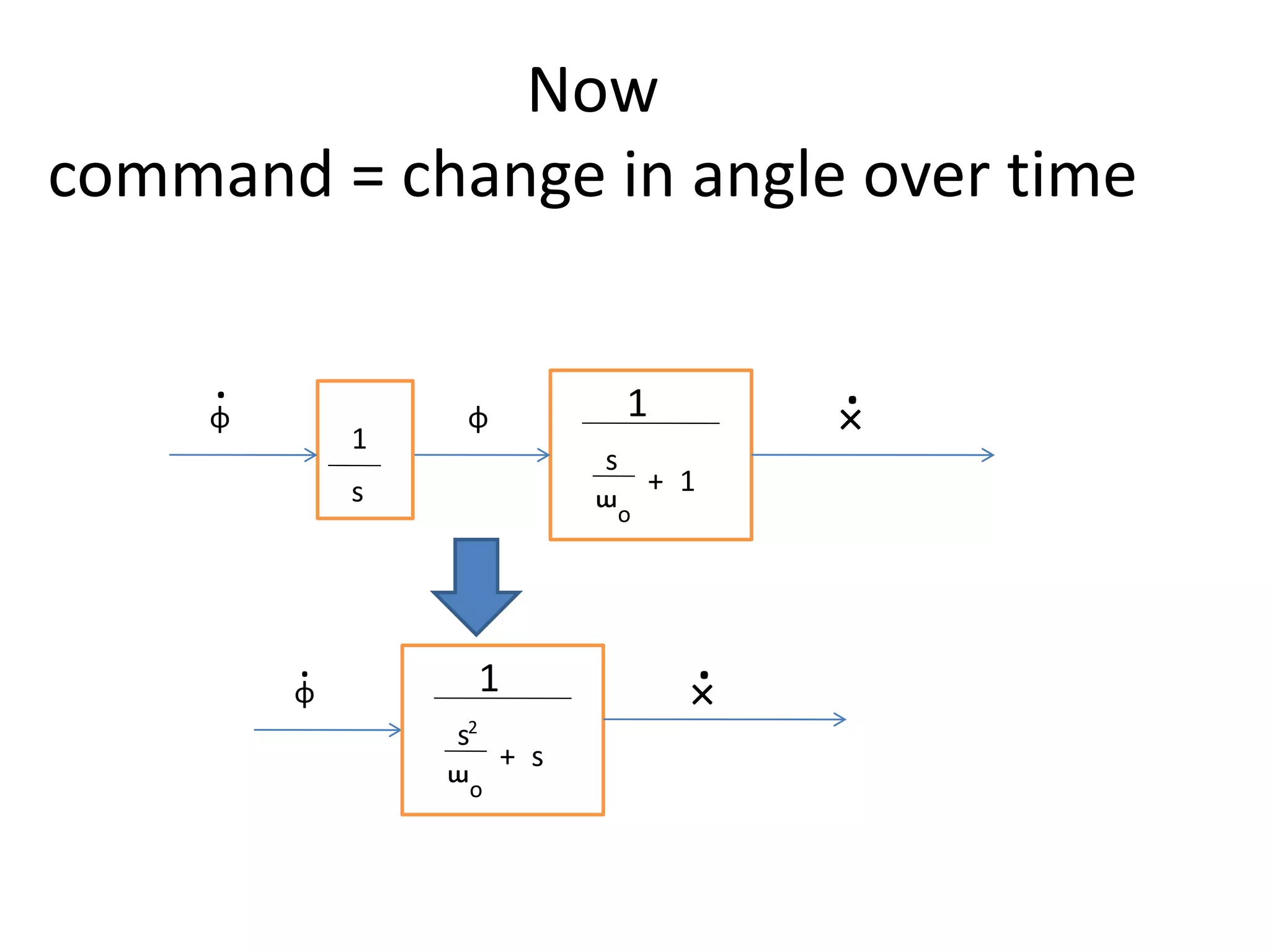

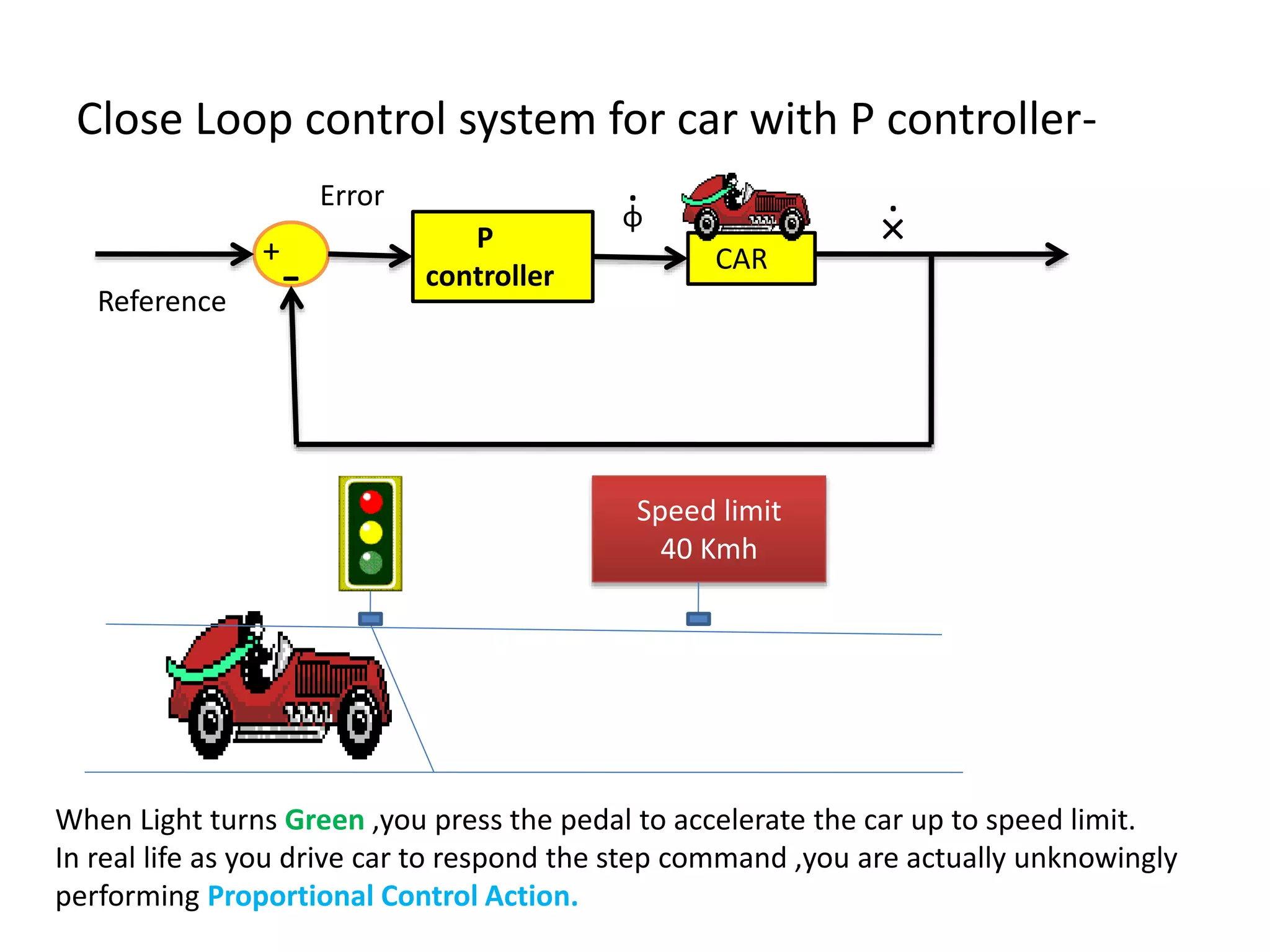

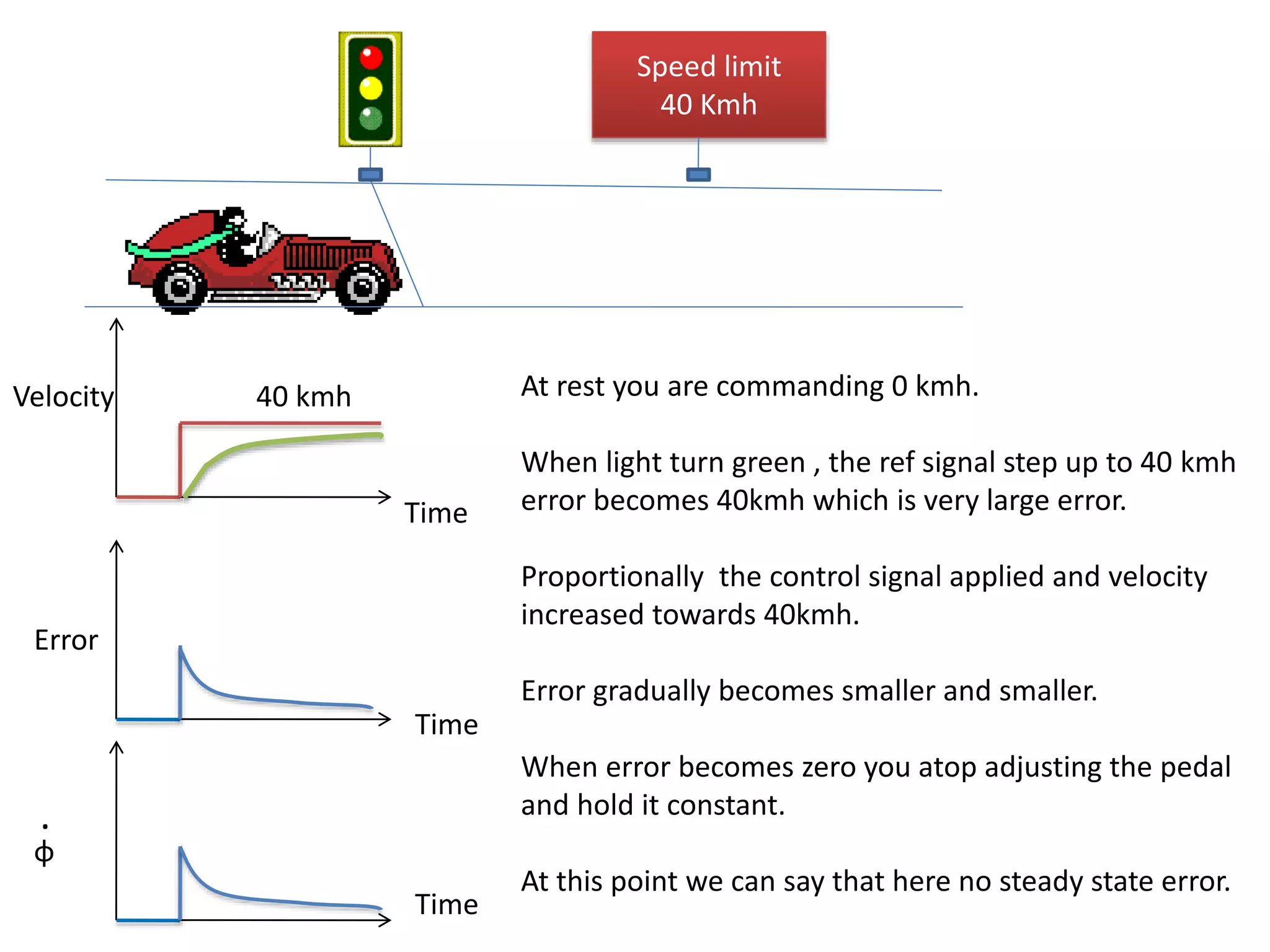

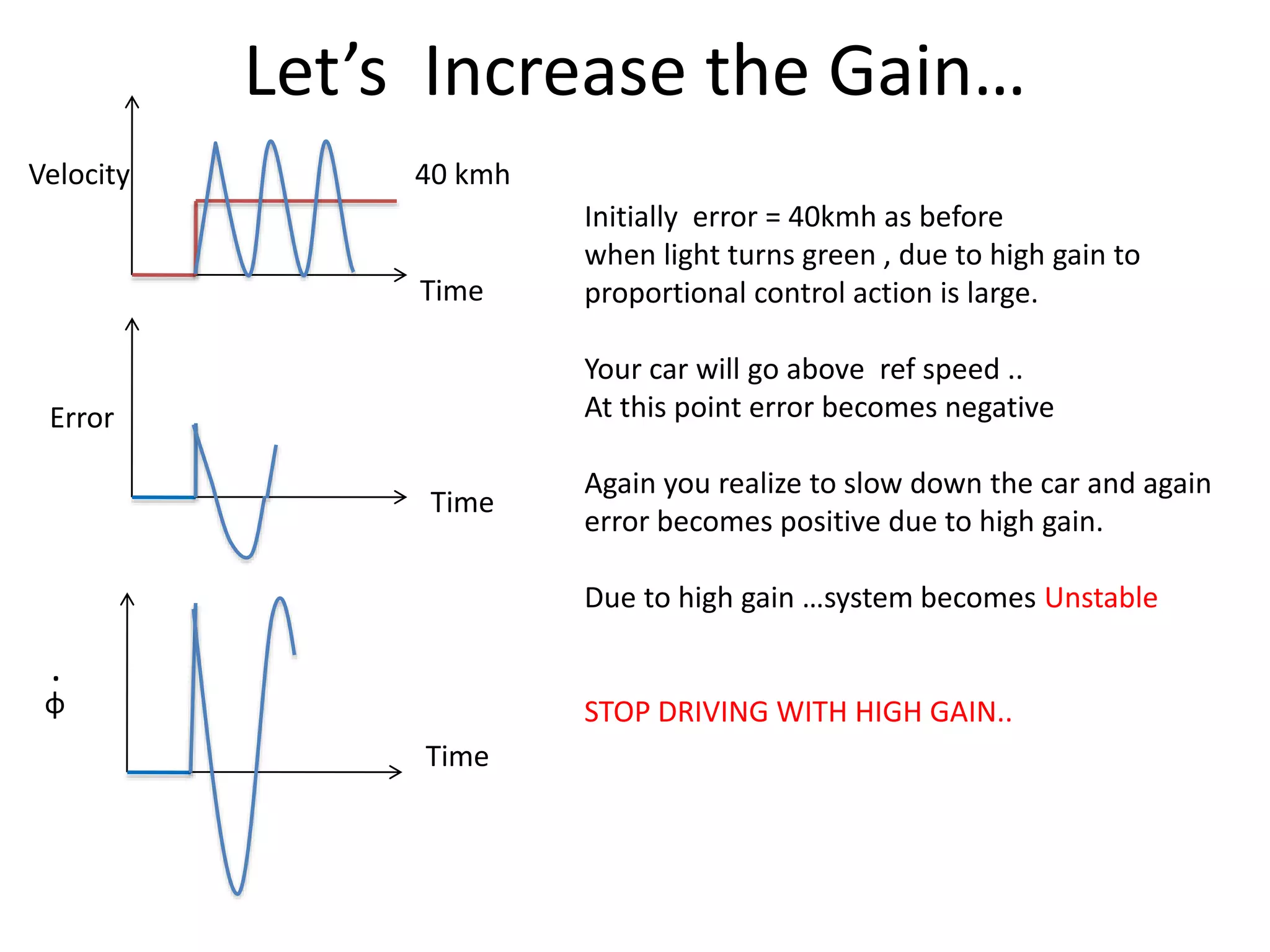

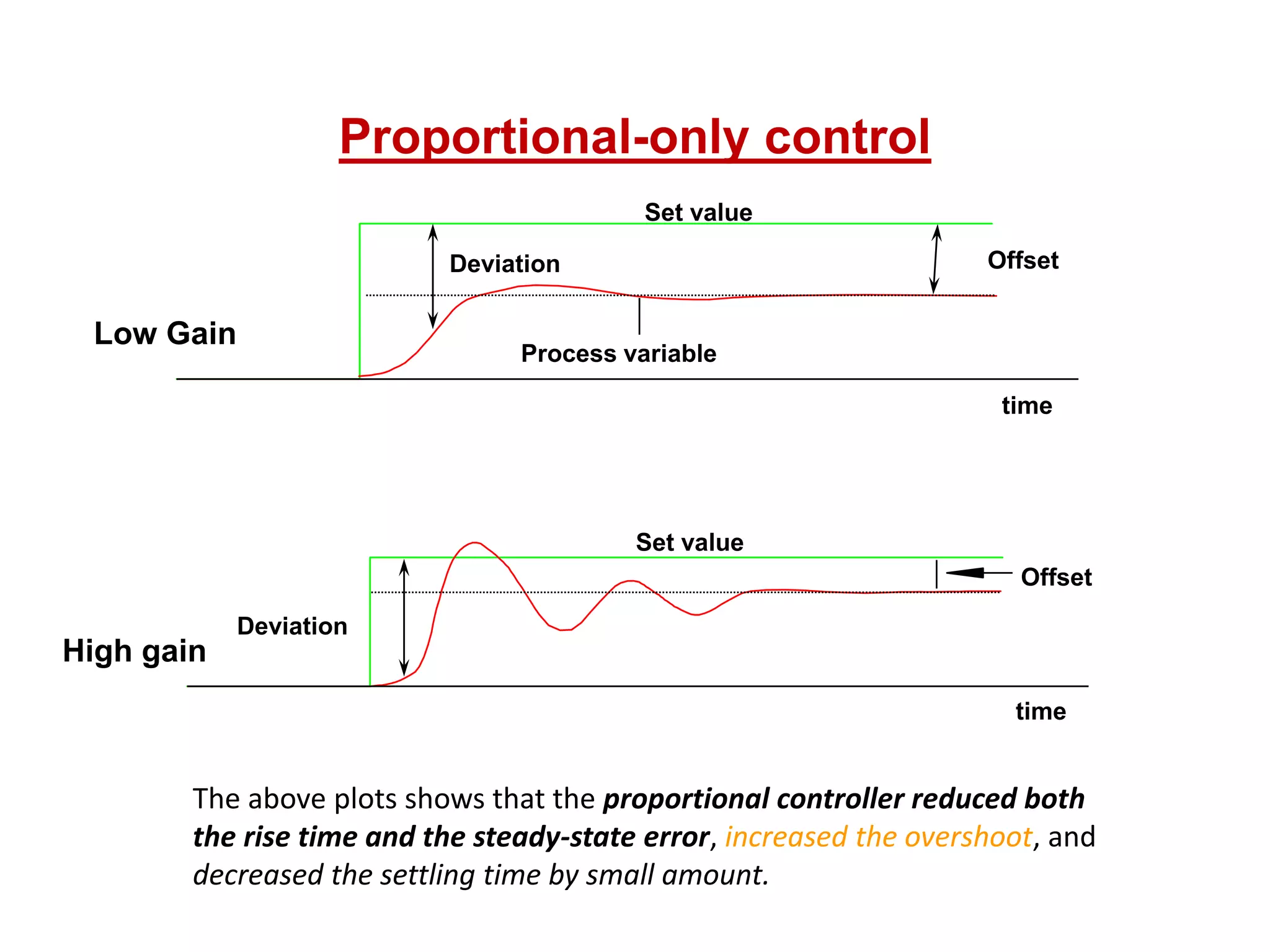

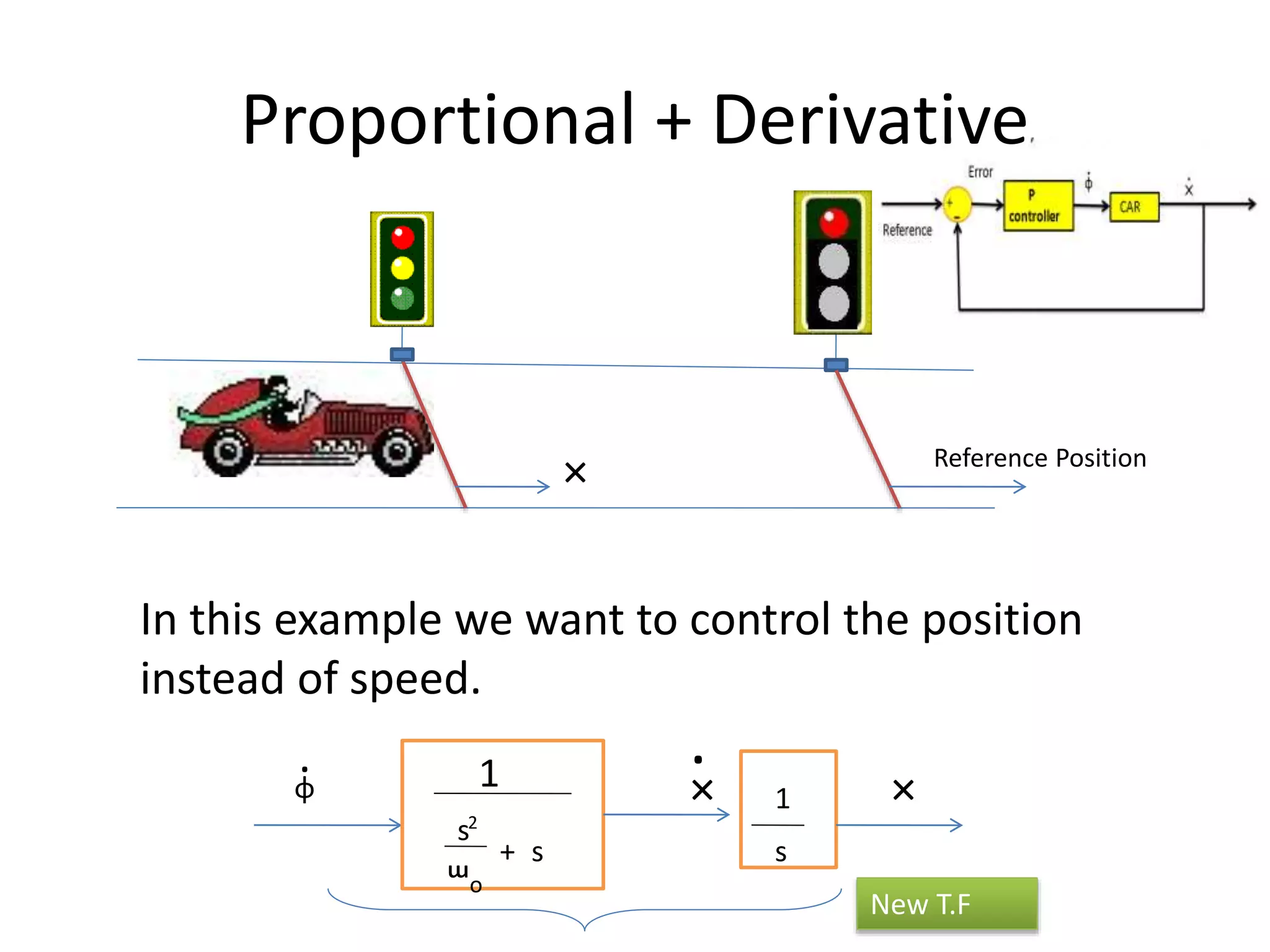

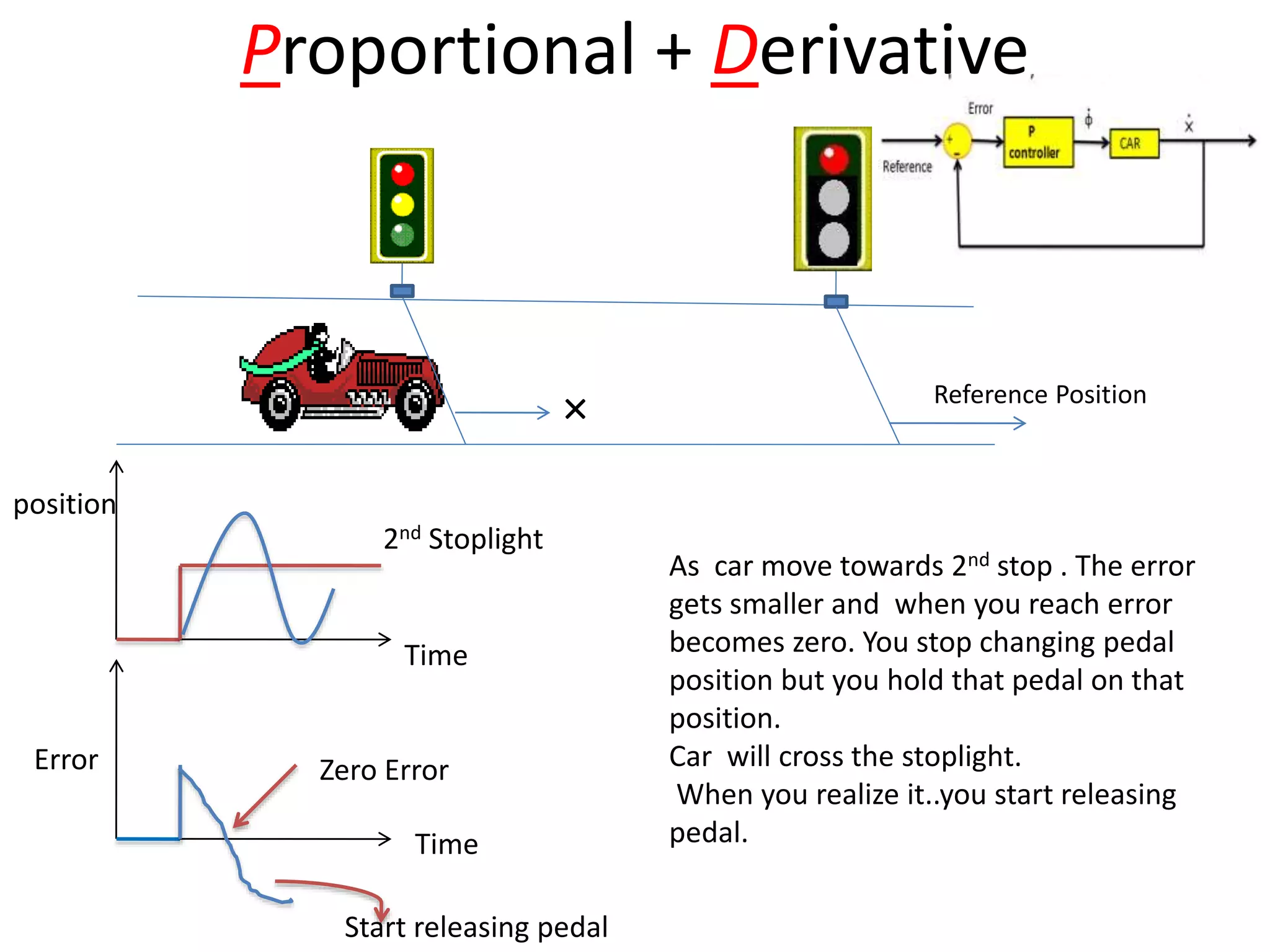

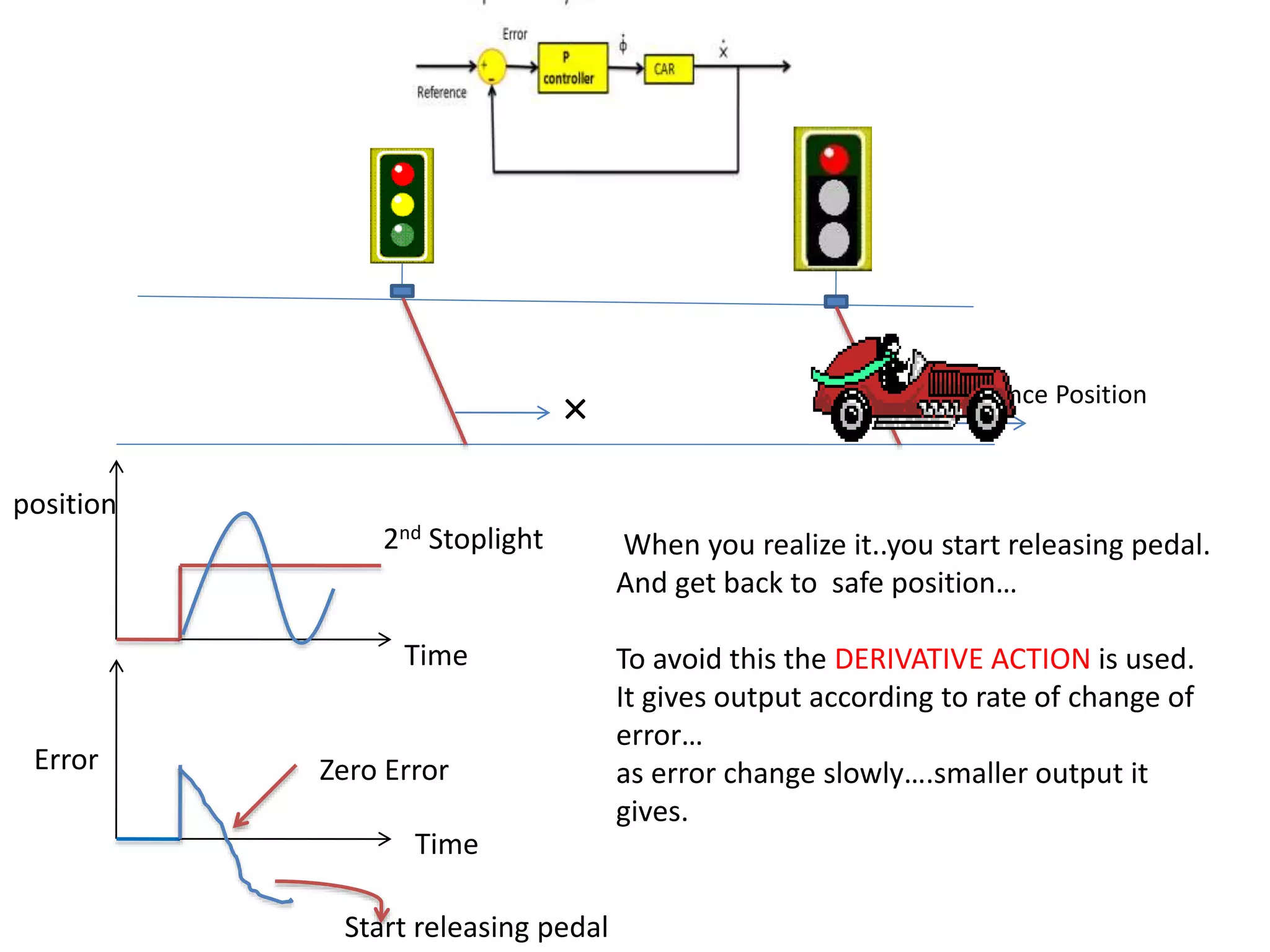

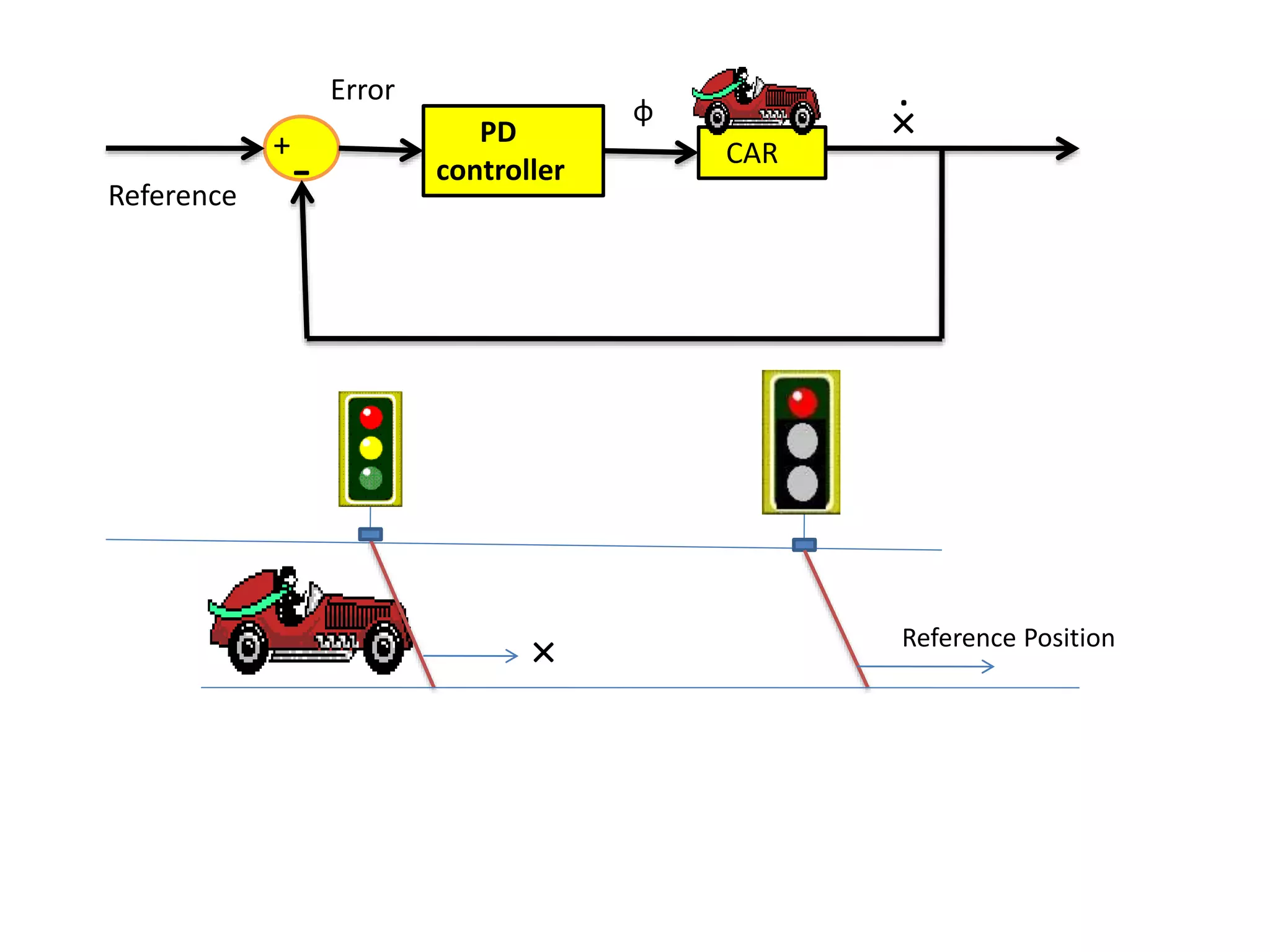

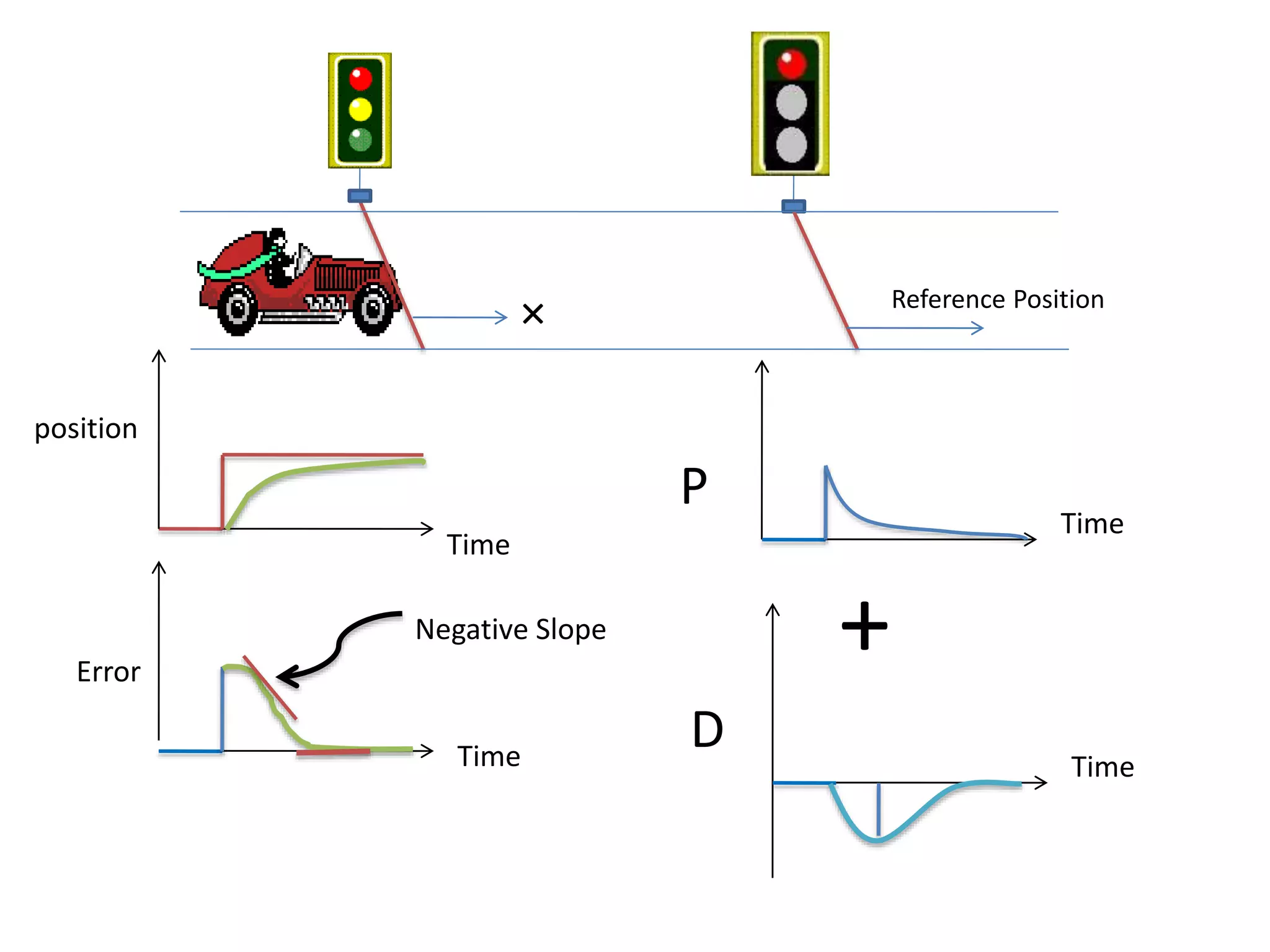

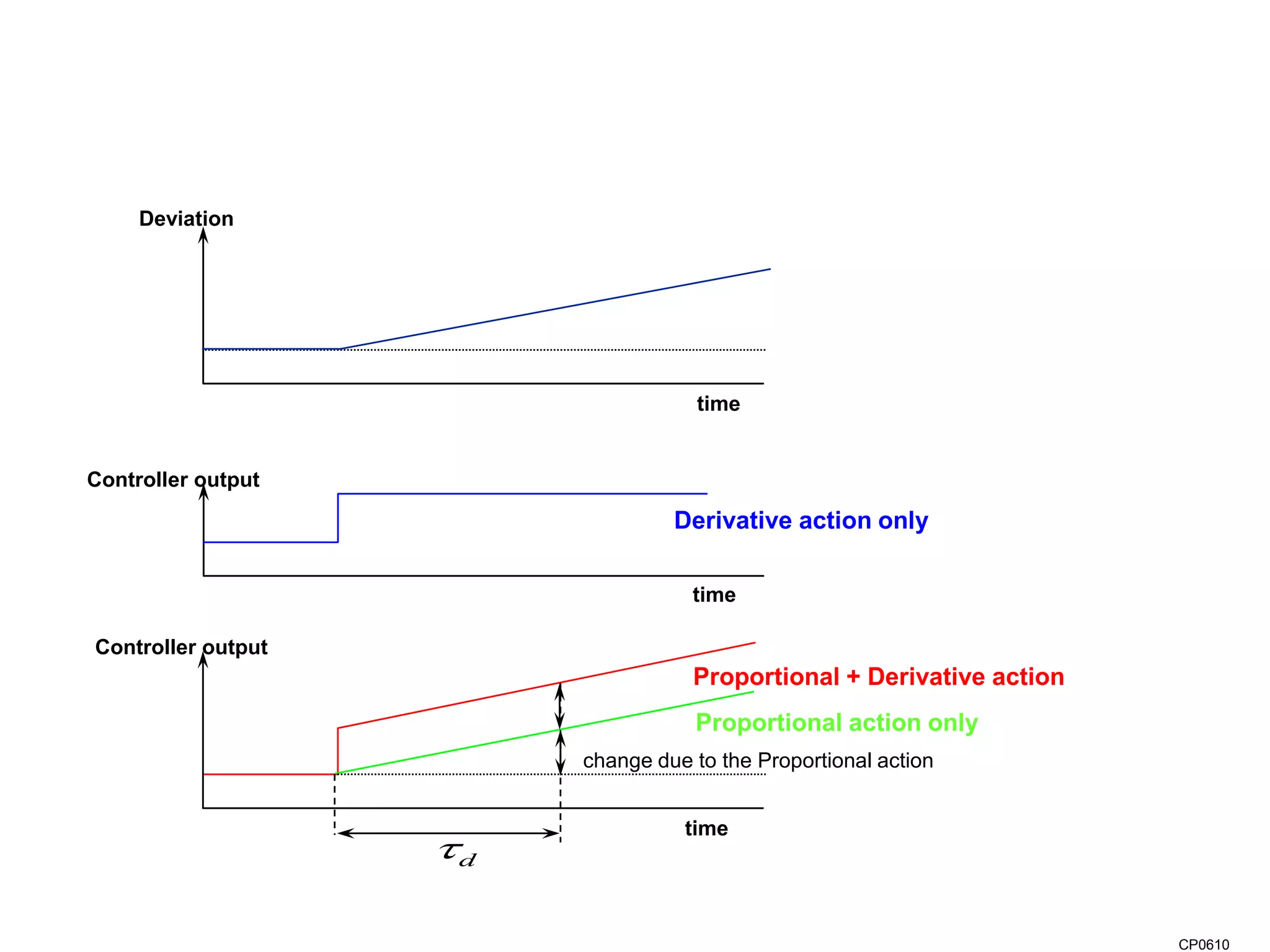

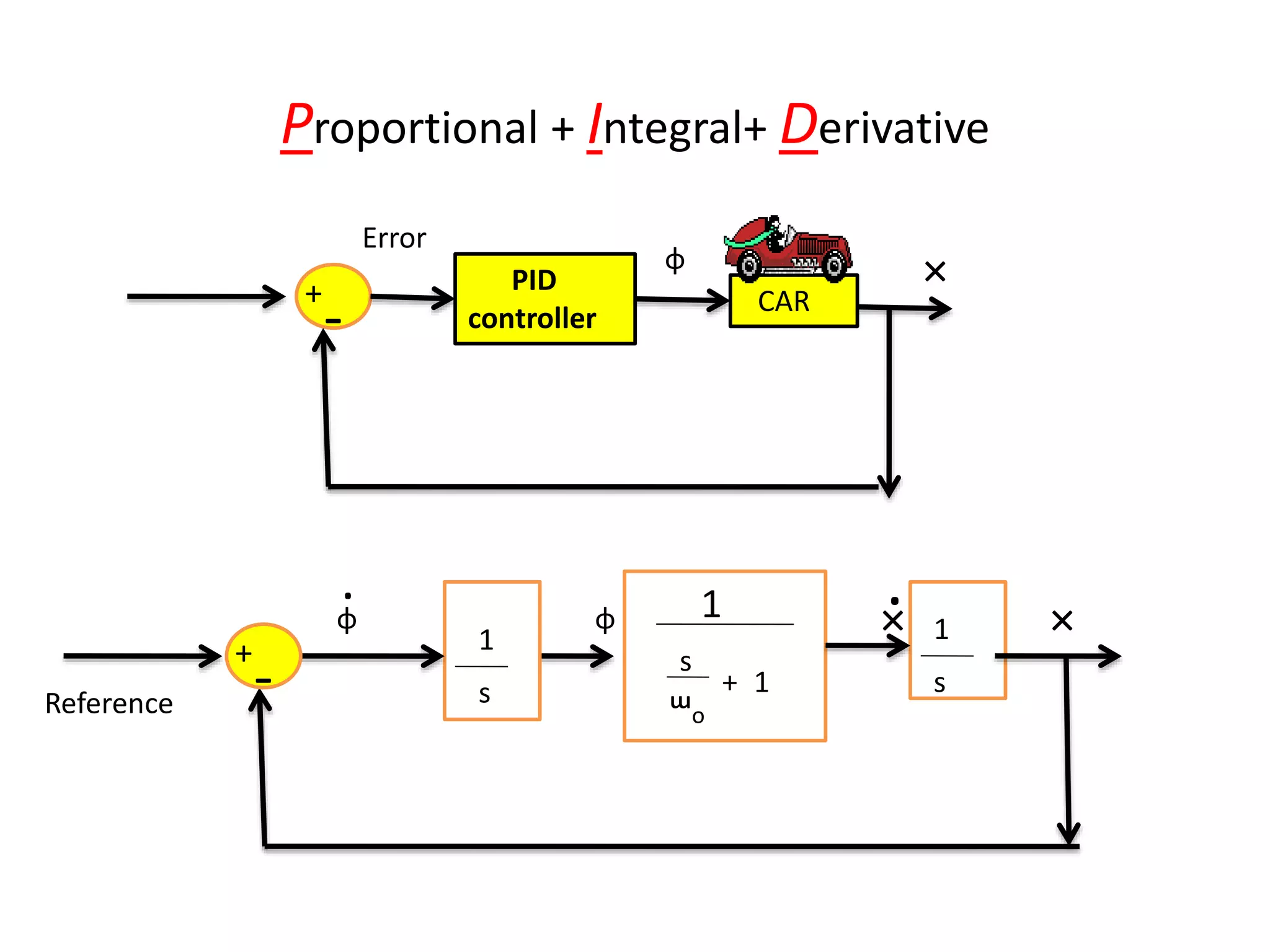

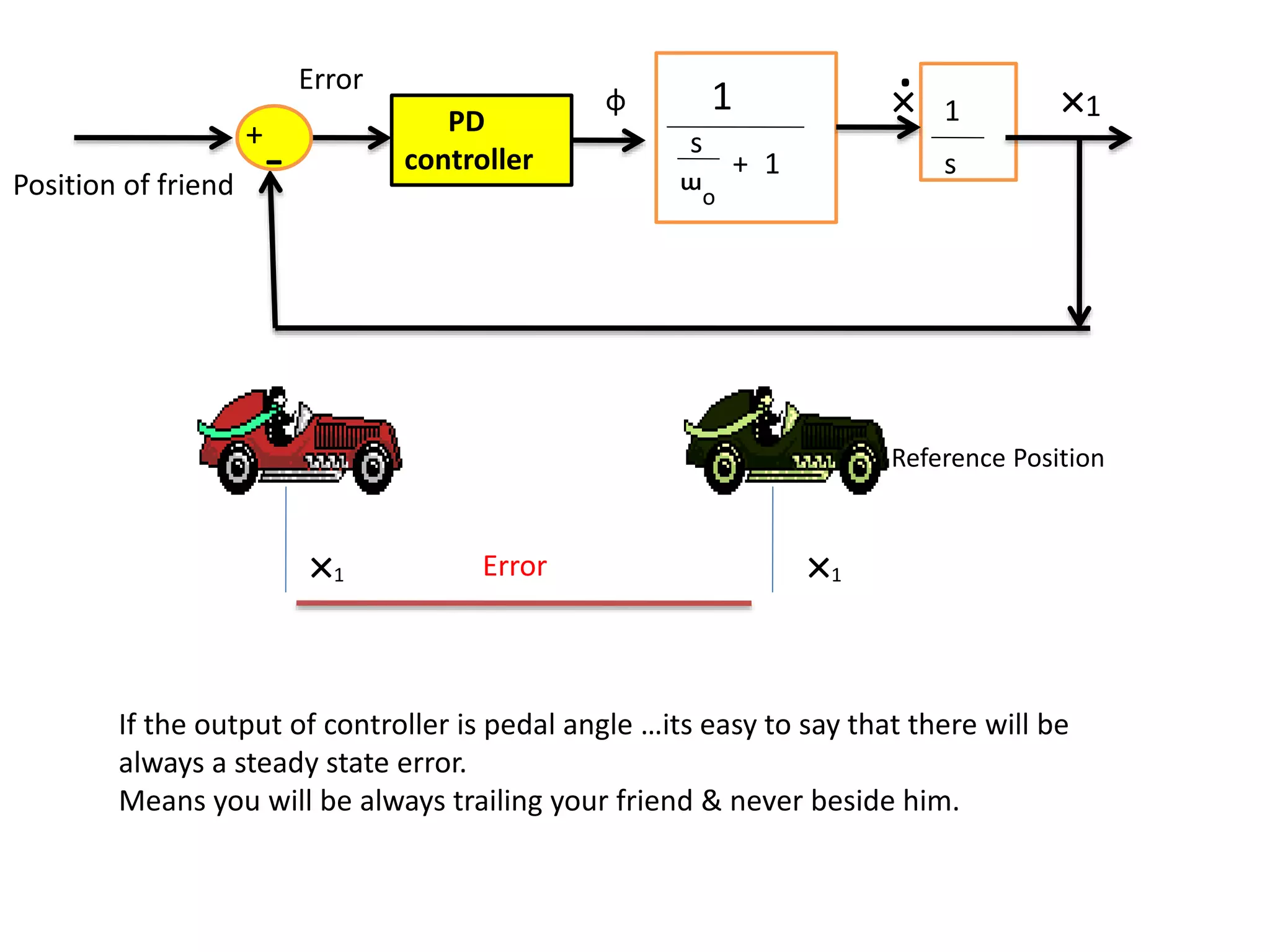

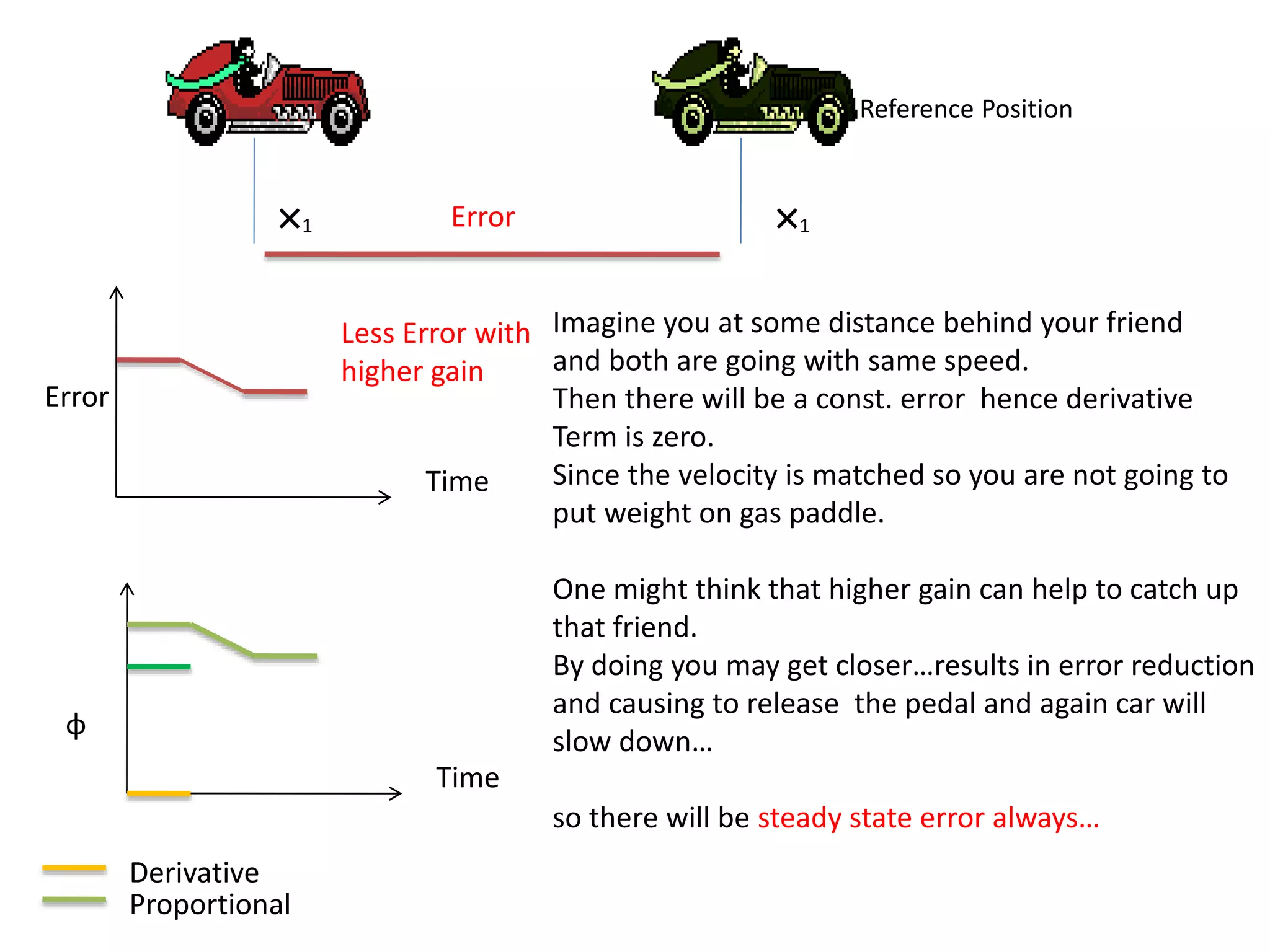

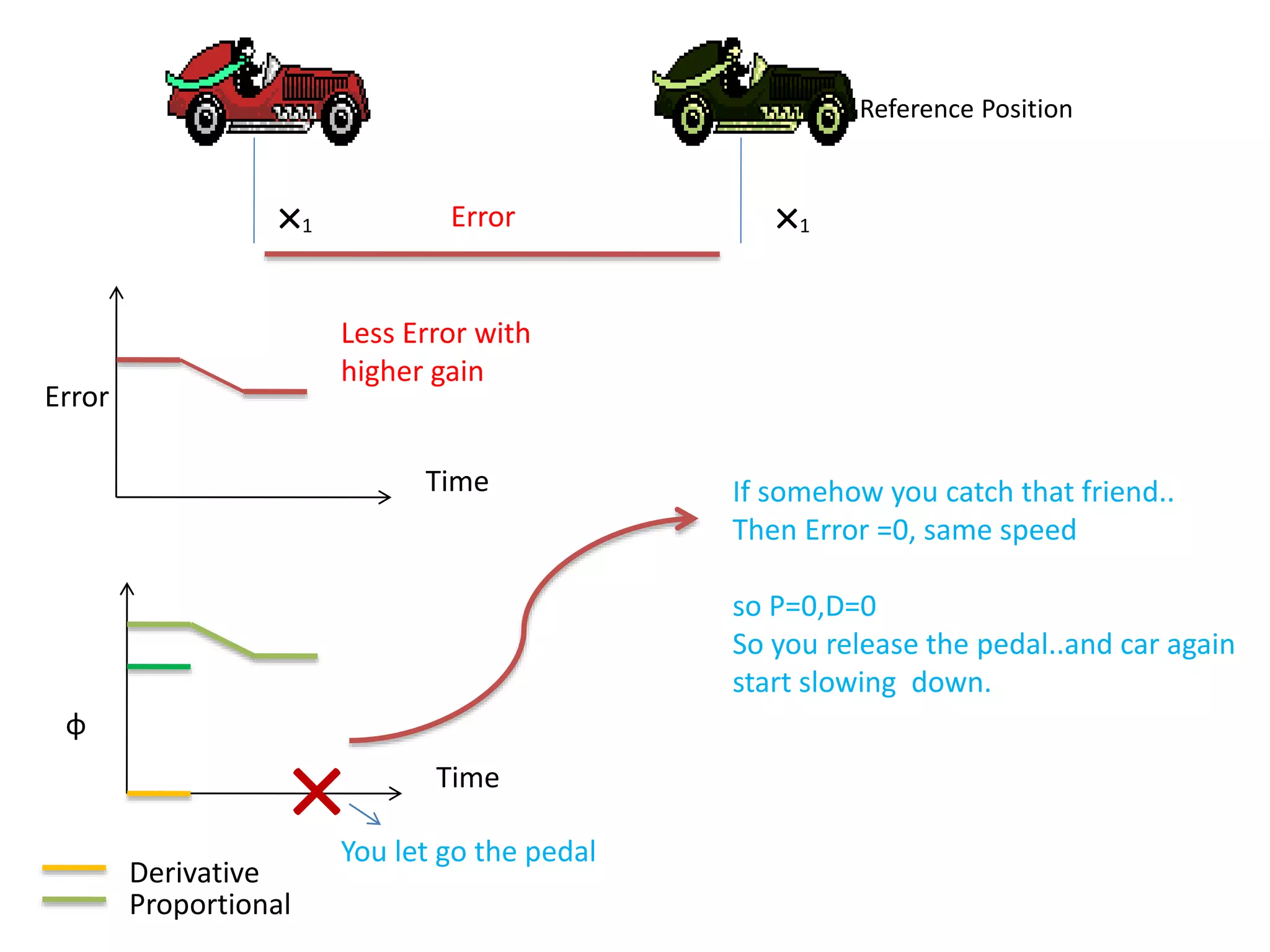

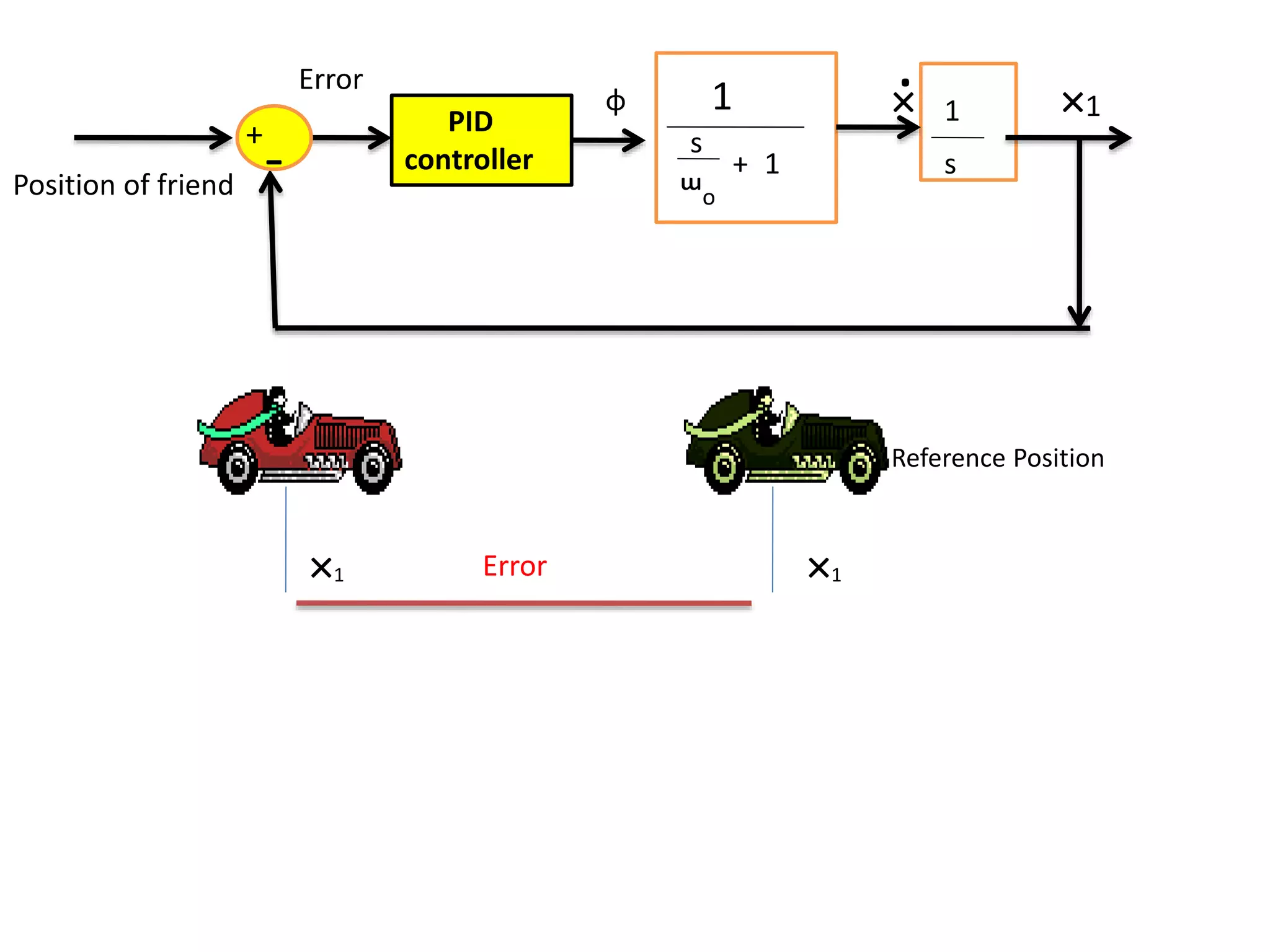

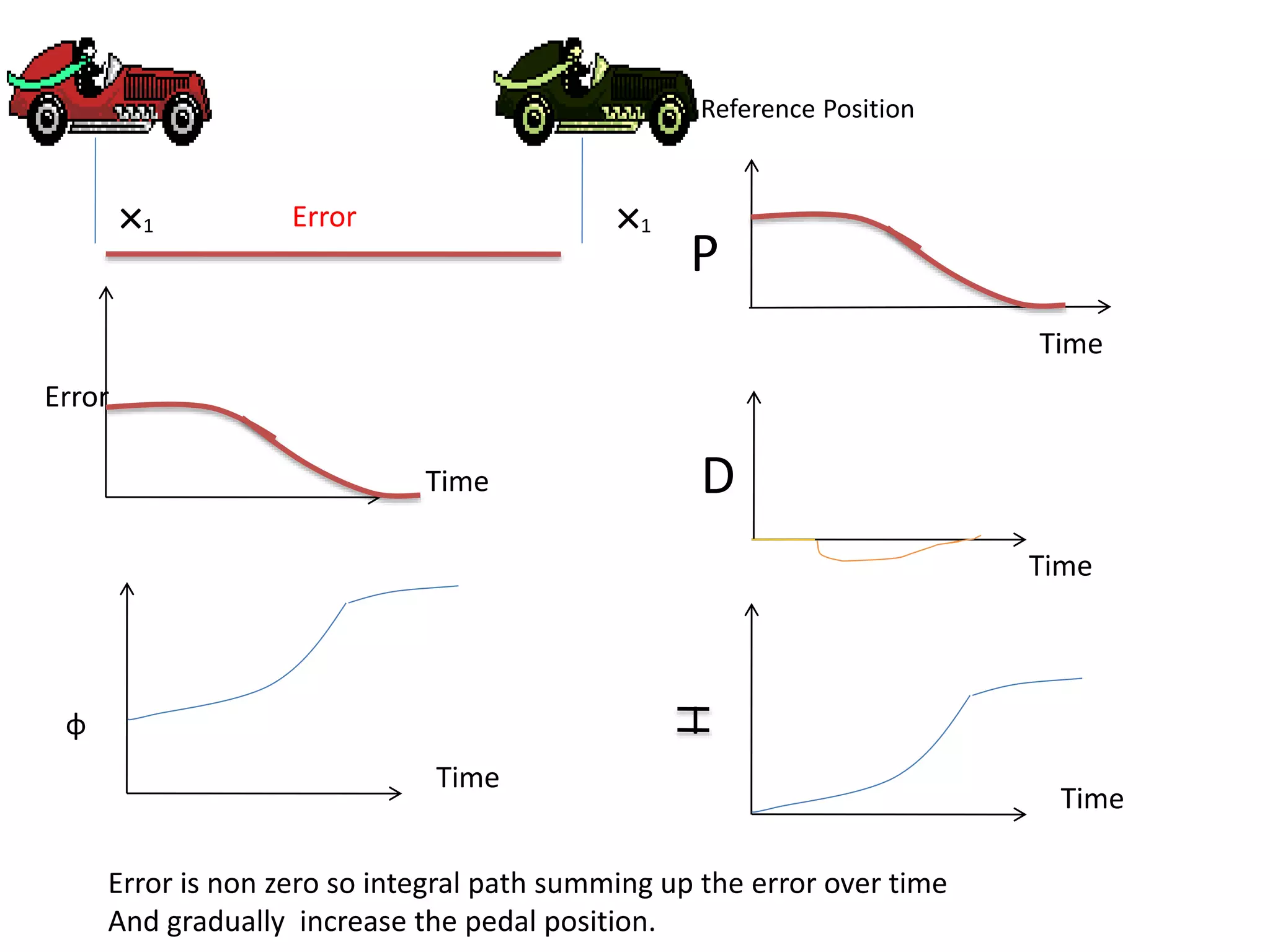

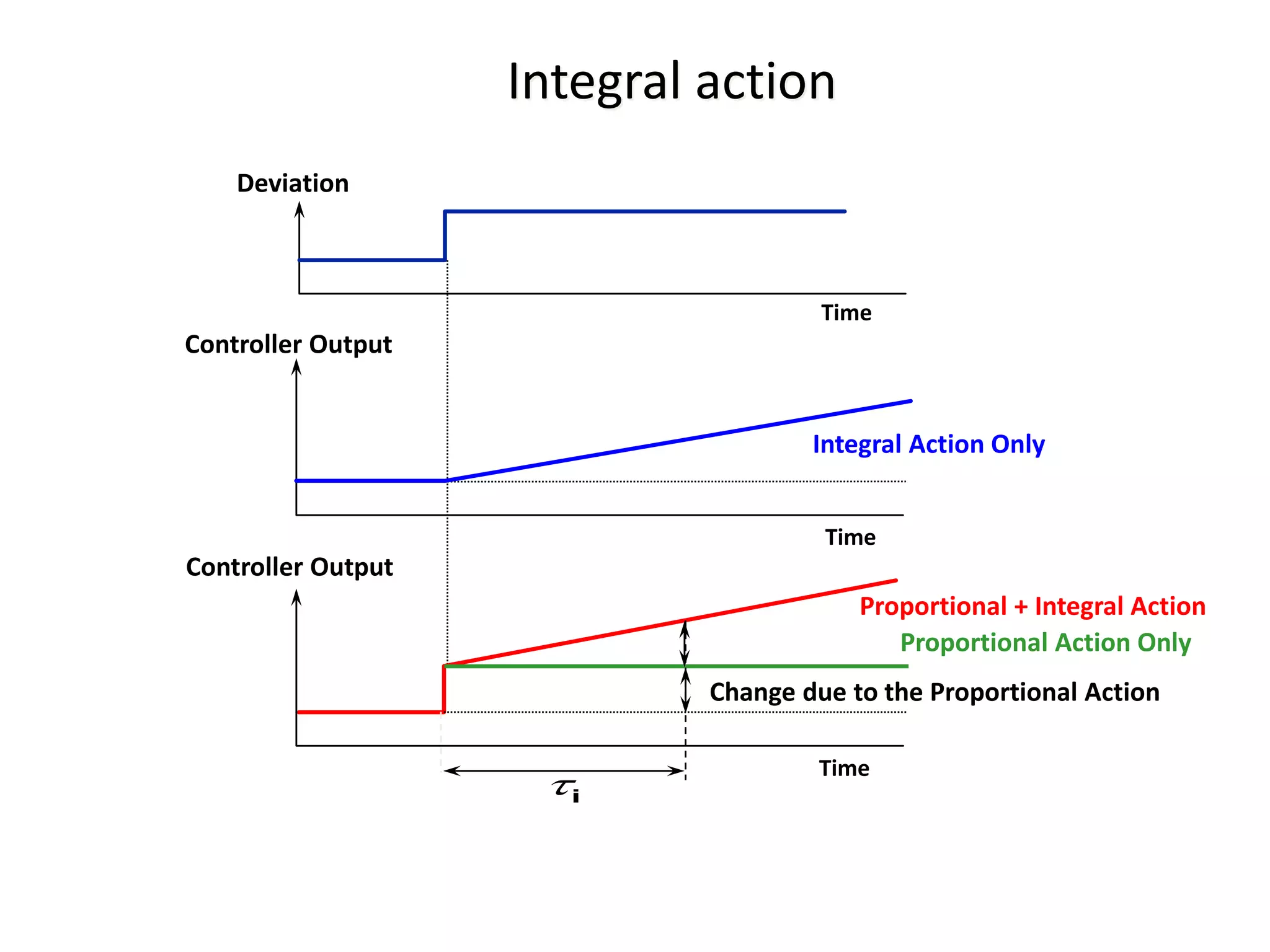

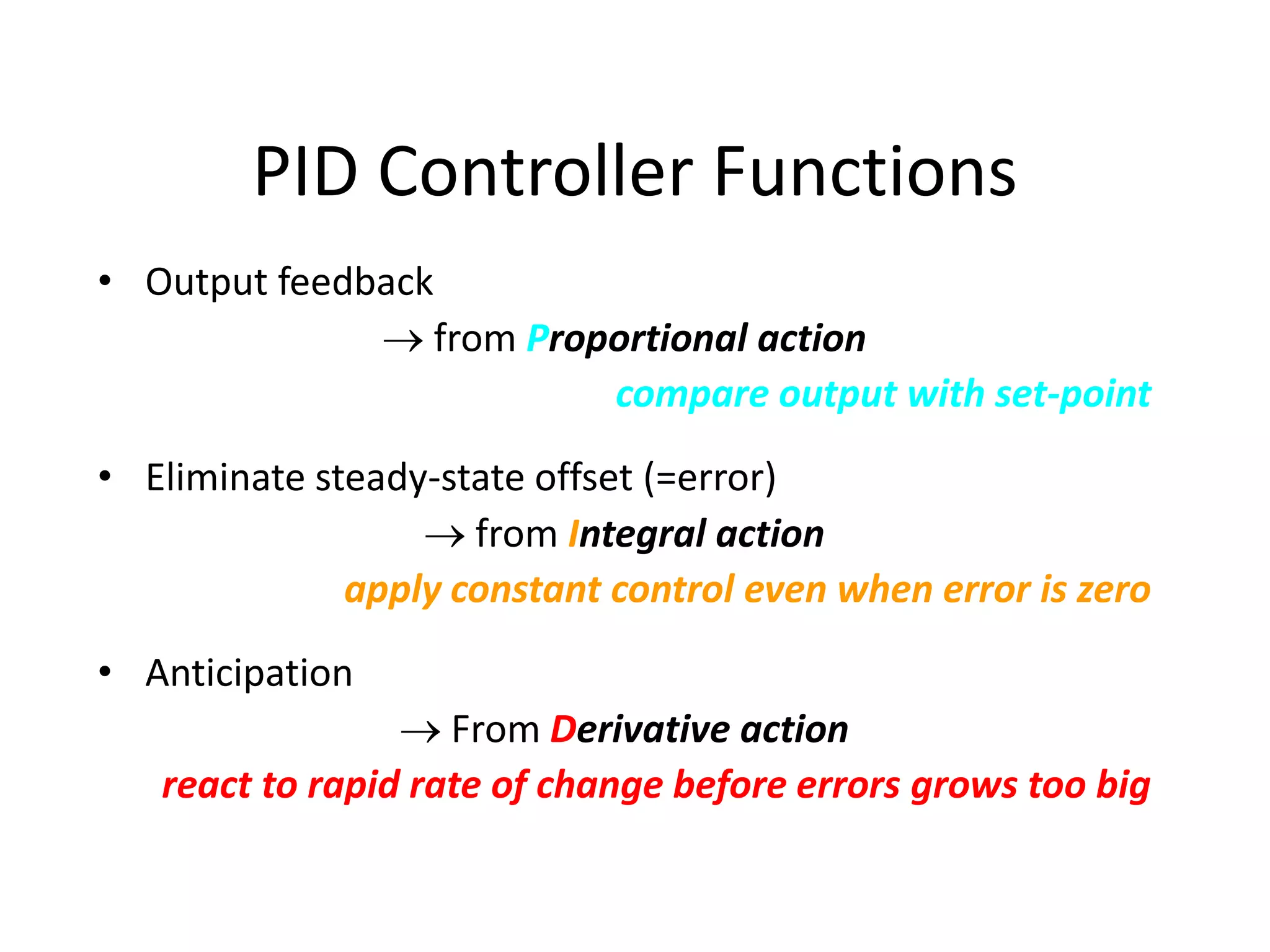

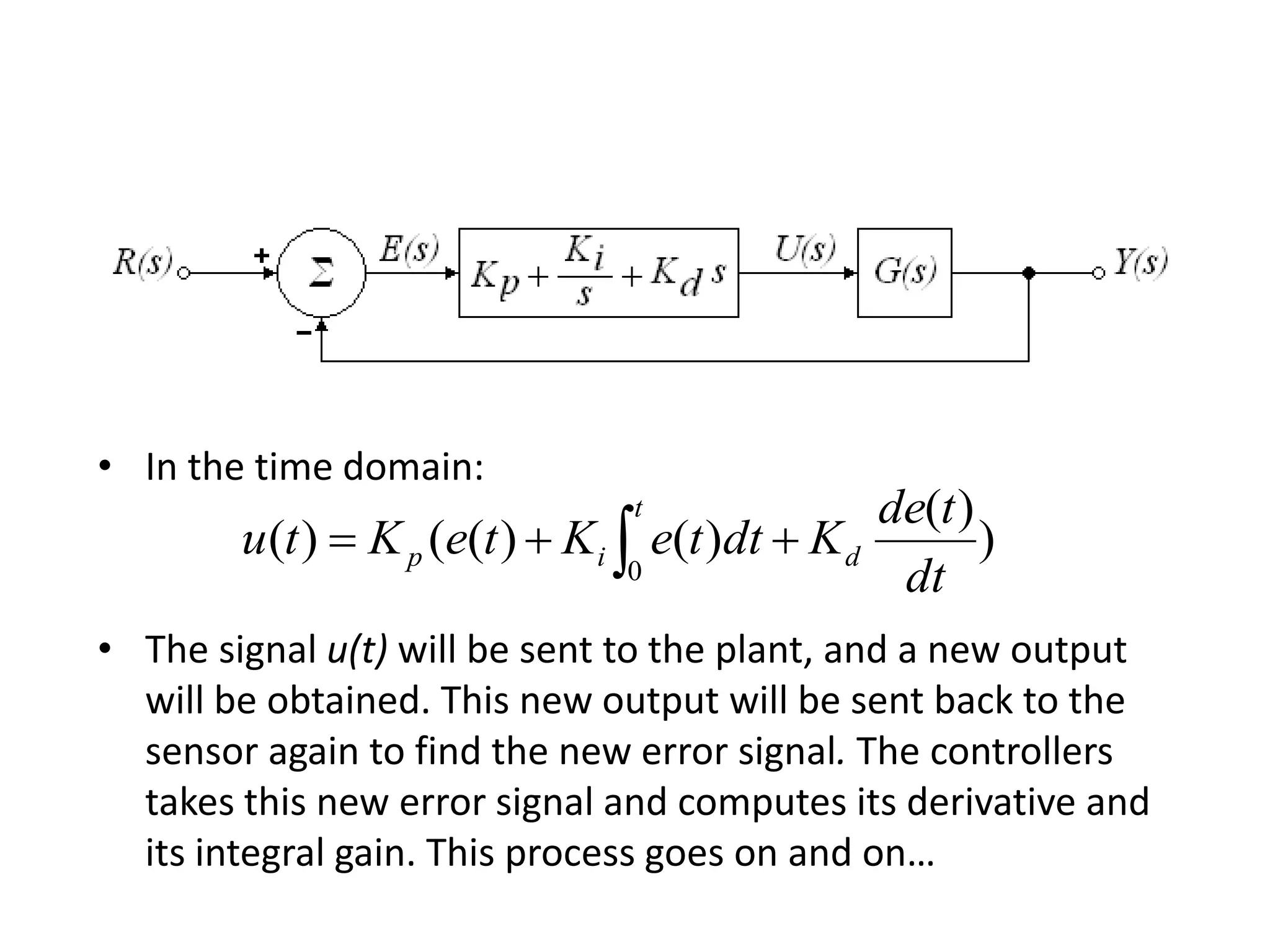

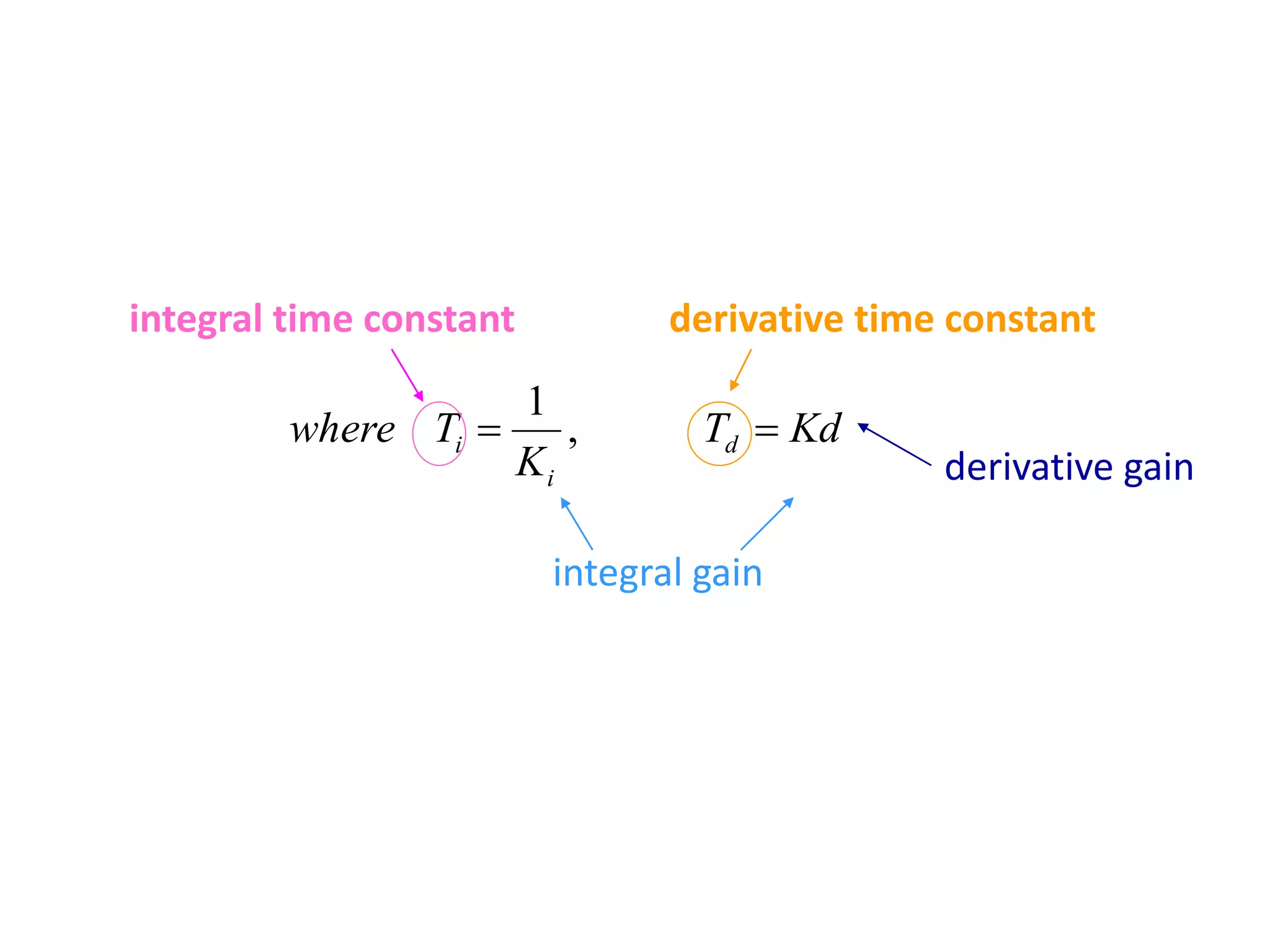

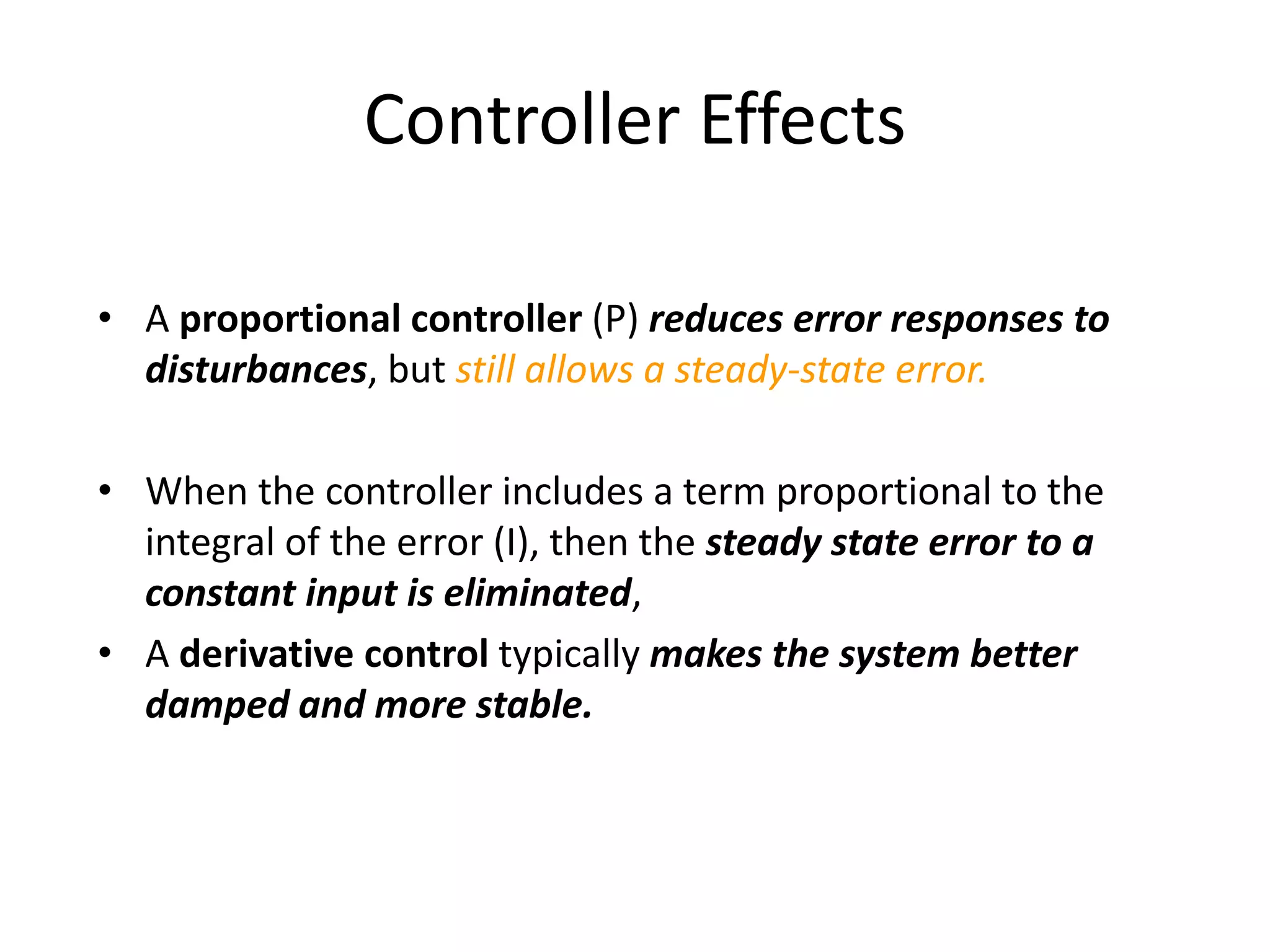

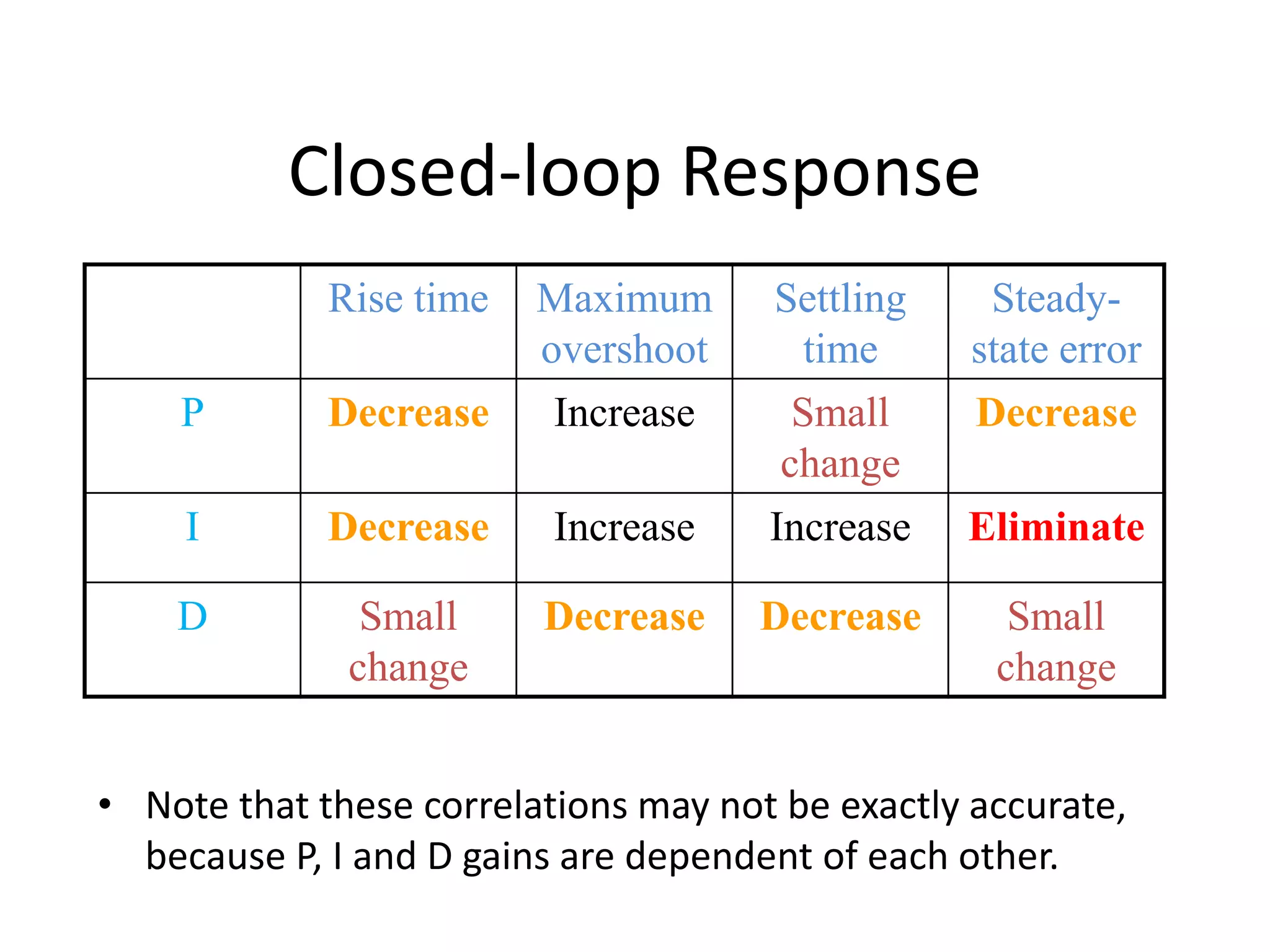

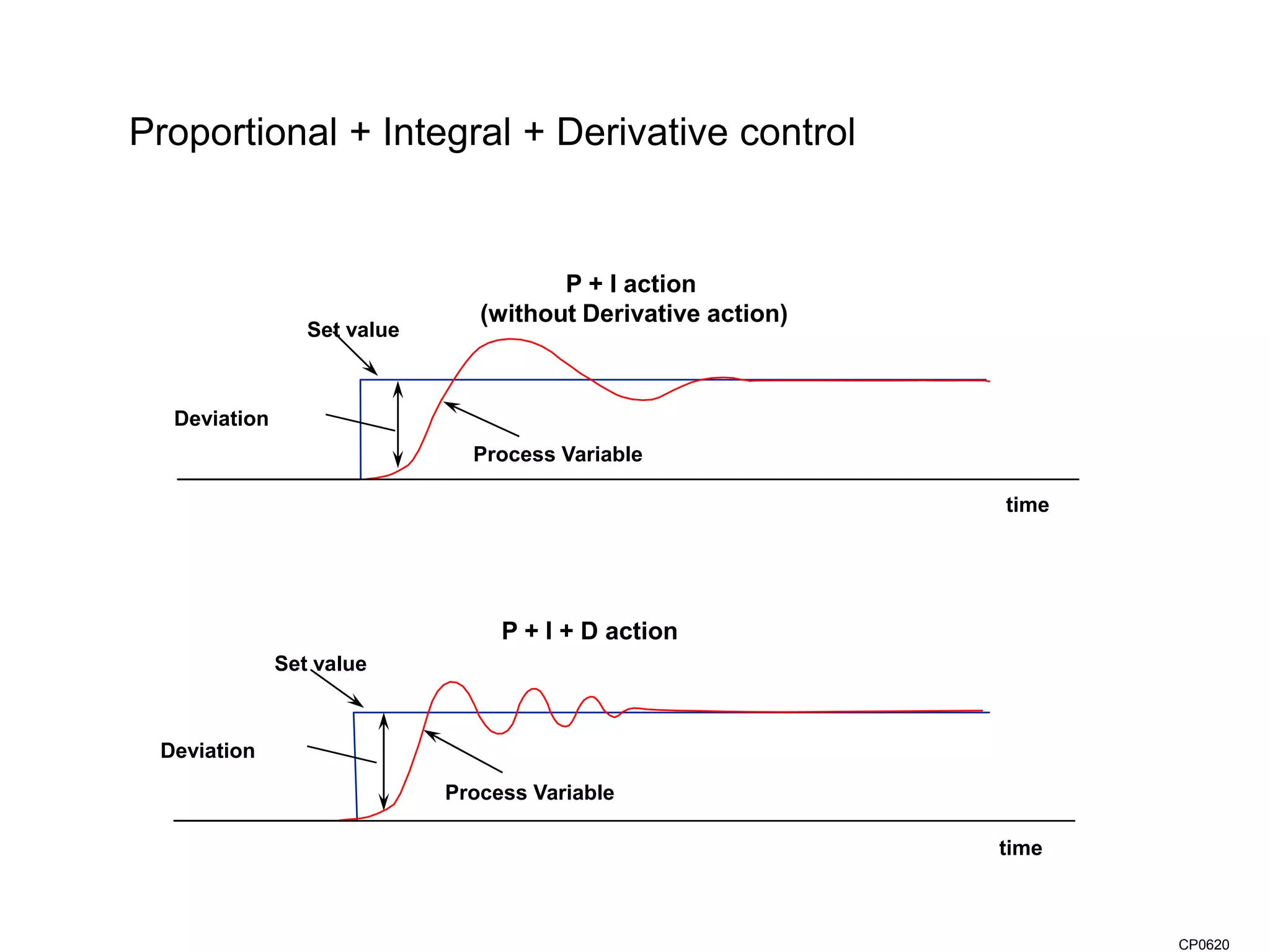

The document discusses the application of PID control in a car's speed regulation, using the gas pedal as a control variable. It explains how proportional, integral, and derivative actions work together to minimize steady-state errors and improve stability while driving, emphasizing the importance of not solely relying on specific pedal angles. Additionally, it highlights the trade-offs between different gains and their effects on car performance and stability during acceleration and deceleration.