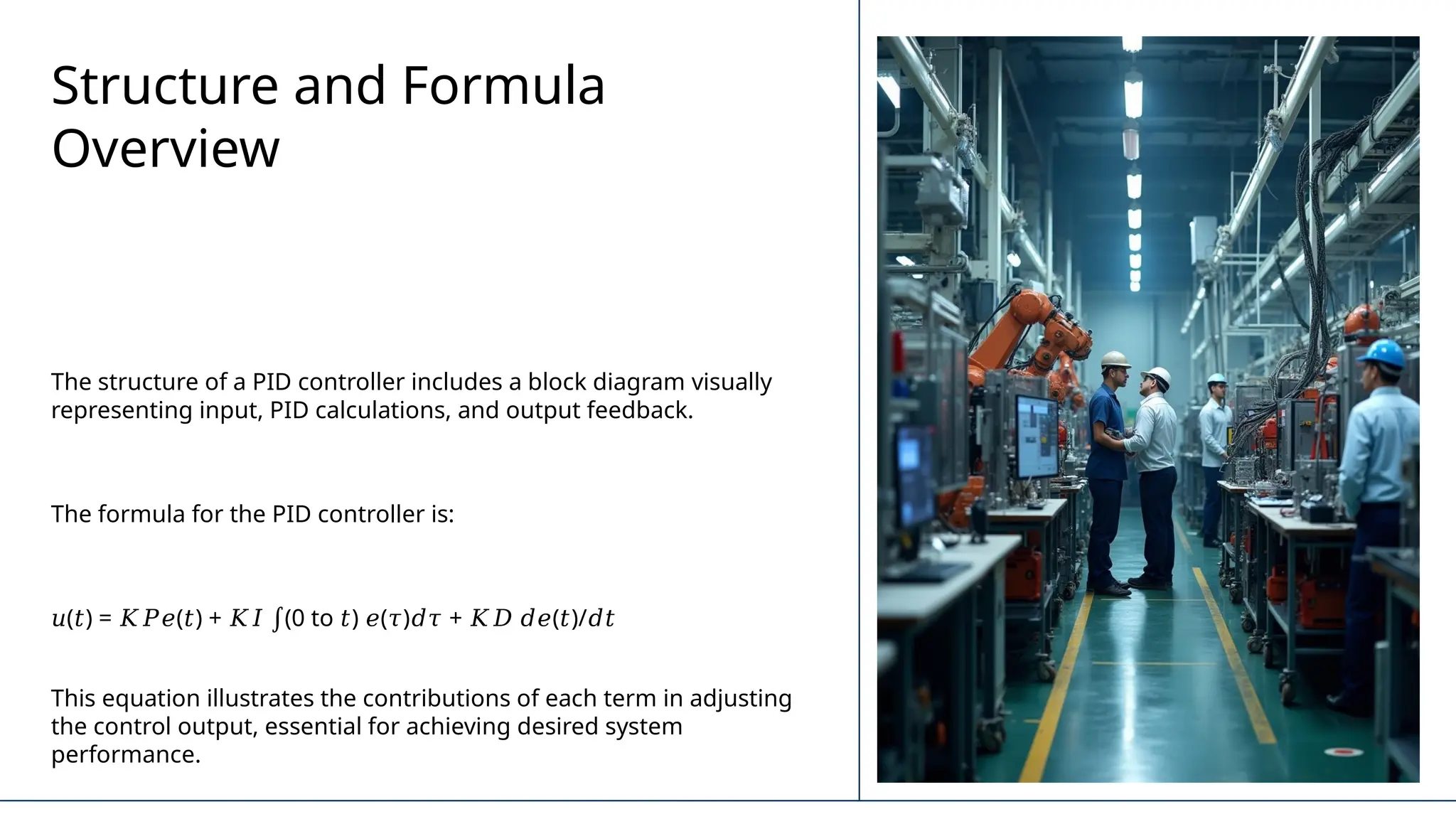

A PID (Proportional-Integral-Derivative) controller is one of the most fundamental and widely used components in control systems. It continuously calculates an error value and applies corrections to bring the system to the desired state. From balancing robots to cruise control in vehicles, PID controllers are everywhere. In this session, we will explore the basic structure of a PID controller, understand the role of each term, and discuss its practical applications in real-world systems. This talk aims to provide a beginner-friendly overview of how PID control works and why it's so effective in both simple and complex automation tasks.