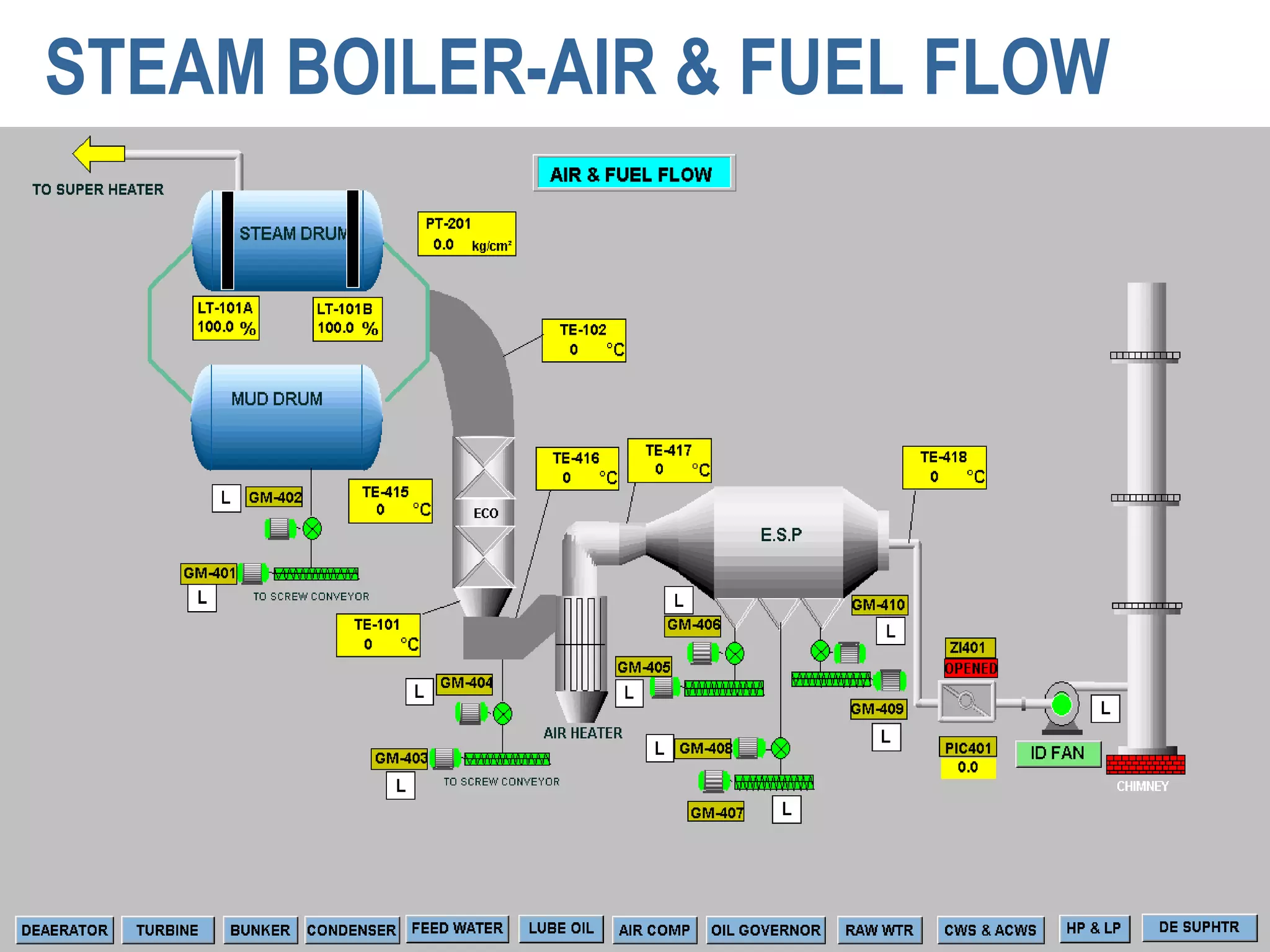

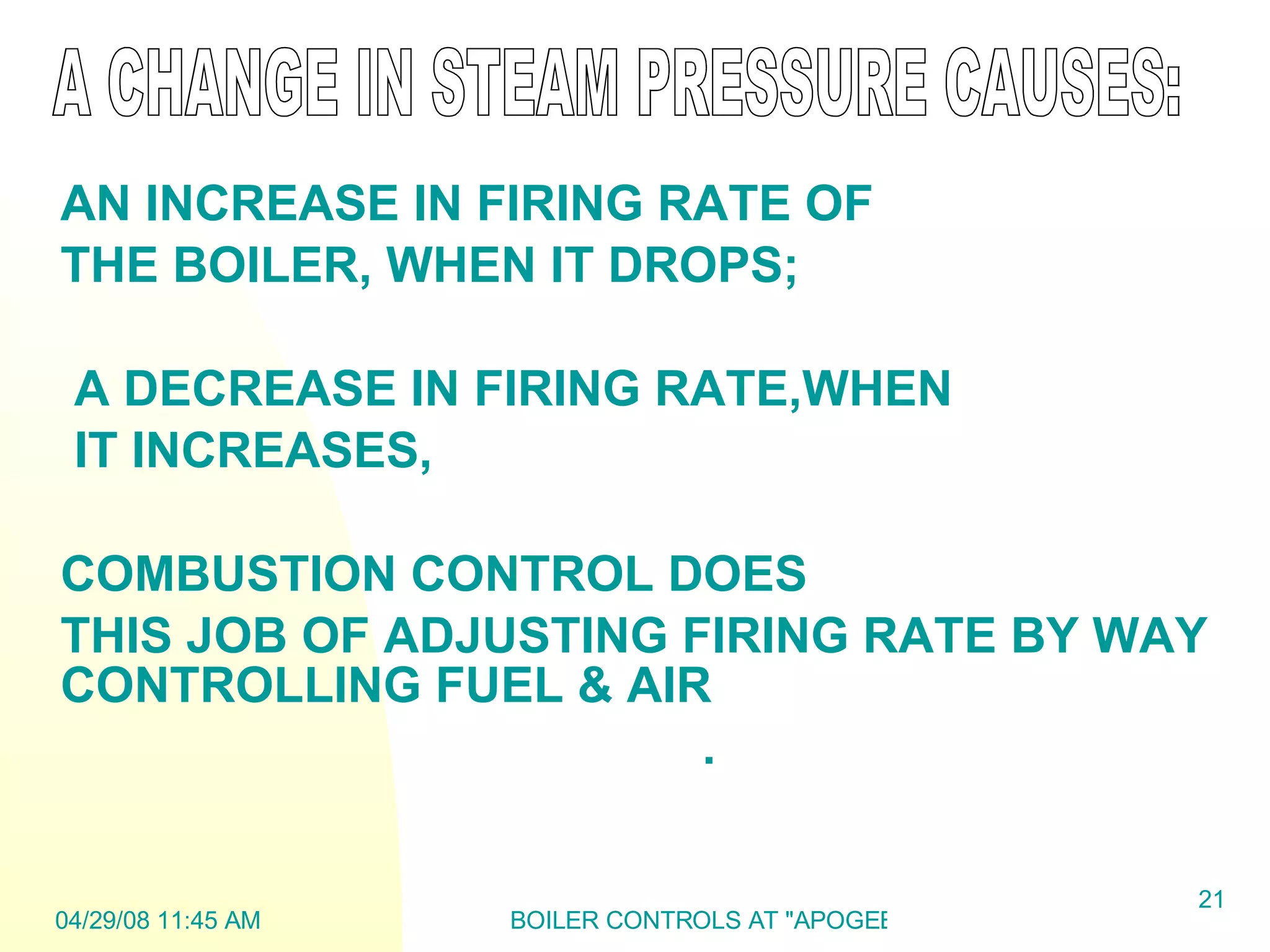

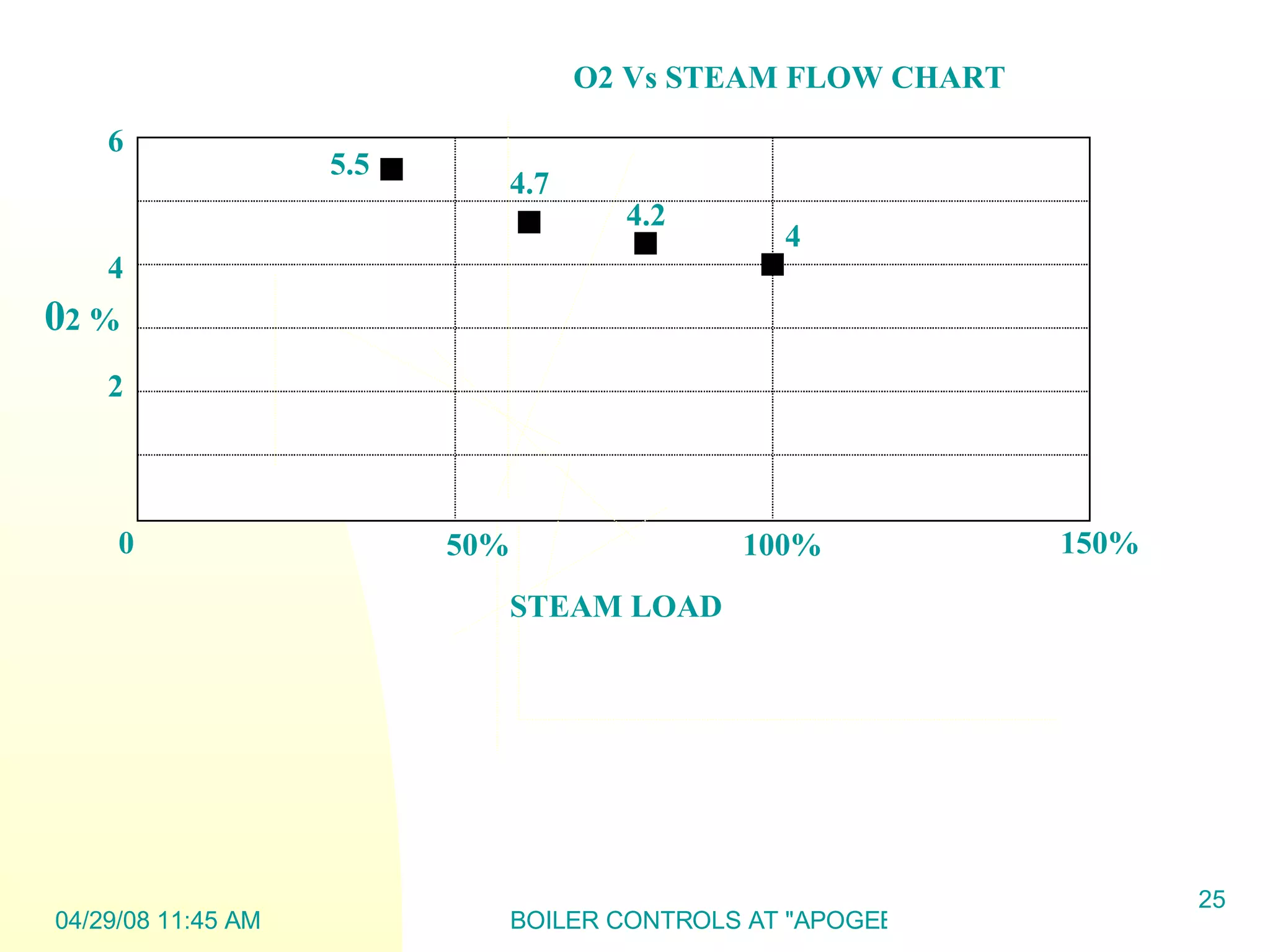

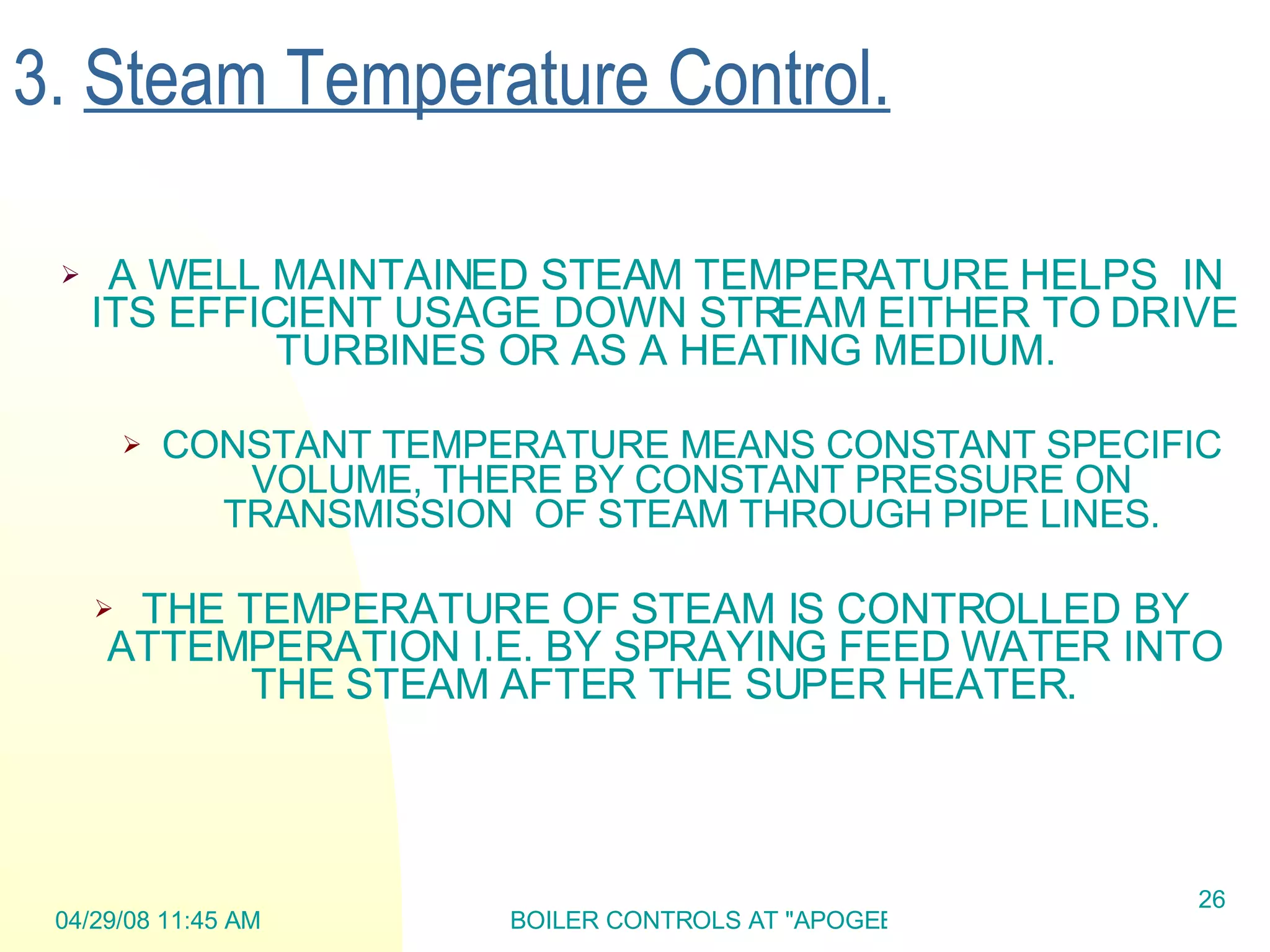

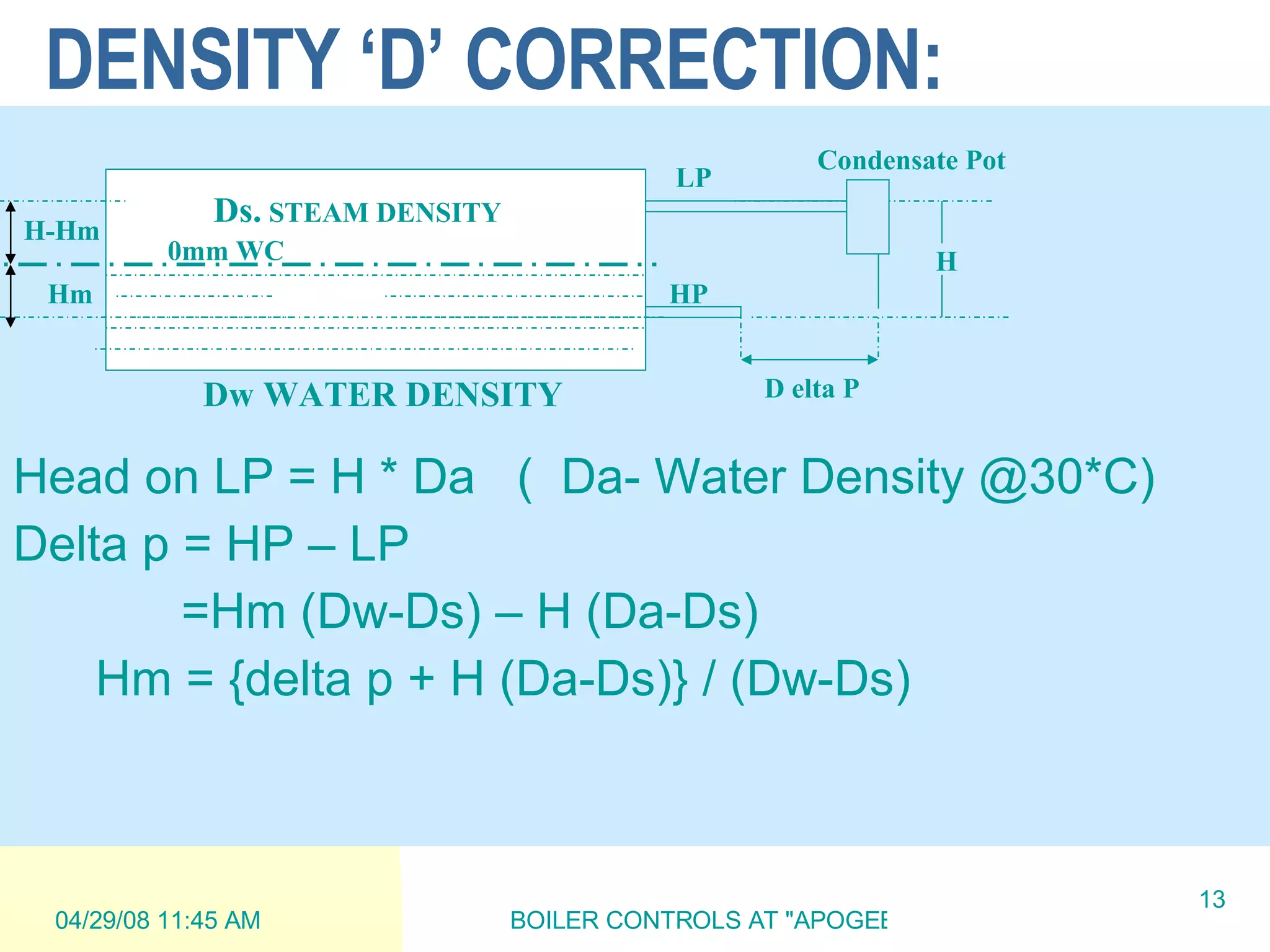

The document discusses instrumentation and controls used in boiler systems. It describes the key objectives of instrumentation including measurement, control, quality control and safety. It then provides details on various control loops used in boiler instrumentation including drum level control, steam temperature control, combustion control, furnace pressure control, deaerator pressure and level control, and soot blower pressure control. It stresses the importance of good maintenance management for instrumentation and controls.

![Temperature & Pressure Compensation for any compressible fluid like steam /air. THE EQUATION FOR COMPENSATION DONE AT FUNCTION BLOCK FX 704 IS AS GIVEN BELOW. ACTUAL STEAM FLOW:= INDICATED STEAM FLOW X SQRT{[(P1+1.209)*(485.0+273)]/[(66.0+1)*(T1+273)]} P1- MEASURED STEAM PRESSURE SIGNAL. T1- MEASURED TEMPERATURE SIGNAL DESIGN PRESSURE (CONSTANT) SAY, 66.0 KG/CM2 &. DESIGN TEMPERATURE (CONSTANT) 485.0 DEG C.](https://image.slidesharecdn.com/boiler-1209494720315024-9/75/Boiler-16-2048.jpg)