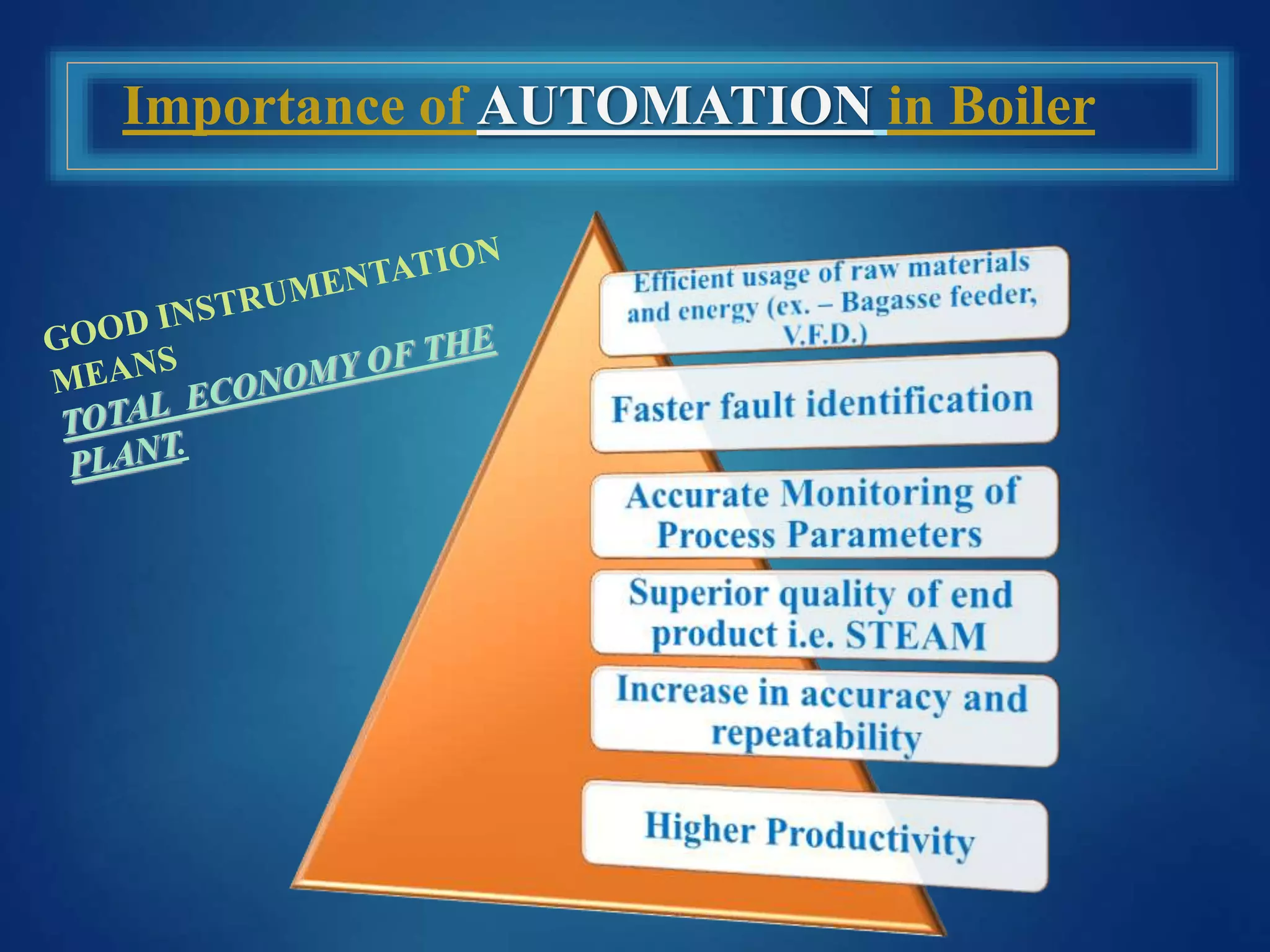

The document outlines the boiler automation system presented by Amar Gupta, highlighting the significance of using an ABB 800M controller for monitoring and controlling various boiler processes, such as drum level, combustion control, and deaerator pressure. It details multiple control loops, including three-element drum level control and combustion control, to manage steam demand and ensure safety through interlocks. The automation aims to enhance efficiency and stability of operations in boiler systems, particularly in applications like sugar production.