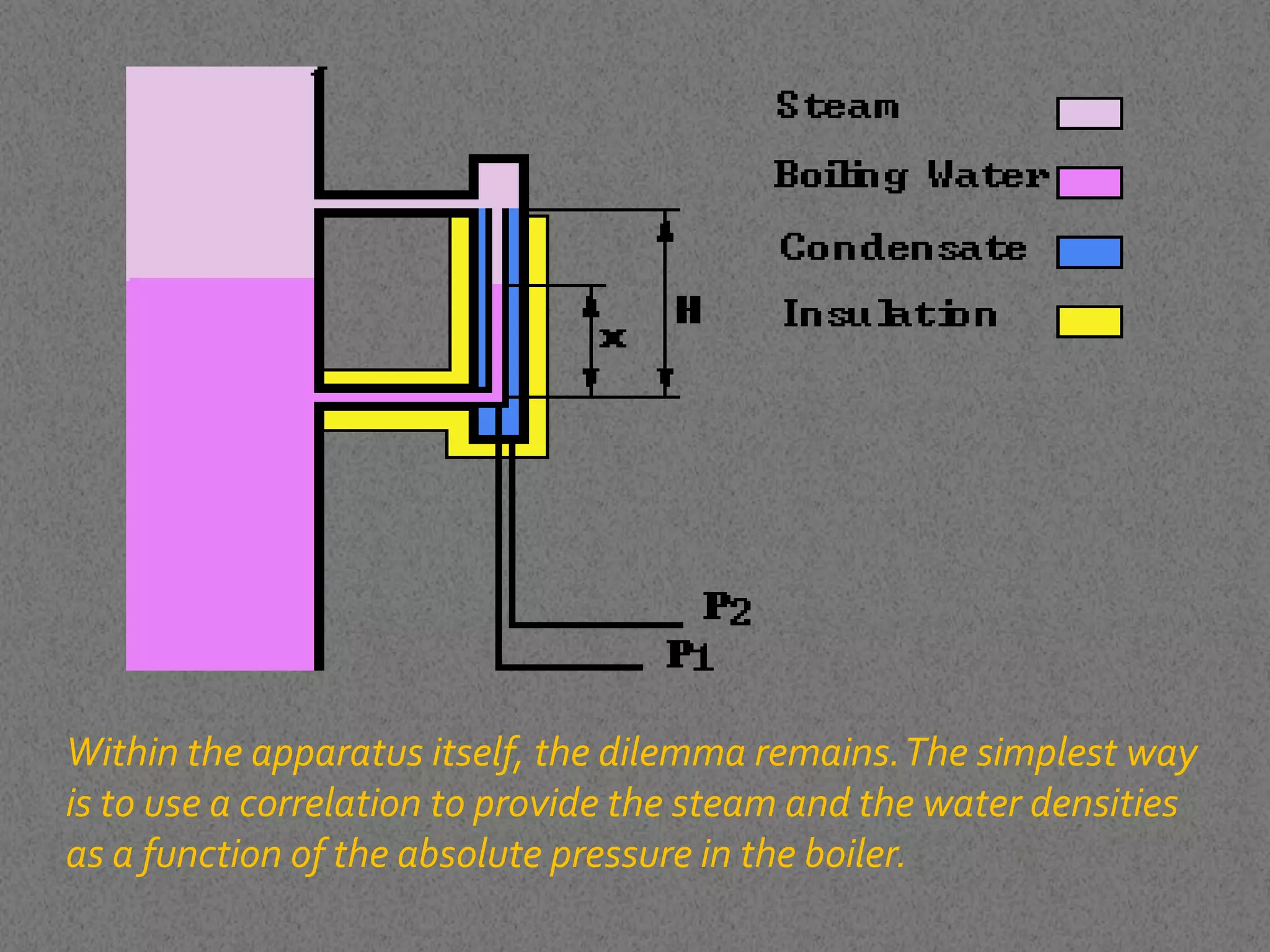

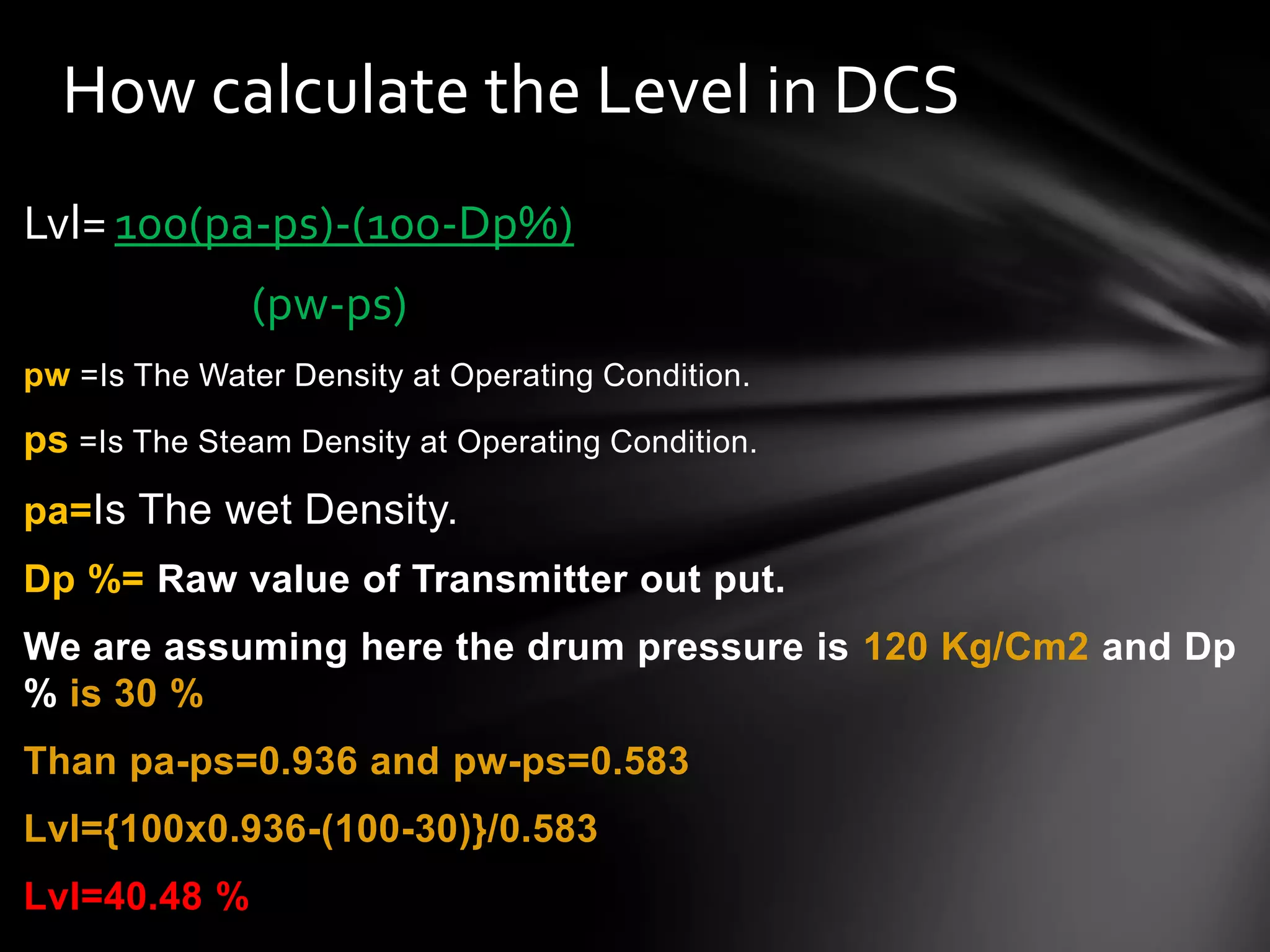

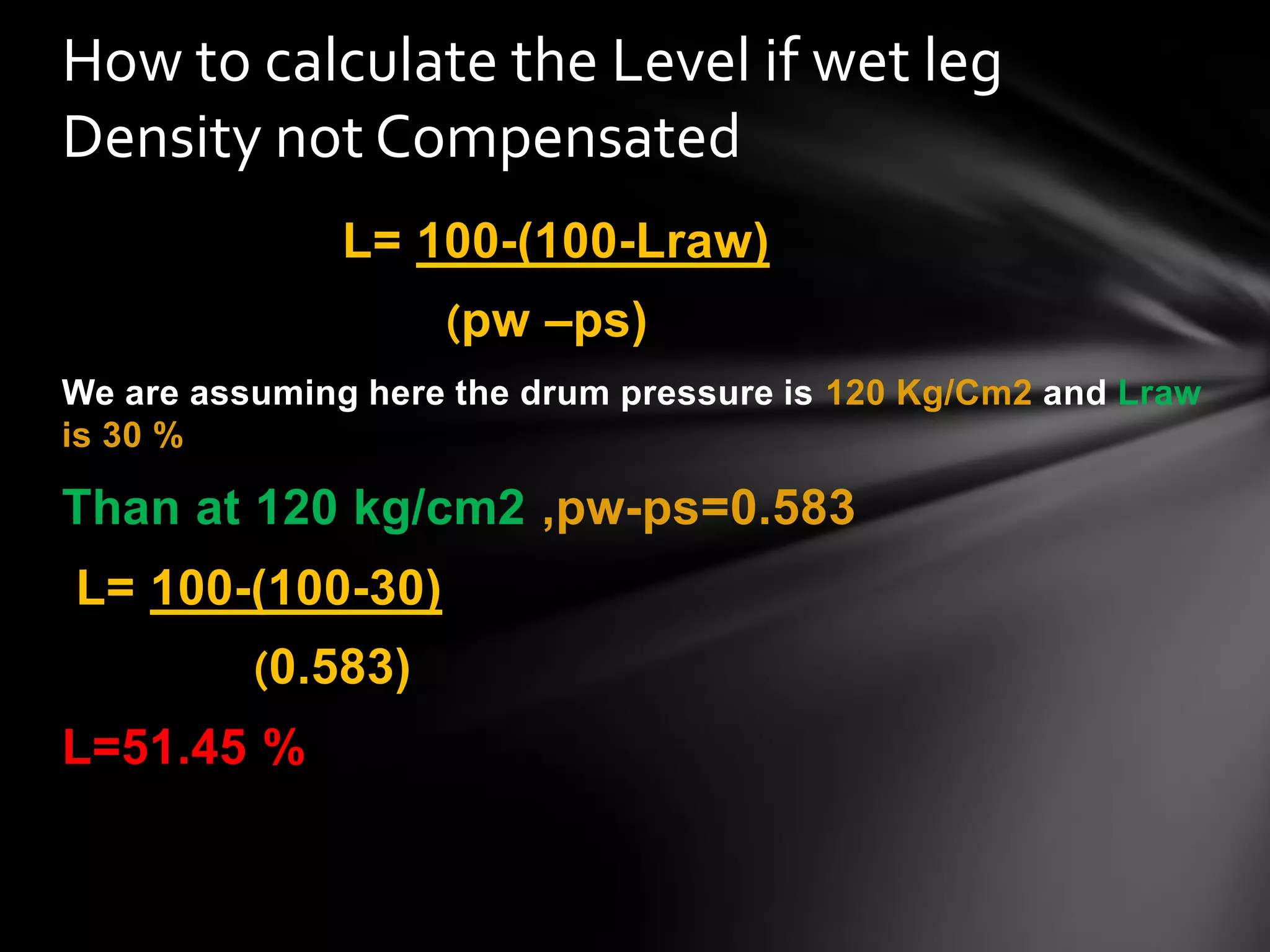

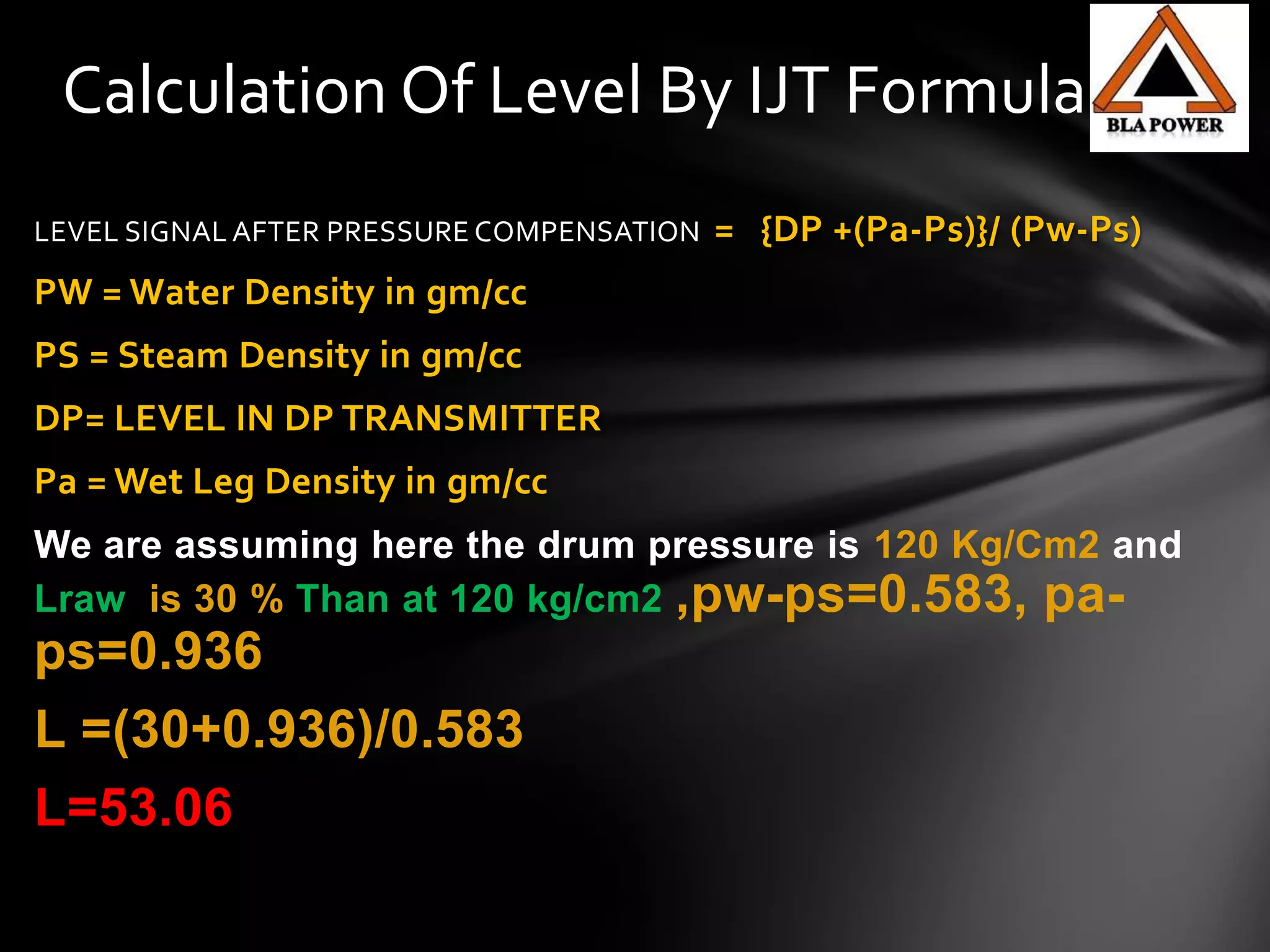

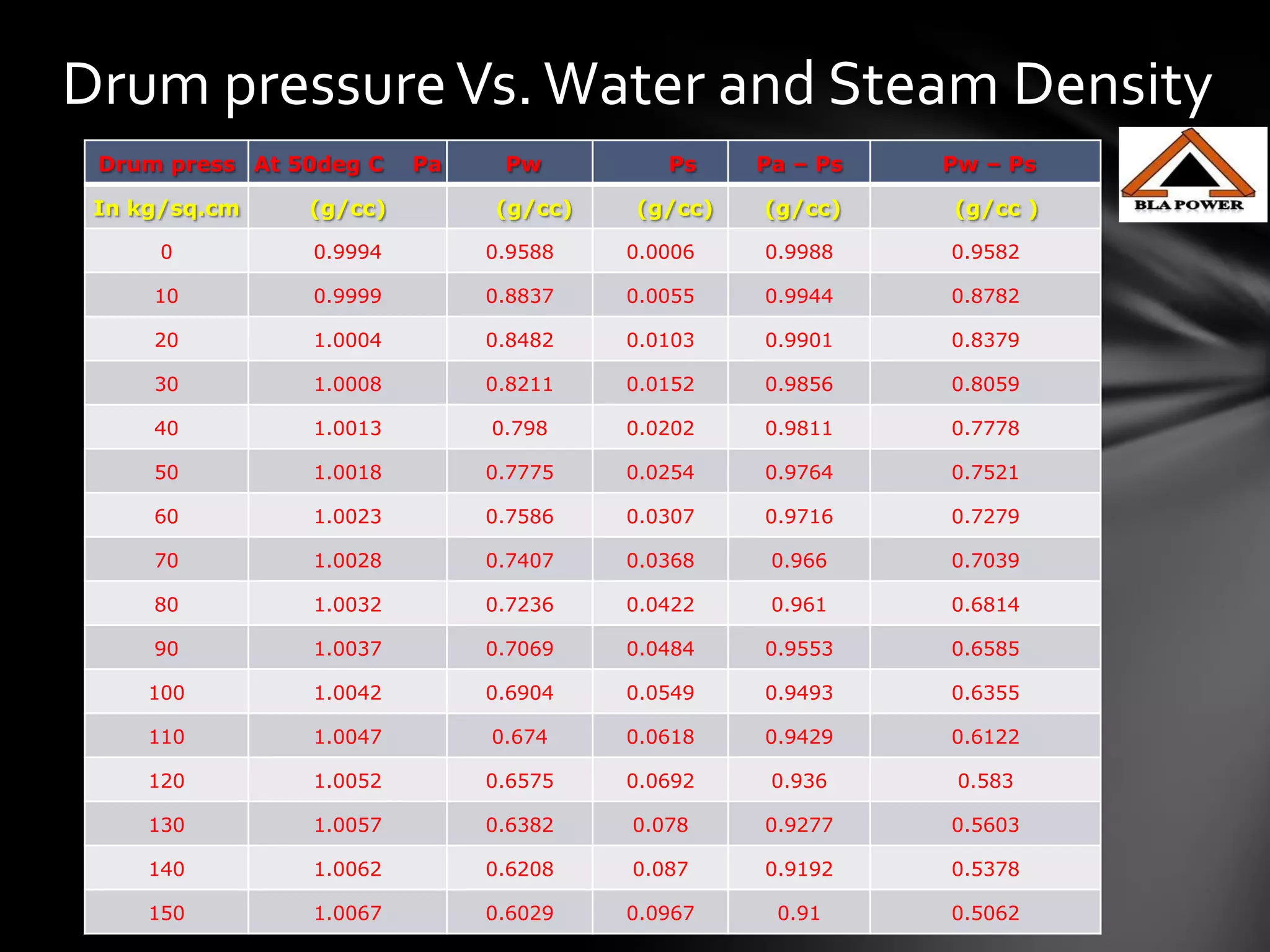

The level measurement in a steam drum is complex due to changing densities of water and steam with temperature. A level capture apparatus maintains a constant wet leg temperature by condensation to ensure consistent densities. The level can be calculated using a correlation of steam and water densities with pressure. The level percentage is determined by subtracting the raw transmitter output from 100%, divided by the difference between water and steam densities.