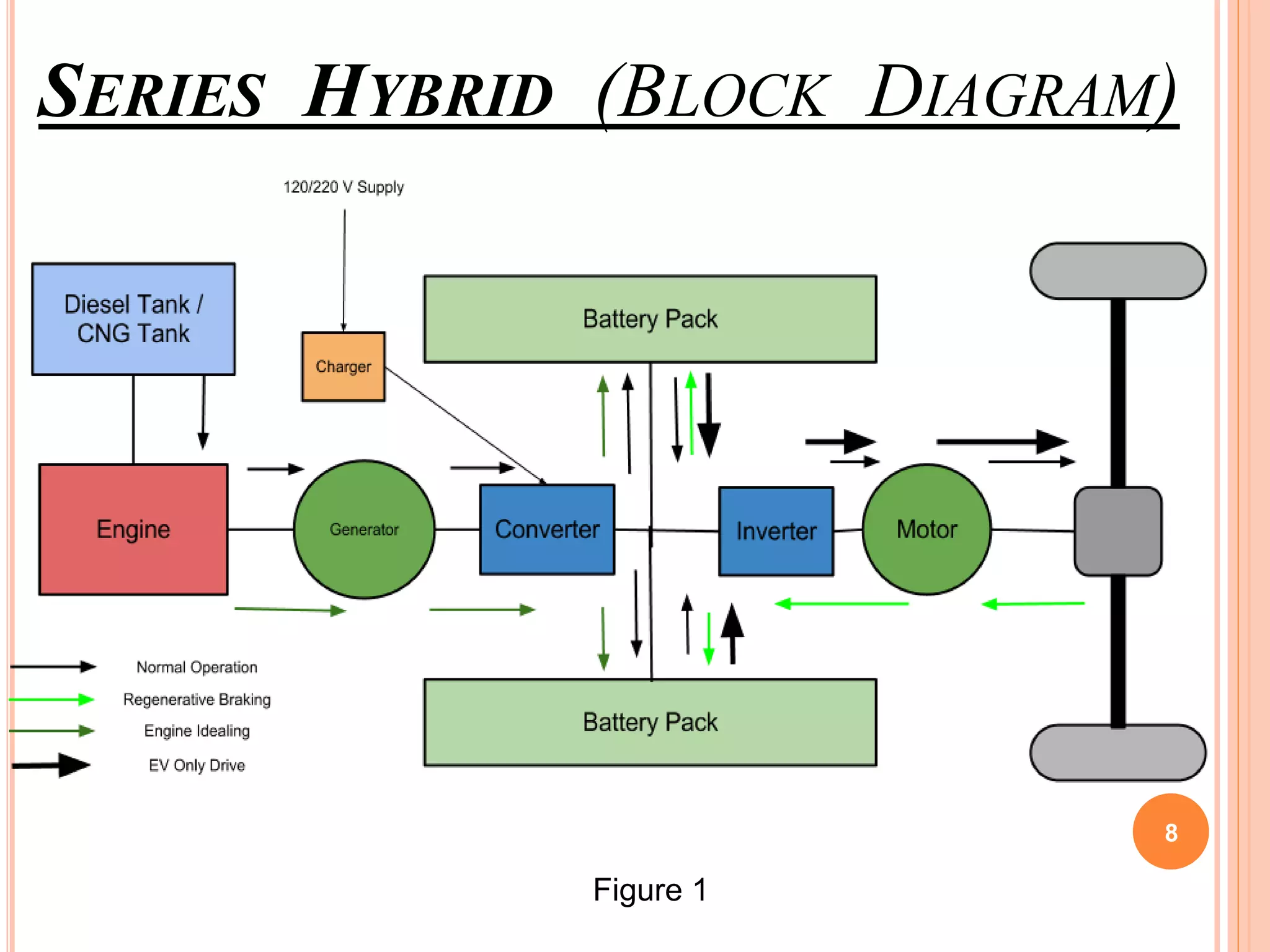

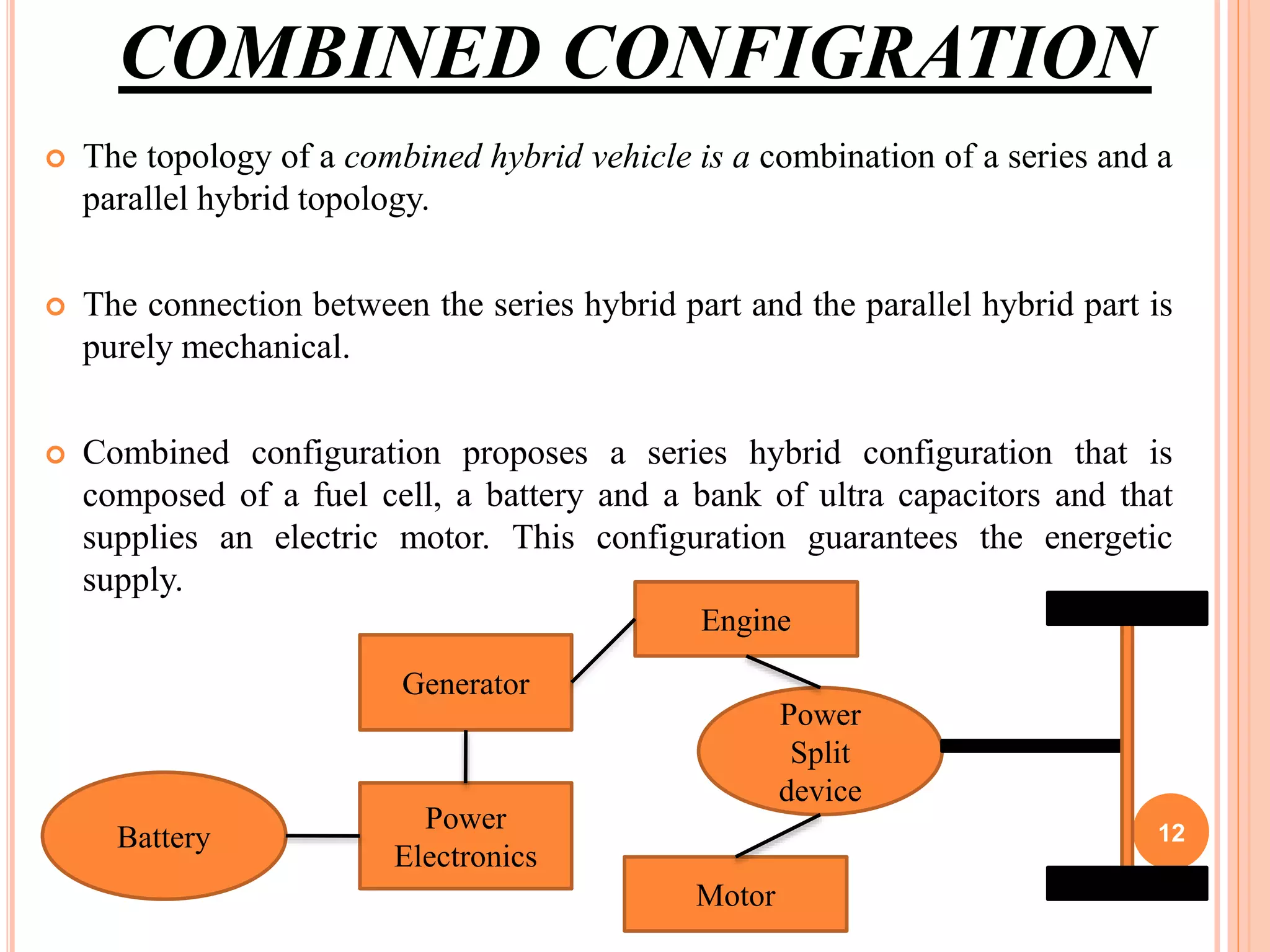

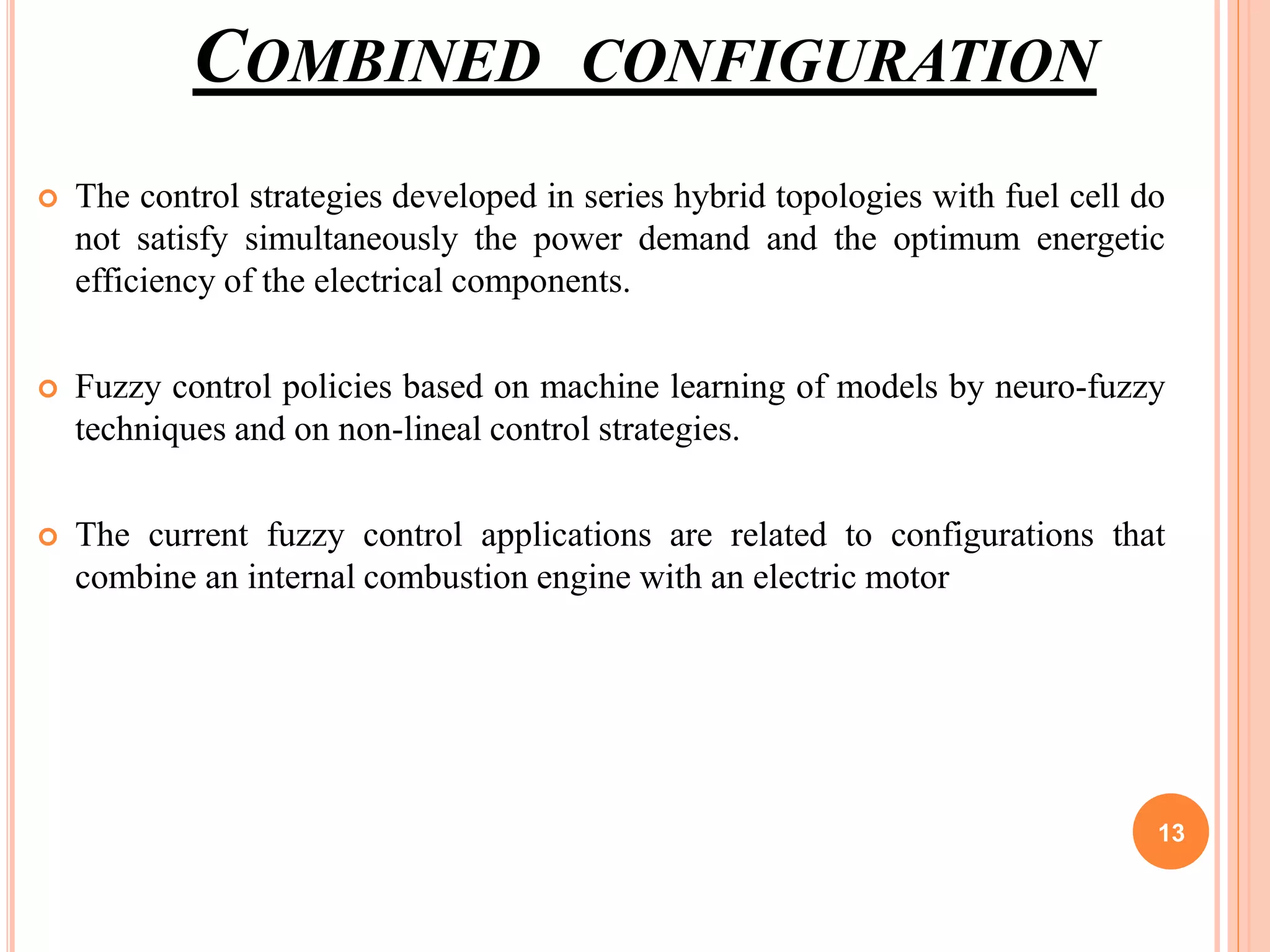

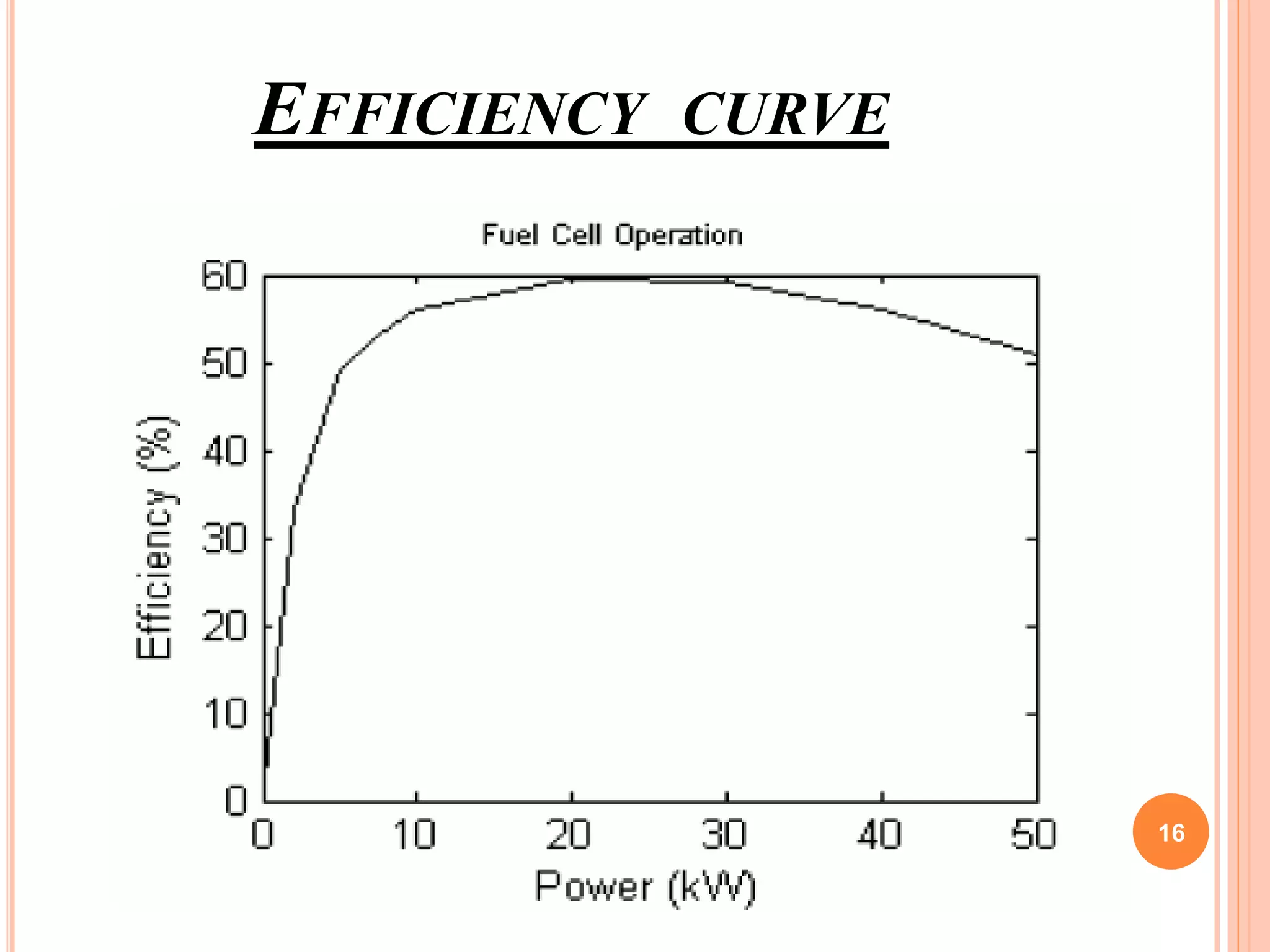

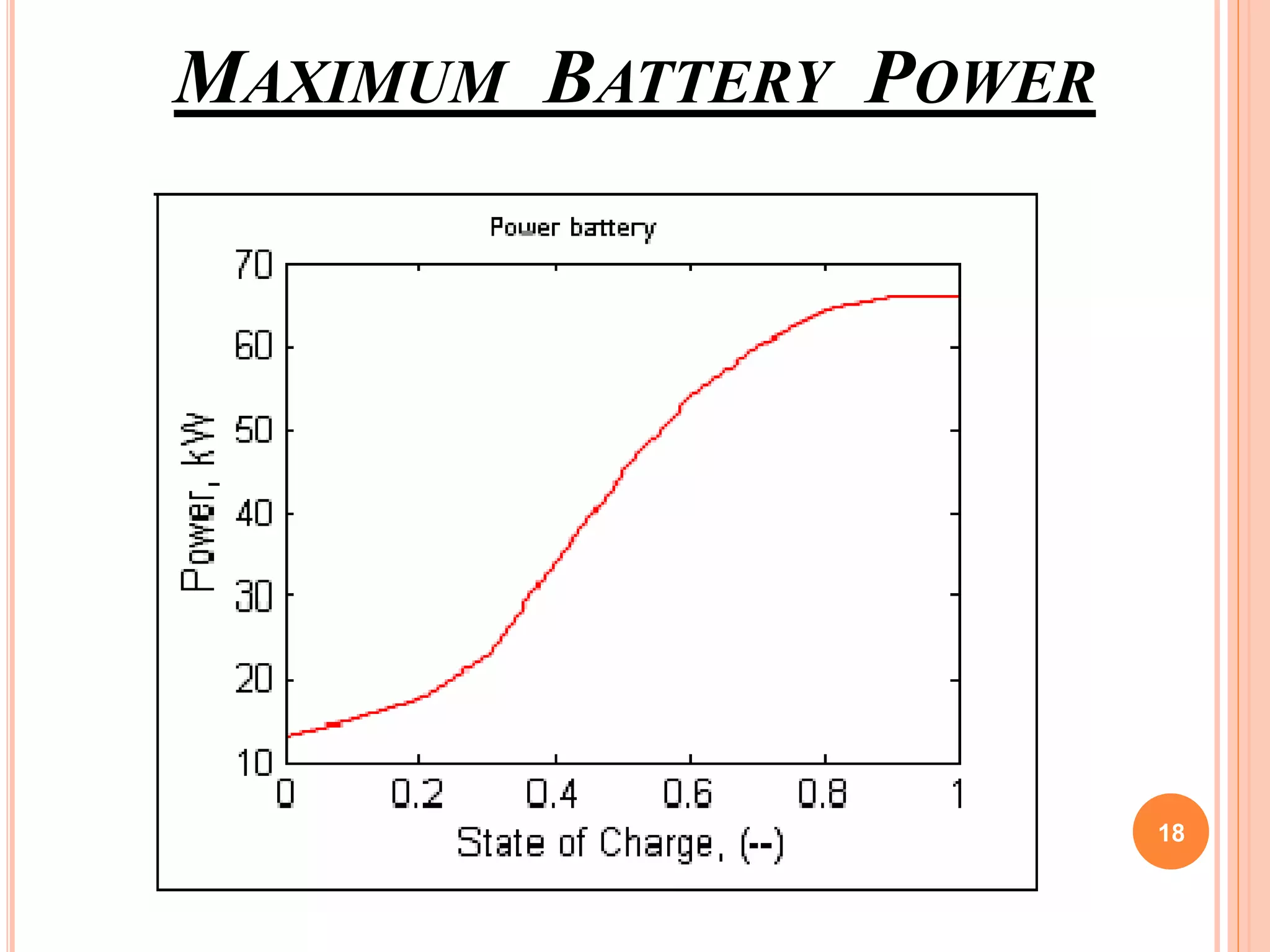

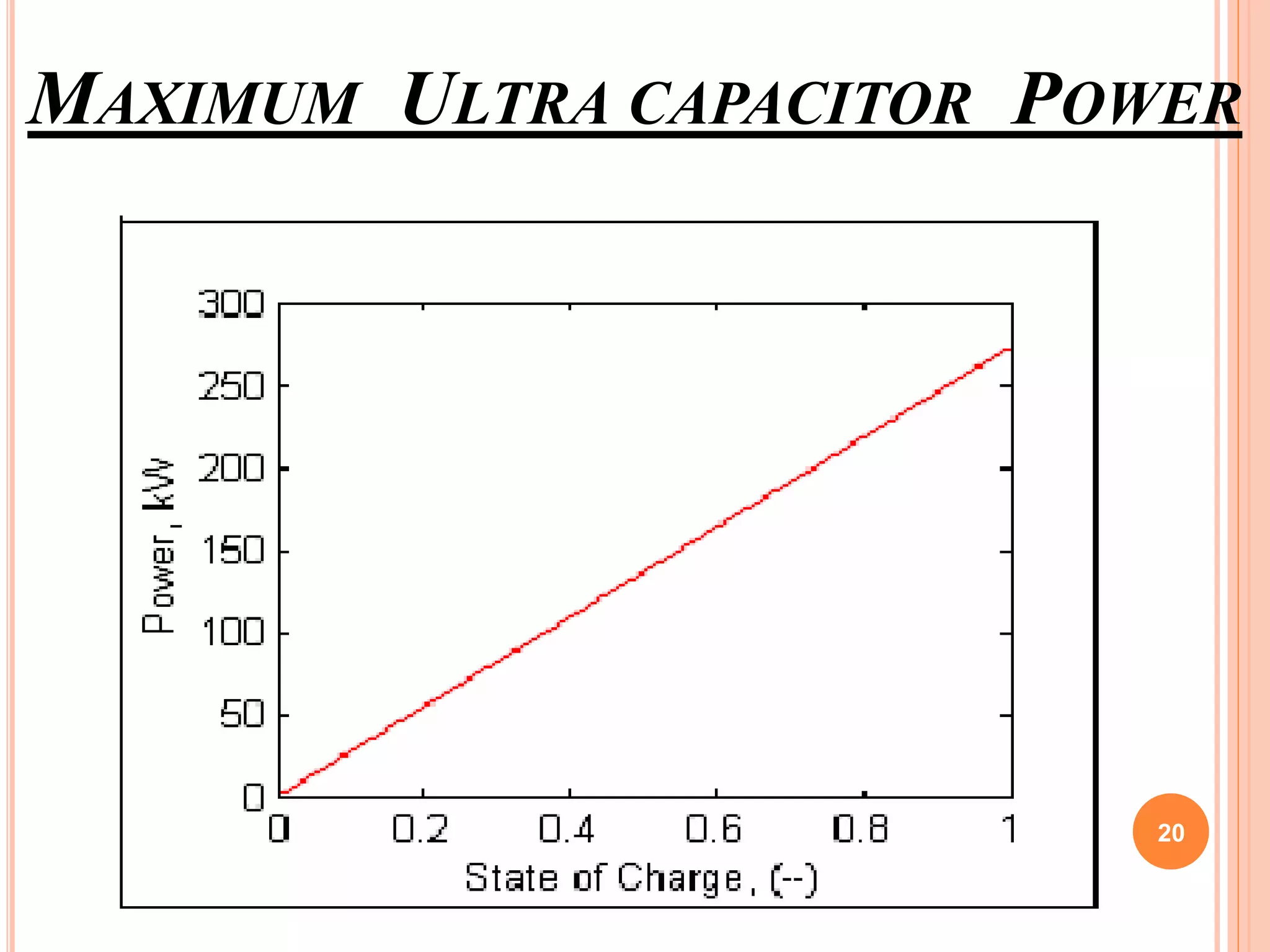

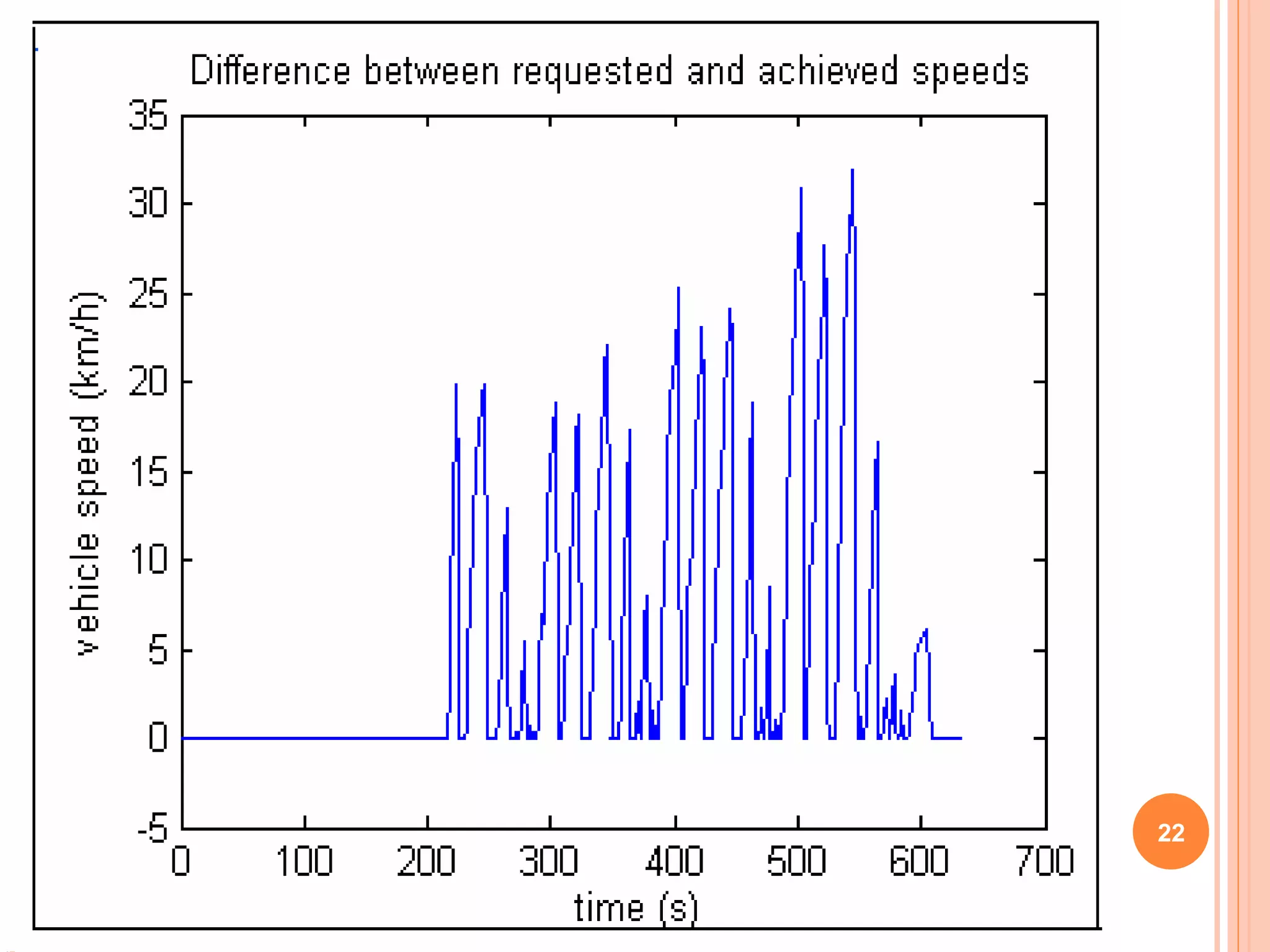

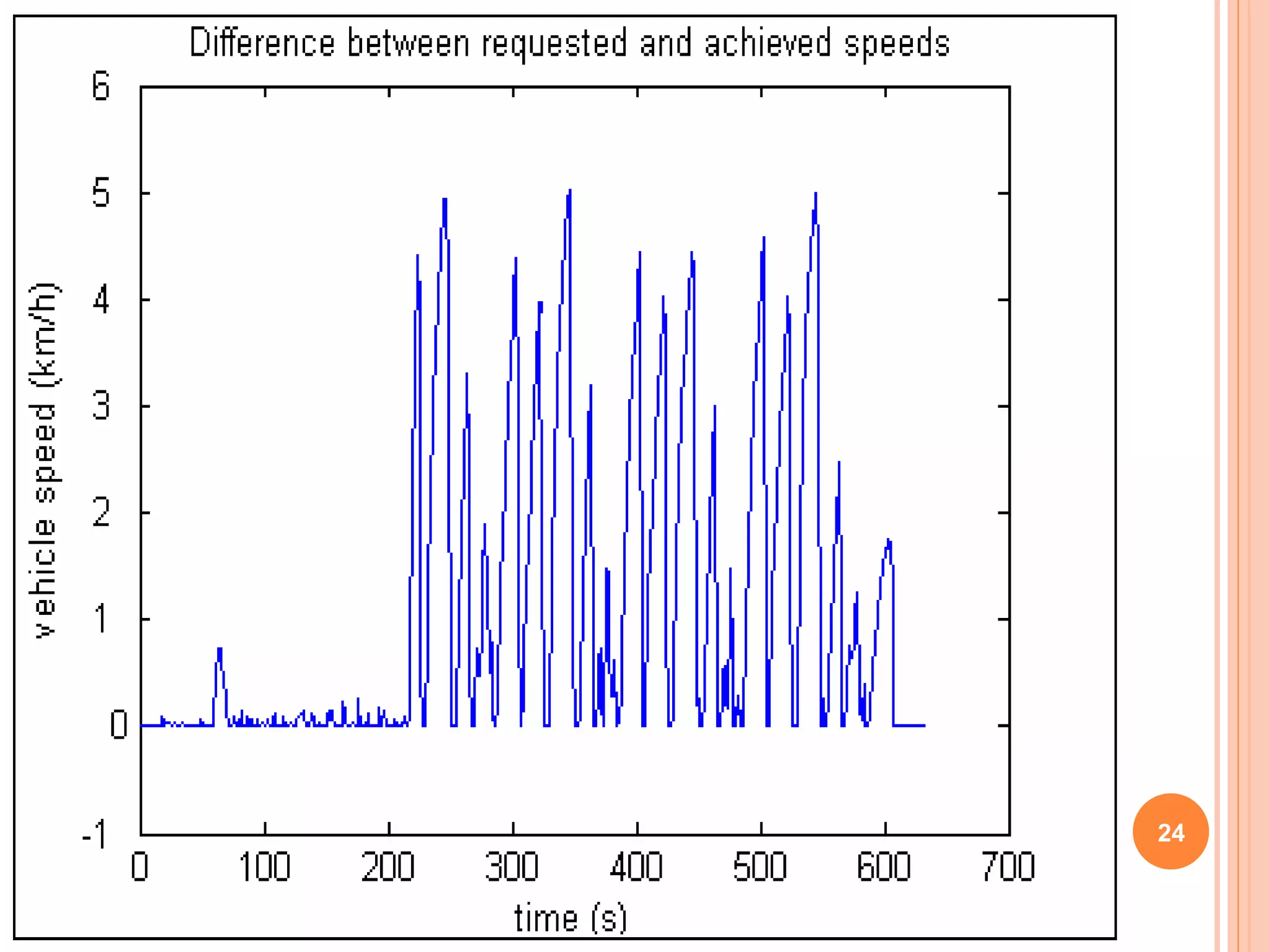

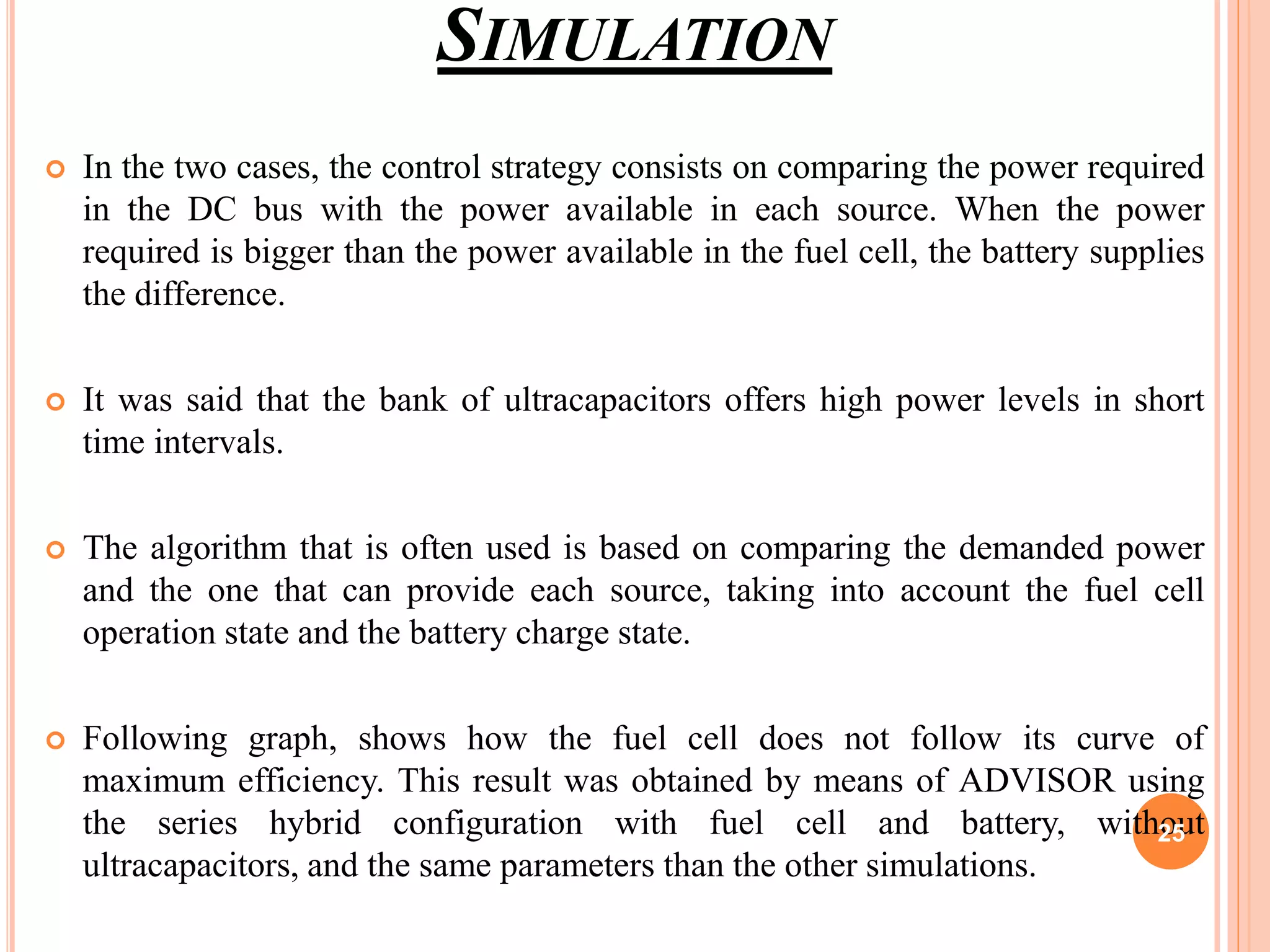

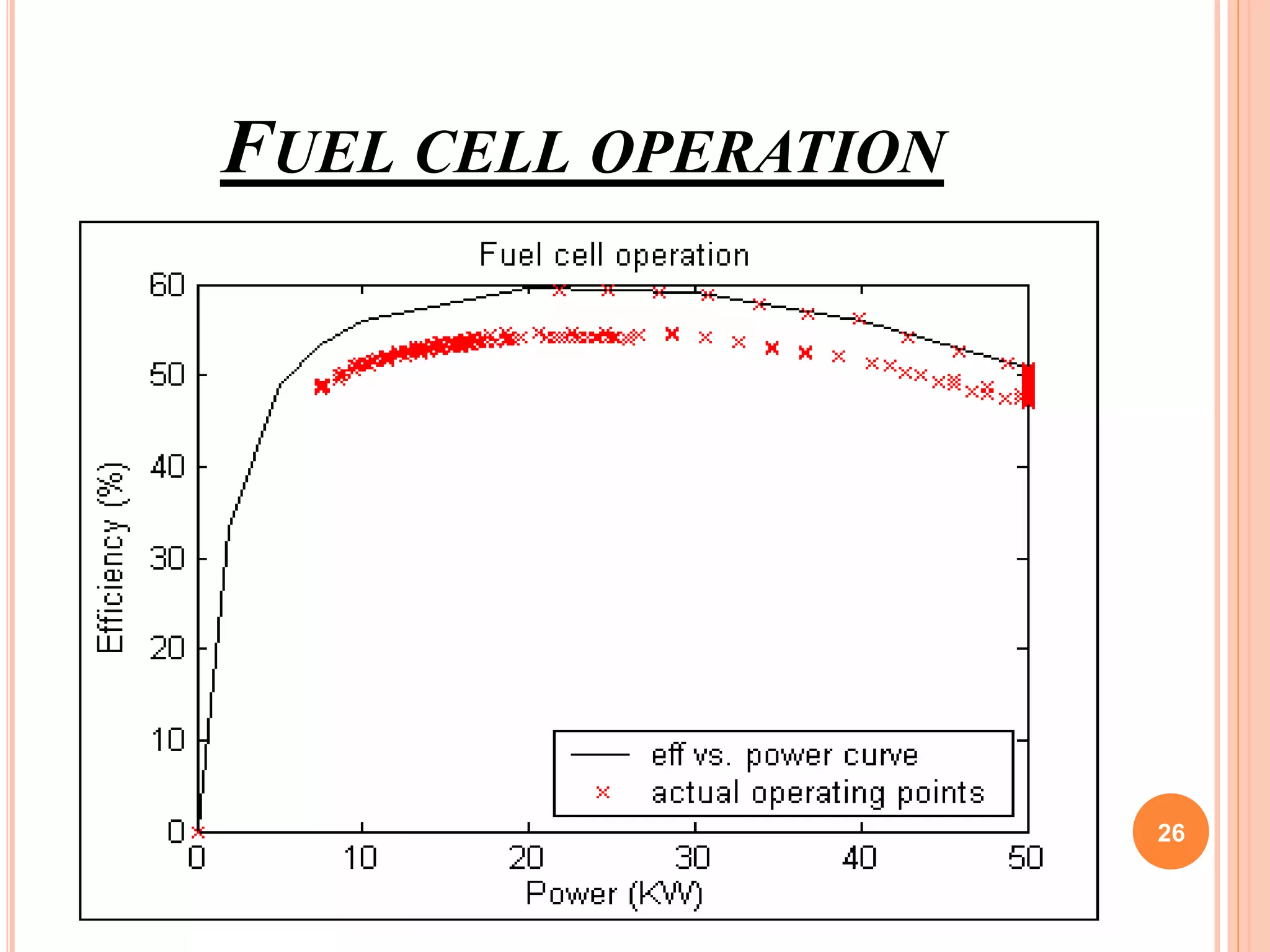

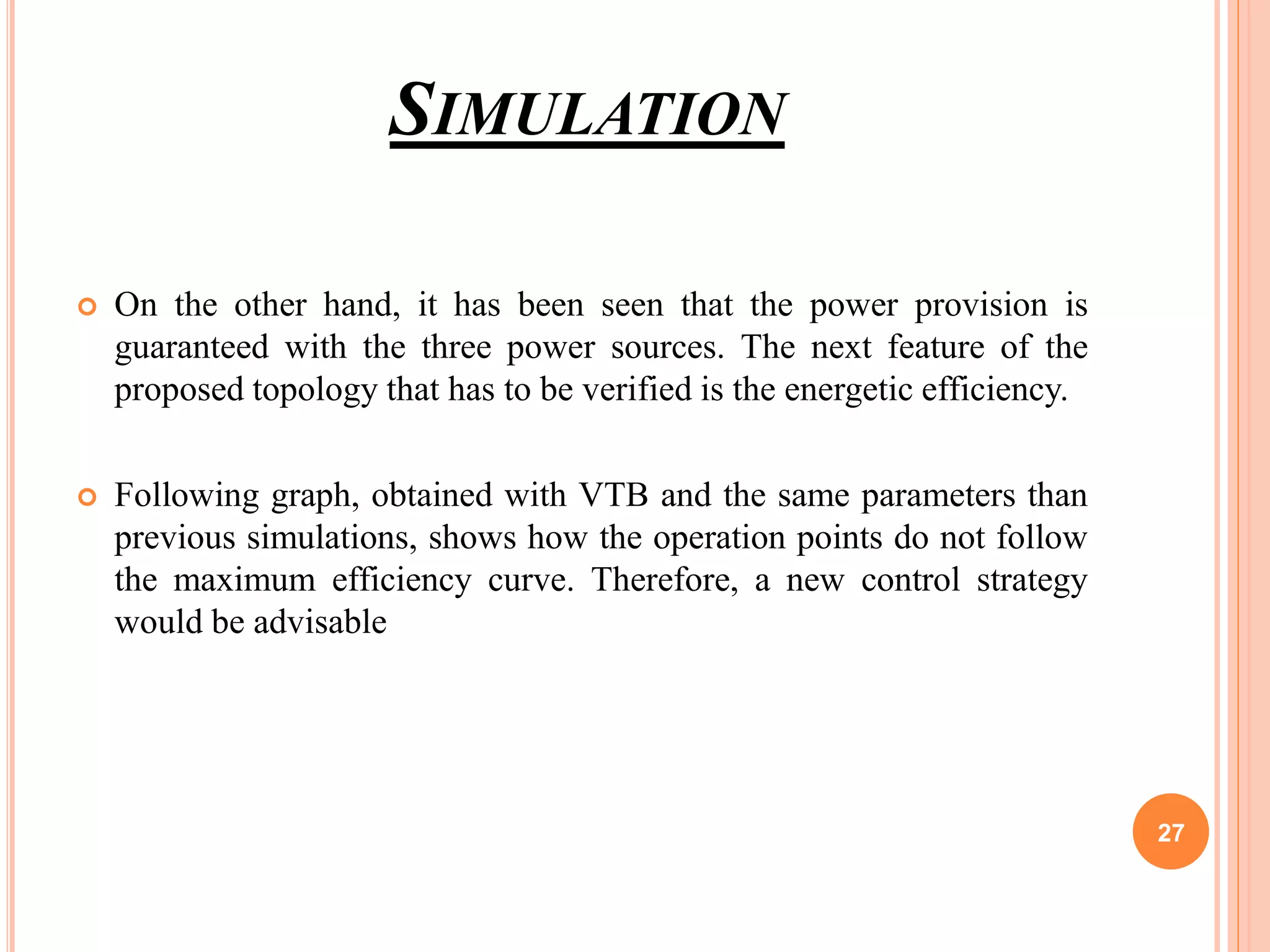

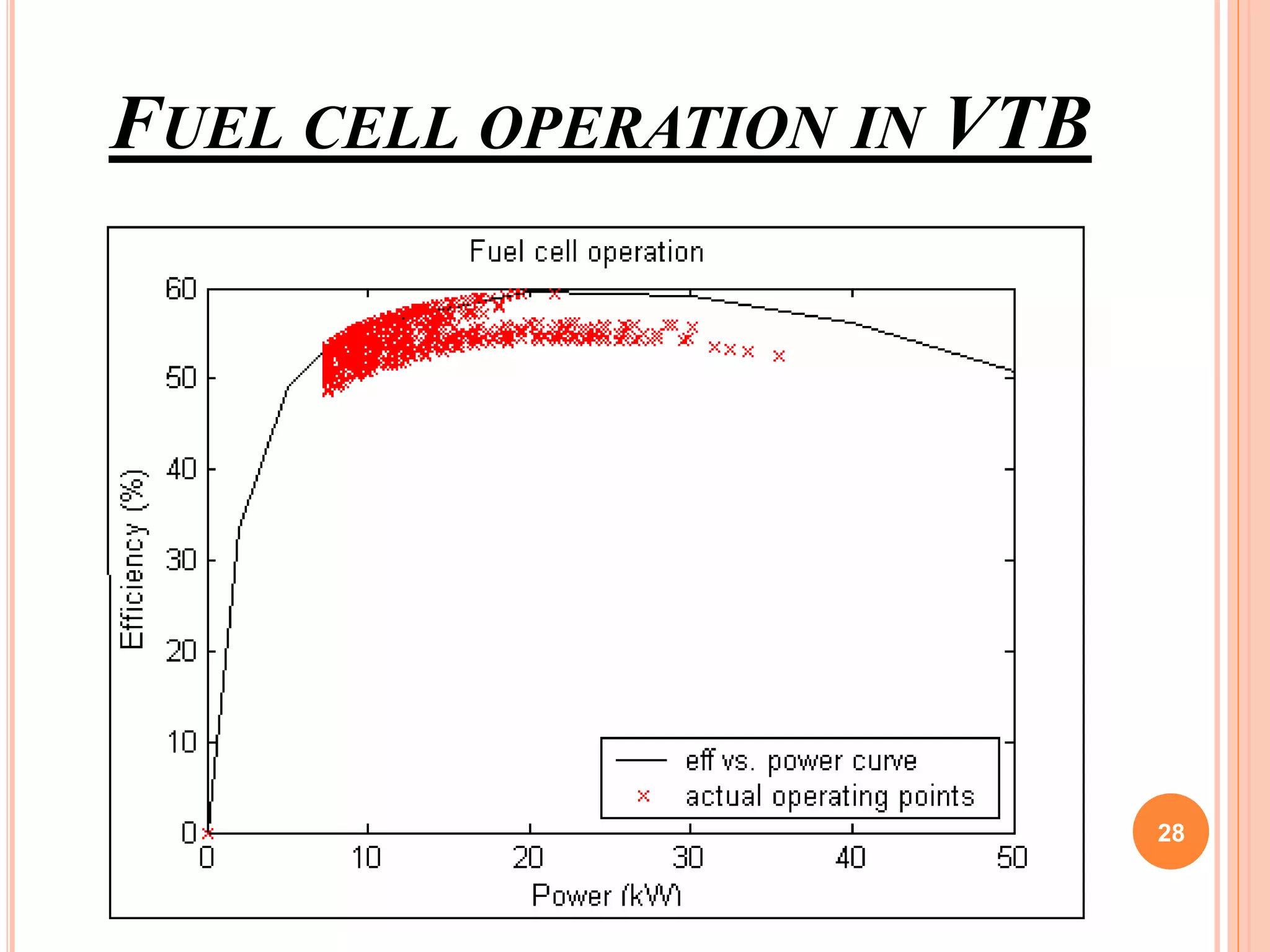

This document describes a proposed hybrid vehicle configuration with zero emissions. It includes three energy sources: a fuel cell, battery, and bank of ultracapacitors. Simulations show this configuration can meet power demands, unlike a configuration with just a fuel cell and battery. However, the fuel cell does not always operate at maximum efficiency. A new fuzzy control strategy is being developed to improve efficiency. In conclusion, the triple energy source configuration can guarantee power supply but requires an updated control approach.

![THANK YOU

[END OF PRESENTATION]

33](https://image.slidesharecdn.com/ahybridvehicleconfigurationwithzeroemission-140727100039-phpapp01/75/A-hybrid-vehicle-configuration-with-zero-emission-33-2048.jpg)