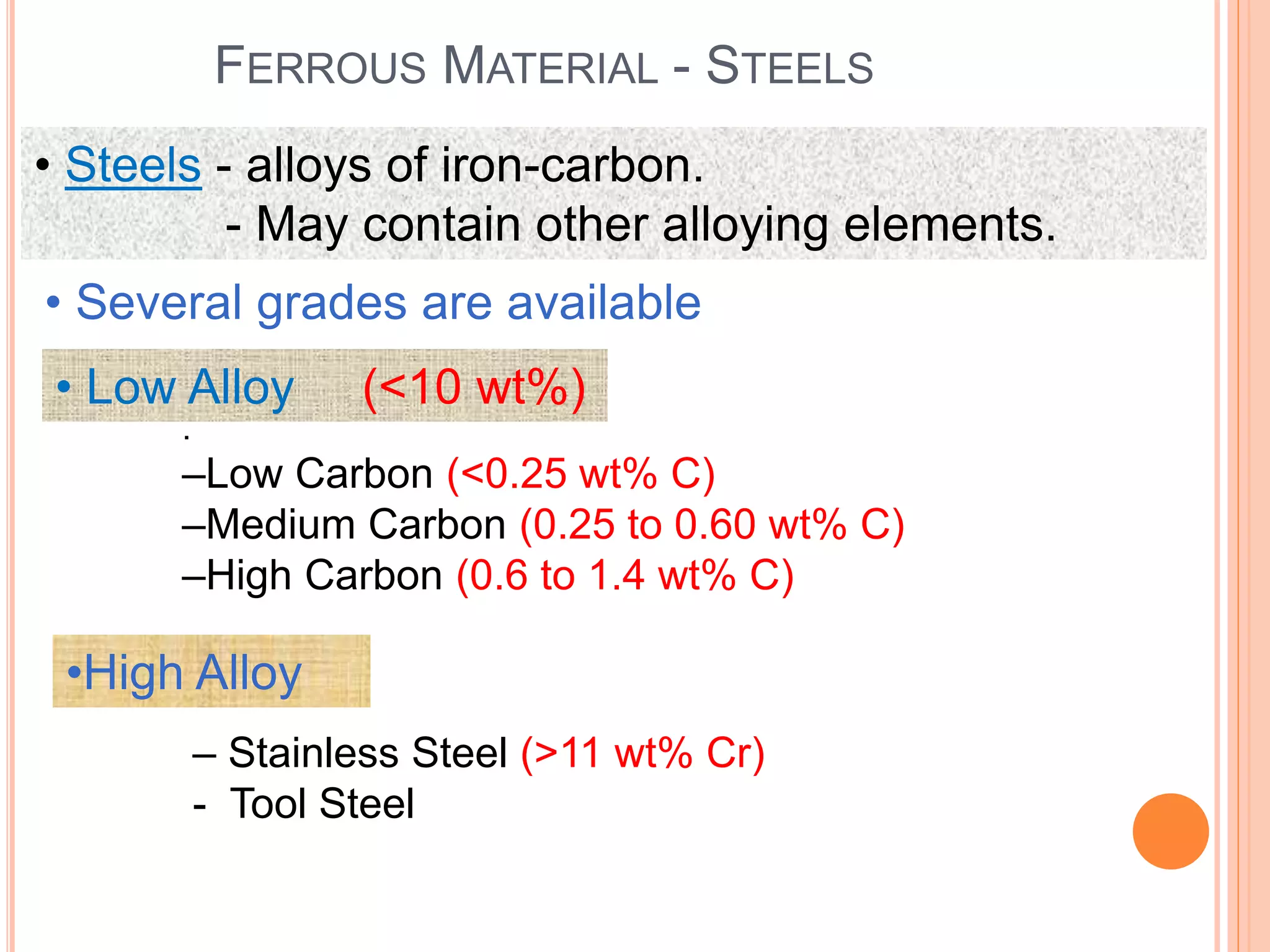

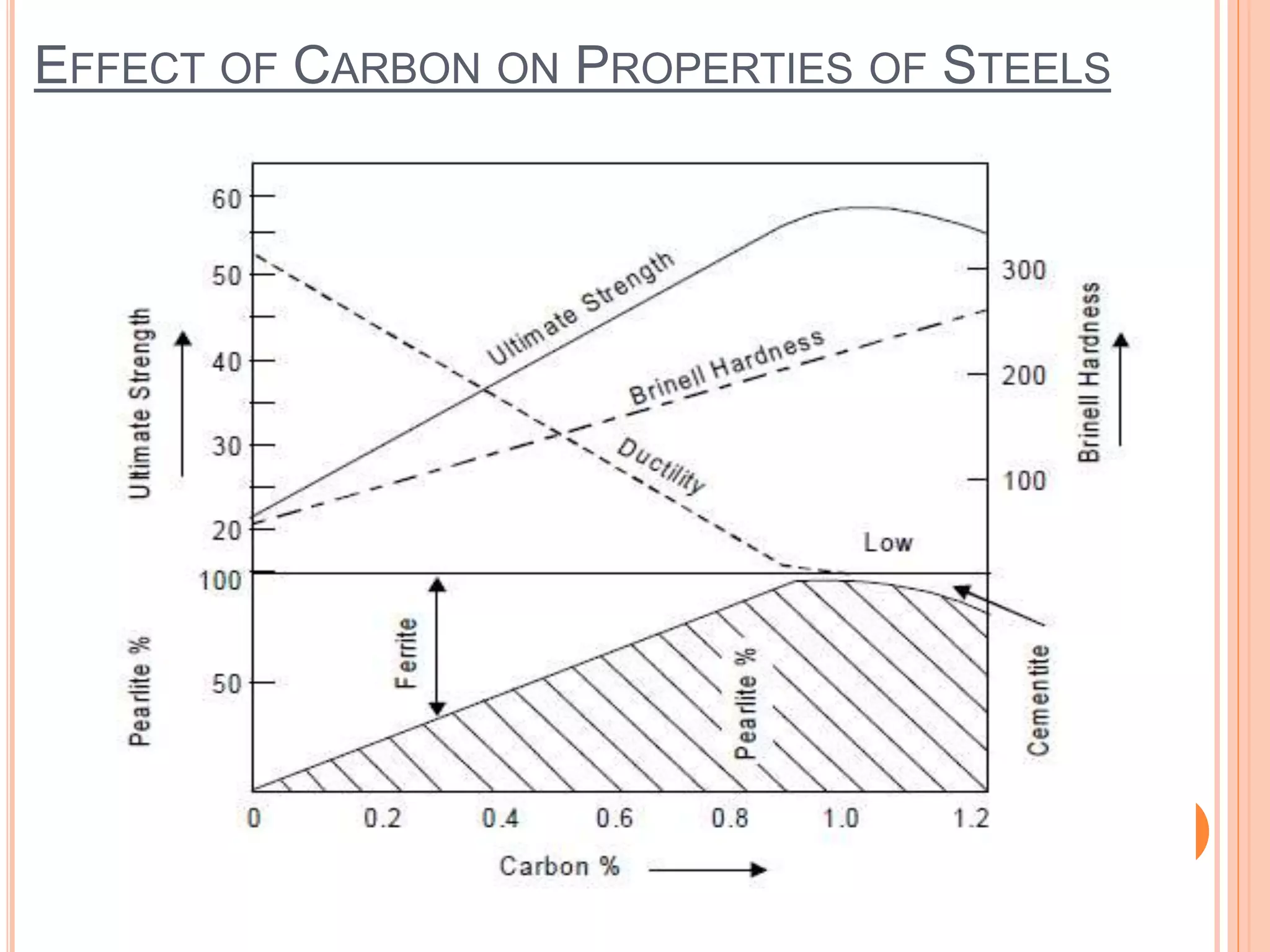

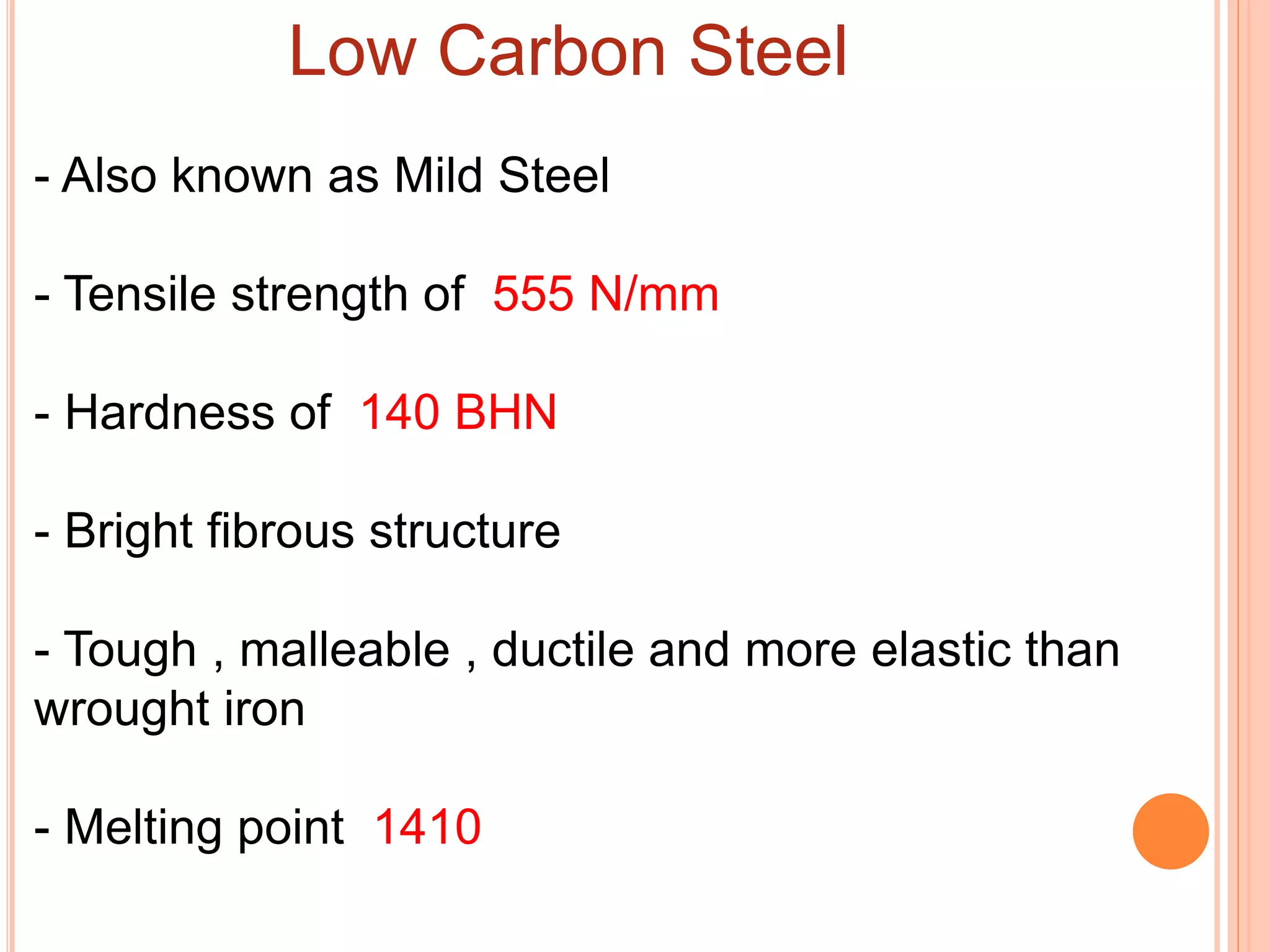

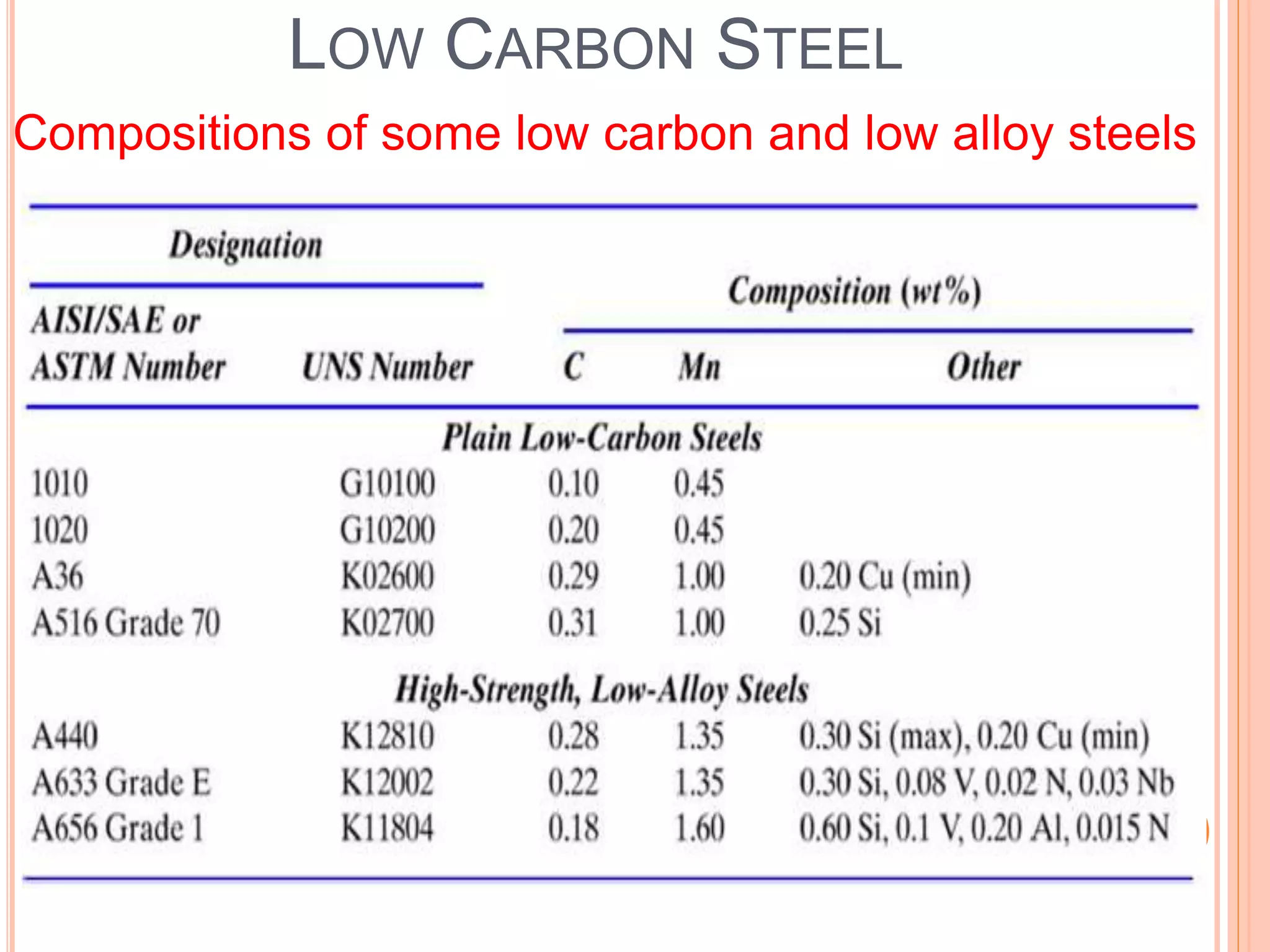

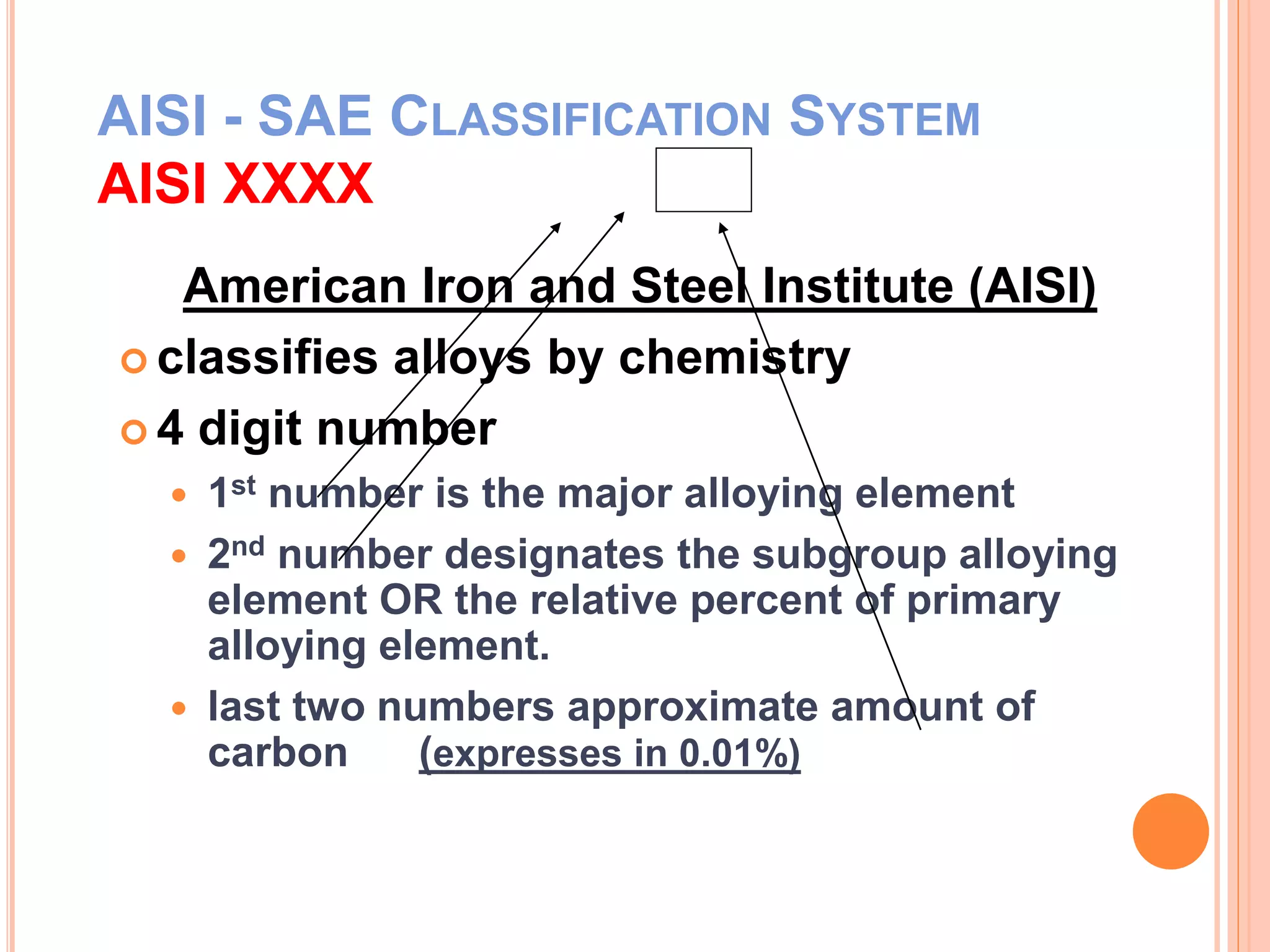

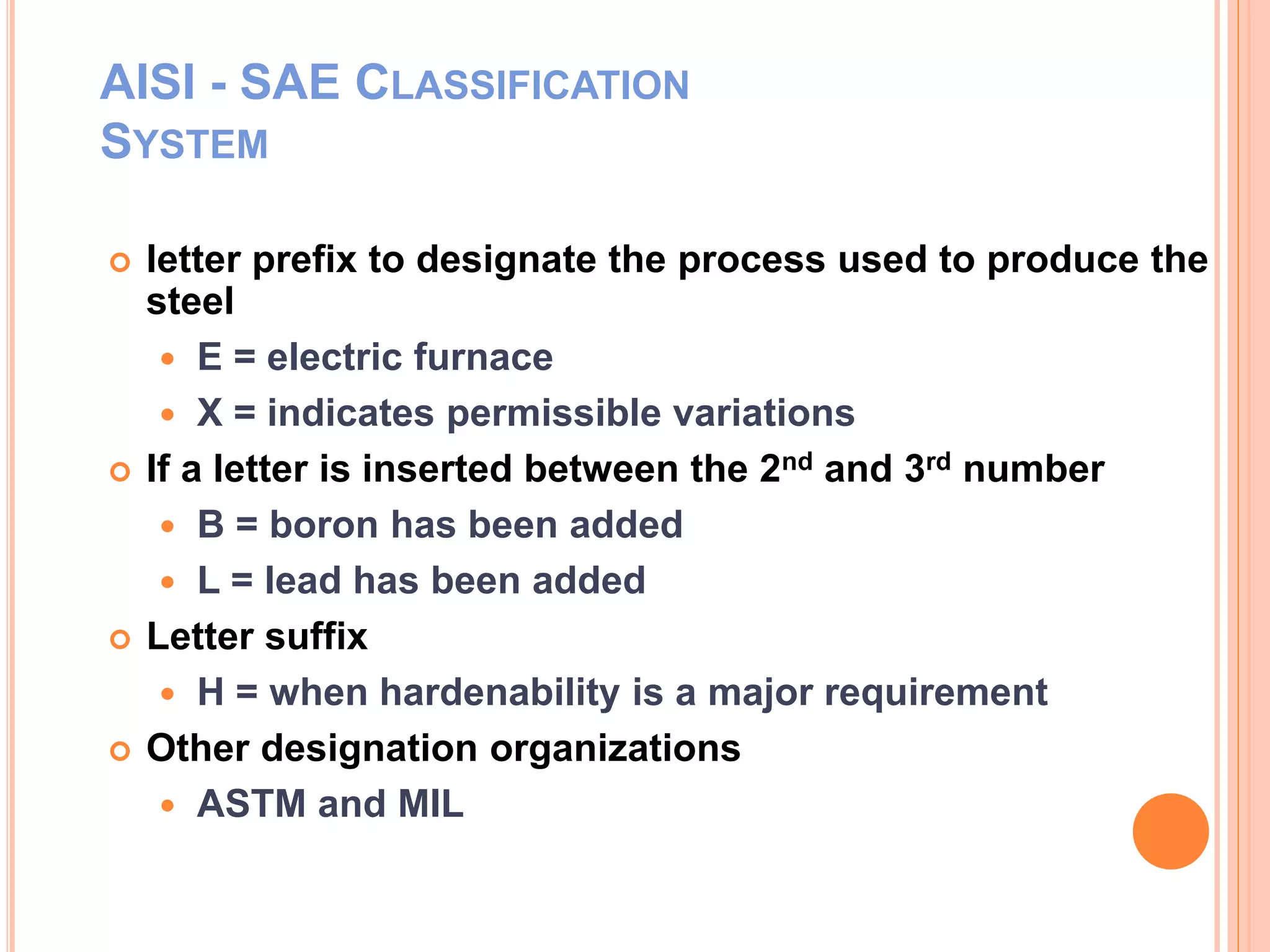

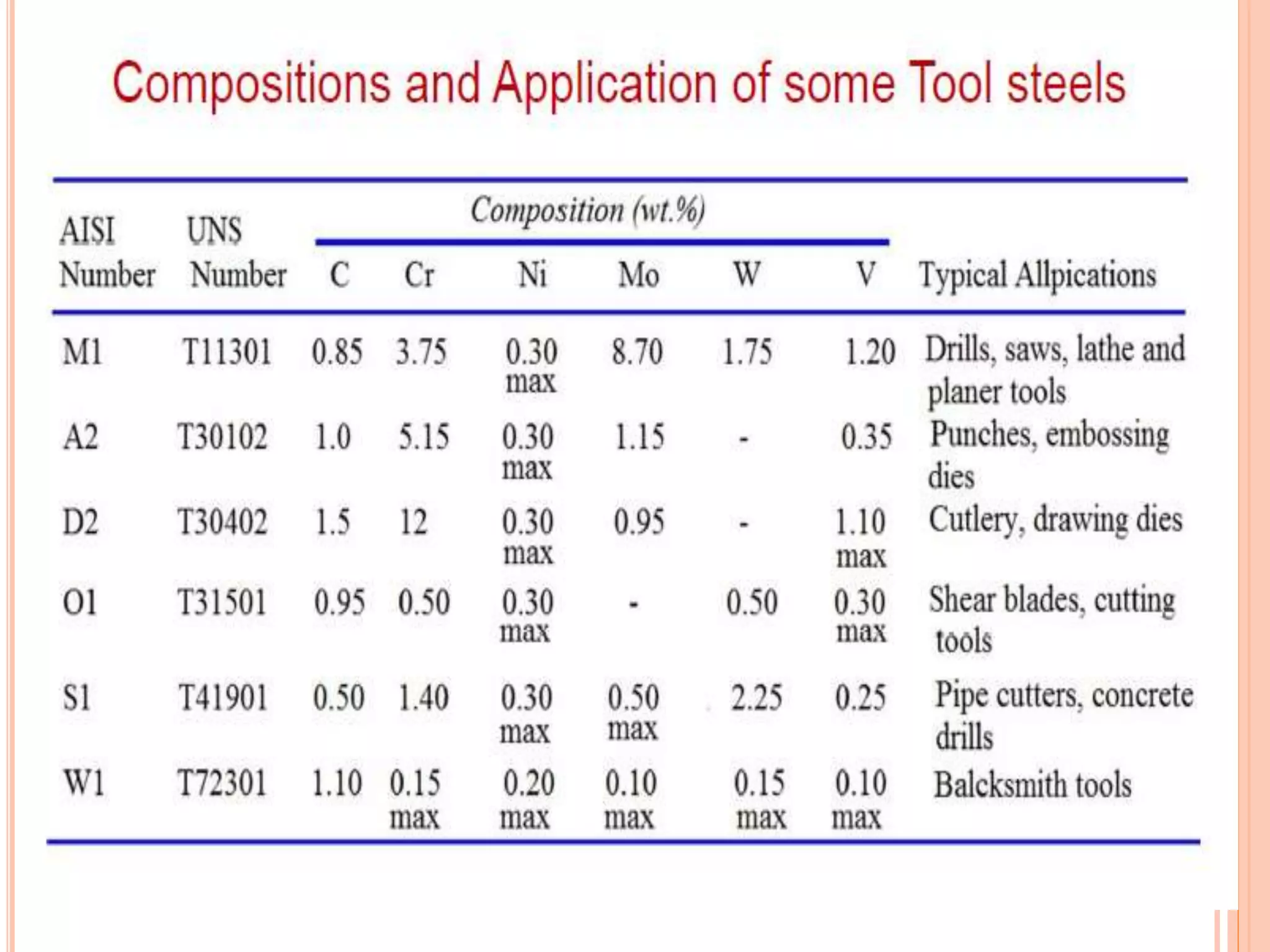

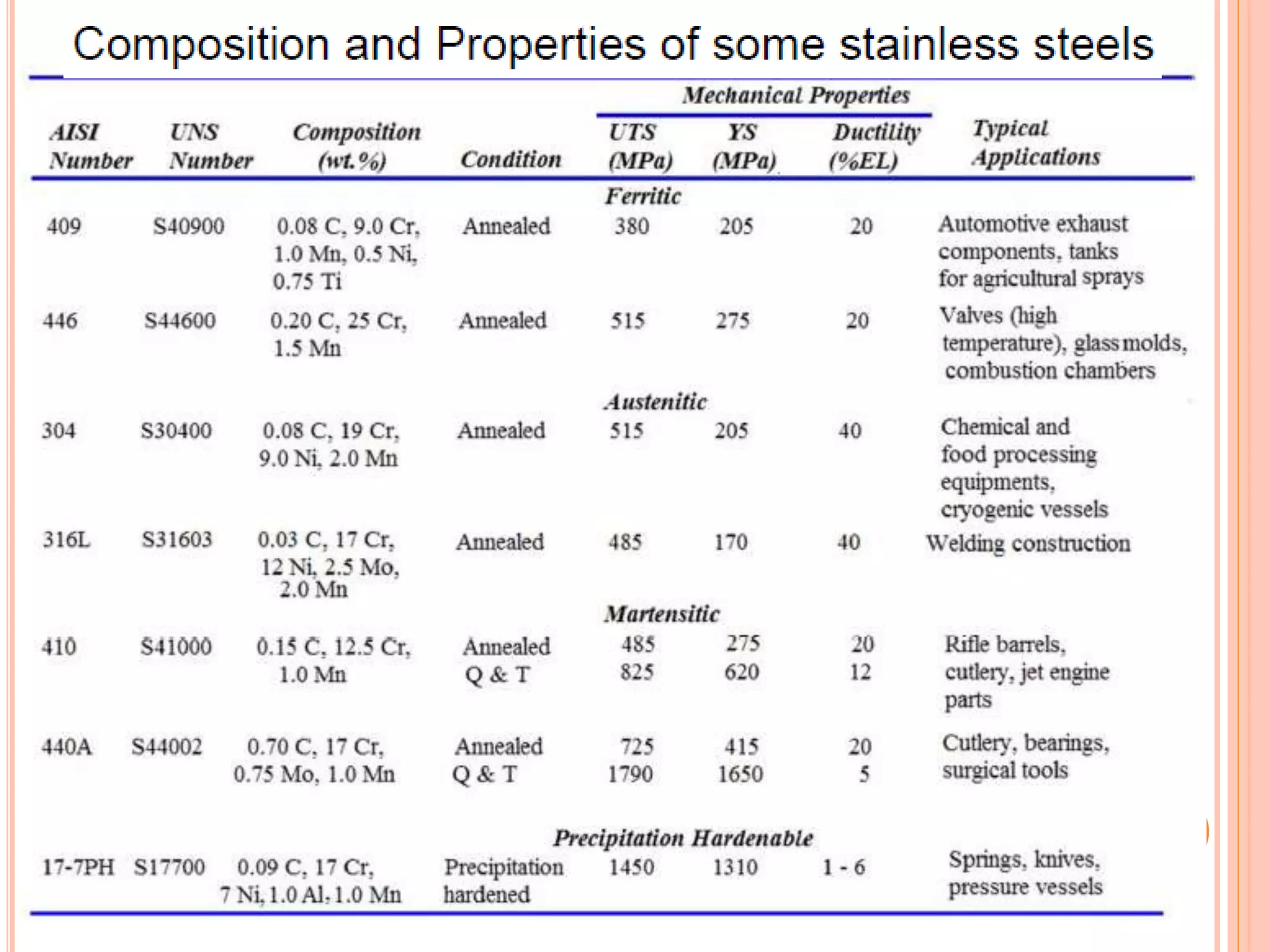

The document provides an overview of the classification and properties of various steels, detailing low, medium, and high carbon steels along with their compositions and characteristics. It outlines the AISI-SAE classification system for alloys, describing how different alloying elements like manganese, phosphorus, and nickel affect the properties of steel. Additionally, it discusses the applications of medium and high carbon steels, highlighting their strength, weldability, and heat treatment capabilities.