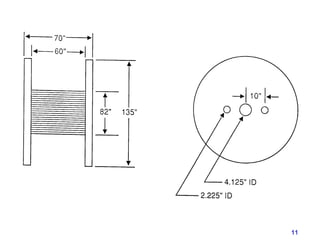

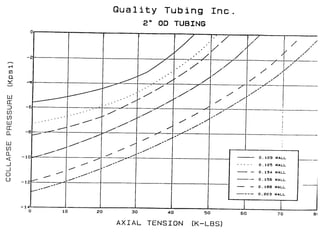

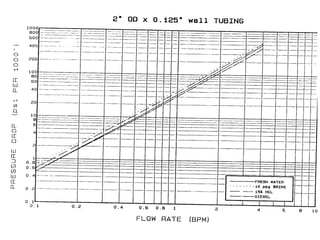

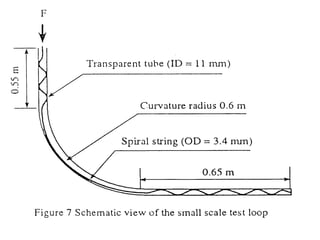

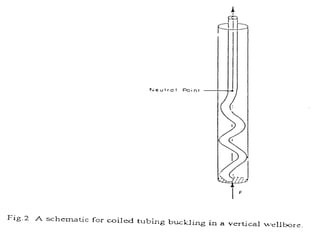

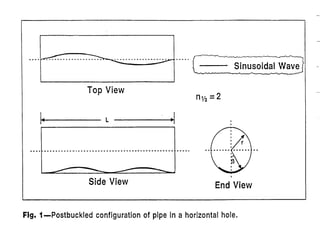

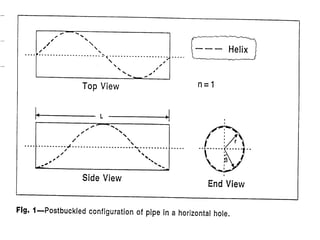

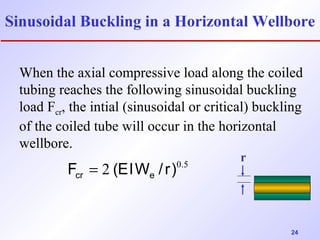

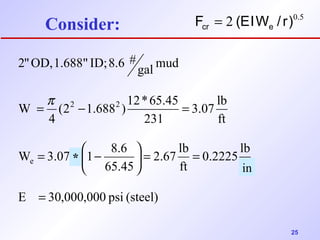

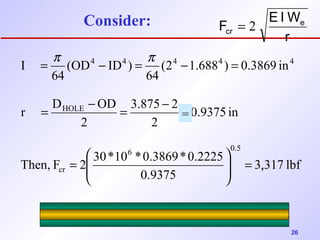

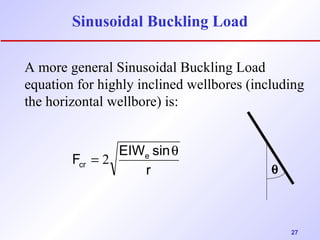

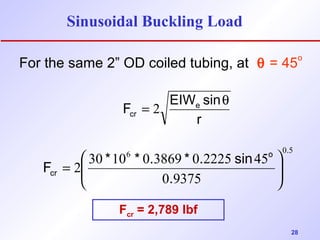

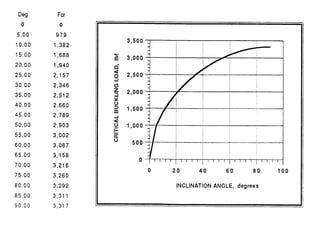

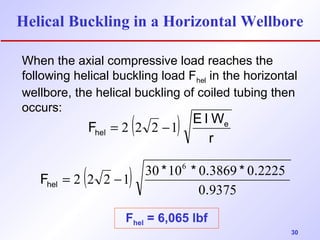

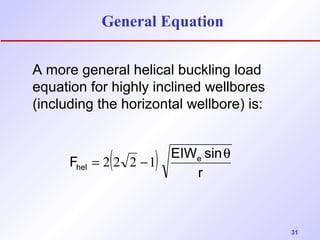

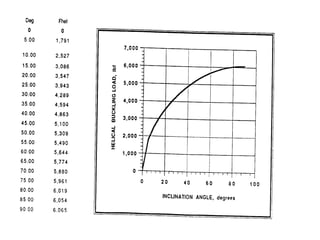

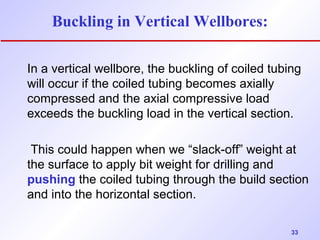

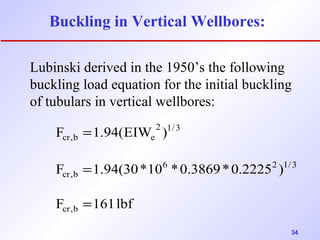

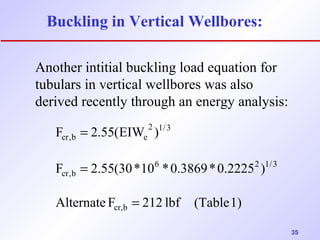

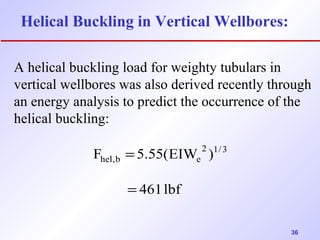

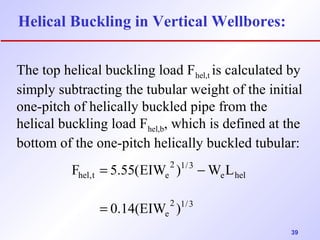

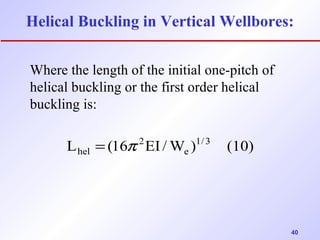

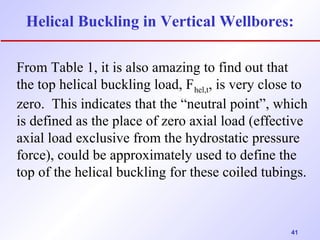

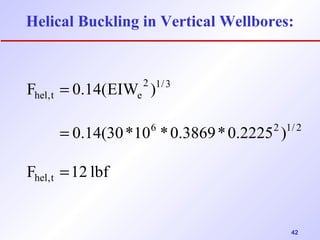

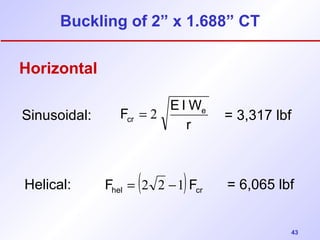

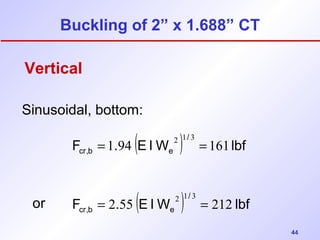

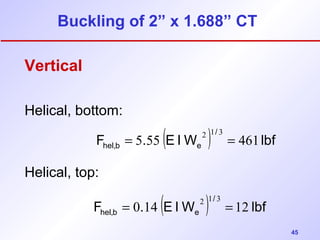

The document discusses buckling of coiled tubing in different wellbore orientations. It defines several buckling modes including sinusoidal, helical, and buckling in vertical or horizontal sections. Equations are provided to calculate the critical buckling loads for these different modes based on the tubing's material properties and dimensions. Examples are shown for a 2" diameter coiled tubing string. Buckling loads are lowest in the horizontal orientation and highest in vertical wells due to additional support from tubing weight.