Xy max

•

0 likes•553 views

The XyMax technology developed by ExxonMobil Chemical offers xylenes isomerization using a unique ZSM-5 based catalyst system to produce paraxylene and orthoxylene from C8 aromatics feedstocks. It provides higher yields and reduces recycle rates compared to competing technologies. The process achieves over 100% paraxylene selectivity and offers advantages like higher ethylbenzene conversion, lower xylene losses, and lower operating costs.

Report

Share

Report

Share

Download to read offline

Recommended

Post-combustion CO2 capture from natural gas combined cycles by solvent supported membranes - presentation by Matteo Romano of Politecnico di Milano at the UKCCSRC Natural Gas CCS Network Meeting at GHGT-12, Austin, Texas, October 2014Post-combustion CO2 capture from natural gas combined cycles by solvent suppo...

Post-combustion CO2 capture from natural gas combined cycles by solvent suppo...UK Carbon Capture and Storage Research Centre

Recommended

Post-combustion CO2 capture from natural gas combined cycles by solvent supported membranes - presentation by Matteo Romano of Politecnico di Milano at the UKCCSRC Natural Gas CCS Network Meeting at GHGT-12, Austin, Texas, October 2014Post-combustion CO2 capture from natural gas combined cycles by solvent suppo...

Post-combustion CO2 capture from natural gas combined cycles by solvent suppo...UK Carbon Capture and Storage Research Centre

More Related Content

What's hot

What's hot (20)

Reconciling Mass And Energy Balances In An Ethylene Complex

Reconciling Mass And Energy Balances In An Ethylene Complex

PRESENTATION ON PLANT DESIGN FOR MANUFACTURING OF HYDROGEN

PRESENTATION ON PLANT DESIGN FOR MANUFACTURING OF HYDROGEN

Similar to Xy max

Similar to Xy max (20)

Epcon is Recognized as one of the World's Leading Industrial Equipment Suppliers

Epcon is Recognized as one of the World's Leading Industrial Equipment Suppliers

Ind. Eng. Chem. Res. 2009, 48, 4866–4871_Synthesis of Ultrahigh Molecular Wei...

Ind. Eng. Chem. Res. 2009, 48, 4866–4871_Synthesis of Ultrahigh Molecular Wei...

Thyssenkrupp uhde advanced ammonia processes dual pressure

Thyssenkrupp uhde advanced ammonia processes dual pressure

Esite Raleigh Hall – Nortonin keraamisten hiomalaikkojen uusi tehdas

Esite Raleigh Hall – Nortonin keraamisten hiomalaikkojen uusi tehdas

Broschyr Raleigh Hall - Ny fabrik för Norton keramiska slipskivor

Broschyr Raleigh Hall - Ny fabrik för Norton keramiska slipskivor

Atlas pipeline-2012 vm-43-c ejemplo de instalaccion compressor scroll (emerson)

Atlas pipeline-2012 vm-43-c ejemplo de instalaccion compressor scroll (emerson)

Recently uploaded

Process of Integration the Laser Scan Data into FEA Model and Level 3 Fitness-for-Service Assessment of Critical Assets in Refinery & Process IndustriesFEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced Loads

FEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced LoadsArindam Chakraborty, Ph.D., P.E. (CA, TX)

Recently uploaded (20)

Kuwait City MTP kit ((+919101817206)) Buy Abortion Pills Kuwait

Kuwait City MTP kit ((+919101817206)) Buy Abortion Pills Kuwait

S1S2 B.Arch MGU - HOA1&2 Module 3 -Temple Architecture of Kerala.pptx

S1S2 B.Arch MGU - HOA1&2 Module 3 -Temple Architecture of Kerala.pptx

"Lesotho Leaps Forward: A Chronicle of Transformative Developments"

"Lesotho Leaps Forward: A Chronicle of Transformative Developments"

FEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced Loads

FEA Based Level 3 Assessment of Deformed Tanks with Fluid Induced Loads

Xy max

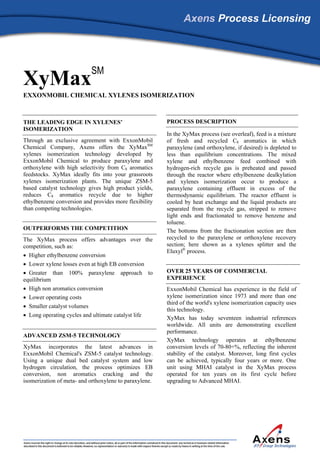

- 1. THE LEADING EDGE IN XYLENES’ ISOMERIZATION Through an exclusive agreement with ExxonMobil Chemical Company, Axens offers the XyMaxSM xylenes isomerization technology developed by ExxonMobil Chemical to produce paraxylene and orthoxylene with high selectivity from C8 aromatics feedstocks. XyMax ideally fits into your grassroots xylenes isomerization plants. The unique ZSM-5 based catalyst technology gives high product yields, reduces C8 aromatics recycle due to higher ethylbenzene conversion and provides more flexibility than competing technologies. OUTPERFORMS THE COMPETITION The XyMax process offers advantages over the competition, such as: • Higher ethylbenzene conversion • Lower xylene losses even at high EB conversion • Greater than 100% paraxylene approach to equilibrium • High non aromatics conversion • Lower operating costs • Smaller catalyst volumes • Long operating cycles and ultimate catalyst life ADVANCED ZSM-5 TECHNOLOGY XyMax incorporates the latest advances in ExxonMobil Chemical's ZSM-5 catalyst technology. Using a unique dual bed catalyst system and low hydrogen circulation, the process optimizes EB conversion, non aromatics cracking and the isomerization of meta- and orthoxylene to paraxylene. PROCESS DESCRIPTION In the XyMax process (see overleaf), feed is a mixture of fresh and recycled C8 aromatics in which paraxylene (and orthoxylene, if desired) is depleted to less than equilibrium concentrations. The mixed xylene and ethylbenzene feed combined with hydrogen-rich recycle gas is preheated and passed through the reactor where ethylbenzene dealkylation and xylenes isomerization occur to produce a paraxylene containing effluent in excess of the thermodynamic equilibrium. The reactor effluent is cooled by heat exchange and the liquid products are separated from the recycle gas, stripped to remove light ends and fractionated to remove benzene and toluene. The bottoms from the fractionation section are then recycled to the paraxylene or orthoxylene recovery section; here shown as a xylenes splitter and the Eluxyl® process. OVER 25 YEARS OF COMMERCIAL EXPERIENCE ExxonMobil Chemical has experience in the field of xylene isomerization since 1973 and more than one third of the world's xylene isomerization capacity uses this technology. XyMax has today seventeen industrial references worldwide. All units are demonstrating excellent performance. XyMax technology operates at ethylbenzene conversion levels of 70-80+%, reflecting the inherent stability of the catalyst. Moreover, long first cycles can be achieved, typically four years or more. One unit using MHAI catalyst in the XyMax process operated for ten years on its first cycle before upgrading to Advanced MHAI. XyMax SM EXXONMOBIL CHEMICAL XYLENES ISOMERIZATION

- 2. EM-4500 THE NEWEST XYLENE ISOMERIZATION CATALYST Commercialized in 2000, EM-4500 is ExxonMobil Chemical's newest xylenes isomerization catalyst incorporating the latest advances in ZSM-5 catalysts. EM-4500 features a drastically reduced level of losses, which will further improve the Xylenes Loop efficiency. This high level of performance is obtained under even more cost effective operating conditions as compared to previous generation catalysts such as Conventional or Advanced MHAI XYMAX: A KEY COMPONENT IN PARAMAX XyMax is ideally suited to play a key role in the ParamaX™ technology suite, especially when maximum paraxylene production with benzene co- production is desired. The XyMax isomerization process will result in a lower investment and operating cost choice for any ParamaX® process suite. XyMax is a trademark of ExxonMobil. ParamaX and Eluxyl are proprietary process names of Axens. Jan.11-XyMax Eluxyl Hydrogen C8 Aromatics Feed Off Gas Benzene And Toluene Paraxylene C9 Aromatics cw cw XyMax Process Limits Simplified XyMax flowscheme