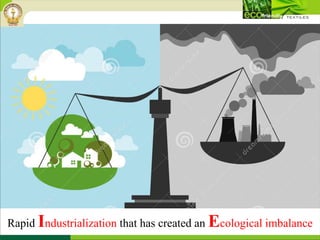

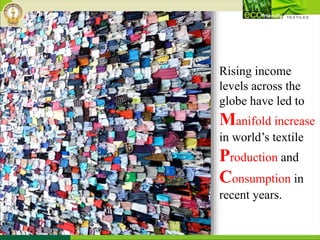

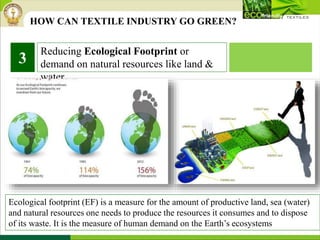

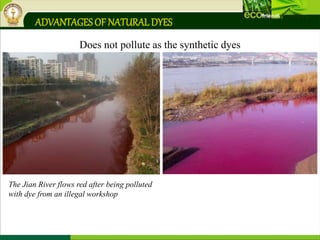

The document discusses the environmental and health impacts of the textile industry, highlighting the extensive use of resources and harmful chemicals in textile production. It emphasizes the need for eco-friendly textiles, which are produced sustainably and have a minimal ecological footprint, promoting organic materials and natural dyes. Additionally, it explores how sustainable practices, such as reducing carbon footprints and utilizing renewable resources, can mitigate adverse effects on the environment and public health.