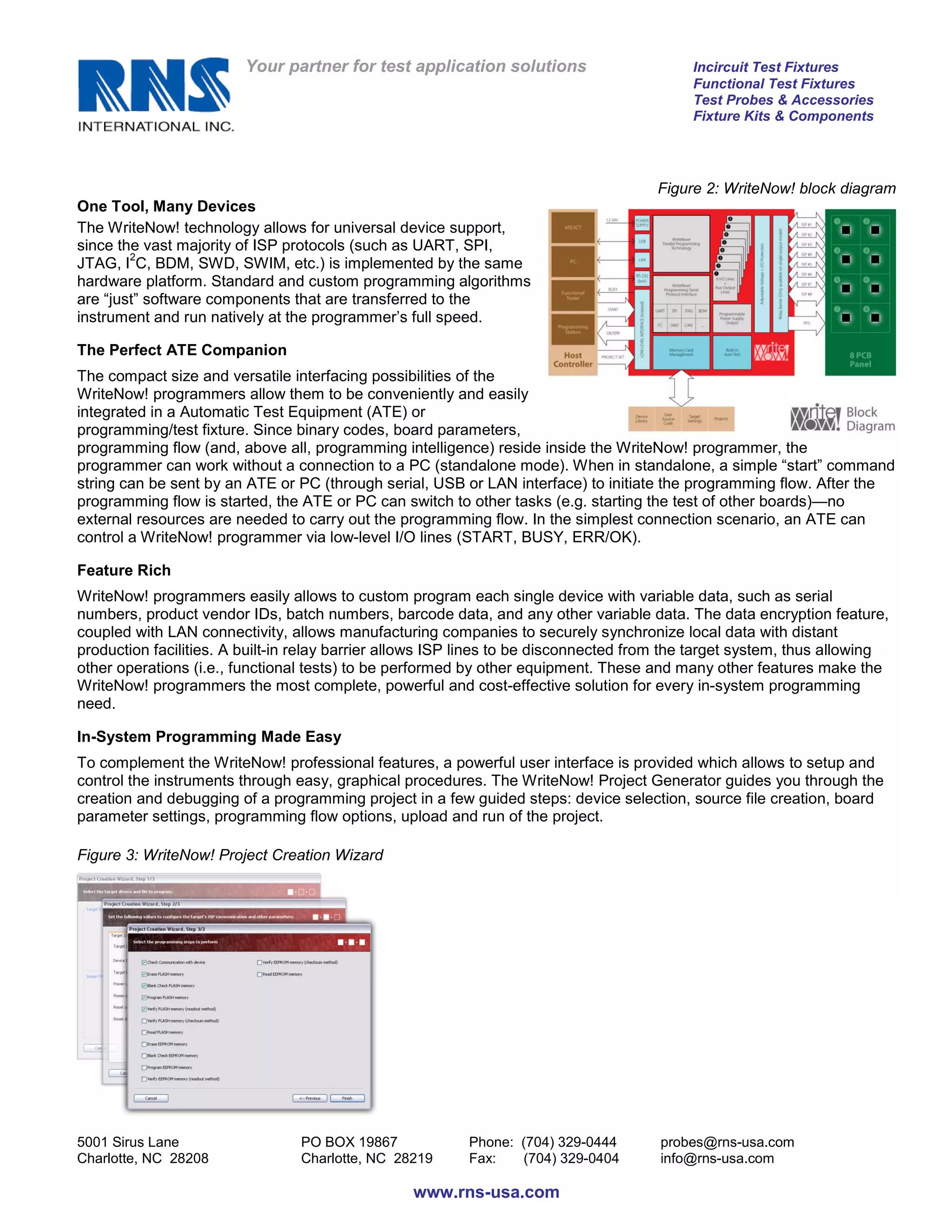

The document discusses in-system programming (ISP) and the WriteNow! series of ISP programmers. ISP allows programming of devices while installed on printed circuit boards, improving manufacturing efficiency. The WriteNow! programmers enable fast, parallel programming of multiple devices simultaneously using various protocols. They can operate standalone or integrated with automatic test equipment. Features include custom data programming, encryption, and an easy-to-use interface.