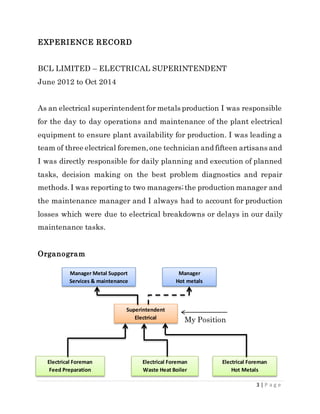

Gaenamele M. Ganamotse has over 15 years of experience in various engineering roles. She began her career at Botswana Power Corporation in their graduate training program. She has held several leadership positions including Area Supply Engineer, Electrical Superintendent, and Section Manager Electrical. As a consultant, she assisted Cadbury Botswana with bill auditing and energy management initiatives. Across her roles, she has successfully managed projects, led teams, developed safe work procedures, and maintained electrical networks and equipment. She attributes her experience to skills in risk assessment, problem analysis, project management, and effective stakeholder communication.