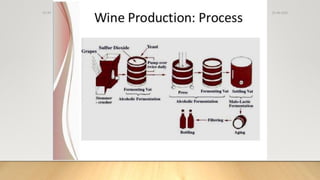

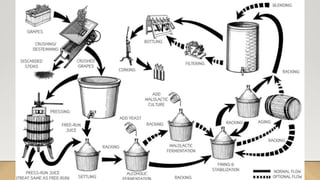

Wine production involves several key steps:

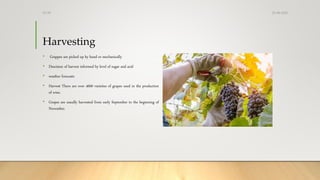

1. Grapes are harvested when sugar levels are high enough for fermentation.

2. The grapes are crushed and pressed to extract juice, called must.

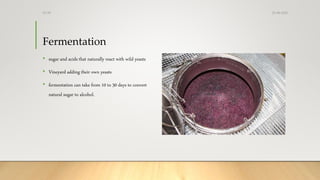

3. Yeast ferments the must into wine through alcoholic fermentation.

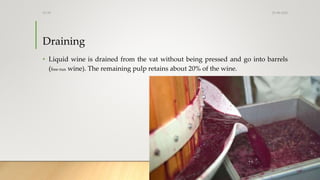

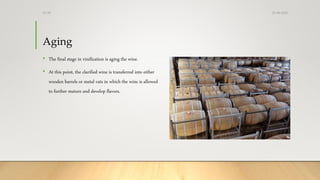

4. The new wine is clarified by removing solids, stabilized, and aged in barrels or tanks.

5. Finally, wine is bottled, sometimes with additional sulfites for preservation.