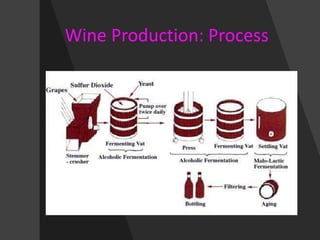

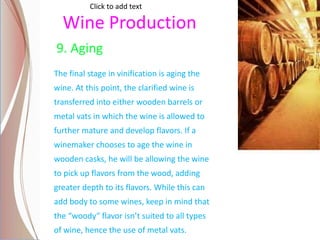

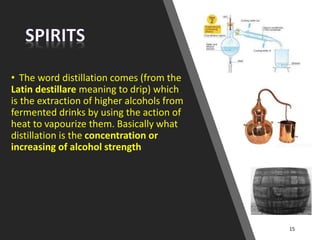

The document discusses the process of wine production from grape cultivation and harvesting to bottling the finished wine. Some key steps include crushing the grapes to release juice, fermentation of the juice into wine using yeast, pressing leftover skins to extract more wine, aging the wine in barrels or tanks to develop flavors, and clarifying and bottling the finished product. Factors like climate, soil, grape variety, and winemaking techniques influence the characteristics of the resulting wine.