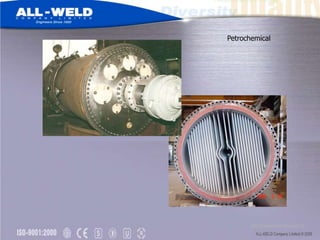

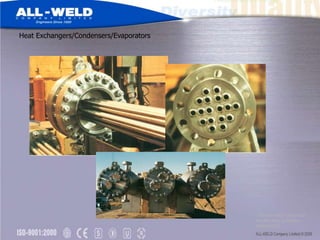

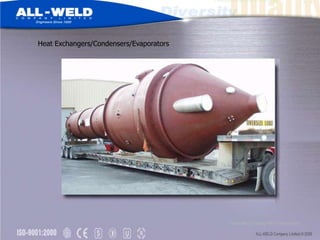

ALL-WELD Company Limited is a specialist in custom metal fabrication and machining with two plants located in Scarborough, Ontario. They have expertise in fabricating pressure vessels, heat exchangers, autoclaves, and process equipment for industries such as petrochemical, biofuel, environmental, and hydrometallurgy. ALL-WELD has over 100 employees and 83 years of experience in the industry.