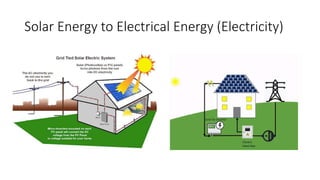

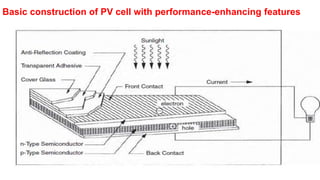

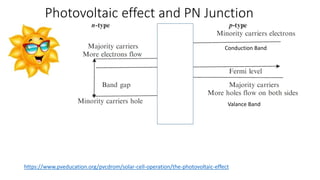

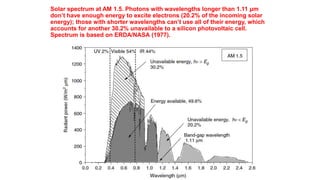

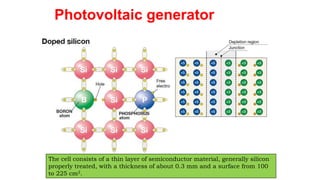

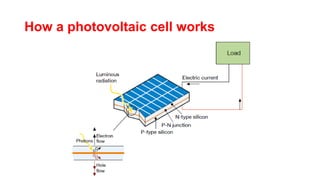

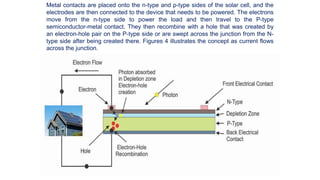

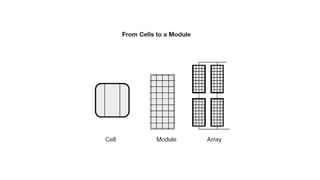

Solar panels convert sunlight into electricity through the photovoltaic effect. When sunlight hits a solar cell, photons are absorbed and dislodge electrons, generating a flow of electricity. Solar cells are combined into modules which are assembled into larger solar arrays to increase power output for applications. The key components of a solar panel include photovoltaic cells, interconnecting wiring, a mounting frame, and a junction box.