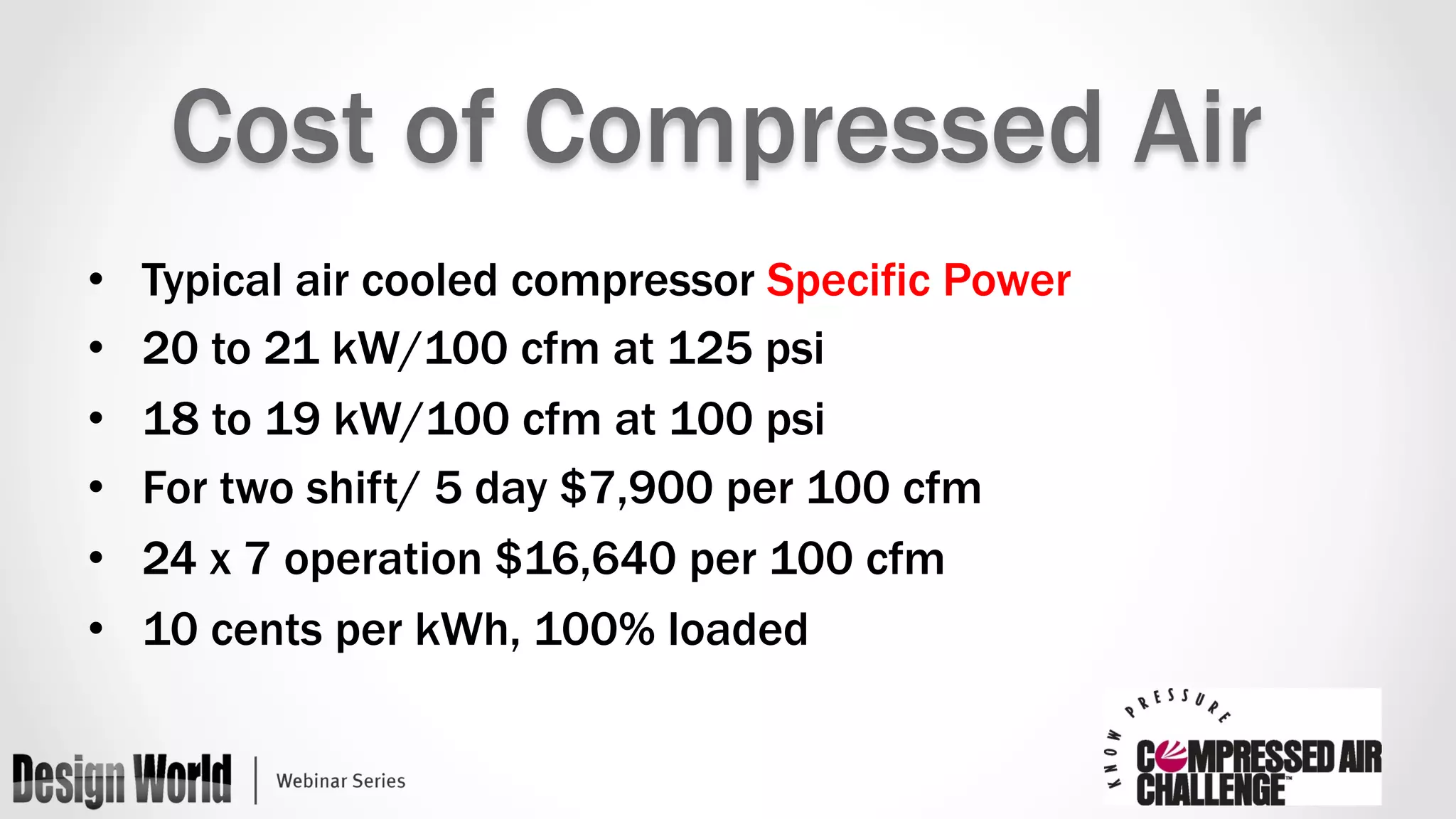

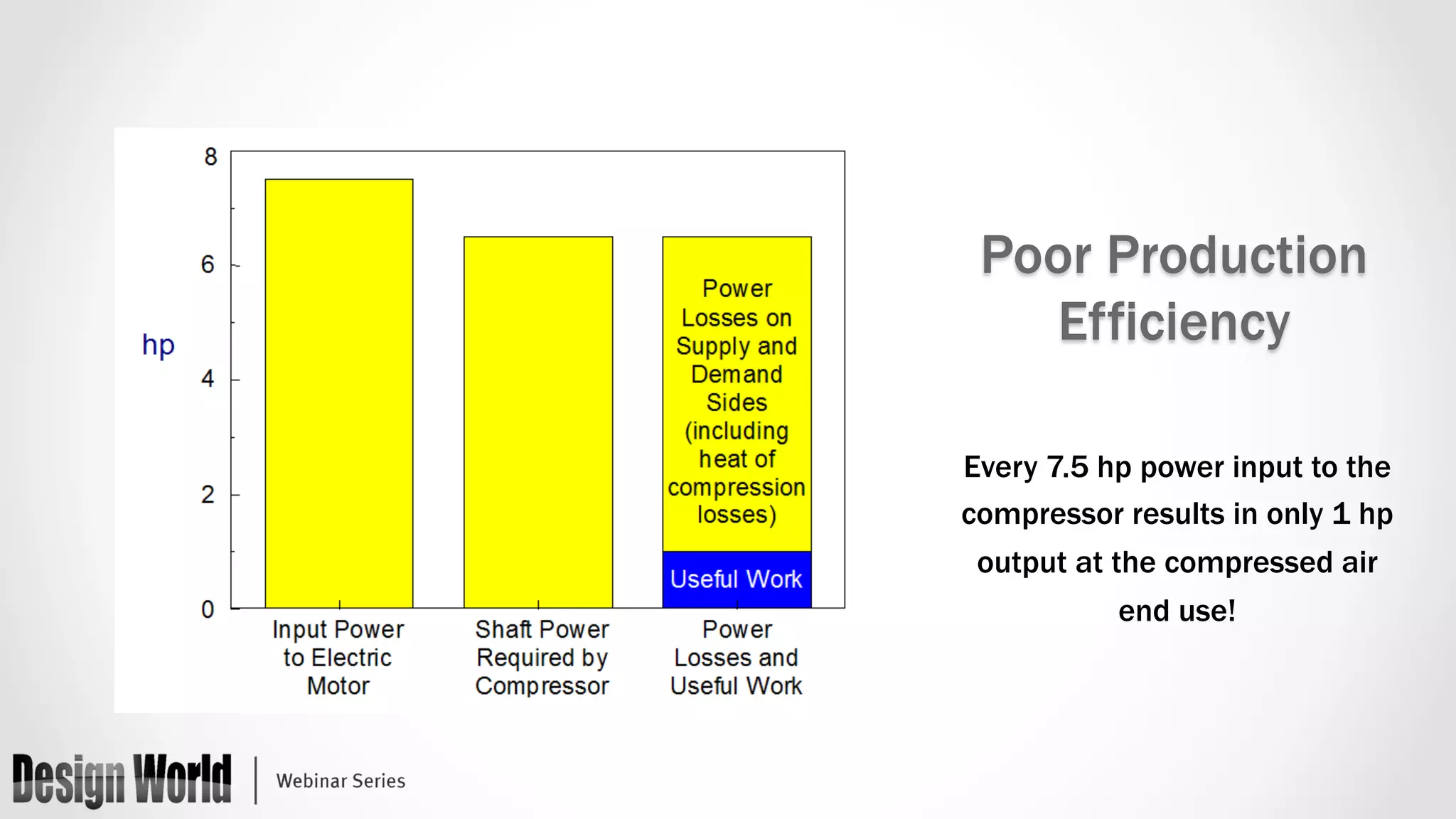

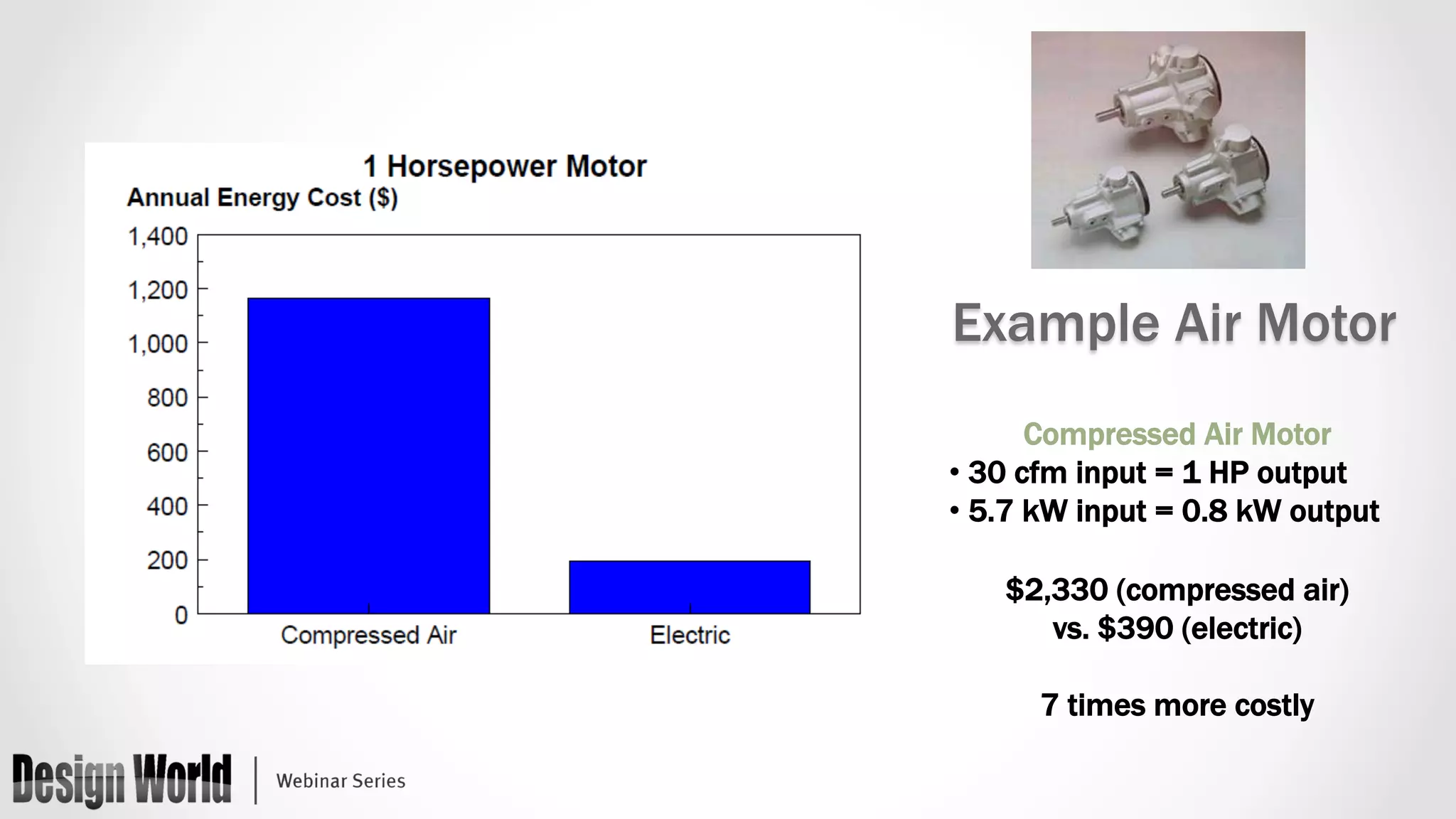

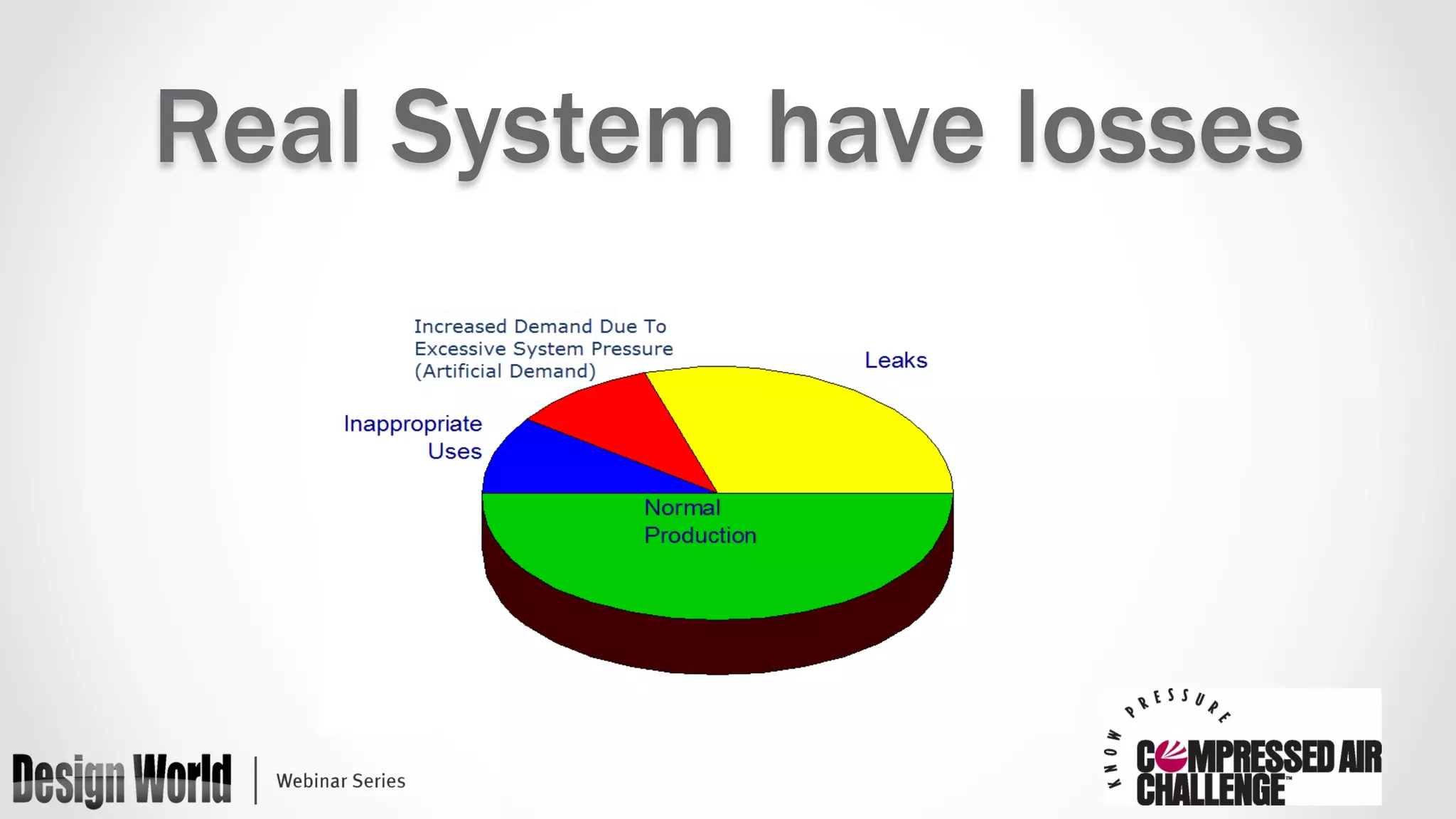

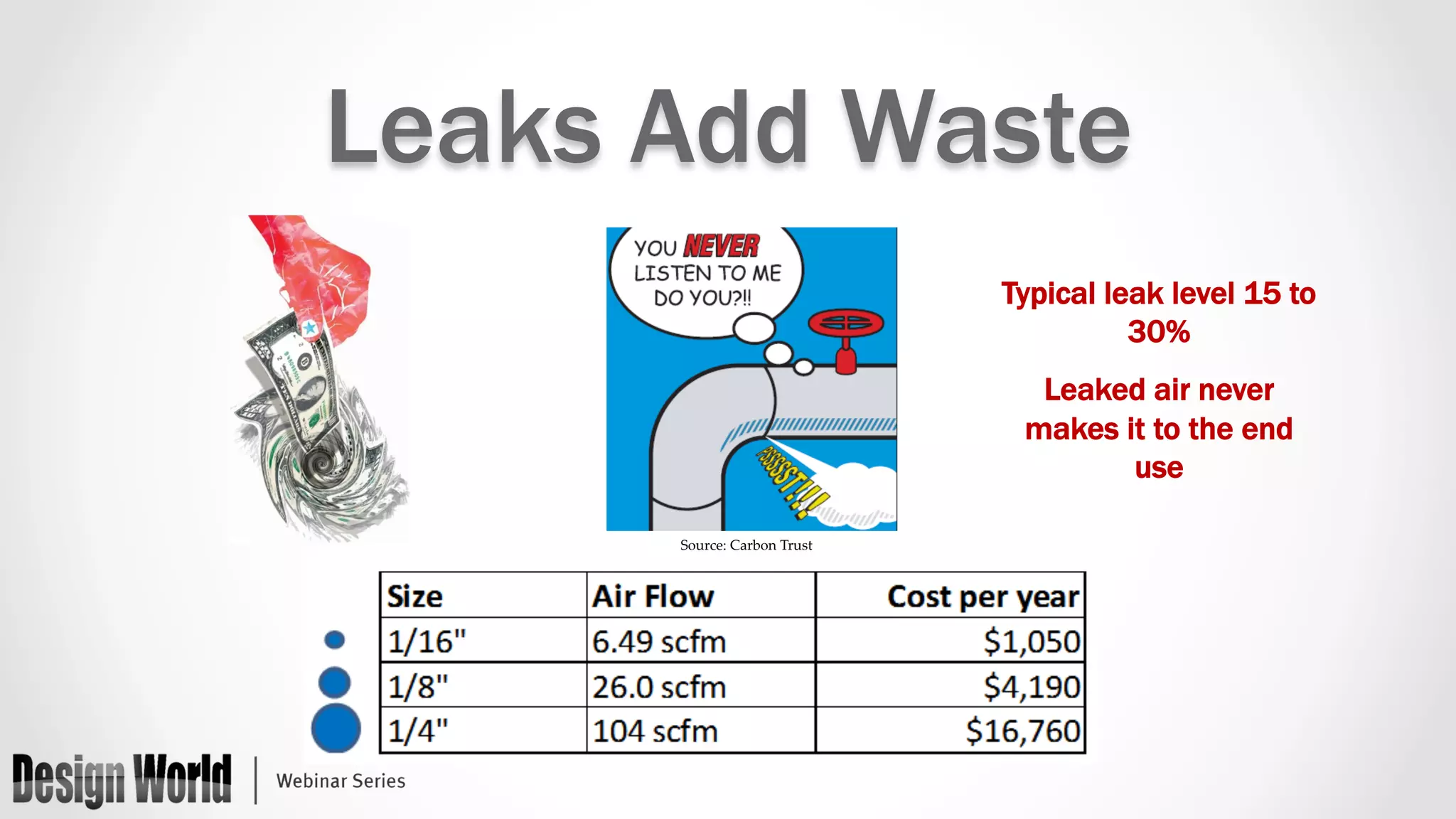

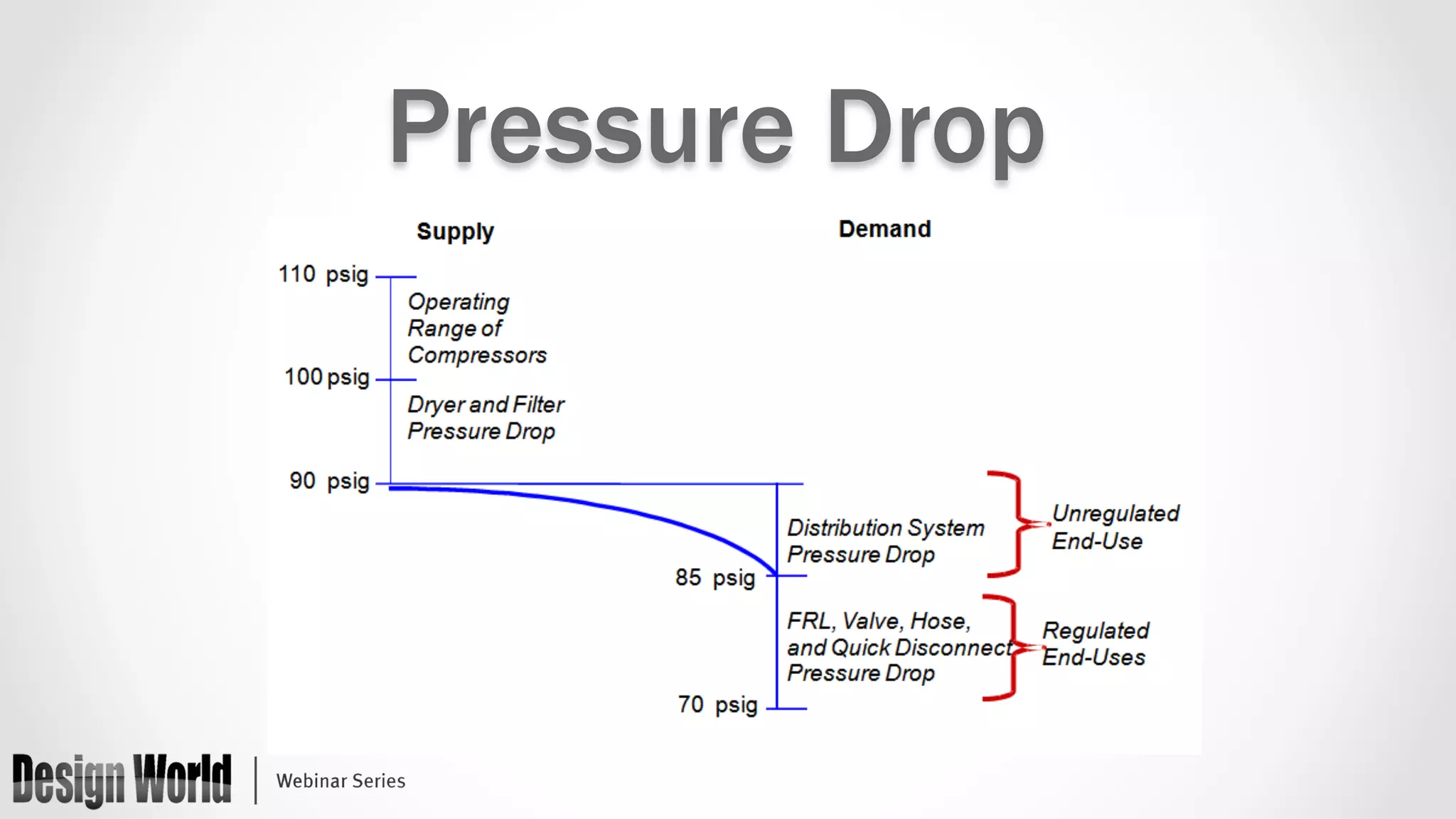

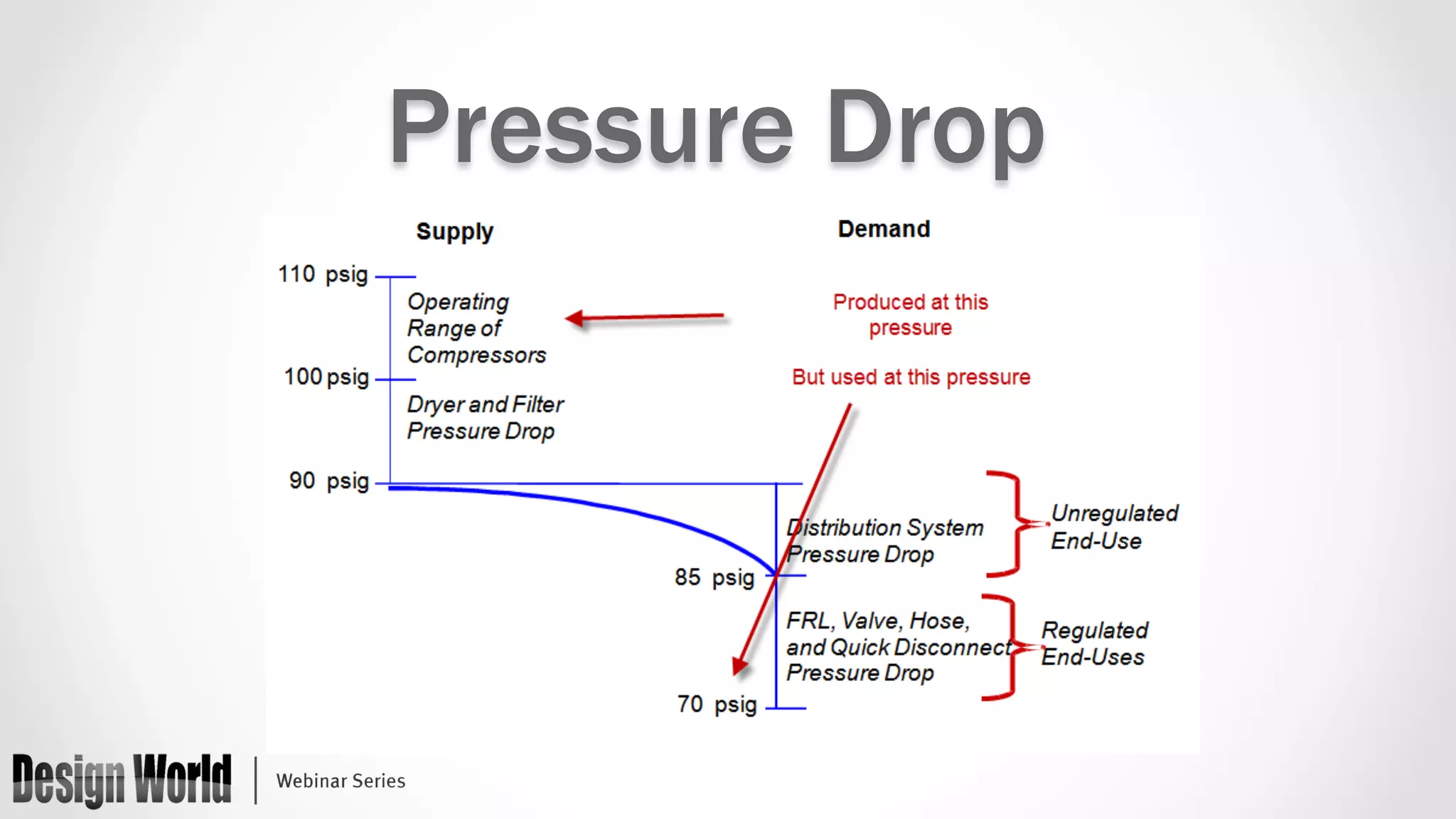

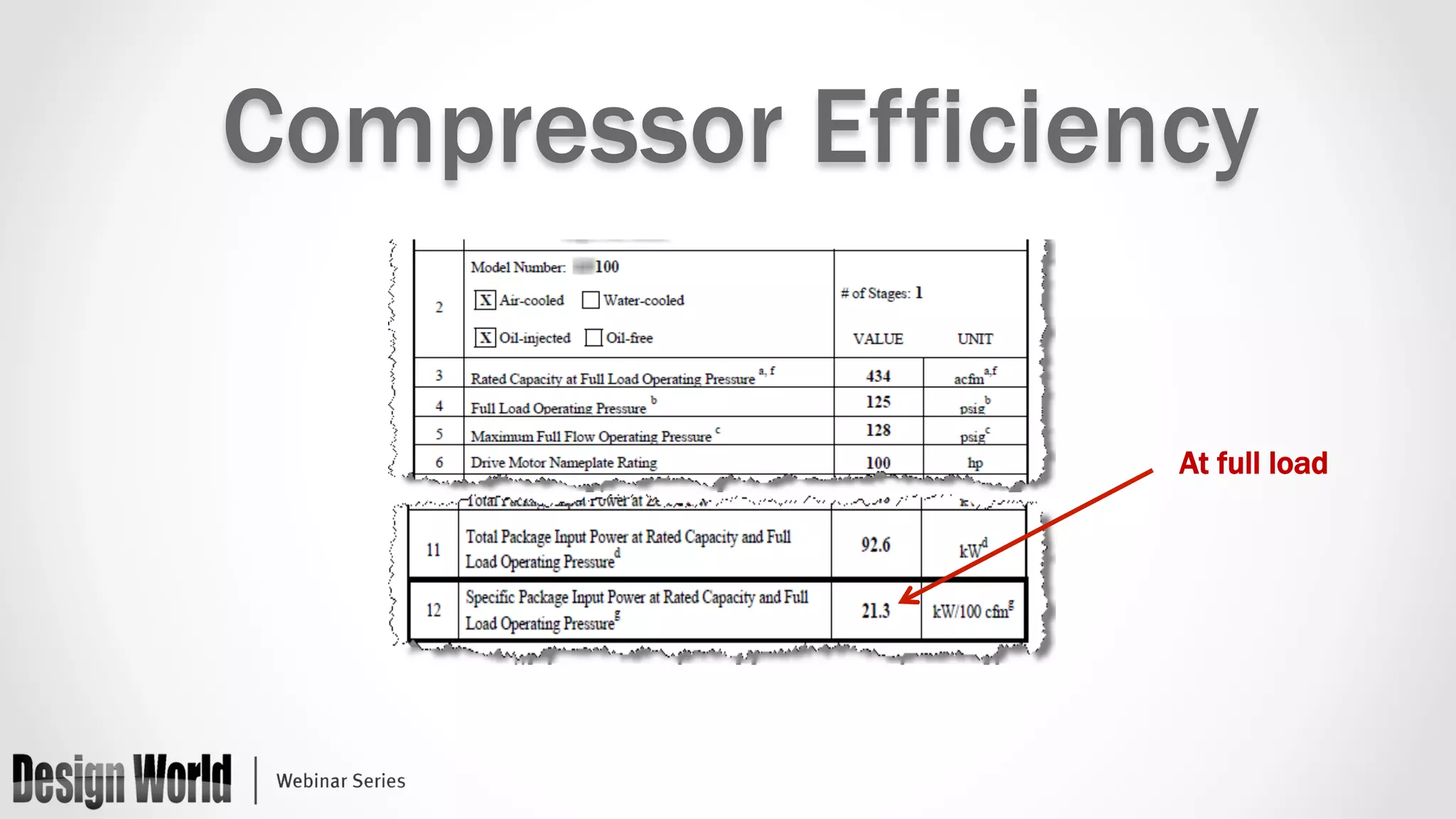

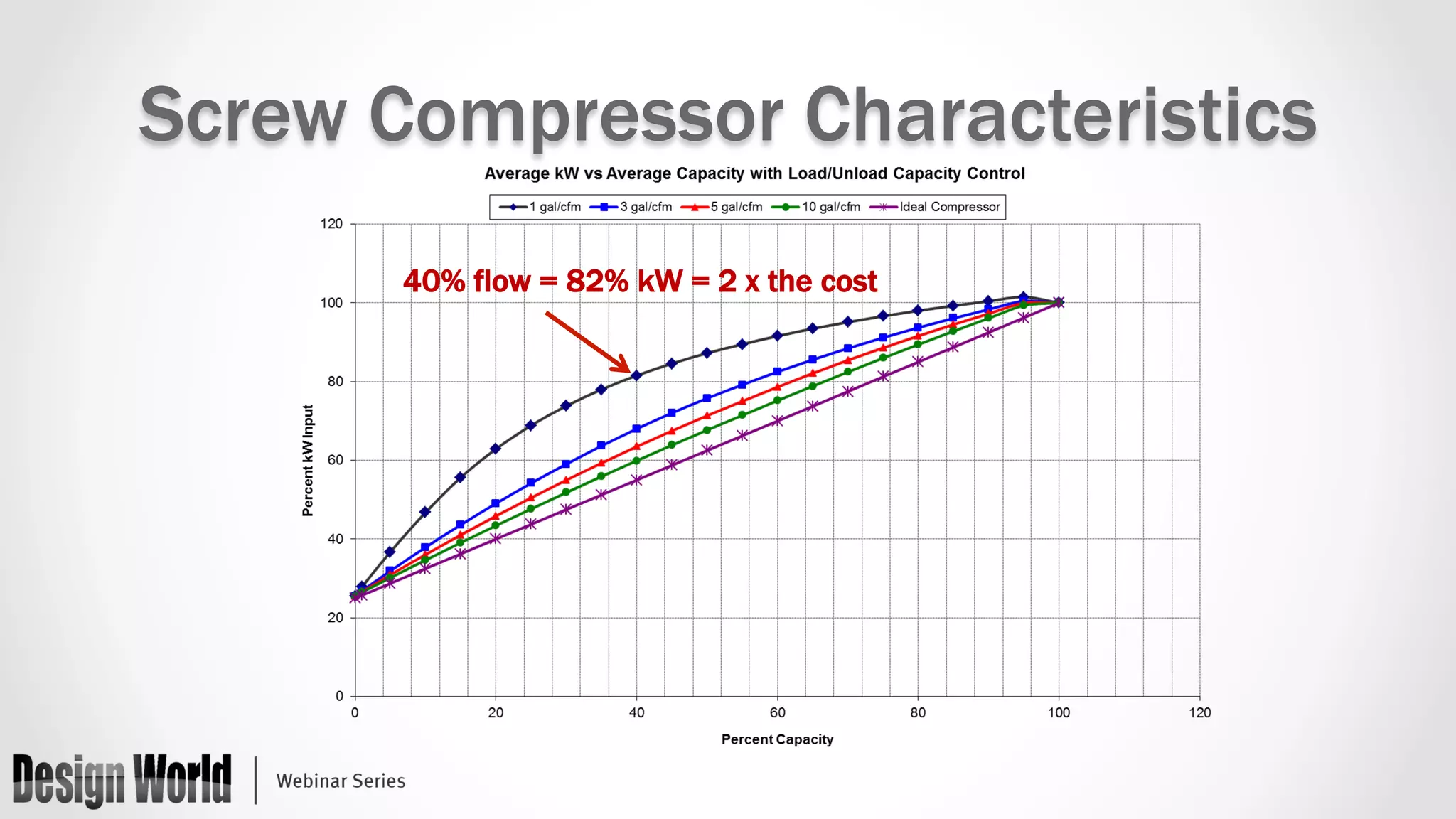

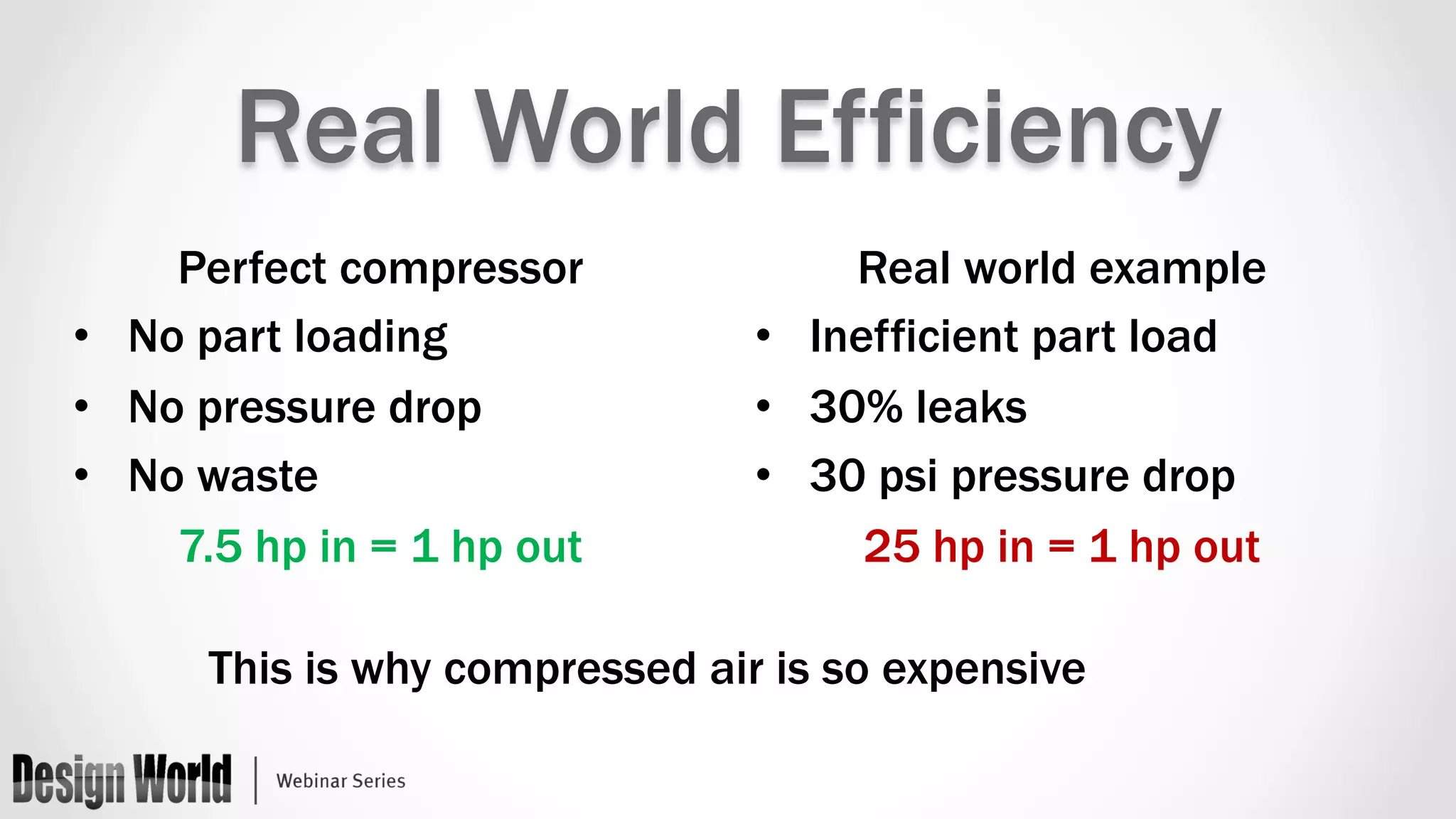

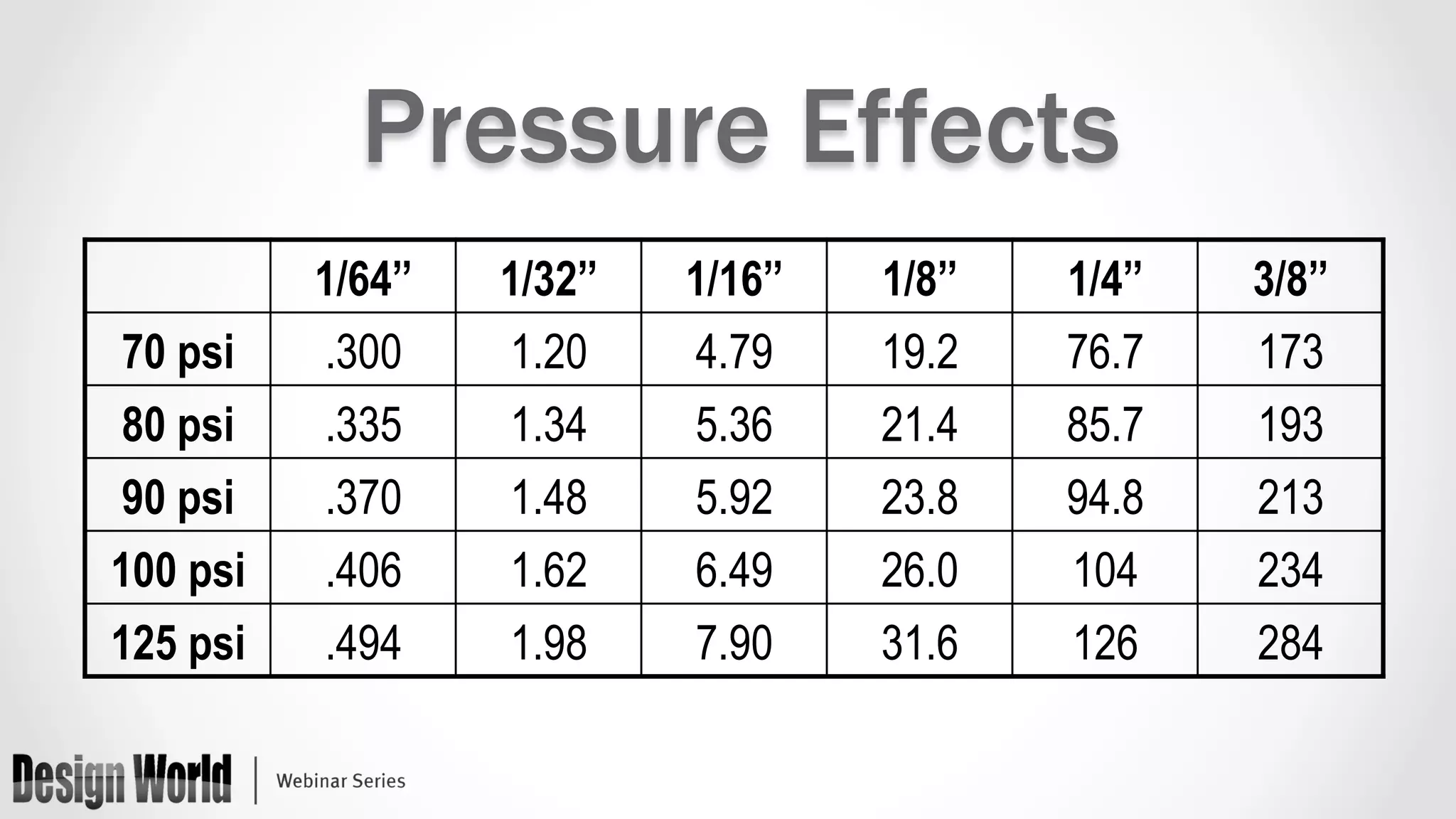

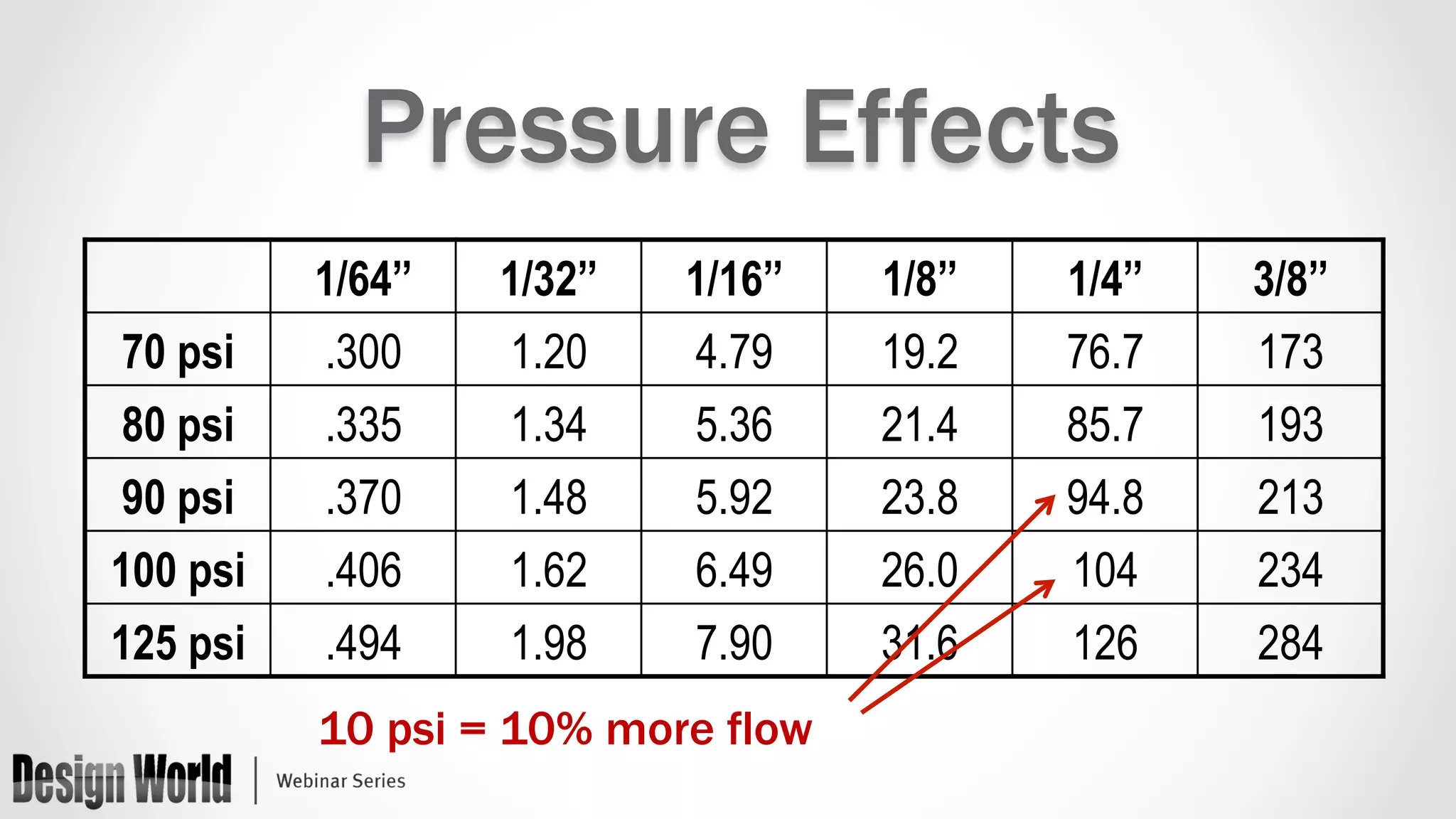

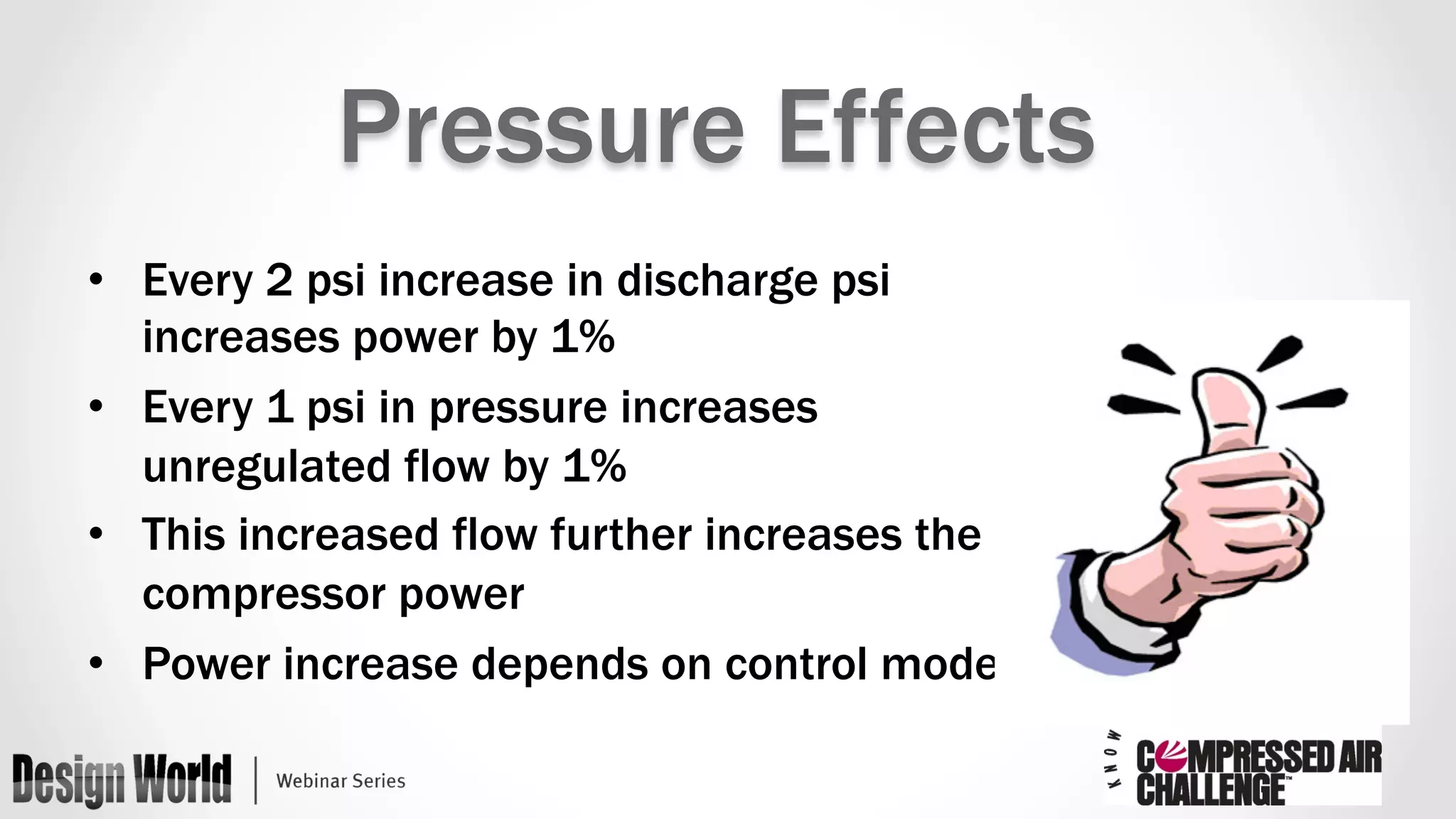

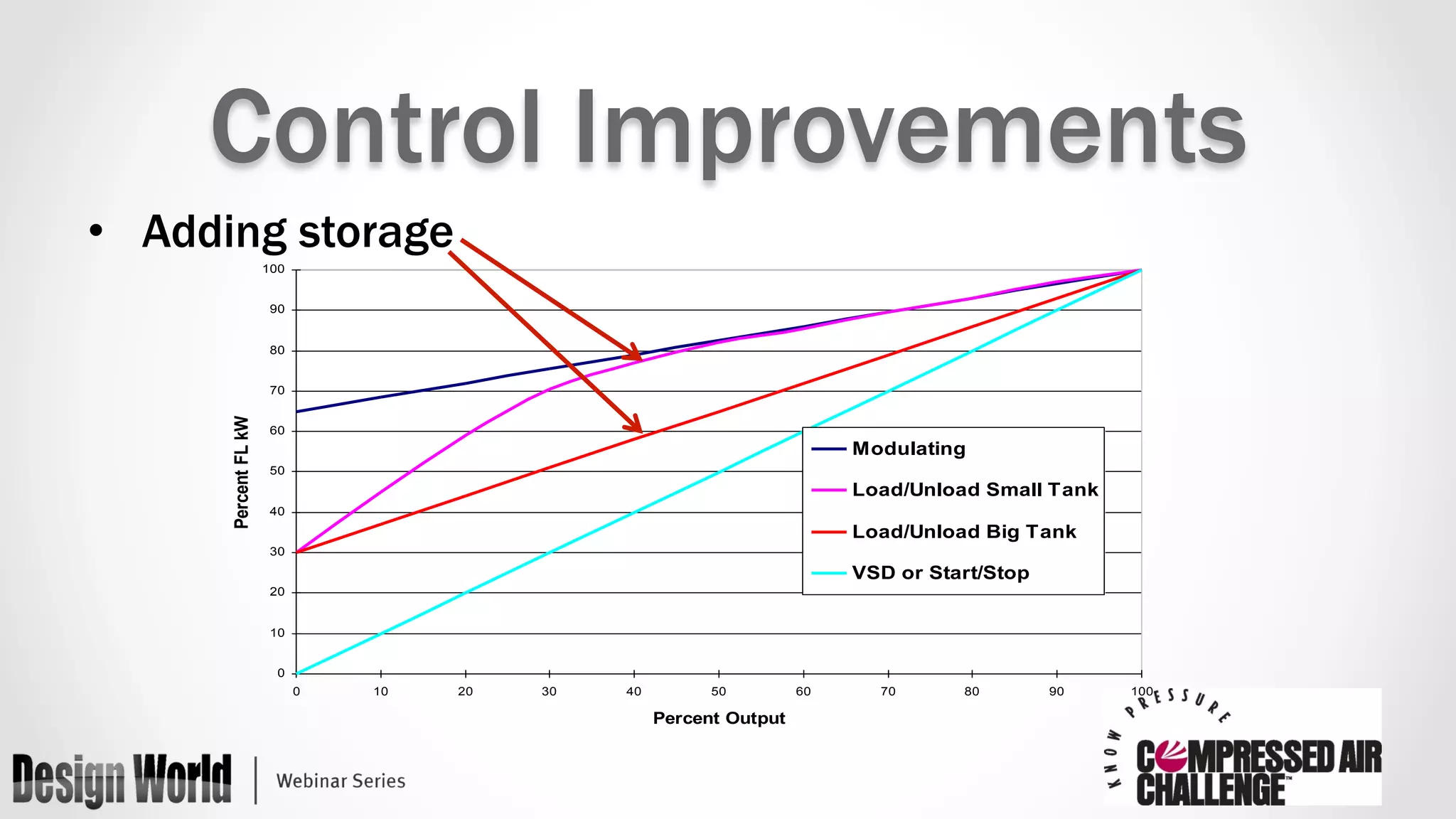

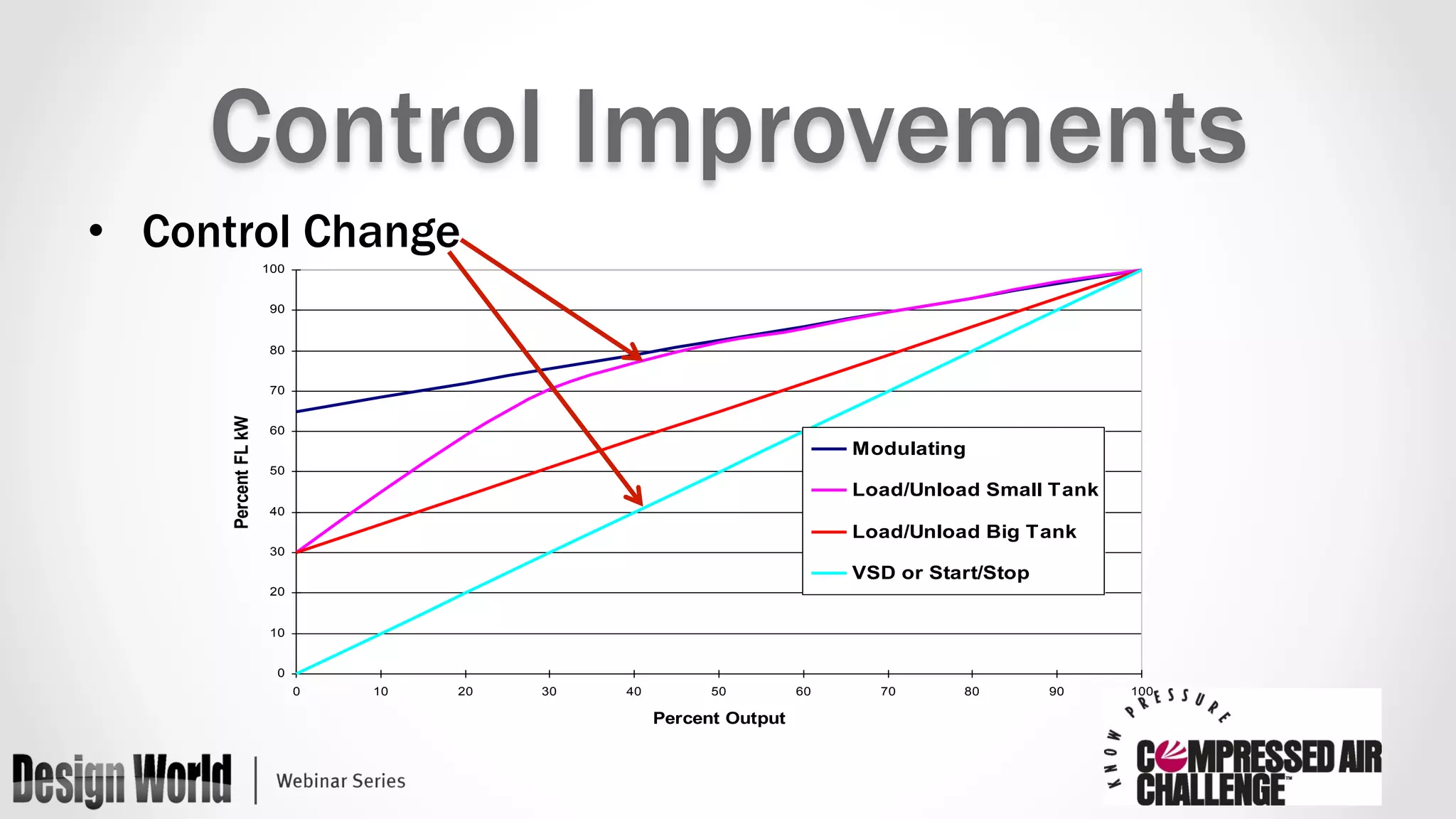

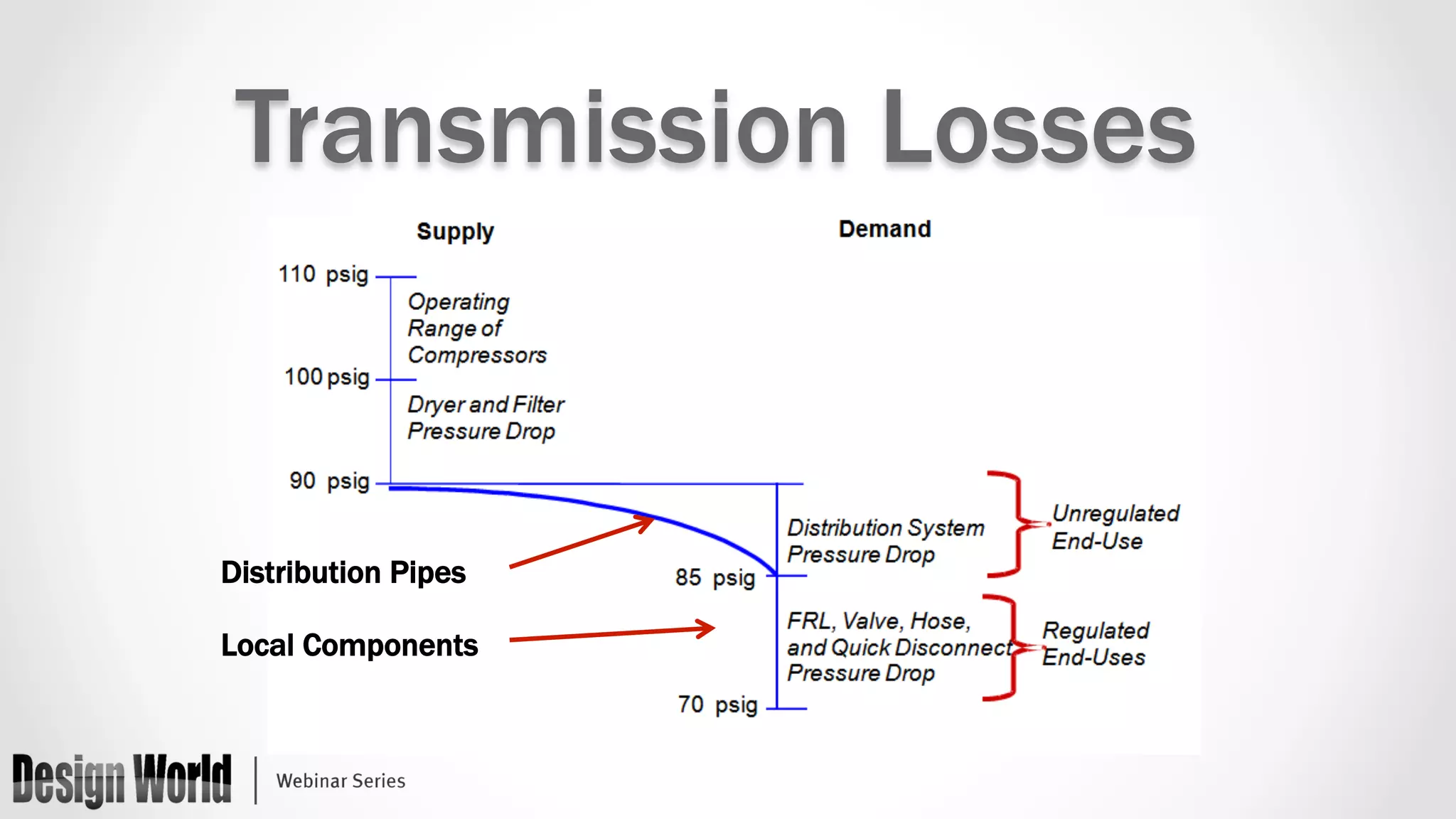

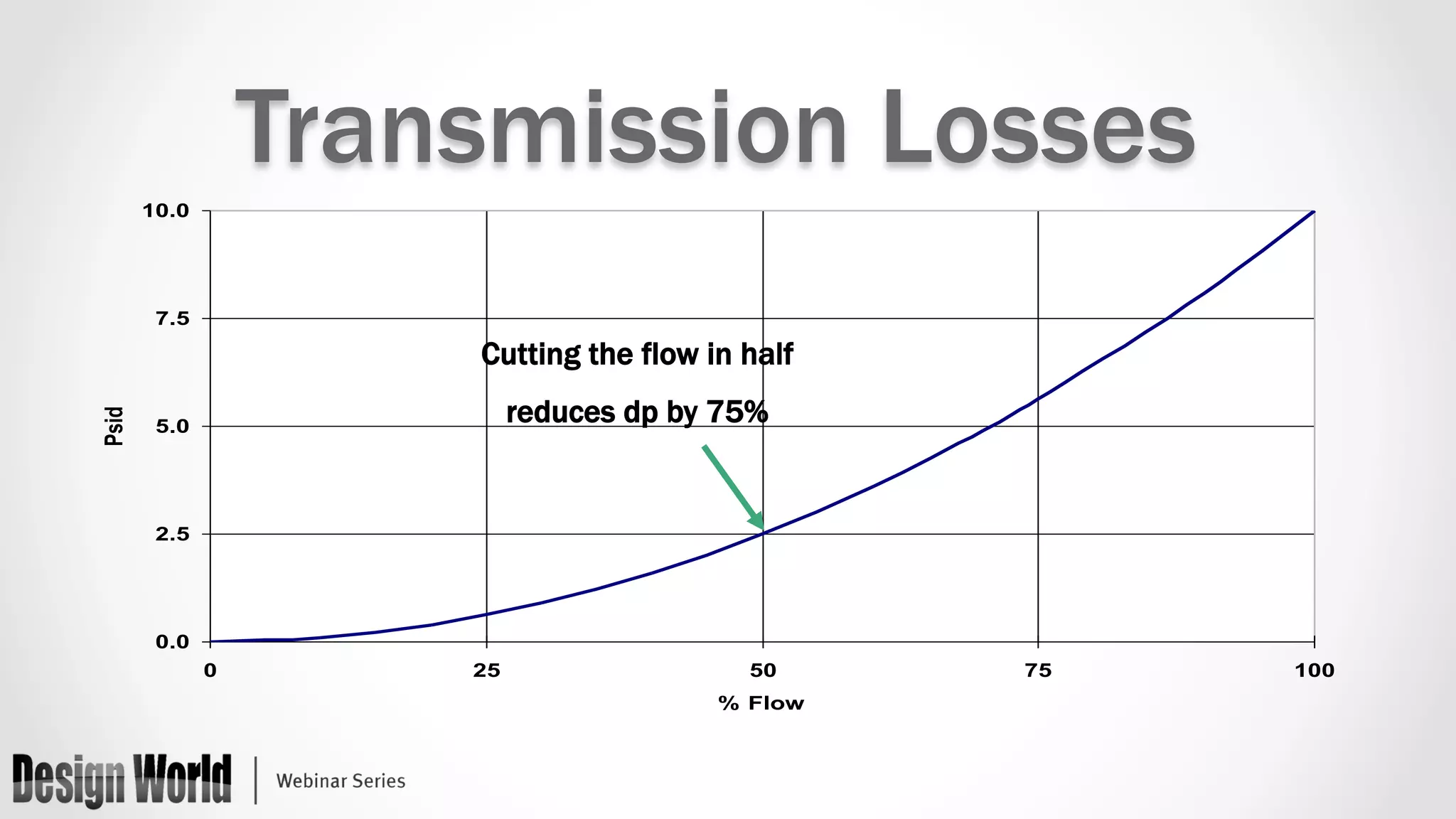

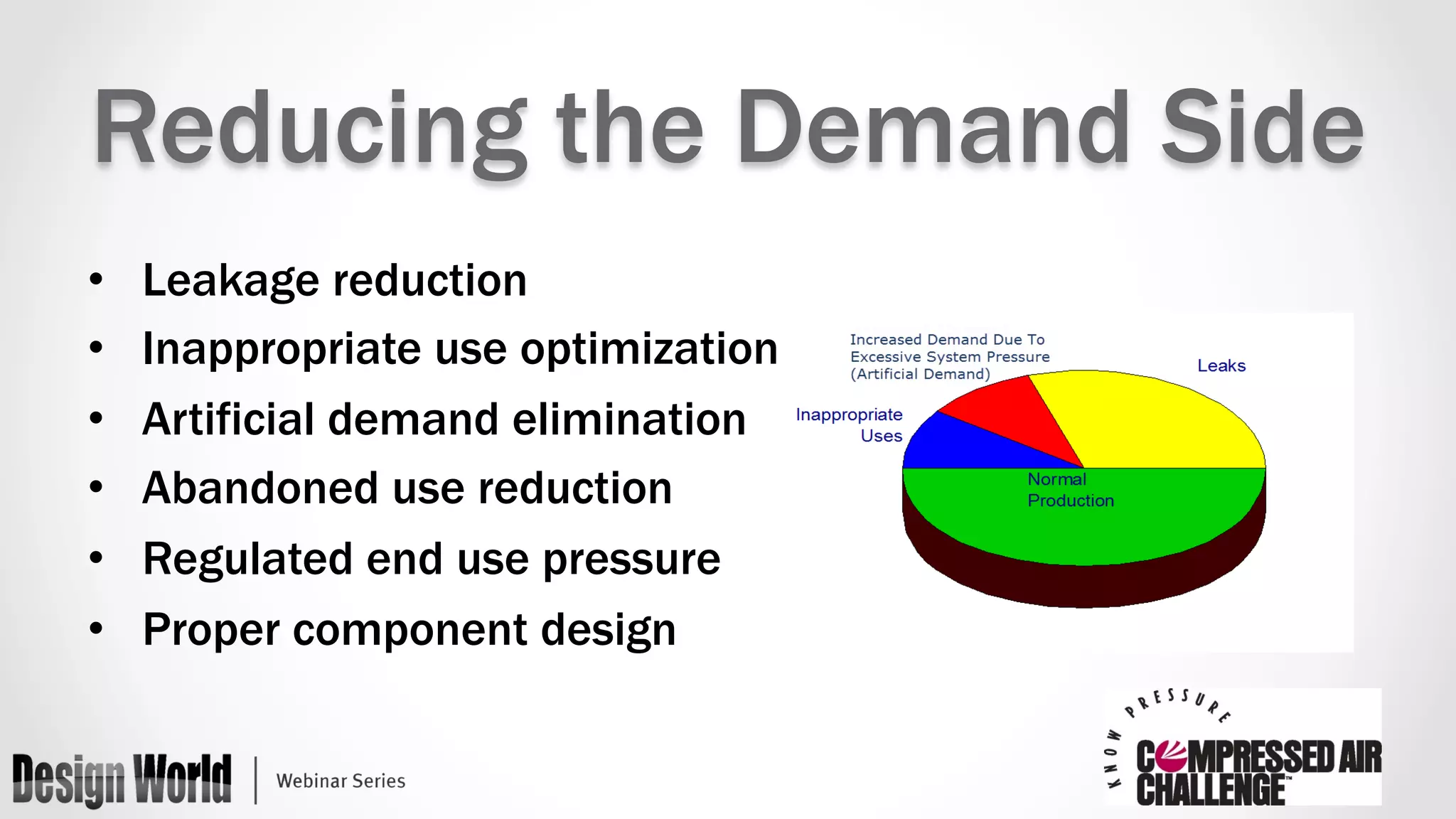

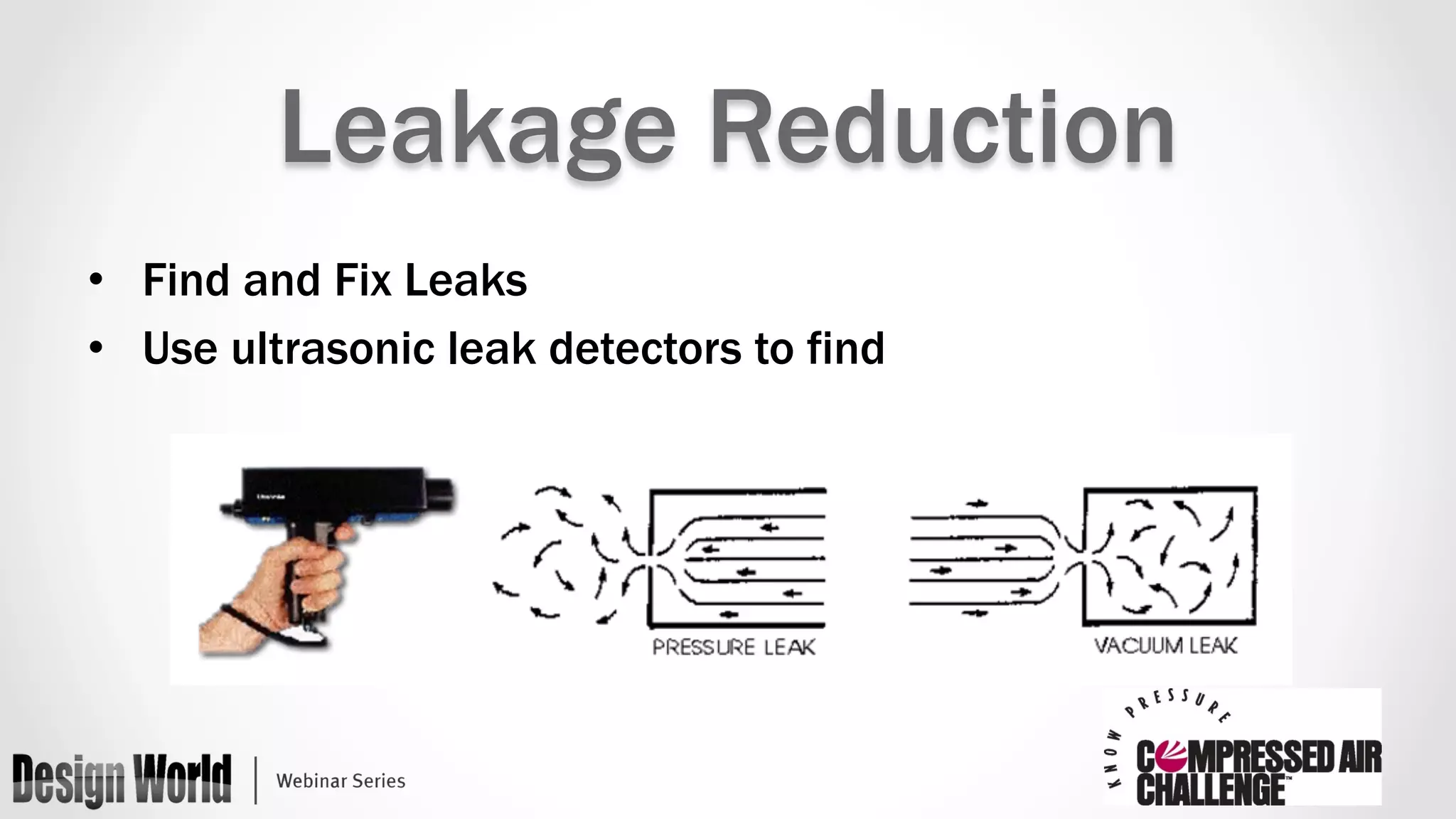

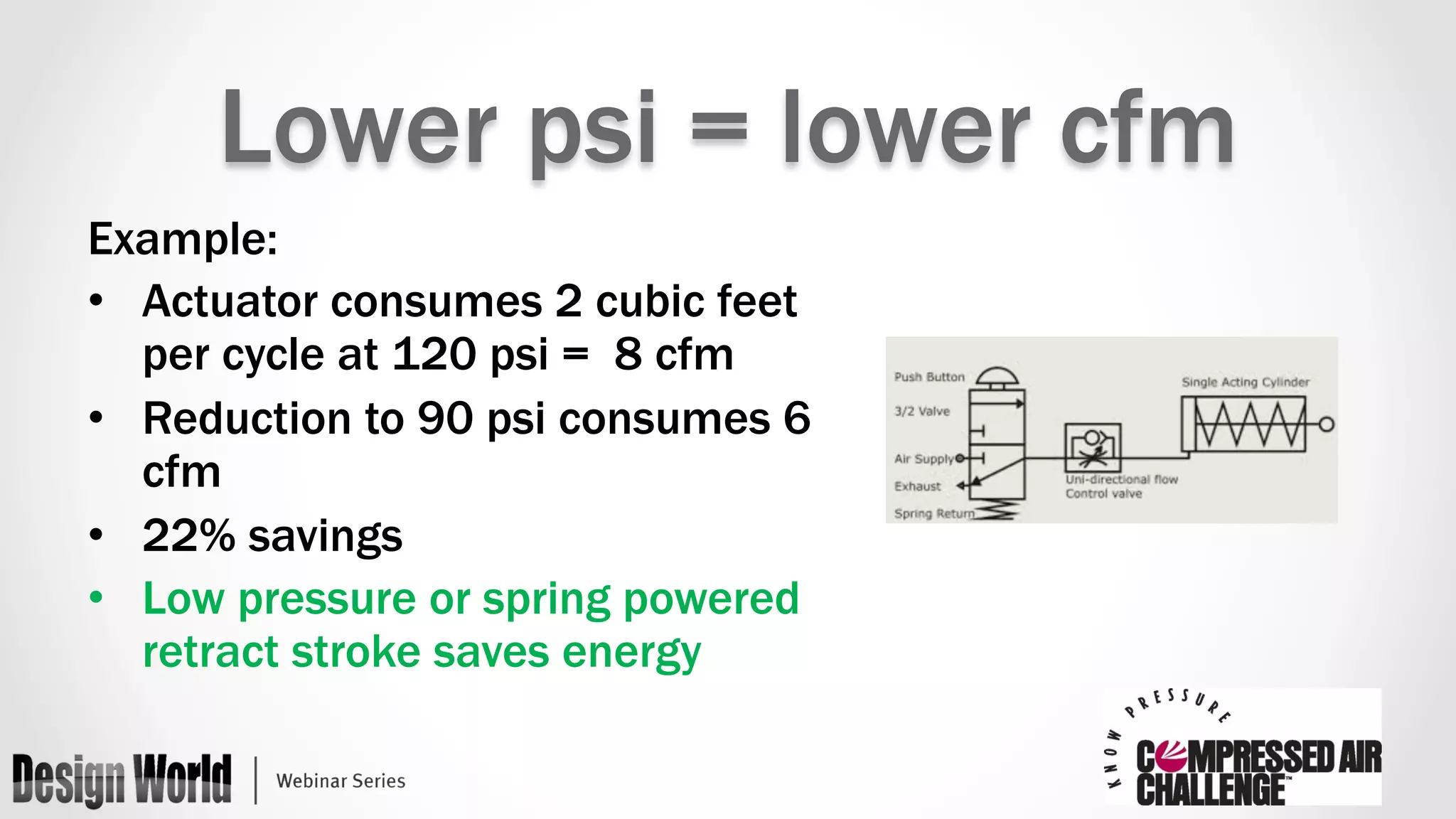

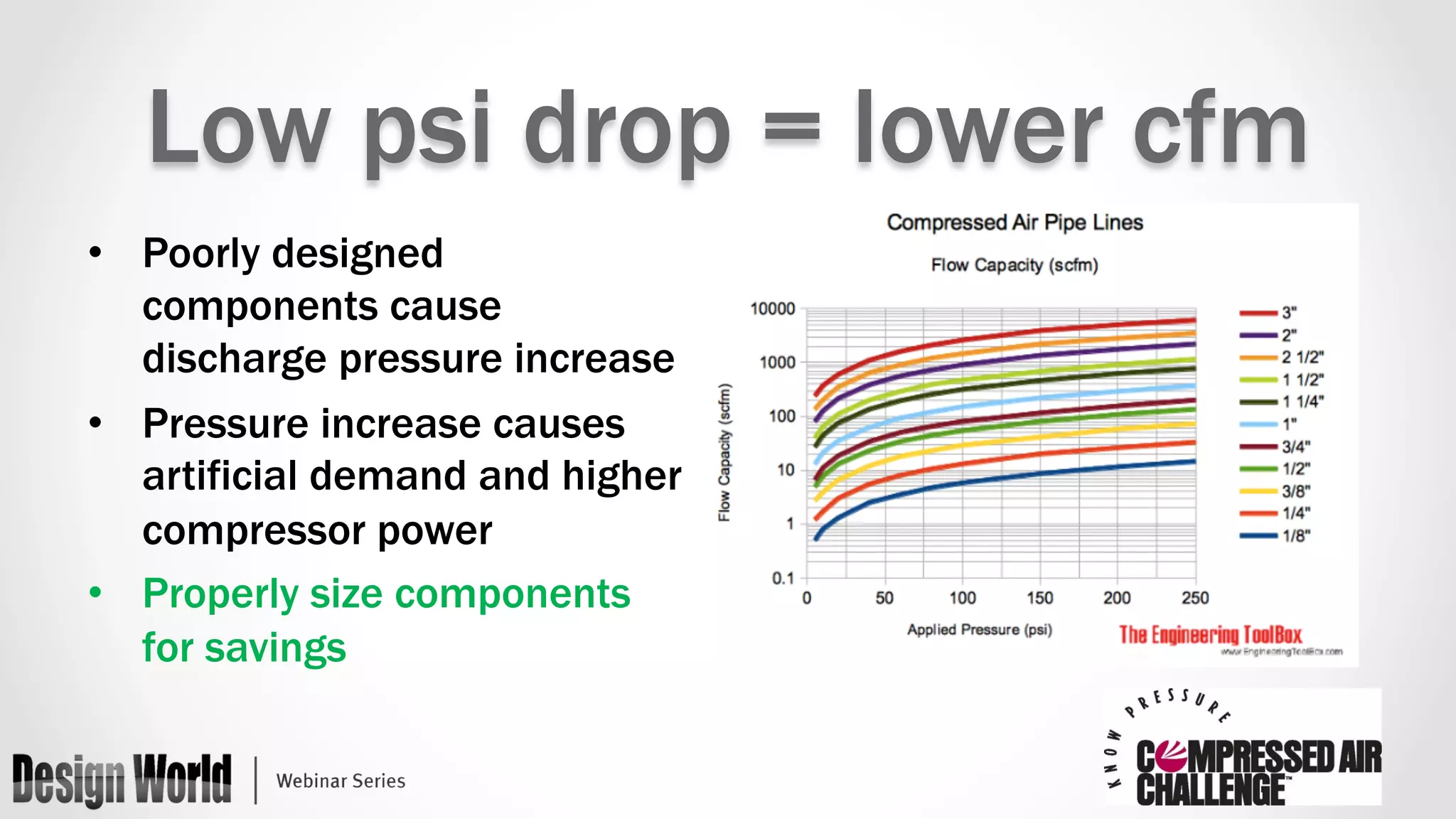

This document discusses why compressed air is so expensive and what can be done to improve efficiency. It notes that typical compressed air systems have poor production efficiency due to factors like leaks, pressure losses, and inefficient equipment. Several "secrets" to improving efficiency are outlined, including producing compressed air more efficiently, using less air, and capturing waste heat. Specific strategies proposed include reducing system pressure and associated losses, improving compressor controls, reducing transmission losses through piping upgrades, and decreasing demand through leak repairs and eliminating inappropriate uses. The presentation encourages addressing both the supply and demand sides to lower the high costs of compressed air.