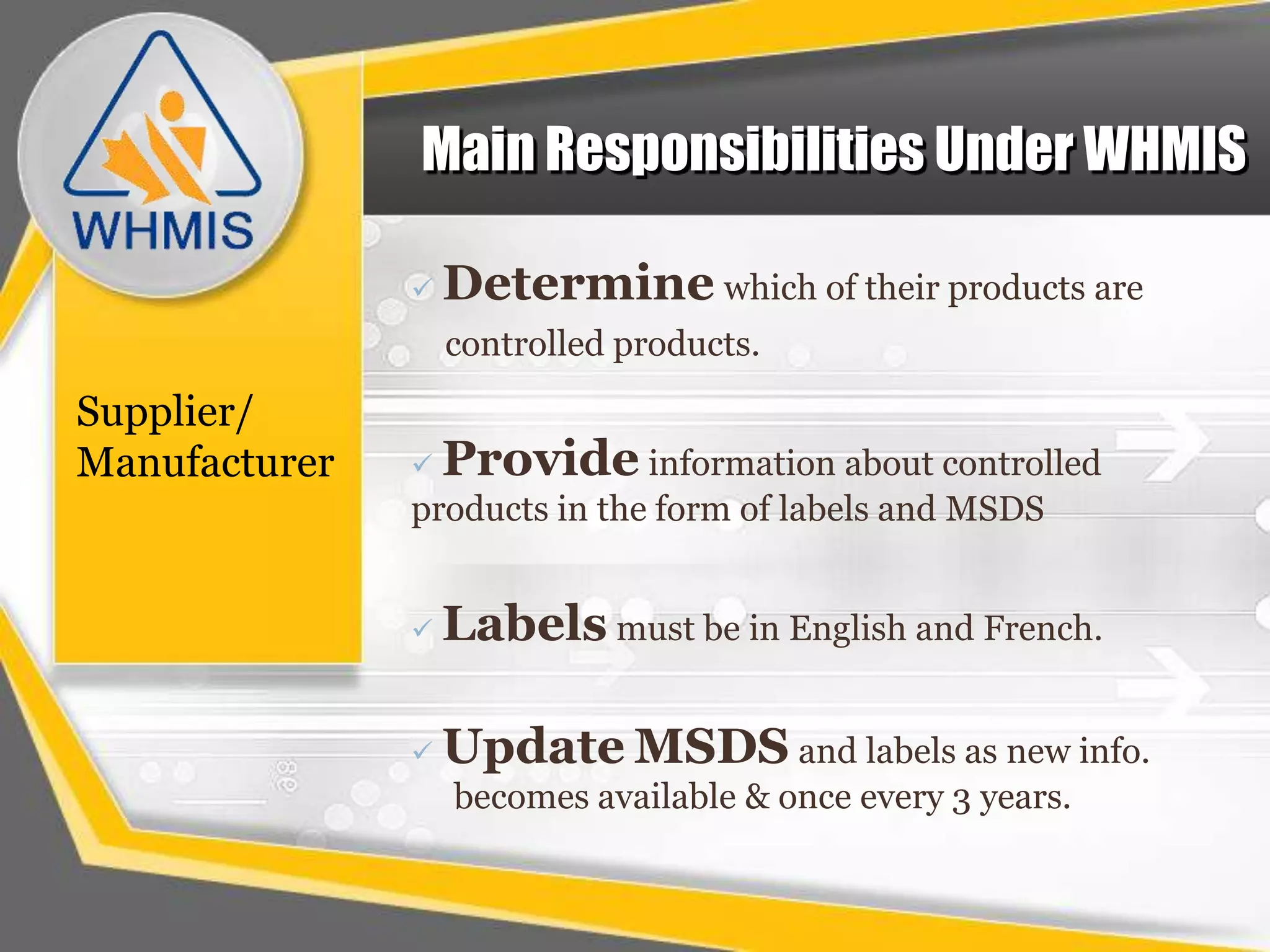

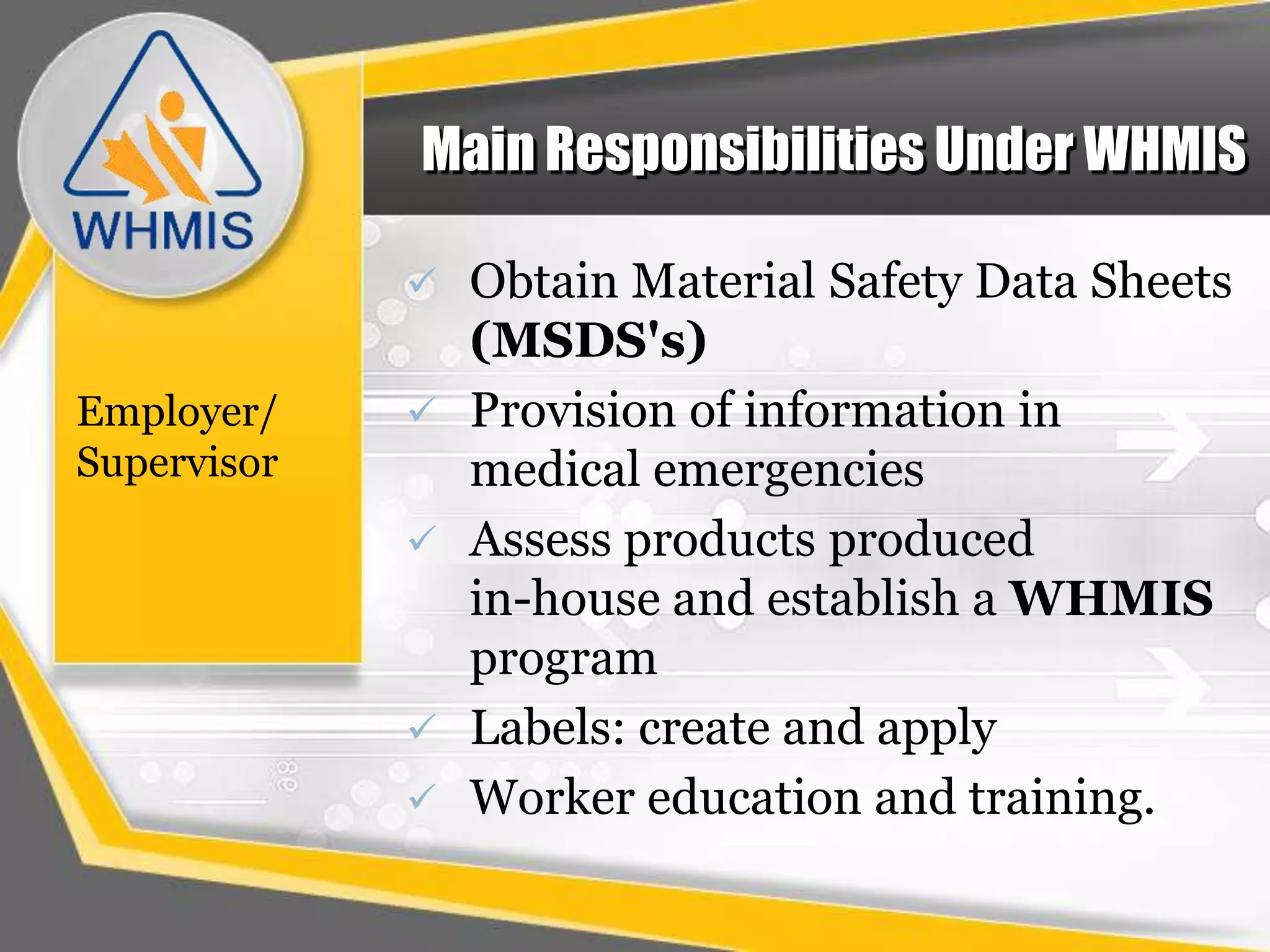

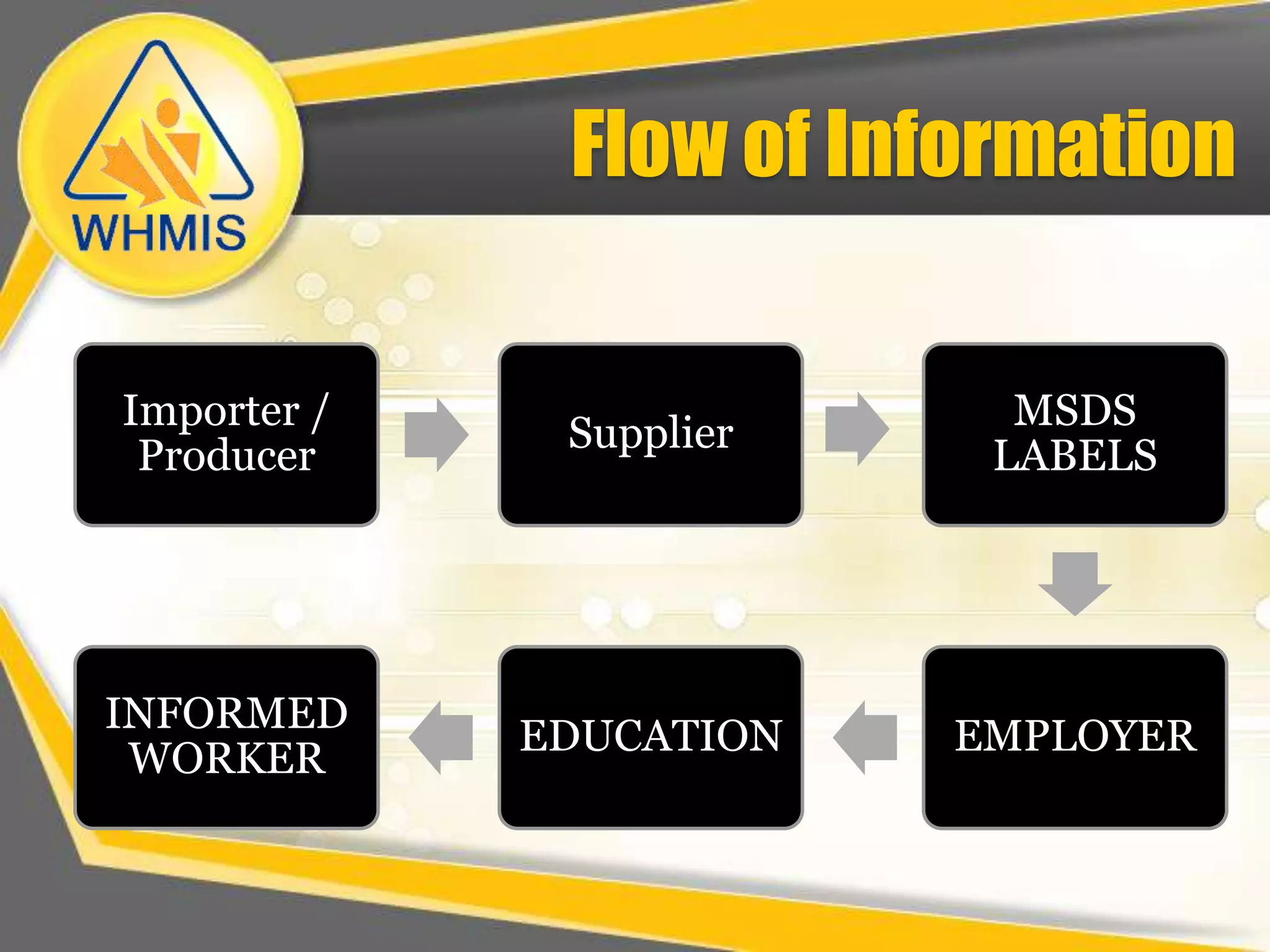

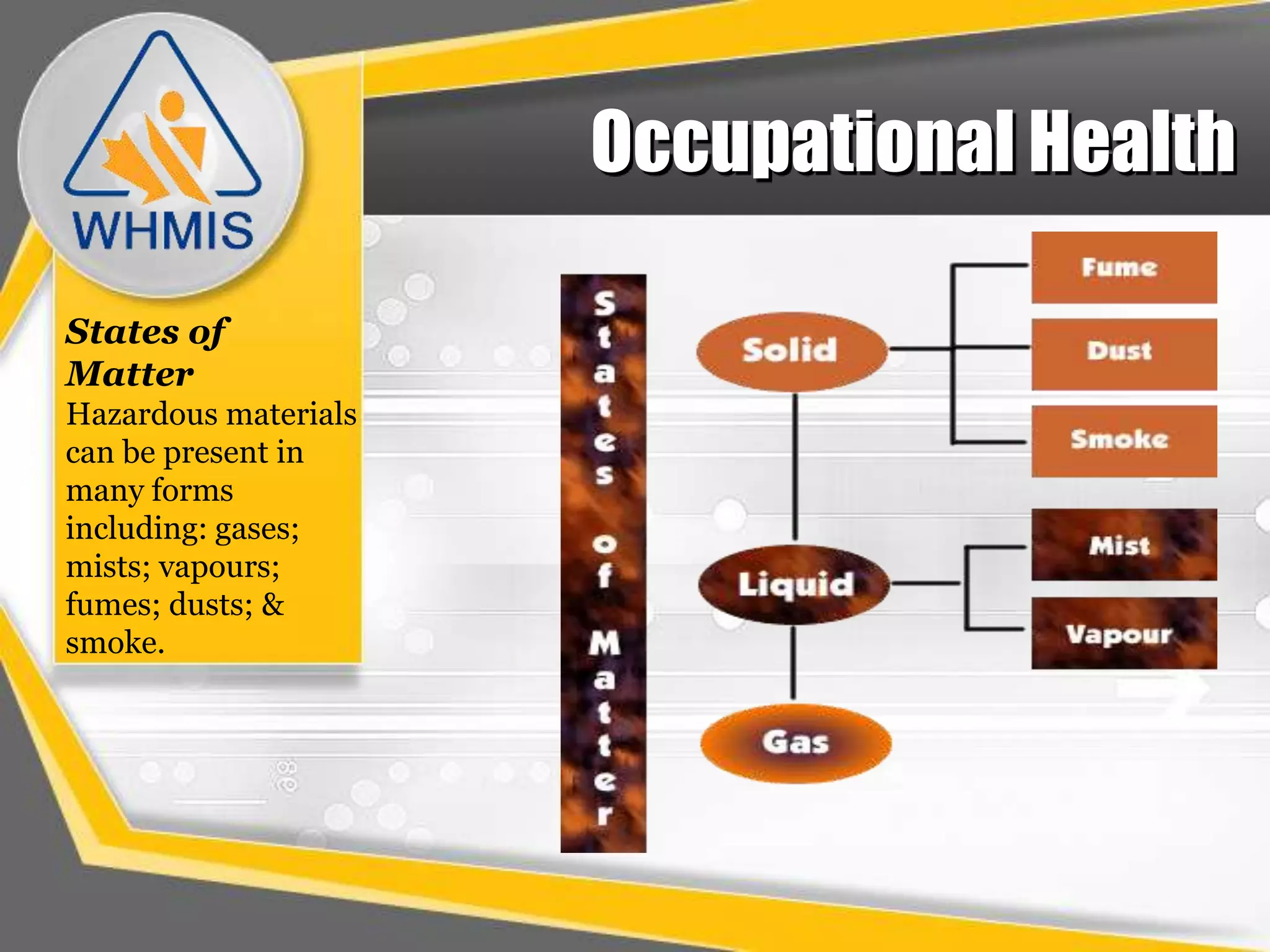

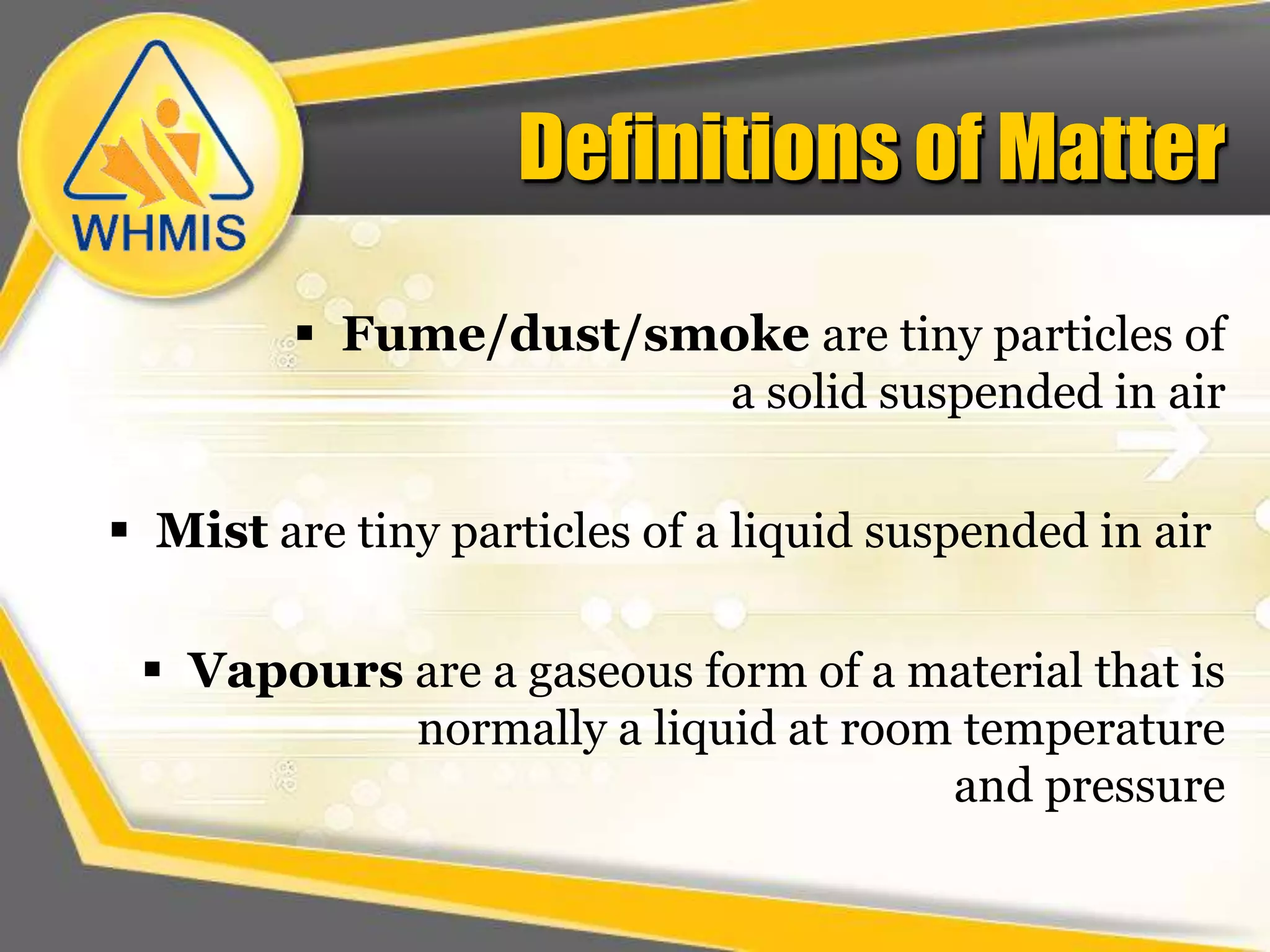

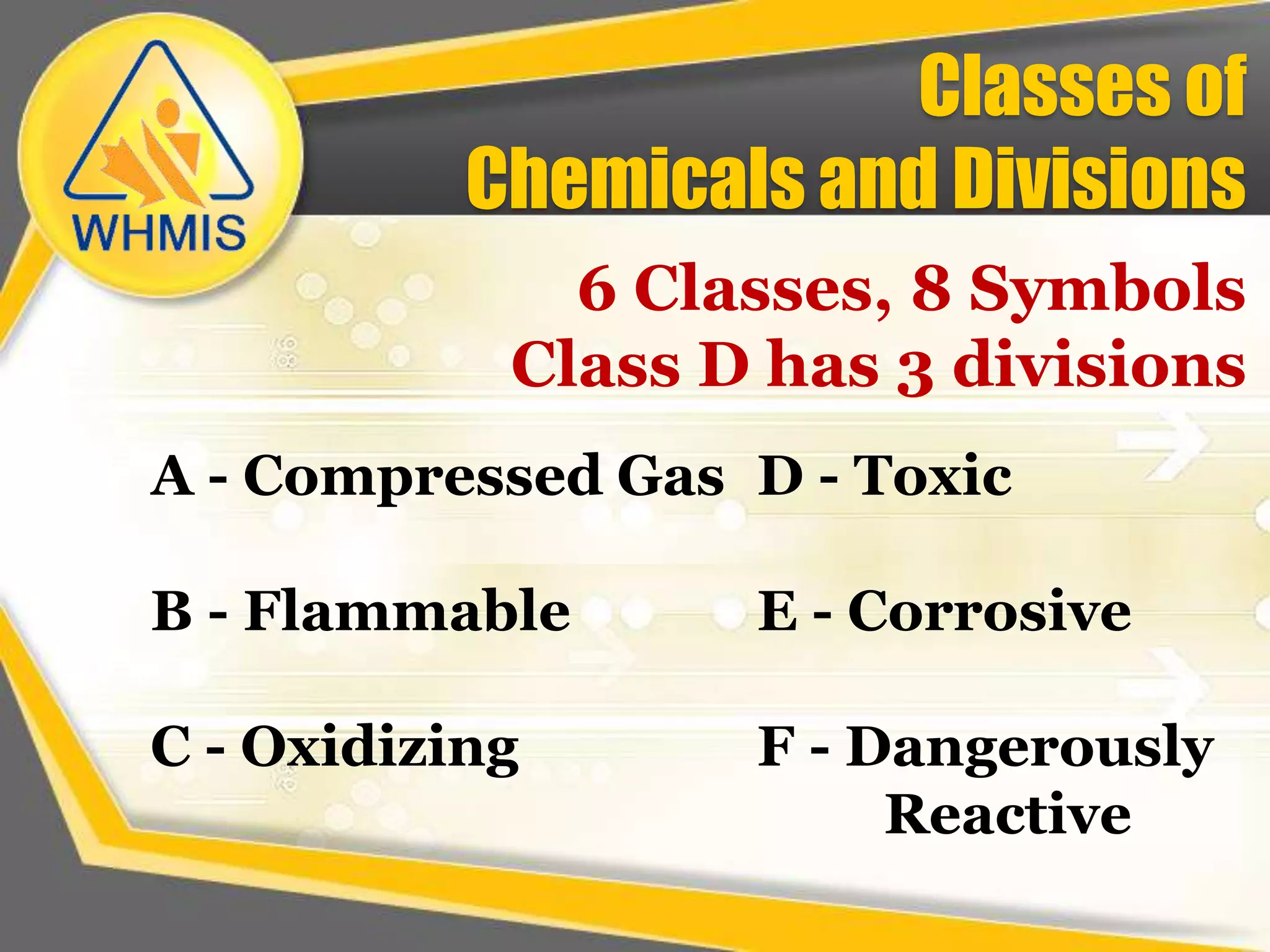

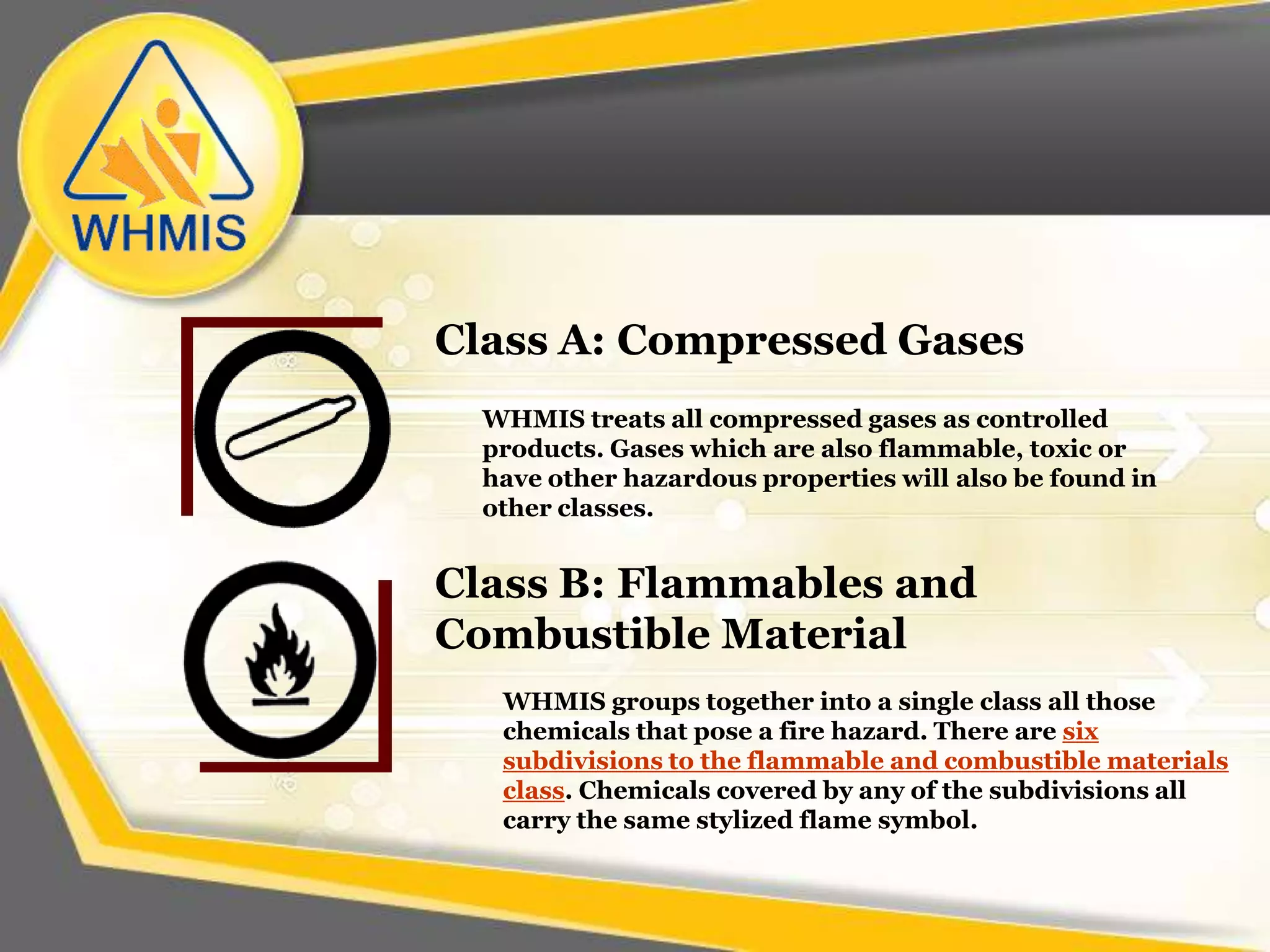

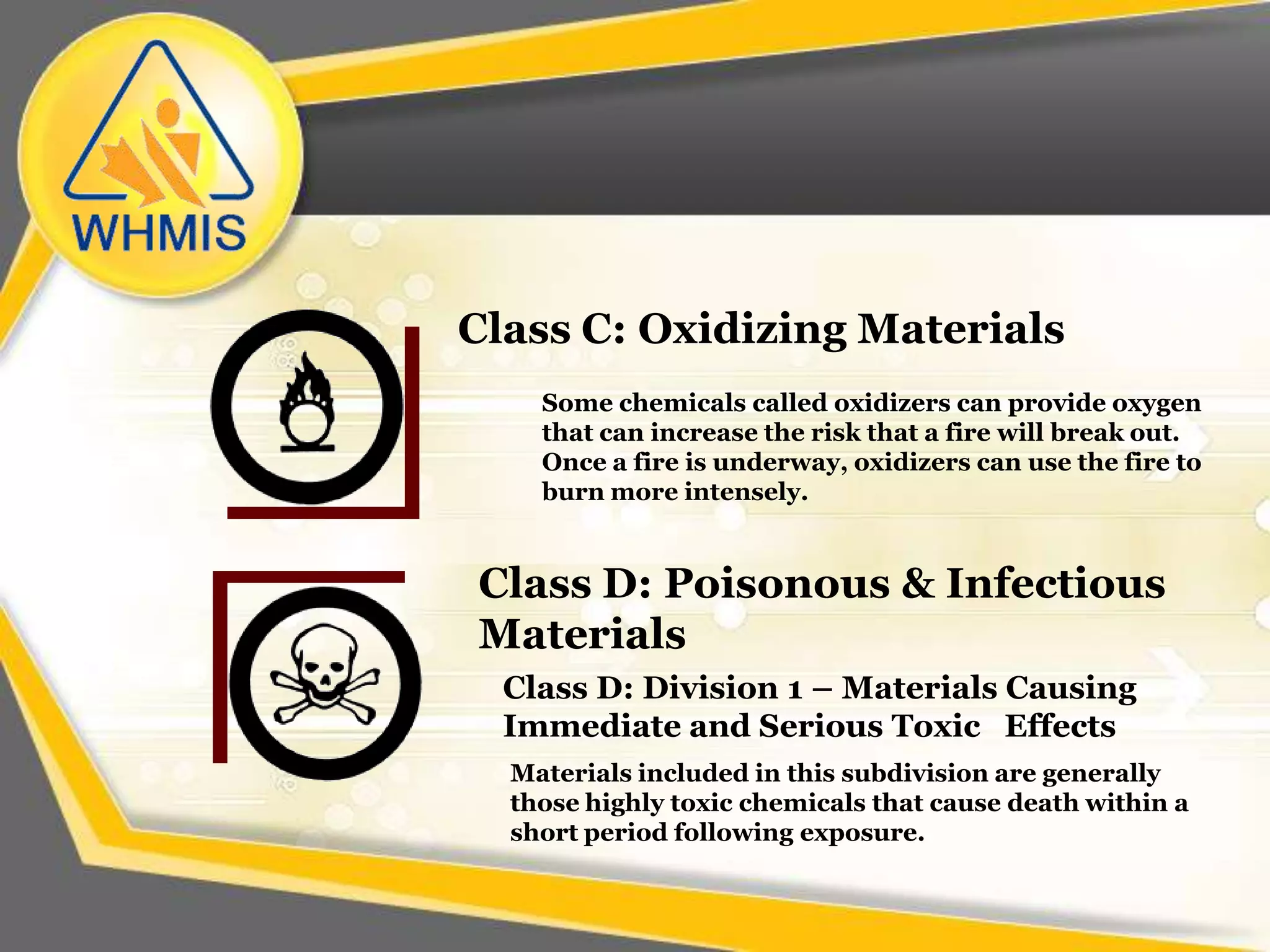

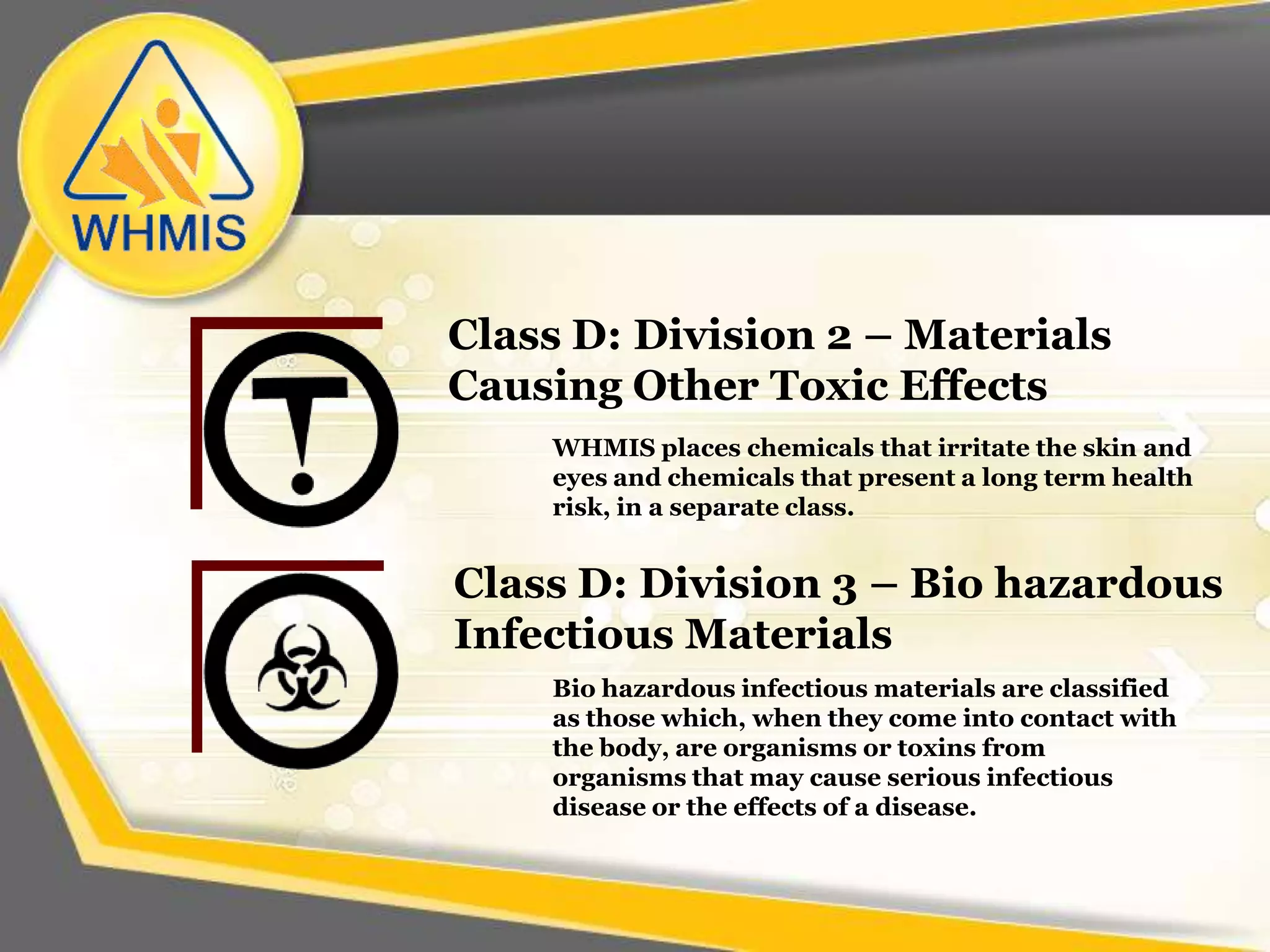

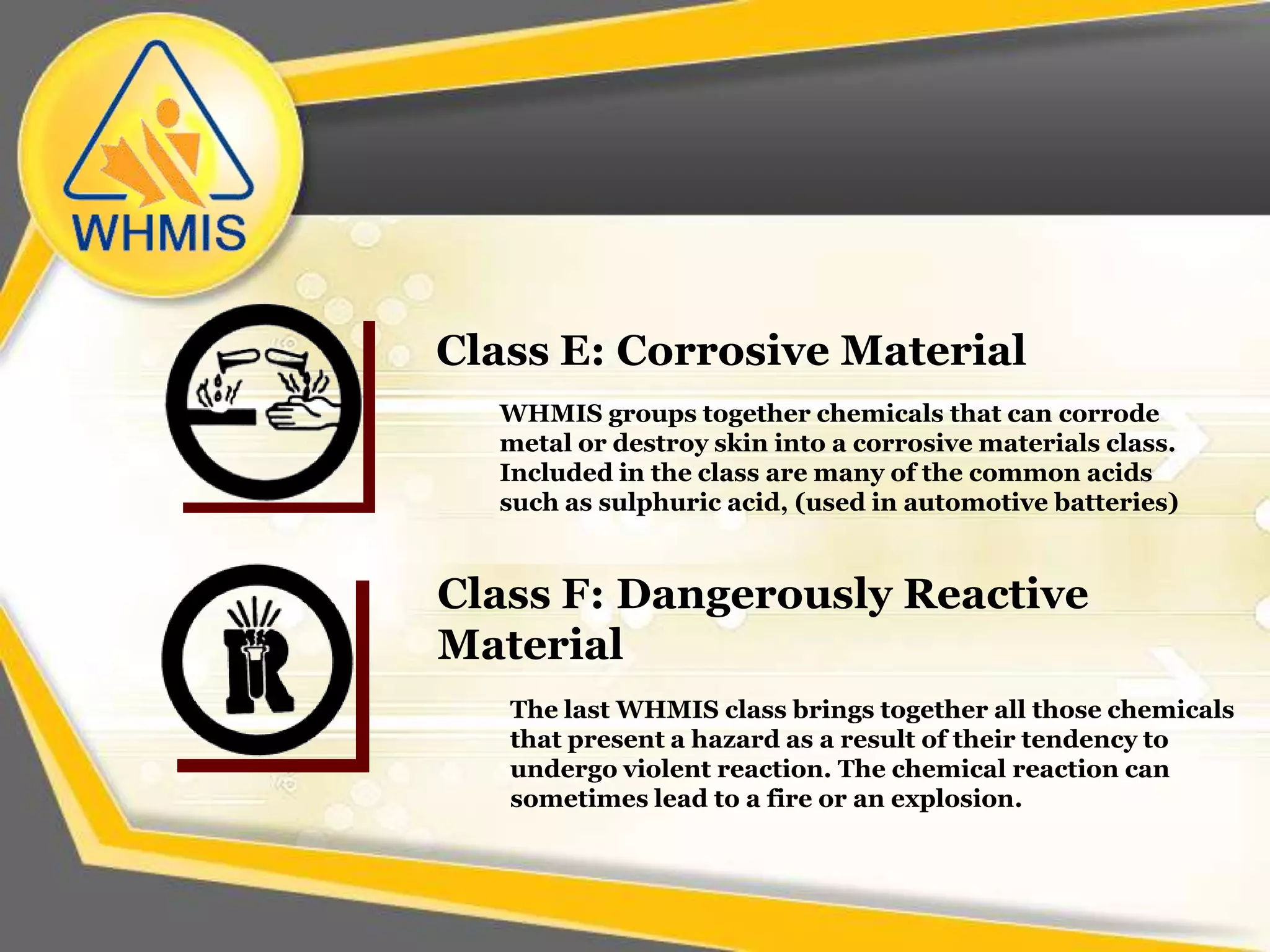

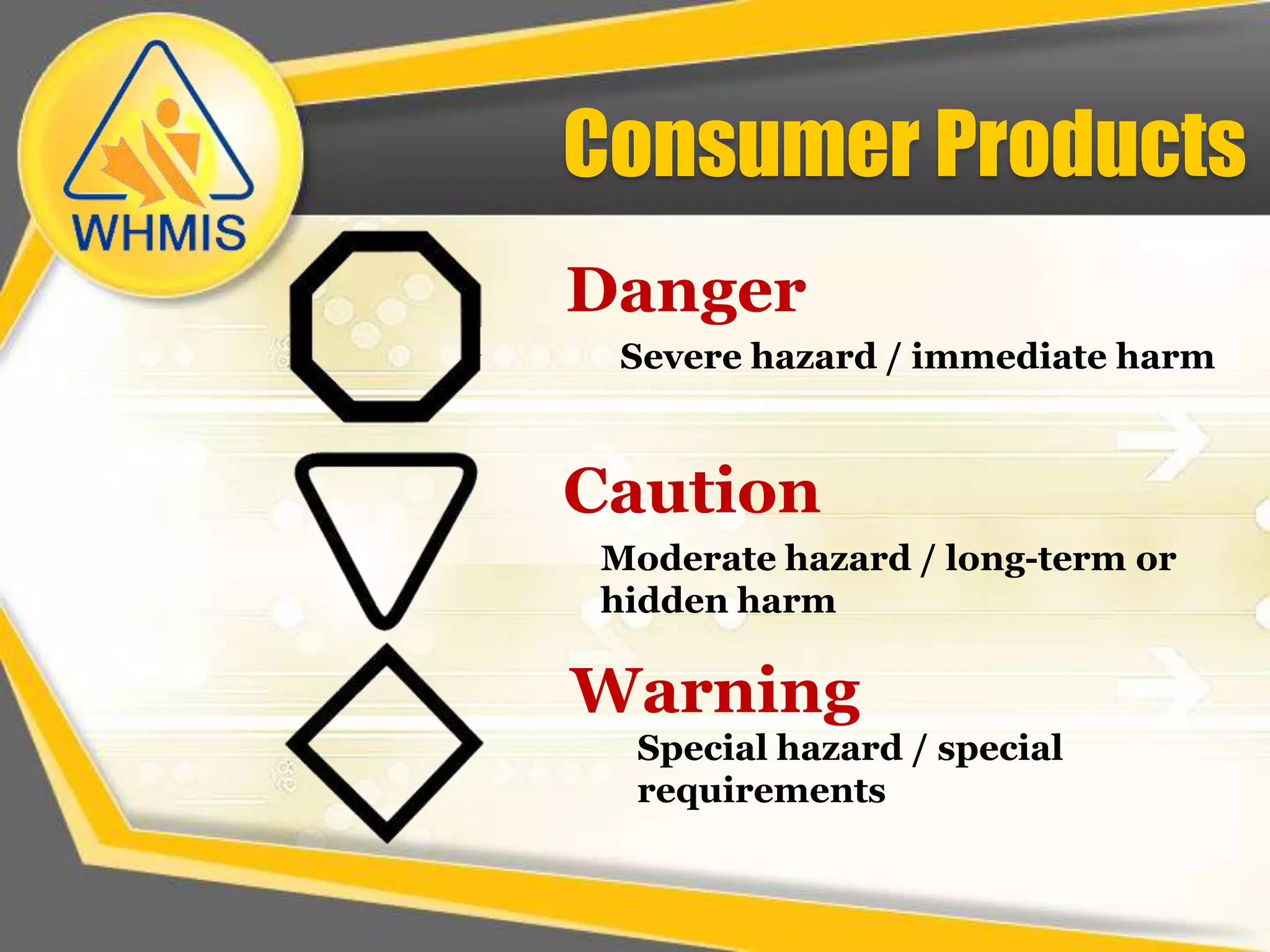

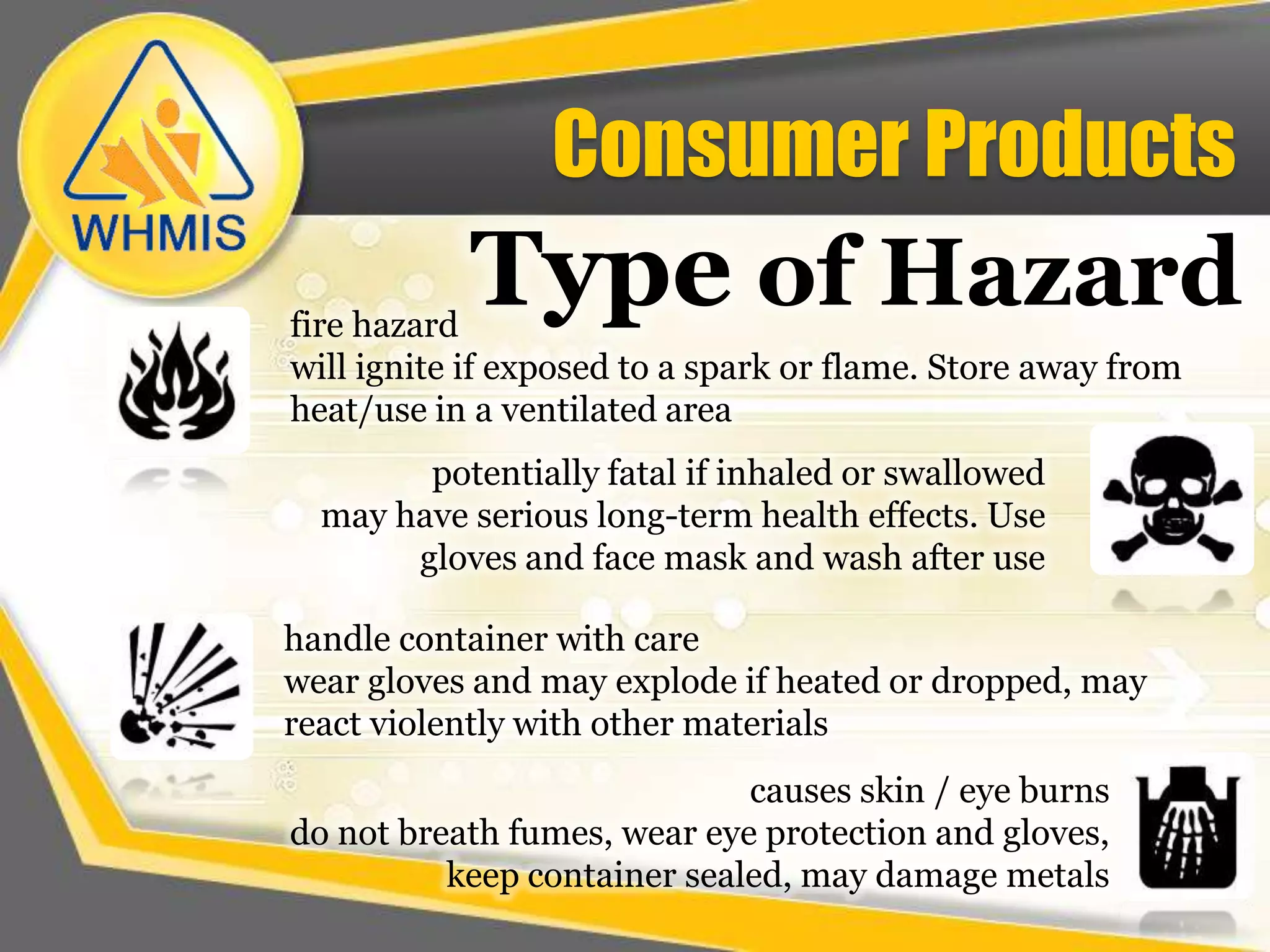

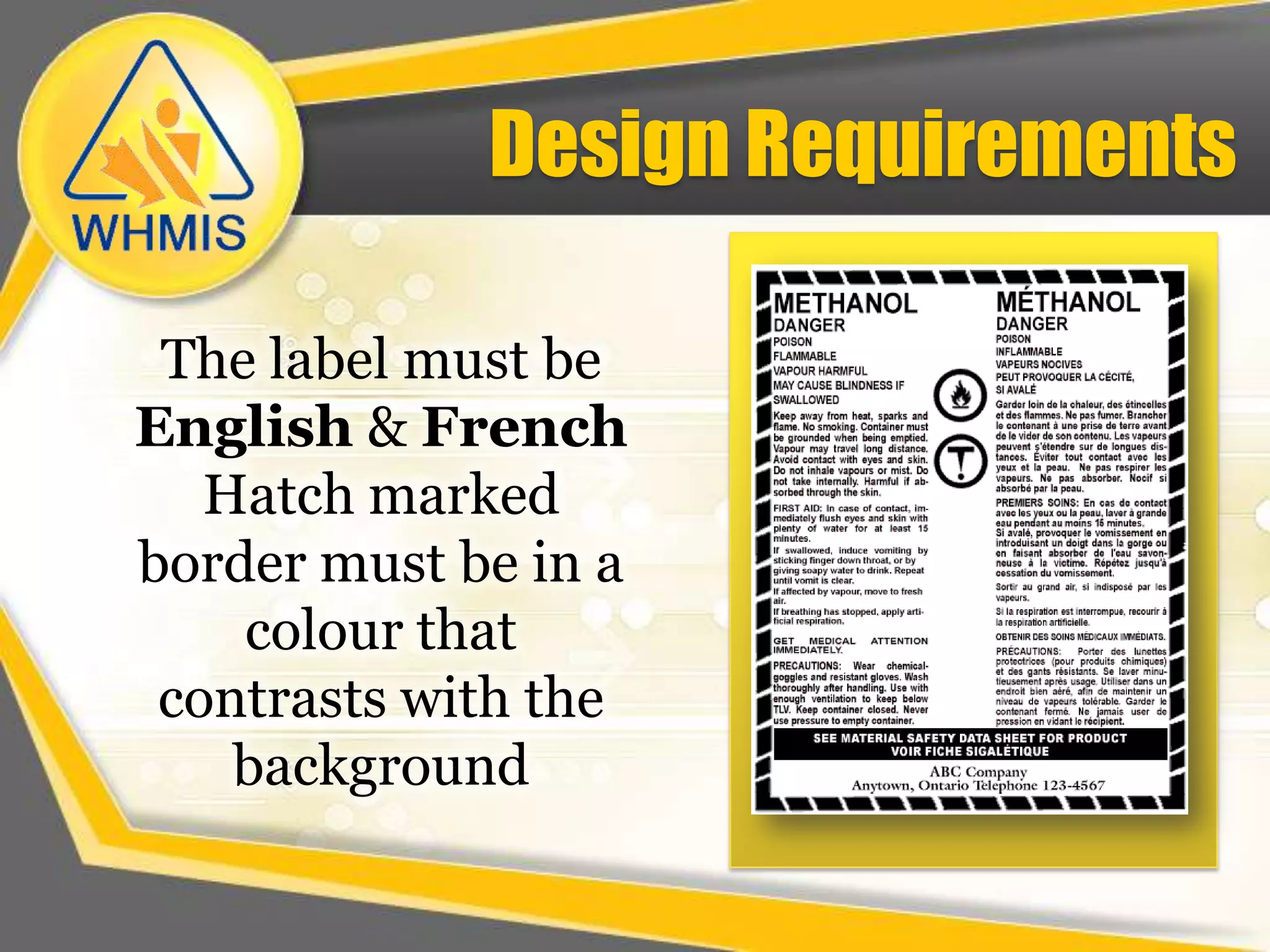

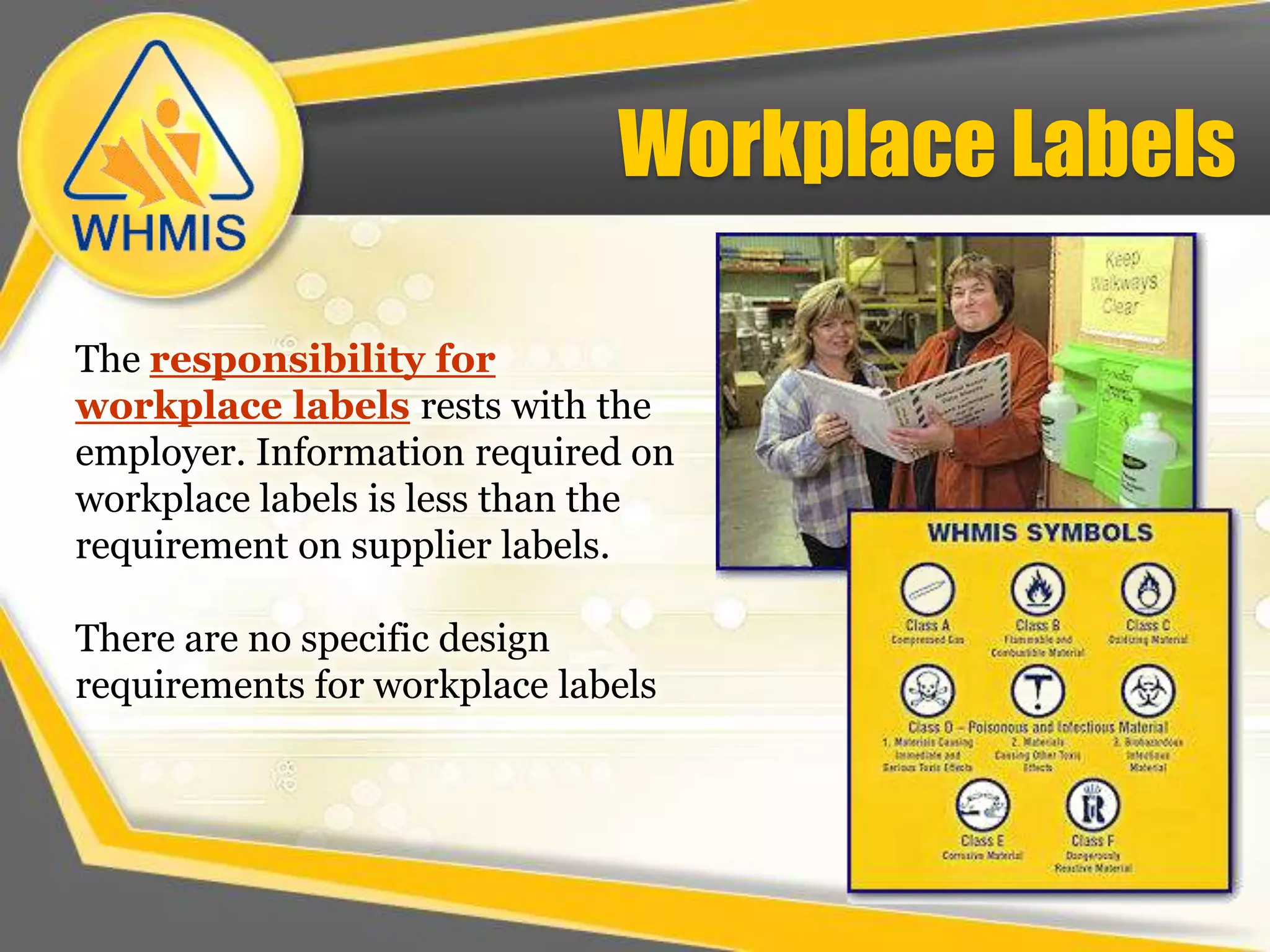

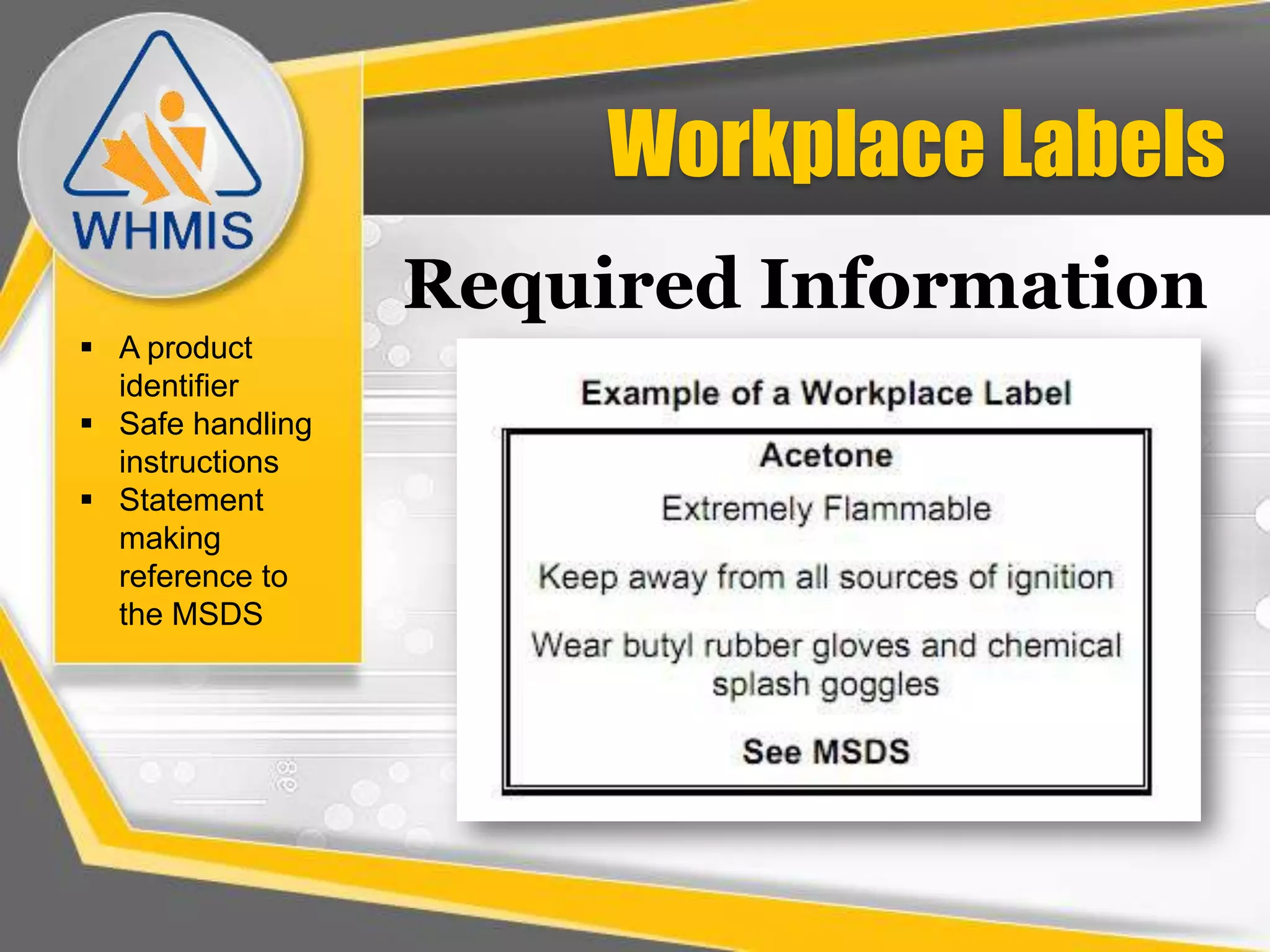

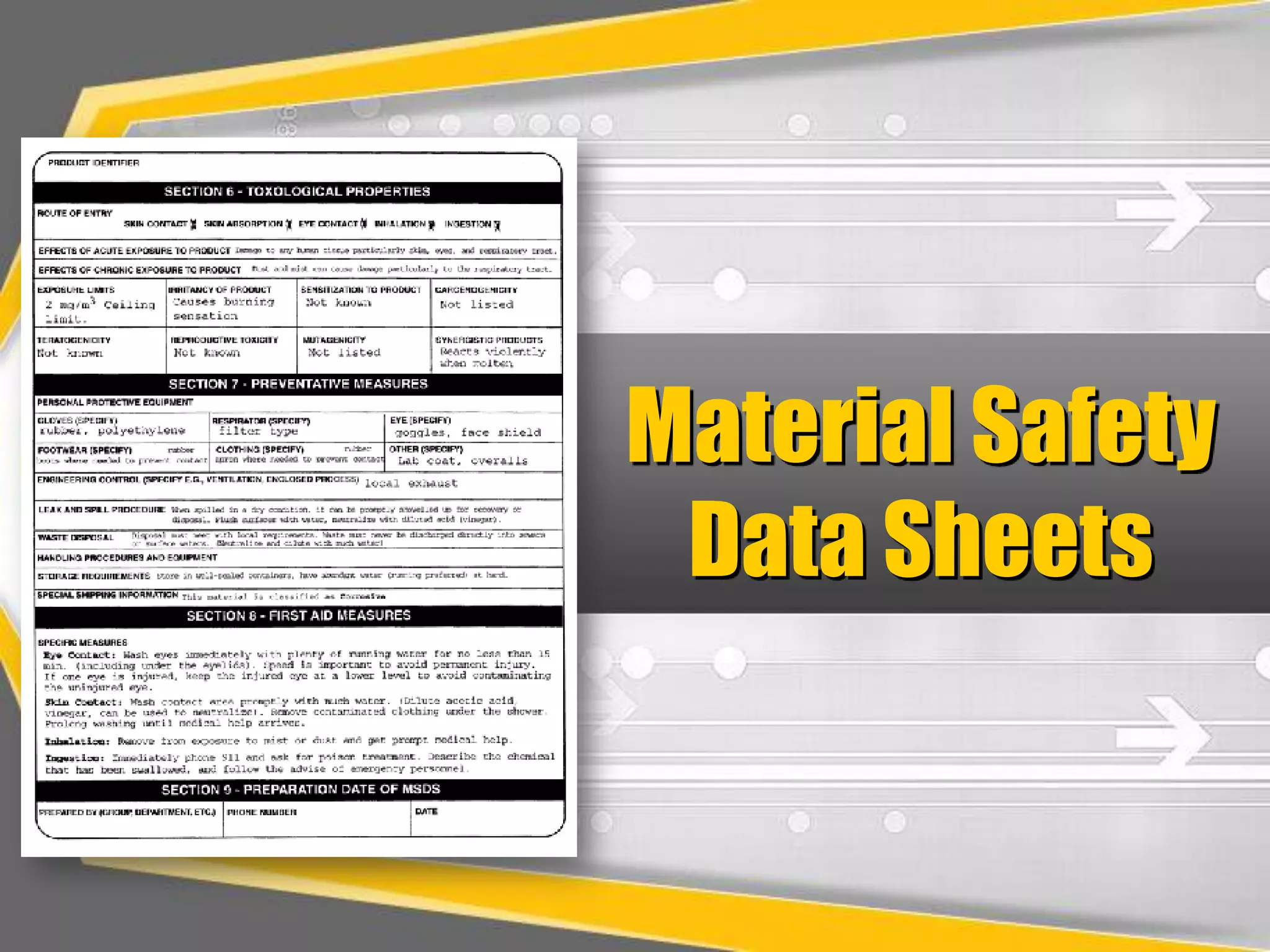

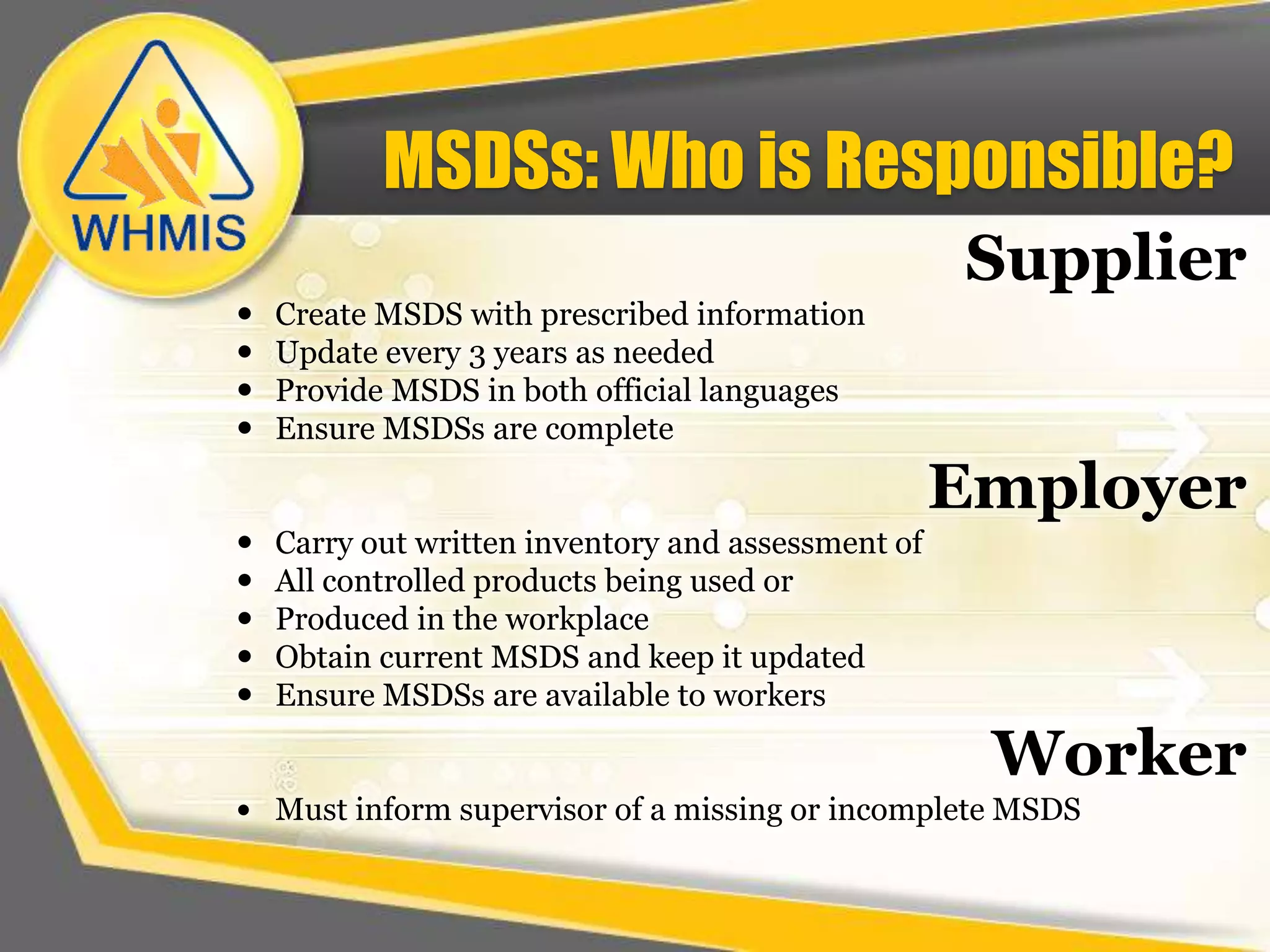

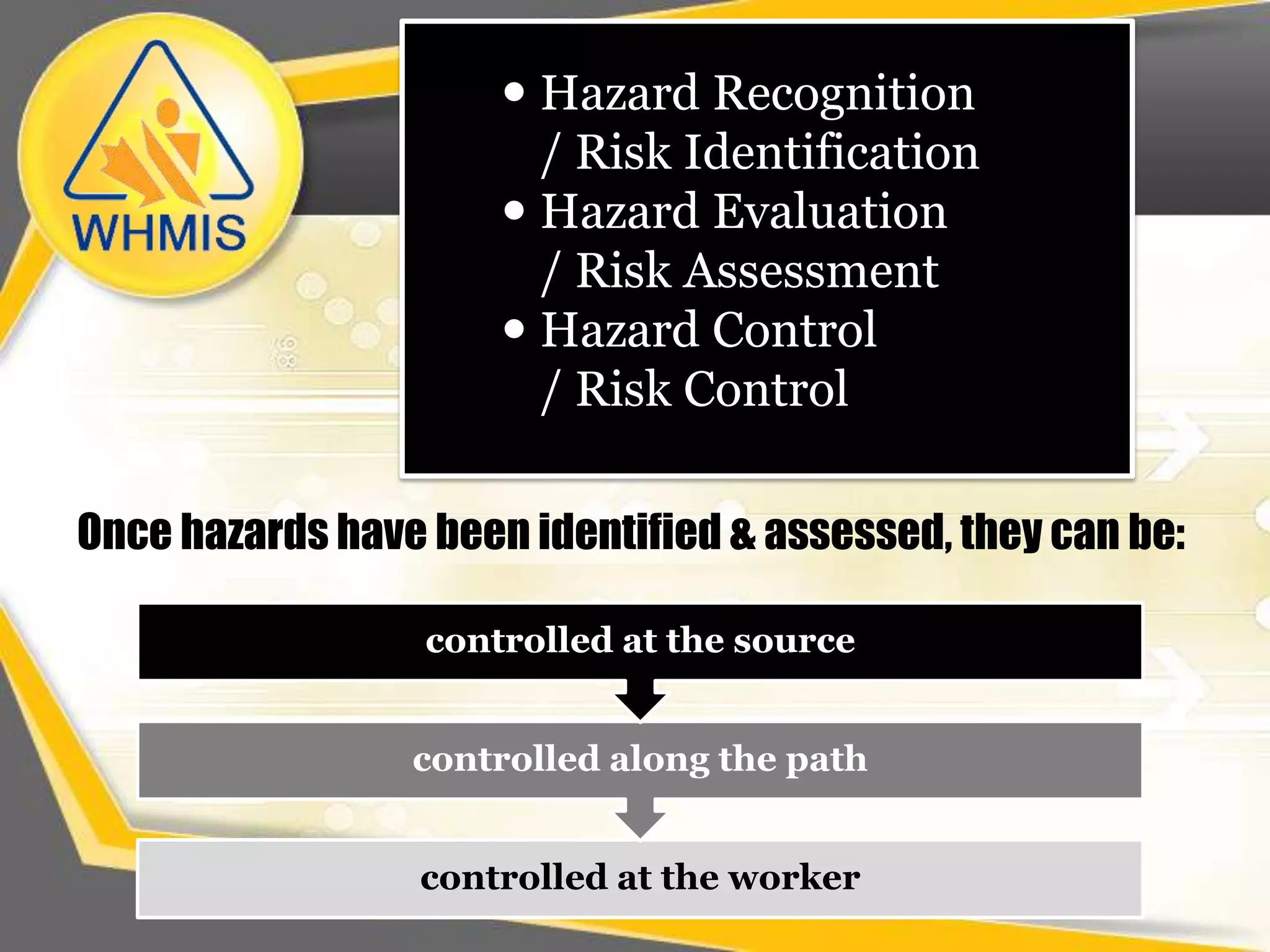

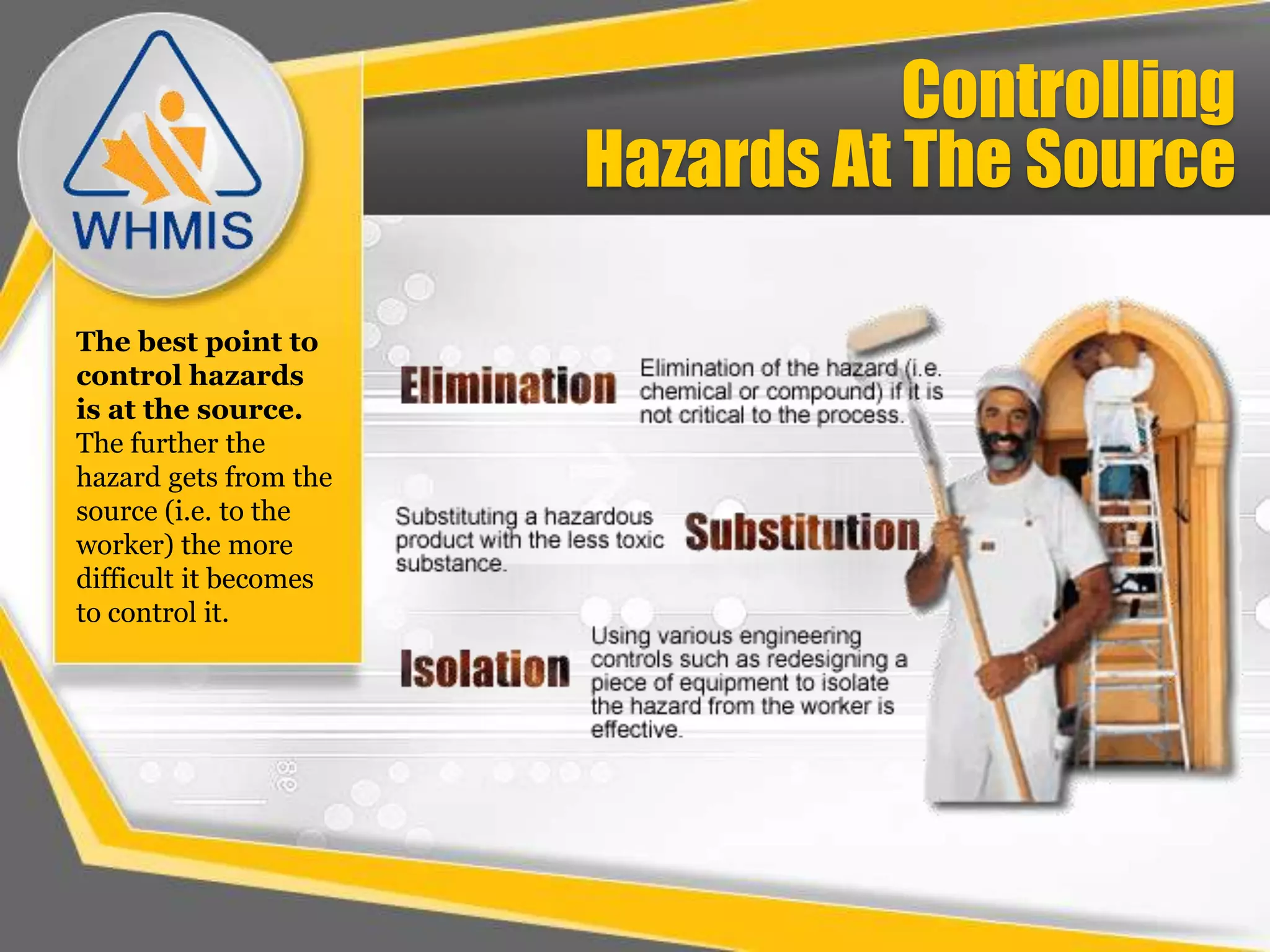

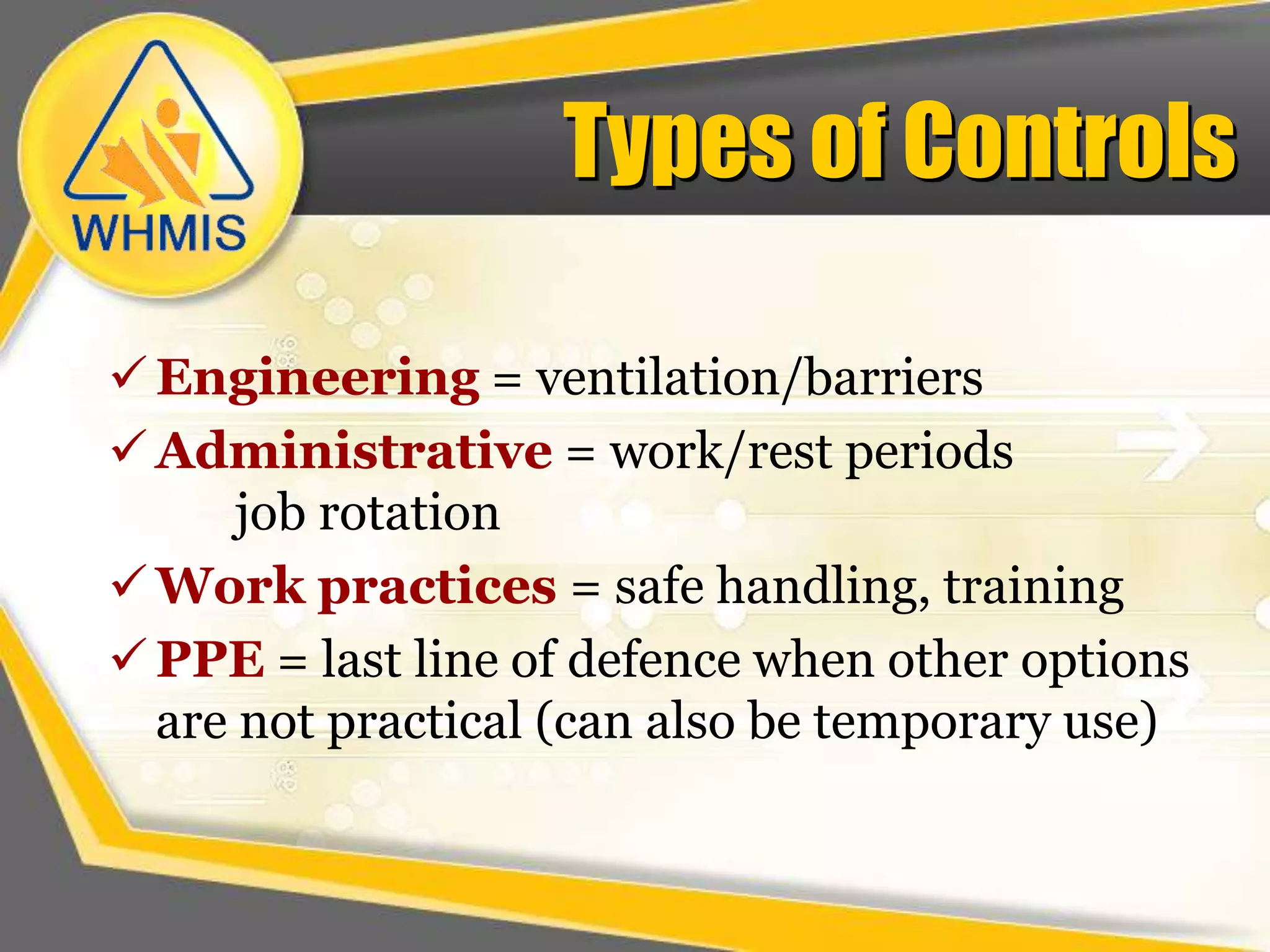

This presentation provides an overview of WHMIS (Workplace Hazardous Materials Information System) for technology and dual-credit students. WHMIS is a nationwide system that provides information on hazardous materials in the workplace. It involves both federal and provincial legislation to balance workers' right to know with industry confidentiality. The key elements of WHMIS are labels, material safety data sheets, and worker training. Hazardous materials can enter the body through inhalation, absorption, injection, or ingestion and can have acute or chronic health effects.