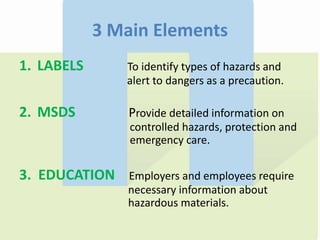

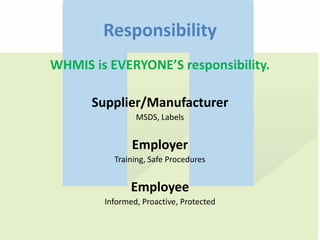

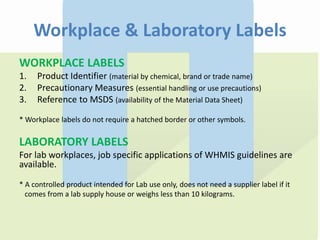

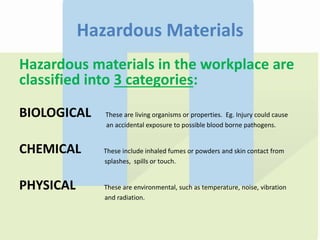

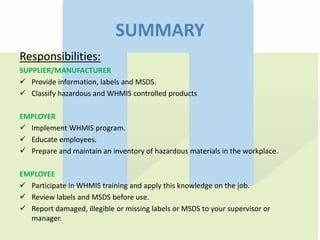

WHMIS is a national program that provides information about hazardous materials used in Canadian workplaces. It requires suppliers to label products and provide material safety data sheets, and requires employers to train employees. The goal of WHMIS is to reduce workplace injuries and deaths by ensuring employees have access to hazard information. All parties - suppliers, employers, and employees - share responsibility for compliance to create a safe working environment.