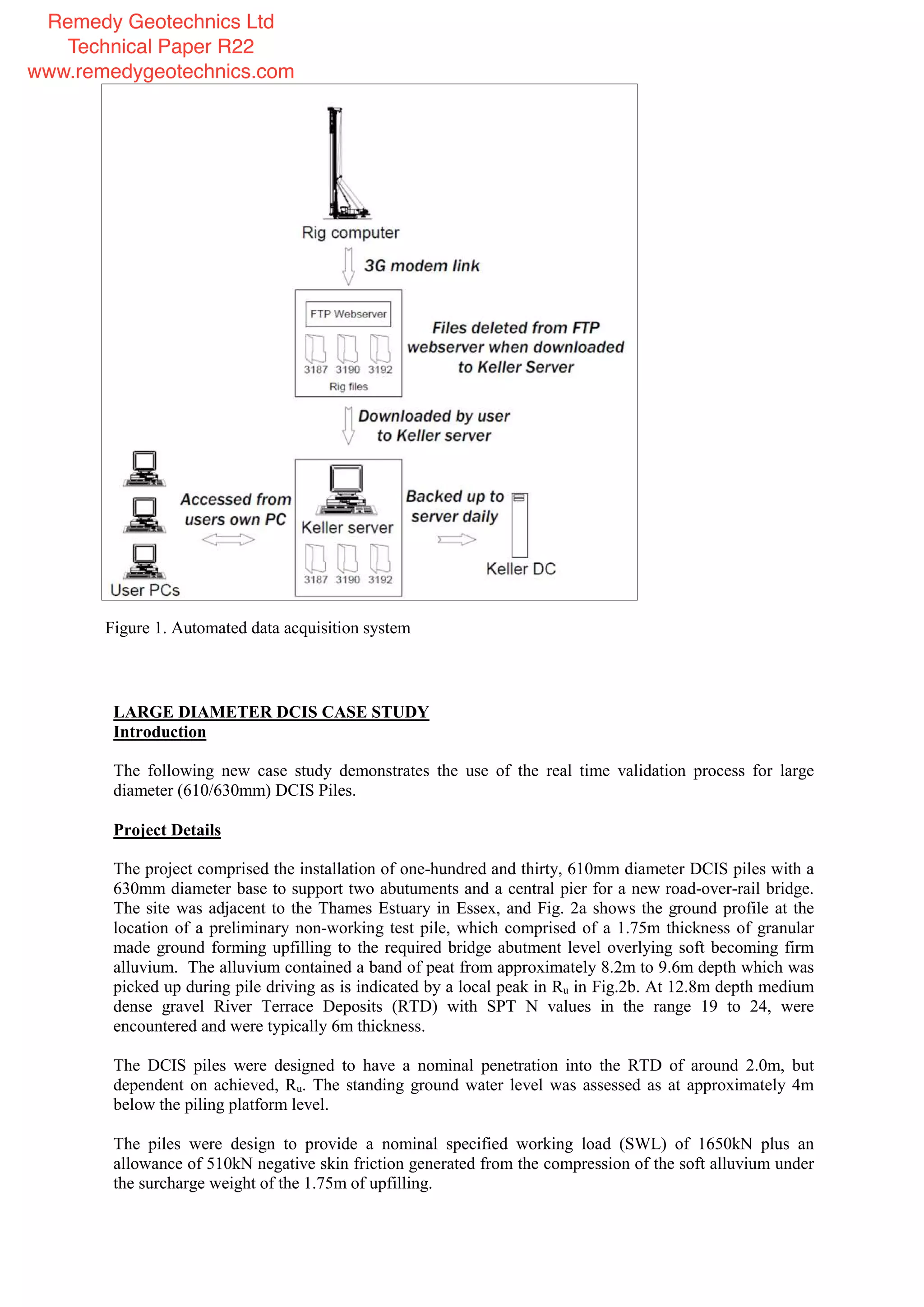

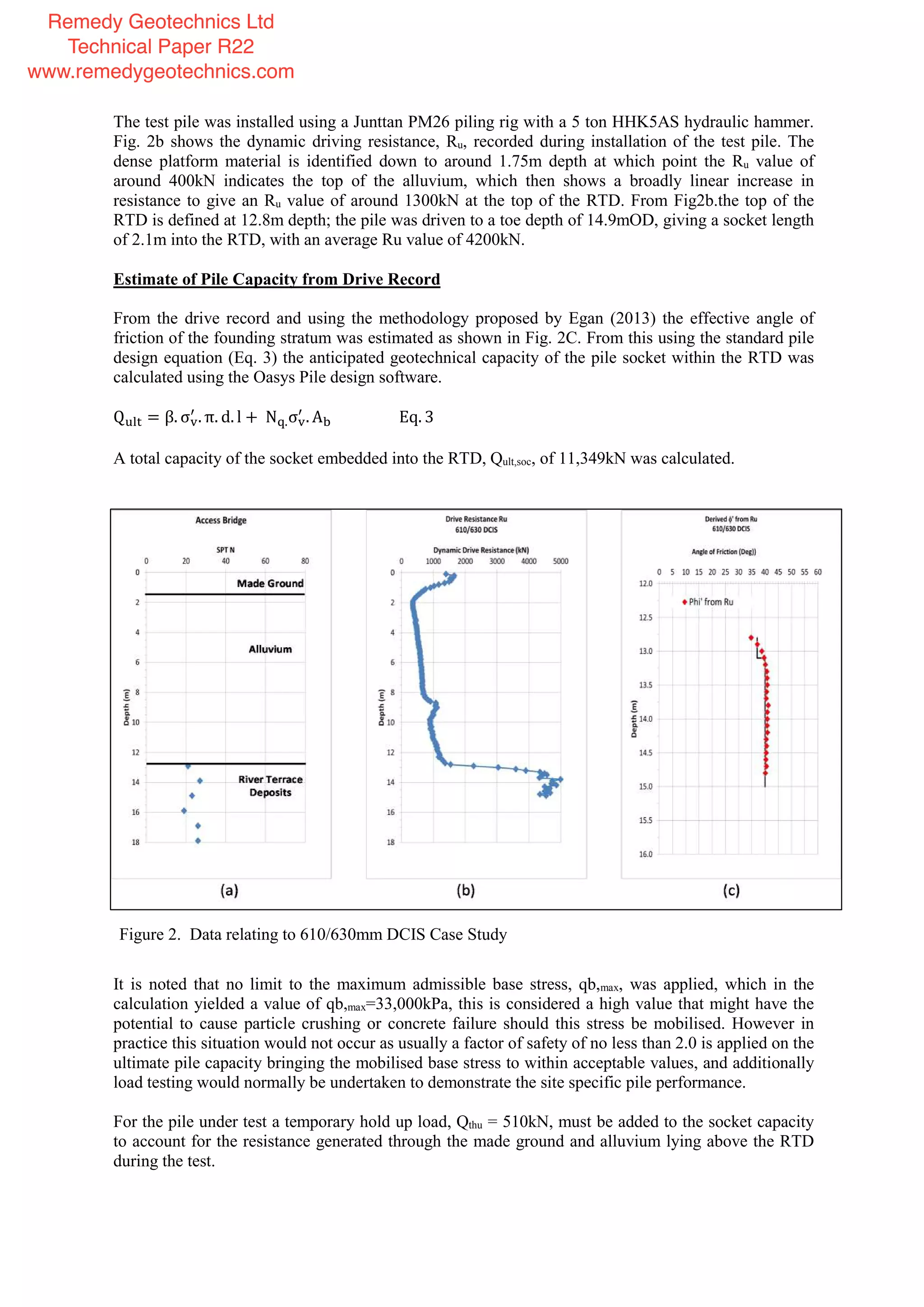

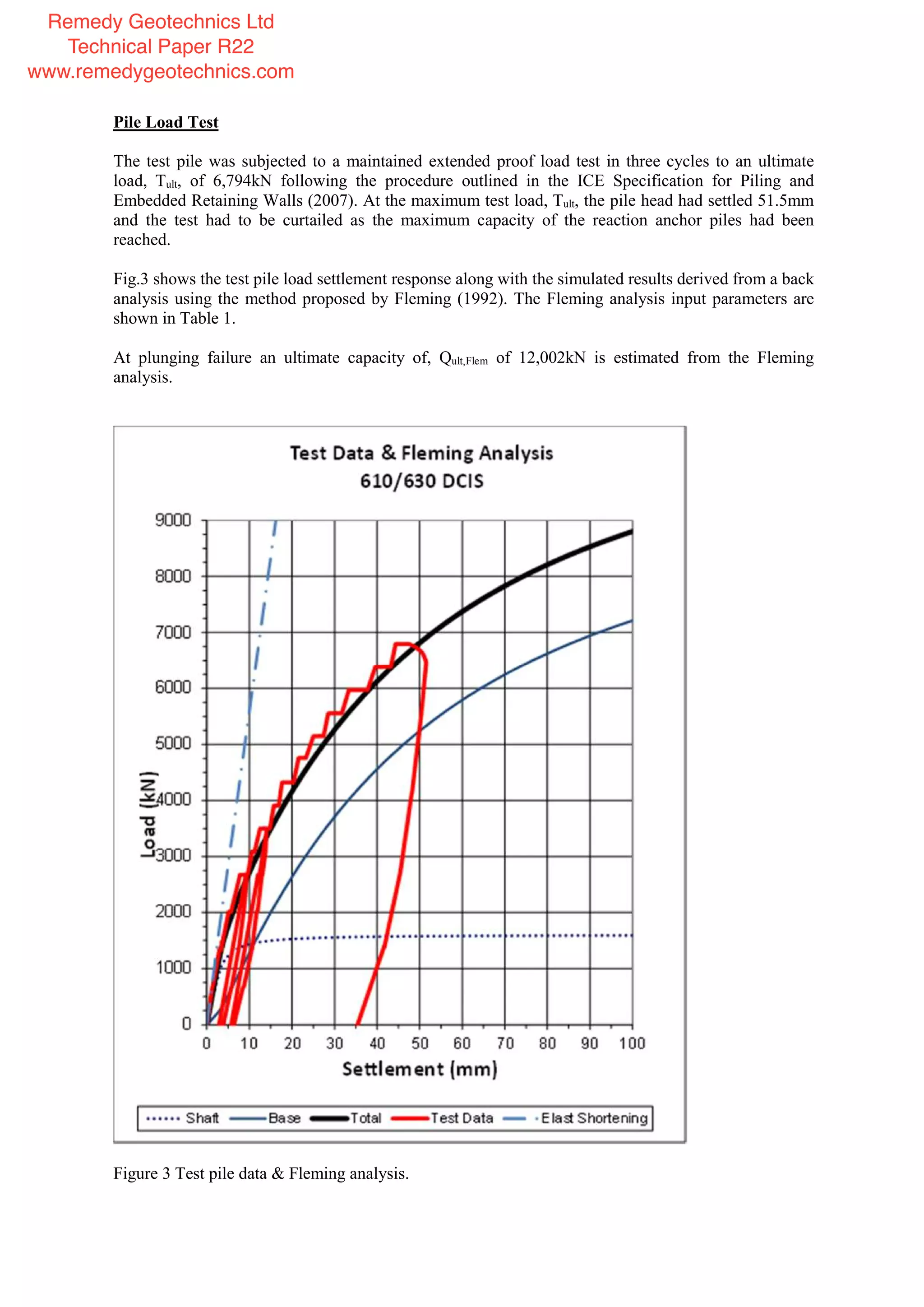

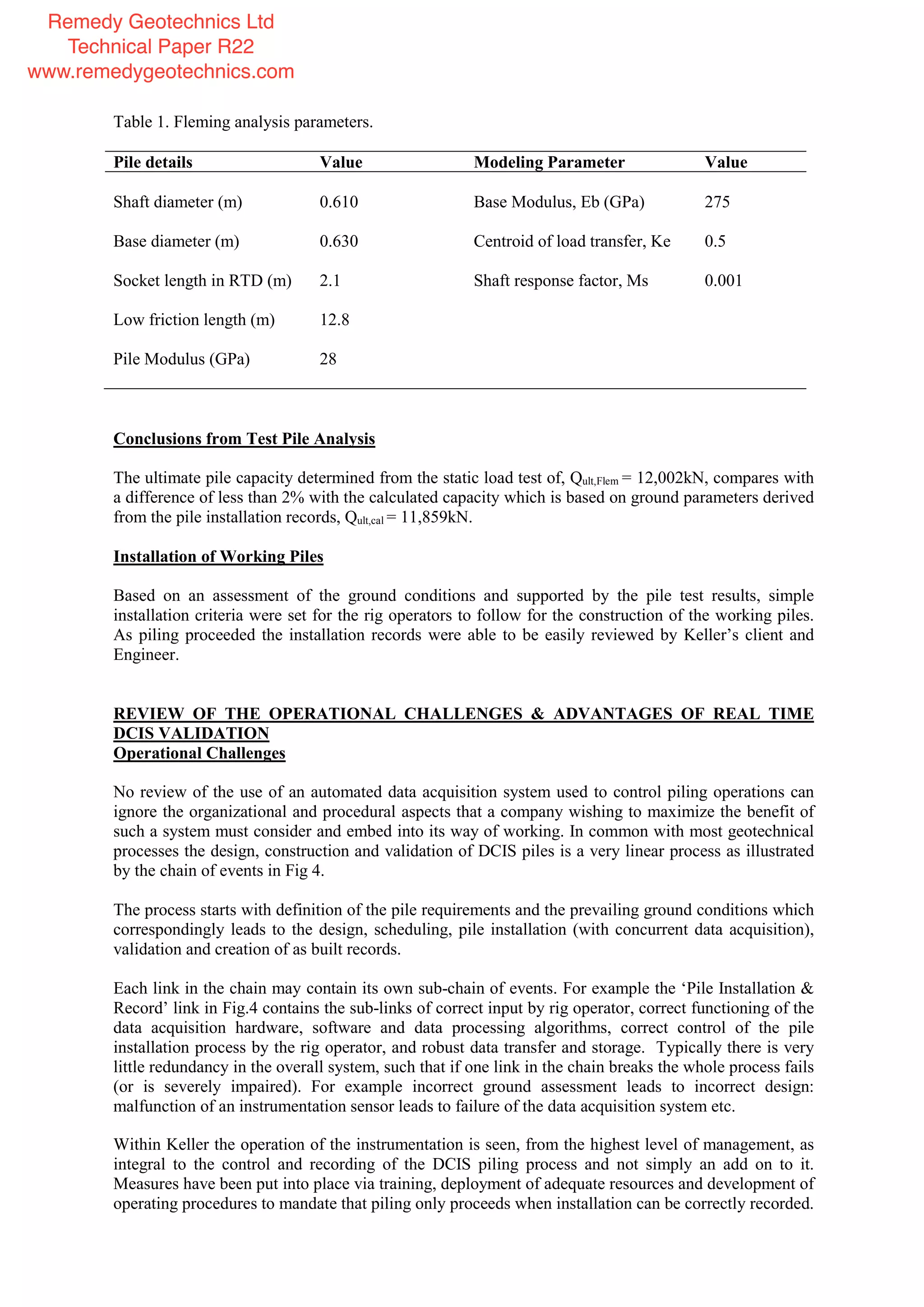

This document summarizes the development and operation of a real-time monitoring system for validating driven cast in-situ (DCIS) pile installation. Key parameters such as length, hammer blows, and resistance are recorded during installation. The data is processed to calculate dynamic drive resistance (Ru) and predict pile performance. The system allows engineers to view installation data in real-time. A case study demonstrates how installation data validated the performance of large diameter DCIS piles used to support a new bridge.