What is parting lock?

•

0 likes•99 views

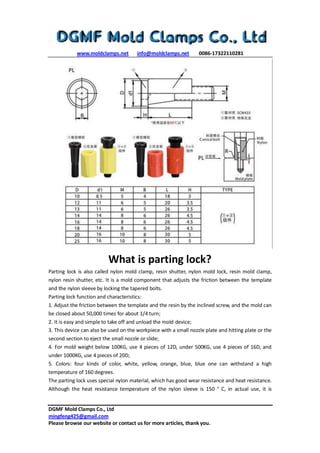

What is parting lock? Parting lock is also called nylon mold clamp, resin shutter, nylon mold lock, resin mold clamp, nylon resin shutter, etc. It is a mold component that adjusts the friction between the template and the nylon sleeve by locking the tapered bolts.

Report

Share

Report

Share

Download to read offline

Recommended

Perfect binding

It is not always easy to perform adhesive binding on soft cover brochures - and it is frequently a cause of complaint.

The problem is that the first and last pages are often not held effectively in place in the spine glue when they are opened. What's more, the top edge of the glue film can be seen around the notch − which is not a very pretty sight. The reasons behind this problem are many and varied - from the physical properties of the paper and glue themselves to incorrect material combinations or operating errors. But so, too, are the solutions. The most important of these are described below.

Specification for grinding and polishing of mold surface of injection mold -d...

This document provides specifications for grinding and polishing mold surfaces for injection molds. It discusses preparation such as tool and material selection, workpiece protection, and inspection requirements. It also covers clamping techniques, polishing procedures like cleaning between steps and determining the process, precautions to avoid going over allowances, and uses of an ultrasonic polishing machine including for removing layers and finishing. Self-inspection and protection of the polished surface is emphasized.

Application Guidelines Ruregold Carbon Fiber Mesh c 84.84

Installation guidelines for Cement Based Carbon Fiber for Masonry with Class A Fire Rating, Breathability and ease of application.

Brittle coating methods

Stress analysis by using brittle coating on the base element.

Experimental stress analysis techniques are used.

Brittle coating and test

This document discusses brittle coat testing, which uses brittle coatings to locate stressed areas and strain directions on products. It describes three main types of coatings - resin-based, ceramic-based, and tensile lacquer. Resin-based coatings like Stress Coat use zinc and carbon disulfide and can withstand temperatures up to 600°C. Ceramic-based coatings like All Temp suspend ceramic particles in solvent and can withstand up to 370°C after melting the particles. Tensile lacquer has high sensitivity below 1000°C. The document outlines the application process and explains that cracking patterns are marked and analyzed after loading to determine stress levels.

Coarse hammer mill 3

The Coarse Hammer Mill is used widely in industries like cement, construction, metallurgy, mining, and chemicals for secondary and fine crushing of rocks with compressive strengths under 320 MPa. It has high capacity and crushing ratio, simple structure, uniform output size, and low energy use, making it easy to operate and maintain. The moisture content of raw materials for the mill should be under 15% to prevent blocking during crushing.

Data of ceramic wear linings and lab

As a professional factory in China, we are manufacturing and exporting the below products since 1997.

1.92%,95%,T95%,99% Alumina ceramic tiles

2.ZTA(Zirconia Toughened Alumina) tiles/brick/block

3.Ceramic Rubber and Rubber-steel impact resistant linings

4.380/466/1000mm Cyclone for mining&mineral processing

5.Ceramic wearing compound for reparing

6.PU liner and PU products

Real life mask

China MS mask company, latex mask manufacturers

we custom made realistic latex mask, silicone mask, scary clown mask, hallowee mask, President donald trump mask, masquerade masks, animal masks, old man masks, old women masks, party mask etc, manufacturer directly. custom halloween masks

Welcome to visit our website to know more about how to do your mask.

Website: www.facemaskmanufacturers.com

2PVC soft board: thickness: 1-10mm maximum width: 1.3m The product is soft and wear-resistant, acid, alkali, corrosion resistant, good tear resistance, good solderability. Widely used in chemical, electroplating, lining of electrolytic cell , insulating mats, etc.

3 environmentally friendly PVC sheet, thickness: 1-20mm, specific gravity: 1.42-1.56 Color: light gray, white, etc. Features: high surface brightness, non-toxic, suitable for export quality requirements. PS (polystyrene) sheet, commonly known as plexiglass sheet or acrylic sheet. It has excellent tensile properties and has the characteristics of electrical conductivity, antistatic performance, non-toxicity and good impact resistance. It is widely used in the deep processing of plastic products in the electronics industry, advertising signs, decoration, handicrafts and other fields. .

Recommended

Perfect binding

It is not always easy to perform adhesive binding on soft cover brochures - and it is frequently a cause of complaint.

The problem is that the first and last pages are often not held effectively in place in the spine glue when they are opened. What's more, the top edge of the glue film can be seen around the notch − which is not a very pretty sight. The reasons behind this problem are many and varied - from the physical properties of the paper and glue themselves to incorrect material combinations or operating errors. But so, too, are the solutions. The most important of these are described below.

Specification for grinding and polishing of mold surface of injection mold -d...

This document provides specifications for grinding and polishing mold surfaces for injection molds. It discusses preparation such as tool and material selection, workpiece protection, and inspection requirements. It also covers clamping techniques, polishing procedures like cleaning between steps and determining the process, precautions to avoid going over allowances, and uses of an ultrasonic polishing machine including for removing layers and finishing. Self-inspection and protection of the polished surface is emphasized.

Application Guidelines Ruregold Carbon Fiber Mesh c 84.84

Installation guidelines for Cement Based Carbon Fiber for Masonry with Class A Fire Rating, Breathability and ease of application.

Brittle coating methods

Stress analysis by using brittle coating on the base element.

Experimental stress analysis techniques are used.

Brittle coating and test

This document discusses brittle coat testing, which uses brittle coatings to locate stressed areas and strain directions on products. It describes three main types of coatings - resin-based, ceramic-based, and tensile lacquer. Resin-based coatings like Stress Coat use zinc and carbon disulfide and can withstand temperatures up to 600°C. Ceramic-based coatings like All Temp suspend ceramic particles in solvent and can withstand up to 370°C after melting the particles. Tensile lacquer has high sensitivity below 1000°C. The document outlines the application process and explains that cracking patterns are marked and analyzed after loading to determine stress levels.

Coarse hammer mill 3

The Coarse Hammer Mill is used widely in industries like cement, construction, metallurgy, mining, and chemicals for secondary and fine crushing of rocks with compressive strengths under 320 MPa. It has high capacity and crushing ratio, simple structure, uniform output size, and low energy use, making it easy to operate and maintain. The moisture content of raw materials for the mill should be under 15% to prevent blocking during crushing.

Data of ceramic wear linings and lab

As a professional factory in China, we are manufacturing and exporting the below products since 1997.

1.92%,95%,T95%,99% Alumina ceramic tiles

2.ZTA(Zirconia Toughened Alumina) tiles/brick/block

3.Ceramic Rubber and Rubber-steel impact resistant linings

4.380/466/1000mm Cyclone for mining&mineral processing

5.Ceramic wearing compound for reparing

6.PU liner and PU products

Real life mask

China MS mask company, latex mask manufacturers

we custom made realistic latex mask, silicone mask, scary clown mask, hallowee mask, President donald trump mask, masquerade masks, animal masks, old man masks, old women masks, party mask etc, manufacturer directly. custom halloween masks

Welcome to visit our website to know more about how to do your mask.

Website: www.facemaskmanufacturers.com

2PVC soft board: thickness: 1-10mm maximum width: 1.3m The product is soft and wear-resistant, acid, alkali, corrosion resistant, good tear resistance, good solderability. Widely used in chemical, electroplating, lining of electrolytic cell , insulating mats, etc.

3 environmentally friendly PVC sheet, thickness: 1-20mm, specific gravity: 1.42-1.56 Color: light gray, white, etc. Features: high surface brightness, non-toxic, suitable for export quality requirements. PS (polystyrene) sheet, commonly known as plexiglass sheet or acrylic sheet. It has excellent tensile properties and has the characteristics of electrical conductivity, antistatic performance, non-toxicity and good impact resistance. It is widely used in the deep processing of plastic products in the electronics industry, advertising signs, decoration, handicrafts and other fields. .

Plaster mould technique

Plaster mould casting is a metalworking process that uses plaster of paris moulds instead of sand. The plaster is mixed with additives to improve its strength and permeability. The process involves spraying a pattern with parting compound, pouring plaster around it, baking the mould to remove water, and then pouring molten metal into the mould cavity. It produces parts with good surface finish and accuracy, and can be used to cast small and complex non-ferrous metal parts.

Lecture3

The AJM process involves removing material from a workpiece using abrasive particles carried by a high-velocity gas stream. The abrasive particles impact the workpiece surface at high velocities, causing brittle fractures and removing small fragments of material. AJM can machine hard and brittle materials and reach difficult internal areas due to the flexible hose used to direct the abrasive stream. It generates less heat than conventional machining and does not require direct tool-workpiece contact. Common applications include cutting glass and ceramics, deburring metal parts, and cleaning or dressing grinding wheels.

Soil lab (Aggregates Testing)

This document provides information on various tests conducted on pavement materials, including aggregate crushing value, impact value, elongation and flakiness index, Los Angeles abrasion, soundness, and sand equivalent tests. It describes the testing procedures and specifications for each test. The aggregate crushing value test indicates an aggregate's ability to resist crushing, with lower values indicating stronger aggregates. The impact value test evaluates an aggregate's resistance to impact loads from traffic. Specifications are provided for what values indicate strong, satisfactory, or weak aggregates for different tests.

Hot Melt Decorative Glass

This document provides product specifications for nine items of super clear hot melt glass. The glass items have thicknesses between 8-12mm, minimum sizes of 100x100mm, maximum customizable sizes of 1830x2440mm or 2440x3660mm, minimum orders of 1sqm, and can all be tempered. The document also provides contact information for Shenzhen Hong Jia Glass Product Co., Ltd and an introduction to hot melt glass, which is made by putting sheet glass and inorganic colorants into a melting furnace and compression molding it using a forming block.

ROAD AGGREGATES 01

This document provides information on pavement materials, specifically road aggregates. It discusses aggregate characterization, including maximum aggregate size, gradation, and other properties like toughness, specific gravity, particle shape, durability, and cleanliness. It describes methods for determining aggregate size distributions and developing target gradations. Graphs and equations for 0.45 power gradations are presented. The document also covers testing methods for aggregate properties like crushing value, impact value, Los Angeles abrasion, and soundness. It provides guidance on blending aggregate stockpiles to achieve design gradations.

Proceso de Trefilado en Materiales Metálicos

This document provides information about the metal forming process of wire drawing. It begins with an introduction discussing how wire drawing has progressed from an art to a science. It then defines wire drawing and describes different types. Key parameters that control the process are discussed, including lubrication, heat generation, speed, and geometric parameters. The document also examines changes to the microstructure and properties that result from wire drawing, as well as common post-drawing treatments. Examples of wire drawing calculations are provided. In summary, the document provides a comprehensive overview of the wire drawing process, its types, controlling parameters, effects, and example calculations.

Finishing Room Management

Finishing room management involves 15 key steps to prepare garments for shipment. Goods received from sewing are heat sealed if needed, then undergo thread sucking, ironing, quality checks. They are tagged, folded, checked for metals, sized on hangers. Garments are poly packed, cartooned, and receive final inspection before shipment. Finishing plays a vital role by providing the final touches, improving quality and defects, and making garments durable and attractive for consumers.

Coining process by satyam diwedi

Coining is a cold working process that uses high pressure to plastically deform a workpiece between a punch and die to conform to their shapes. The metal flows under compressive forces to take on the impressions of the completely closed dies. Coining provides a finer, more detailed surface finish than other metal forming processes and work hardens the surface. It is commonly used for minting coins and medallions, making jewelry, badges, buttons, springs, and complex electronic and precision parts that require close tolerances and smooth polished surfaces.

Flashless forging

Flashless forging is a type of precision forging where the work material is completely surrounded by the die cavity during compression, allowing no flash to form. It involves designing dies without flash areas to minimize material waste. Key parameters include billet volume, preform weight/shape, and tool/workpiece temperatures. Forces required are calculated based on flow stress and projected area. Flashless forging provides advantages like lower material usage, better dimensional accuracy, and surface finish compared to conventional forging, though it requires more complex dies and tooling. Common applications include gears, connecting rods, pistons, and aerospace/defense components.

780104

This document describes a press member for garment pressing machines. It consists of gritty particles secured to a rigid backing member. The gritty particles are resistant to crushing, heat and moisture and have sharp edges. This creates an irregularly roughened pressing surface that eliminates wrinkles and creates sharp creases without imparting shine or moire patterns to fabrics. The gritty particles form a layer between the fabric and backing member to prevent any patterns on the backing from being transferred.

780104

This document describes a press member for garment pressing machines. It consists of gritty particles secured to a rigid backing member. The gritty particles are resistant to crushing, heat and moisture and have sharp edges. This creates an irregularly roughened pressing surface that eliminates wrinkles and creates sharp creases without imparting shine or moire patterns to fabrics. The gritty particles form a layer between the fabric and backing member to prevent any patterns on the backing from being transferred.

Abrasive jet machining

Abrasive jet machining (AJM) is a metal removal process invented in 1967 that uses a high-velocity jet of abrasive particles carried by an inert gas to erode material from a workpiece. Key factors that influence the machining include the abrasive material, carrier gas, nozzle characteristics, and workpiece material. AJM is effective for hard, brittle materials like ceramics and glass but less so for soft materials like aluminum. It can produce intricate shapes and details and cut fragile materials without risk of breaking. However, it has low material removal rates and machining accuracy.

Honing, Lapping & Electroplating

Honing is an abrasive machining process that produces a precision surface on a metal work piece by scrubbing an abrasive stone against it along a controlled path.

Honing is primarily used to improve the geometric form of a surface, but may also improve the surface texture.

Continuous drawing die -dgmf mold clamps co., ltd

There are many types of products in the mold industry, of which the stretch mold is one of the higher technical content. The reason why the drawing mold is difficult is that 1, the calculation of the design, and the test work 2 after the mold design is completed.

Shivam pandey ppt on ajm

Abrasive jet machining involves a high velocity stream of gas or water mixed with abrasive particles being directed at a material to remove it. The process uses a mixing chamber to combine the abrasive particles like aluminum oxide or silicon carbide that are 10-50 micrometers in size with a gas like nitrogen or air. This mixture is then passed through a small tungsten carbide nozzle at speeds of 150-300 meters per second to machine the material.

Abrasive Jet Machining

This document presents information on abrasive jet machining (AJM). It discusses the working principle of AJM, which involves a focused stream of abrasive particles carried by compressed air or gas impacting the work surface through a nozzle to remove material by erosion. The key components of an AJM system are identified as the pump, control system, mixing chamber, and nozzle. Applications of AJM include micro-machining of brittle objects, deburring, cutting of optical fibers, and machining of lenses. Advantages include the ability to machine intricate shapes in hard materials without contact or heat, while disadvantages include lower accuracy and material removal rates compared to other machining methods.

Metallography and microscopy

This document provides an overview of microstructural analysis and the specimen preparation process. Microstructural analysis is used for quality control, failure analysis, and research studies to understand the relationship between processing, structure, and properties of materials. The specimen preparation process includes sectioning, mounting, grinding, polishing, and etching samples to reveal the microstructure for analysis. Etching involves chemically attacking the surface to provide contrast between grains and grain boundaries under an optical microscope. Microstructural analysis provides information about the structure of materials.

Metallographic sample prepartion

The slide contains basic sample preparation procedures for examining under optical microscope, SEM etc

PLAIN AND REINFORCED CONRETE (LAB MANUAL)

This manual contains all the fundamental experiments performed on "PLAIN AND REINFORCED CONcRETE" in the field and laboratory

specimen preparation for microscopic observation

This document provides instructions for preparing a metal specimen for microscopic examination. The key steps are:

1. Mounting the specimen to facilitate handling during preparation. Thermosetting resins like bakelite or diallyl phthalate are commonly used.

2. Grinding the specimen using progressively finer grit papers or belts to create a flat, scratch-free surface. This includes coarse, fine, and polishing stages.

3. Polishing the specimen by hand or machine to achieve a mirror-like finish, using compounds with particles down to 1 micron in size.

4. Etching the polished surface with chemical or electrolytic methods to reveal microstructural details like grain boundaries otherwise not visible

Common faults of injection mold

Injection mold is a tool for producing plastic products; it is also a tool for giving plastic products a complete structure and precise dimensions. The structure of the injection mold and the quality of mold processing directly affects the quality and production efficiency of plastic parts. The most common and most common causes of injection mold failures and troubleshooting methods in the production of injection molds and plastic products are described in detail as follows:

Demolding angle and product wall thickness design

This document provides guidelines for designing the demolding angle and wall thickness of injection molded plastic parts. It recommends a demolding angle between 0.5-1 degrees generally, but notes it may need to be larger for parts with thicker walls, larger sizes, higher shrinkage plastics, or detailed surface textures. It also stresses the importance of having a uniform, gradually changing wall thickness between 1-5mm to avoid molding issues and stresses having a minimum thickness of 0.4mm.

More Related Content

What's hot

Plaster mould technique

Plaster mould casting is a metalworking process that uses plaster of paris moulds instead of sand. The plaster is mixed with additives to improve its strength and permeability. The process involves spraying a pattern with parting compound, pouring plaster around it, baking the mould to remove water, and then pouring molten metal into the mould cavity. It produces parts with good surface finish and accuracy, and can be used to cast small and complex non-ferrous metal parts.

Lecture3

The AJM process involves removing material from a workpiece using abrasive particles carried by a high-velocity gas stream. The abrasive particles impact the workpiece surface at high velocities, causing brittle fractures and removing small fragments of material. AJM can machine hard and brittle materials and reach difficult internal areas due to the flexible hose used to direct the abrasive stream. It generates less heat than conventional machining and does not require direct tool-workpiece contact. Common applications include cutting glass and ceramics, deburring metal parts, and cleaning or dressing grinding wheels.

Soil lab (Aggregates Testing)

This document provides information on various tests conducted on pavement materials, including aggregate crushing value, impact value, elongation and flakiness index, Los Angeles abrasion, soundness, and sand equivalent tests. It describes the testing procedures and specifications for each test. The aggregate crushing value test indicates an aggregate's ability to resist crushing, with lower values indicating stronger aggregates. The impact value test evaluates an aggregate's resistance to impact loads from traffic. Specifications are provided for what values indicate strong, satisfactory, or weak aggregates for different tests.

Hot Melt Decorative Glass

This document provides product specifications for nine items of super clear hot melt glass. The glass items have thicknesses between 8-12mm, minimum sizes of 100x100mm, maximum customizable sizes of 1830x2440mm or 2440x3660mm, minimum orders of 1sqm, and can all be tempered. The document also provides contact information for Shenzhen Hong Jia Glass Product Co., Ltd and an introduction to hot melt glass, which is made by putting sheet glass and inorganic colorants into a melting furnace and compression molding it using a forming block.

ROAD AGGREGATES 01

This document provides information on pavement materials, specifically road aggregates. It discusses aggregate characterization, including maximum aggregate size, gradation, and other properties like toughness, specific gravity, particle shape, durability, and cleanliness. It describes methods for determining aggregate size distributions and developing target gradations. Graphs and equations for 0.45 power gradations are presented. The document also covers testing methods for aggregate properties like crushing value, impact value, Los Angeles abrasion, and soundness. It provides guidance on blending aggregate stockpiles to achieve design gradations.

Proceso de Trefilado en Materiales Metálicos

This document provides information about the metal forming process of wire drawing. It begins with an introduction discussing how wire drawing has progressed from an art to a science. It then defines wire drawing and describes different types. Key parameters that control the process are discussed, including lubrication, heat generation, speed, and geometric parameters. The document also examines changes to the microstructure and properties that result from wire drawing, as well as common post-drawing treatments. Examples of wire drawing calculations are provided. In summary, the document provides a comprehensive overview of the wire drawing process, its types, controlling parameters, effects, and example calculations.

Finishing Room Management

Finishing room management involves 15 key steps to prepare garments for shipment. Goods received from sewing are heat sealed if needed, then undergo thread sucking, ironing, quality checks. They are tagged, folded, checked for metals, sized on hangers. Garments are poly packed, cartooned, and receive final inspection before shipment. Finishing plays a vital role by providing the final touches, improving quality and defects, and making garments durable and attractive for consumers.

Coining process by satyam diwedi

Coining is a cold working process that uses high pressure to plastically deform a workpiece between a punch and die to conform to their shapes. The metal flows under compressive forces to take on the impressions of the completely closed dies. Coining provides a finer, more detailed surface finish than other metal forming processes and work hardens the surface. It is commonly used for minting coins and medallions, making jewelry, badges, buttons, springs, and complex electronic and precision parts that require close tolerances and smooth polished surfaces.

Flashless forging

Flashless forging is a type of precision forging where the work material is completely surrounded by the die cavity during compression, allowing no flash to form. It involves designing dies without flash areas to minimize material waste. Key parameters include billet volume, preform weight/shape, and tool/workpiece temperatures. Forces required are calculated based on flow stress and projected area. Flashless forging provides advantages like lower material usage, better dimensional accuracy, and surface finish compared to conventional forging, though it requires more complex dies and tooling. Common applications include gears, connecting rods, pistons, and aerospace/defense components.

780104

This document describes a press member for garment pressing machines. It consists of gritty particles secured to a rigid backing member. The gritty particles are resistant to crushing, heat and moisture and have sharp edges. This creates an irregularly roughened pressing surface that eliminates wrinkles and creates sharp creases without imparting shine or moire patterns to fabrics. The gritty particles form a layer between the fabric and backing member to prevent any patterns on the backing from being transferred.

780104

This document describes a press member for garment pressing machines. It consists of gritty particles secured to a rigid backing member. The gritty particles are resistant to crushing, heat and moisture and have sharp edges. This creates an irregularly roughened pressing surface that eliminates wrinkles and creates sharp creases without imparting shine or moire patterns to fabrics. The gritty particles form a layer between the fabric and backing member to prevent any patterns on the backing from being transferred.

Abrasive jet machining

Abrasive jet machining (AJM) is a metal removal process invented in 1967 that uses a high-velocity jet of abrasive particles carried by an inert gas to erode material from a workpiece. Key factors that influence the machining include the abrasive material, carrier gas, nozzle characteristics, and workpiece material. AJM is effective for hard, brittle materials like ceramics and glass but less so for soft materials like aluminum. It can produce intricate shapes and details and cut fragile materials without risk of breaking. However, it has low material removal rates and machining accuracy.

Honing, Lapping & Electroplating

Honing is an abrasive machining process that produces a precision surface on a metal work piece by scrubbing an abrasive stone against it along a controlled path.

Honing is primarily used to improve the geometric form of a surface, but may also improve the surface texture.

Continuous drawing die -dgmf mold clamps co., ltd

There are many types of products in the mold industry, of which the stretch mold is one of the higher technical content. The reason why the drawing mold is difficult is that 1, the calculation of the design, and the test work 2 after the mold design is completed.

Shivam pandey ppt on ajm

Abrasive jet machining involves a high velocity stream of gas or water mixed with abrasive particles being directed at a material to remove it. The process uses a mixing chamber to combine the abrasive particles like aluminum oxide or silicon carbide that are 10-50 micrometers in size with a gas like nitrogen or air. This mixture is then passed through a small tungsten carbide nozzle at speeds of 150-300 meters per second to machine the material.

Abrasive Jet Machining

This document presents information on abrasive jet machining (AJM). It discusses the working principle of AJM, which involves a focused stream of abrasive particles carried by compressed air or gas impacting the work surface through a nozzle to remove material by erosion. The key components of an AJM system are identified as the pump, control system, mixing chamber, and nozzle. Applications of AJM include micro-machining of brittle objects, deburring, cutting of optical fibers, and machining of lenses. Advantages include the ability to machine intricate shapes in hard materials without contact or heat, while disadvantages include lower accuracy and material removal rates compared to other machining methods.

Metallography and microscopy

This document provides an overview of microstructural analysis and the specimen preparation process. Microstructural analysis is used for quality control, failure analysis, and research studies to understand the relationship between processing, structure, and properties of materials. The specimen preparation process includes sectioning, mounting, grinding, polishing, and etching samples to reveal the microstructure for analysis. Etching involves chemically attacking the surface to provide contrast between grains and grain boundaries under an optical microscope. Microstructural analysis provides information about the structure of materials.

Metallographic sample prepartion

The slide contains basic sample preparation procedures for examining under optical microscope, SEM etc

PLAIN AND REINFORCED CONRETE (LAB MANUAL)

This manual contains all the fundamental experiments performed on "PLAIN AND REINFORCED CONcRETE" in the field and laboratory

specimen preparation for microscopic observation

This document provides instructions for preparing a metal specimen for microscopic examination. The key steps are:

1. Mounting the specimen to facilitate handling during preparation. Thermosetting resins like bakelite or diallyl phthalate are commonly used.

2. Grinding the specimen using progressively finer grit papers or belts to create a flat, scratch-free surface. This includes coarse, fine, and polishing stages.

3. Polishing the specimen by hand or machine to achieve a mirror-like finish, using compounds with particles down to 1 micron in size.

4. Etching the polished surface with chemical or electrolytic methods to reveal microstructural details like grain boundaries otherwise not visible

What's hot (20)

Similar to What is parting lock?

Common faults of injection mold

Injection mold is a tool for producing plastic products; it is also a tool for giving plastic products a complete structure and precise dimensions. The structure of the injection mold and the quality of mold processing directly affects the quality and production efficiency of plastic parts. The most common and most common causes of injection mold failures and troubleshooting methods in the production of injection molds and plastic products are described in detail as follows:

Demolding angle and product wall thickness design

This document provides guidelines for designing the demolding angle and wall thickness of injection molded plastic parts. It recommends a demolding angle between 0.5-1 degrees generally, but notes it may need to be larger for parts with thicker walls, larger sizes, higher shrinkage plastics, or detailed surface textures. It also stresses the importance of having a uniform, gradually changing wall thickness between 1-5mm to avoid molding issues and stresses having a minimum thickness of 0.4mm.

15 mold common problem solutions -dgmf mold clamps co., ltd

This document provides information about DGMF Mold Clamps Co., Ltd and discusses 15 common molding problems and their solutions. It addresses issues such as punch wear, hopping waste, scratches, missing punches, abnormal discharge, bent edges that are not straight, thin extrusions on curved surfaces, and concave parts that are not flat. Solutions include adjusting mold gaps, lubricating molds, sharpening cutting edges, modifying guide structures, and controlling stamping speed and pressure. The document aims to help users identify and resolve molding issues.

8 tips to troubleshoot injection mold failures -dgmf mold clamps co., ltd

1. The document provides 8 tips for troubleshooting injection mold failures, including issues like guide column damage, difficult gates to discharge, movement and fixed mold offset, bending of moving templates, bent or missing jacks, poor cooling or water leakage, guide grooves that are too short, and failed fixed distance tensioning mechanisms.

2. Common causes of failures include poor finishing of tapered gate holes, use of low strength materials, misalignment of moving and fixed molds, insufficient thickness of moving templates, clearance issues with ejector pins, inadequate mold cooling design, guide grooves that are too short, and loss of synchronization in tensioning mechanisms.

3. Recommendations to address the failures include adding strong

What is mold clamp?

Mold clamp tools definition

What is mold clamp? The mold clamp (also called mould clamp) is a kind of auxiliary clamping unit often used in injection mold processing, its main function is to keep the machined parts not shaking not moving in the processing.

The most complete stamping die information -by dg mf mold components co., ltd

Stamping dies, also known as metal molds, are used to shape metal or non-metal plates by applying pressure. They consist of an upper and lower die assembled from various inserts and standard parts. Stamping die numbers provide information about the die, such as the year produced and whether it is for continuous or single production. Common materials used in stamping include various grades of steel, copper, brass, and aluminum sheets or strips. The material selected must meet requirements for the part's use and stamping process, such as formability and surface quality.

18 basic injection molding technologies

The document discusses 18 basic injection molding technologies that injection molding technicians must understand. It covers topics such as nozzles, filters, screws, temperatures, cooling, and more. Proper understanding and application of these technologies is important for producing quality injection molded parts and ensuring safety during the injection molding process. Maintaining appropriate temperatures, speeds, and residence times is key to avoiding decomposition of plastics.

4 points for injection molds installation

This document discusses four points for proper injection mold installation: 1) preparation before installation including confirming cooling channels and screw depth, 2) hanging the mold level to ensure cavity alignment, 3) screwing the mold clamping screws diagonally and waiting for the mold to reach temperature before final tightening, and 4) using attachments like templates and insulation plates to ensure mold flatness and parallelism which affects product quality.

Influence of injection molding process on product quality -dgmf mold clamps c...

During the molding process of converting plastic particles into plastic products, plastics are often subjected to high temperature and high pressure and flow molding at high shear rates. Different molding conditions and processes will have different effects on product quality. Plastic injection molding has plastics. Raw materials, injection molding machines, molds and injection molding processes are composed of four aspects.

Specification for grinding and polishing of mold surface of injection mold -d...

This document provides specifications for grinding and polishing mold surfaces for injection molds. It details several important steps in the preparation and polishing process, including checking for defects, selecting proper tools, and protecting the workpiece. Specific guidelines are given for clamping and protecting different types of workpieces. The document also outlines the content and scope of self-inspections, precautions for polishing operations, and the uses of an ultrasonic polishing machine.

Waterstops

Hengshui Jingtong Rubber Co., Ltd. specializes in manufacturing and exporting waterstop products since the establishment in 1983. Adhering to the principle that quality determines the success and failures. Our company pays much attention to quality managements and today we are one of the leading companies owning customers in many countries.

Waterstop products including PVC, TPV, HDPE and rubber waterstops

Two main ranges of products including waterstop series and strip waterstop series are supplied by our company. Waterstop series includes the products of PVC waterstop, HDPE waterstop, TPV & TPER waterstop, rubber waterstop, steel-edge waterstop as well reinforced waterstop. Meanwhile, strips waterstops contain PZ waterstop, butyl waterstop and mastic waterstops. Additionally, as your request, waterstops can be made of other materials such as EPDM and silicone, etc.

To suit your specific scheme, waterstops can be made to order as your designs, even with complex profiles and different materials. So if you want to make a custom order, don't forget to enclose your design drawing, sizes and standards.

Jingtong also can give you some professional advice about how to install the waterstops you purchased. If you have some questions, please feel free to contact us directly via sales@jointwaterstop.com.

How to solve the profile problem of injection molded parts -dgmf mold clamps ...

Generally speaking, automotive series components, and some parts with sealing requirements, usually put forward the concept of contour size requirements.

NIC-MfrsGuide-Ebook2

This document provides guidance on plastic injection molding for manufacturers. It discusses 5 tips for issue-free injection molding including consistent wall thickness, proper gate location, optimal wall thickness, avoiding sharp corners, and adding sufficient draft. It also examines different plastic materials and their properties and moldability characteristics. Finally, it provides two case studies on how plastic injection molding companies can help optimize part designs.

Summary of stamping die skills -dgmf mold clamps co., ltd

The document provides information on stamping die skills and reasons for mold burst. It discusses the main points of continuous mold maintenance including maintenance of convex and concave dies, stripper plates, and guide parts. It also discusses the main reasons for mold burst, including issues with mold material, heat treatment, grinding, design process, wire cutting process, equipment selection, and stamping process. Maintaining molds properly and addressing design and manufacturing flaws can help prevent early mold failure and bursting.

.3mm CSP and LFCSP Reliability

This document summarizes the manufacturability and reliability challenges of implementing 0.3mm pitch chip scale packages (CSPs) and quad flat no-lead packages (QFNs). Key challenges include fine trace widths and spacing on PCBs, smaller stencil apertures and solder pastes, increased thermal cycling fatigue from higher die ratios, and potential for electrochemical migration due to trapped fluxes under packages. Success will require leveraging lessons from other technologies like wafer bumping and applying best practices for profiles, cleanliness and inspection to understand interconnect robustness.

Basic requirements for plastic injection molded part design

Plastic Part Design Basic Requirements

Unreasonable design of plastic injection molded parts often results in some inherent defects in the product. For example, the structure of the parts is unreasonable, the parts use too much material, etc. Here are a series of basic requirements for plastic injection molded parts design for reference.

What is a mold clamp used for?

The mold clamping is an area where the processor (mold setter) has significant influence over the cost of the molding parts.

Solder Paste Screen Printing

The document discusses improving the quality of SMT solder paste printing processes using Six Sigma methodology. It describes how the DMAIC process was used to identify key printing parameters, conduct experiments to understand their impact, and optimize the process. Testing found the average paste thickness increased from 137.95μm to 144.98μm while reducing variation. Process capability improved from 1.16 to 3.16 indicating a significant quality enhancement.

W2 Standard Adjustable Crimping Tool

The W2 Standard Adjustable Crimping Tool, has virtually limitless application within the specified wire range of 12AWG (3.33mm2) through 26AWG (0.128mm2). Over a thousand turret heads are available to adapt the tool frame to your specific military or proprietary contact/wire combination. The 8 impression crimp, which is standard in the W2, assures absolute maximum tensile strength with almost every closed barrel contact. Special indent configurations and gaging are available upon request.

What is cold forging?

The cold forging, cold extrusion, and cold heading are general terms for plastic processing. Cold forging, also called cold volume forming, is a manufacturing process and a processing method. Cold forging is the forming process below the recrystallization temperature of the material, and the forging performed below the recovery temperature.

Similar to What is parting lock? (20)

15 mold common problem solutions -dgmf mold clamps co., ltd

15 mold common problem solutions -dgmf mold clamps co., ltd

8 tips to troubleshoot injection mold failures -dgmf mold clamps co., ltd

8 tips to troubleshoot injection mold failures -dgmf mold clamps co., ltd

The most complete stamping die information -by dg mf mold components co., ltd

The most complete stamping die information -by dg mf mold components co., ltd

Influence of injection molding process on product quality -dgmf mold clamps c...

Influence of injection molding process on product quality -dgmf mold clamps c...

Specification for grinding and polishing of mold surface of injection mold -d...

Specification for grinding and polishing of mold surface of injection mold -d...

How to solve the profile problem of injection molded parts -dgmf mold clamps ...

How to solve the profile problem of injection molded parts -dgmf mold clamps ...

Summary of stamping die skills -dgmf mold clamps co., ltd

Summary of stamping die skills -dgmf mold clamps co., ltd

Basic requirements for plastic injection molded part design

Basic requirements for plastic injection molded part design

More from JasmineHL

What determines high performance plastics

The following six factors determine the high-performance plastics.

(1) The type of polymer determines high-performance plastics

The performance is also different because of the different polymer links, such as acetal resin (POM) impact strength, then the unsaturated polyester resin (UP) is more excellent. Even if the same material, structure, and polymerization degree are different, the performance varies significantly.

What is mold temperature in injection molding?

The mold temperature in injection molding is probably the most important temperature in terms of quality and this affects quality in many ways. The mold temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mold cavity after it has stabilized.

Progressive stamping die

What is progressive stamping die?

Progressive stamping is a metalworking method that can encompass punching, coining, bending, and several other ways of modifying metal raw material, combined with an automatic feeding system. The feeding system pushes a strip of metal through all of the stations of a progressive stamping die.

The progressive stamping die refers to a cold stamping die that uses a strip of stamping raw material to complete multiple stamping processes simultaneously with several different stations on one die in one stamping stroke, and the material strip moves at a fixed distance once for each stamping stroke until the product is finished.

How to design injection molding product?

Reasonable product design and mold design are key technologies that affect the success of injection molding. This article introduces some basic principles of injection molded product design and mold design.

1. The basic conditions of plastic product design

1.1. Record the product usage conditions as detailed as possible.

These conditions are:

A. Use environment

Outdoor conditions (sunlight, rain, ice, snow, dust), sunlight (ultraviolet rays, radiation, etc.), contact with gas (corrosive gas, water vapor), contact with liquid (water, detergent, oil, medicine, etc.), other (plasticizers), copper);

B. Use intensity

Common temperature, maximum temperature, minimum temperature (usually, special circumstances, outdoor, warehouse, window, car, etc.), repeated cold and hot

C. Use load

Common load, maximum load (normal, special circumstances. Static, dynamic, repeated, continuous, impact, drop, etc.).

The name and function of mold components

This document introduces 60 types of mold components used in stamping dies, plastic molds, or automation equipment exclusively for the mold industry. It begins by explaining that mold components refer to the general name of metal accessories used. It then provides brief 1-2 sentence descriptions of 5 components: sprue bushing, position locating ring, guide pin, angle pin, and sleeve pin. The document aims to provide an overview of the various components that make up molds.

How to remove mold dents?

1. Causes of dents

1.1 The thickness of each part of the product is different

1.2 Insufficient pressure inside the mold

1.3 Insufficient mold cooling

1.4 Deformation due to the insufficient cooling time

Precautions for injection mold maintenance

Injection mold, as the most important production tool of injection molding factory, determines the shape, specification, size and appearance finish of the product. The material of the mold is steel, which is generally composed of a front mold and a back mold.

What are the key points of precision injection molding

Precision injection molding is affected by many related factors and environmental conditions, and the most basic are the four basic factors of plastic materials, injection molds, injection molding processes, and injection molding equipment.

In the early stage of designing plastic products, engineering plastics with corresponding performance requirements should be selected according to the application environment.

Secondly, the appropriate injection molding machine should be selected according to the selected plastic material, finished product dimensional accuracy, part weight, quality requirements, and expected mold structure.

Five elements of injection molding process parameters

The injection molding process is one of the four major plastic molding processes. The barrels, basins, toys, and other daily products we use in our lives are all formed by the injection molding process. So what are the important factors to pay attention to in the plastic injection molding process?

The completion of the injection molding process generally requires six processes of clamping, filling, holding pressure, cooling, demolding, and opening the mold. In these six processes, we must remember these five elements, namely pressure, speed, position, temperature, and time.

14 FAQ in the field of mold manufacturing

This article answers some common questions in the field of mold manufacturing in the form of questions and answers.

What is the 4 process of plastic injection molding?

The plastic injection molding process mainly includes four stages: filling, holding pressure, cooling, and demolding. These four stages directly determine the molding quality of the product, and these four stages are a complete continuous process.

10 plastic injection molding methods

Plastic products are made of a mixture of synthetic resin and various additives as raw materials, using injection, extrusion, pressing, pouring, and other methods. While plastic products are being molded, they also obtain the final performance, so plastic molding is a key production process.

The following are 10 common plastic Injection molding methods.

How to solve flow lines in injection molded products?

This document discusses different types of flow lines that can occur in injection molded products and methods to solve them. The four main types of flow lines are: 1) Snake lines from unstable jet flow, 2) Wave lines from inconsistent melt flow speeds, 3) Radial lines from melt fracture, and 4) Fluorescent lines from molecular orientation. Solutions include optimizing process parameters like injection speed and pressure, increasing mold/melt temperatures, changing gate and cavity designs, extending runners, and applying post-molding heat treatments.

How to deal with sink marks on the surface of injection molded products

Uneven product wall thickness causes uneven surface shrinkage and sinks marks.How to deal with sink marks on the surface of injection molded products?

Secrets of injection molding process adjustment

The close relationship between injection speed and product quality makes it a key parameter of injection molding. By determining the start, middle, and end of the filling speed segment, And to achieve a smooth transition from one set point to another set point, a stable melt surface speed can be ensured to produce the desired molecule and the smallest internal stress.

What is the difference between blow molding and injection molding

What Is The Difference Between Blow Molding And Injection Molding?

First, the process is different

Blow molding: Blow molding uses gas pressure to inflate the hot parison closed in the mold into a hollow product, or the tube parison is inflated into a tube film without a mold.

Injection molding: injection molding is to melt plastic materials, and then inject them into the film cavity to form.

What is blow molding

Blow molding is a manufacturing process for forming and joining together hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding.

What is the inclined top mold?

The inclined top mold is also known as the inclined tip. It is the mechanism used to mold the internal barbs of the product in the mold design. It is suitable for relatively simple barbs.

How to design injection mold air vent?

Appropriate opening of the injection mold air vent can greatly reduce the injection molding pressure, injection molding time, holding time, and injection mold clamping pressure, making the plastic parts from difficult to easy, thereby improving production efficiency, reducing production costs, and reducing the energy consumption of the machine.

How complex molds are demolded dynamic pictures

Today we will share with you a wave of dynamic pictures of how complex molds are demolded, including rotary core pulling, complex slider mechanisms, complex inclined top mechanisms, and so on. These dynamic pictures can be said to be the essence of a set of molds. We recommend everyone to collect them. They can really help everyone to increase their knowledge.

More from JasmineHL (20)

What are the key points of precision injection molding

What are the key points of precision injection molding

Five elements of injection molding process parameters

Five elements of injection molding process parameters

What is the 4 process of plastic injection molding?

What is the 4 process of plastic injection molding?

How to solve flow lines in injection molded products?

How to solve flow lines in injection molded products?

How to deal with sink marks on the surface of injection molded products

How to deal with sink marks on the surface of injection molded products

What is the difference between blow molding and injection molding

What is the difference between blow molding and injection molding

Recently uploaded

Goodbye Windows 11: Make Way for Nitrux Linux 3.5.0!

As the digital landscape continually evolves, operating systems play a critical role in shaping user experiences and productivity. The launch of Nitrux Linux 3.5.0 marks a significant milestone, offering a robust alternative to traditional systems such as Windows 11. This article delves into the essence of Nitrux Linux 3.5.0, exploring its unique features, advantages, and how it stands as a compelling choice for both casual users and tech enthusiasts.

Alt. GDG Cloud Southlake #33: Boule & Rebala: Effective AppSec in SDLC using ...

Effective Application Security in Software Delivery lifecycle using Deployment Firewall and DBOM

The modern software delivery process (or the CI/CD process) includes many tools, distributed teams, open-source code, and cloud platforms. Constant focus on speed to release software to market, along with the traditional slow and manual security checks has caused gaps in continuous security as an important piece in the software supply chain. Today organizations feel more susceptible to external and internal cyber threats due to the vast attack surface in their applications supply chain and the lack of end-to-end governance and risk management.

The software team must secure its software delivery process to avoid vulnerability and security breaches. This needs to be achieved with existing tool chains and without extensive rework of the delivery processes. This talk will present strategies and techniques for providing visibility into the true risk of the existing vulnerabilities, preventing the introduction of security issues in the software, resolving vulnerabilities in production environments quickly, and capturing the deployment bill of materials (DBOM).

Speakers:

Bob Boule

Robert Boule is a technology enthusiast with PASSION for technology and making things work along with a knack for helping others understand how things work. He comes with around 20 years of solution engineering experience in application security, software continuous delivery, and SaaS platforms. He is known for his dynamic presentations in CI/CD and application security integrated in software delivery lifecycle.

Gopinath Rebala

Gopinath Rebala is the CTO of OpsMx, where he has overall responsibility for the machine learning and data processing architectures for Secure Software Delivery. Gopi also has a strong connection with our customers, leading design and architecture for strategic implementations. Gopi is a frequent speaker and well-known leader in continuous delivery and integrating security into software delivery.

Cosa hanno in comune un mattoncino Lego e la backdoor XZ?

ABSTRACT: A prima vista, un mattoncino Lego e la backdoor XZ potrebbero avere in comune il fatto di essere entrambi blocchi di costruzione, o dipendenze di progetti creativi e software. La realtà è che un mattoncino Lego e il caso della backdoor XZ hanno molto di più di tutto ciò in comune.

Partecipate alla presentazione per immergervi in una storia di interoperabilità, standard e formati aperti, per poi discutere del ruolo importante che i contributori hanno in una comunità open source sostenibile.

BIO: Sostenitrice del software libero e dei formati standard e aperti. È stata un membro attivo dei progetti Fedora e openSUSE e ha co-fondato l'Associazione LibreItalia dove è stata coinvolta in diversi eventi, migrazioni e formazione relativi a LibreOffice. In precedenza ha lavorato a migrazioni e corsi di formazione su LibreOffice per diverse amministrazioni pubbliche e privati. Da gennaio 2020 lavora in SUSE come Software Release Engineer per Uyuni e SUSE Manager e quando non segue la sua passione per i computer e per Geeko coltiva la sua curiosità per l'astronomia (da cui deriva il suo nickname deneb_alpha).

UiPath Test Automation using UiPath Test Suite series, part 6

Welcome to UiPath Test Automation using UiPath Test Suite series part 6. In this session, we will cover Test Automation with generative AI and Open AI.

UiPath Test Automation with generative AI and Open AI webinar offers an in-depth exploration of leveraging cutting-edge technologies for test automation within the UiPath platform. Attendees will delve into the integration of generative AI, a test automation solution, with Open AI advanced natural language processing capabilities.

Throughout the session, participants will discover how this synergy empowers testers to automate repetitive tasks, enhance testing accuracy, and expedite the software testing life cycle. Topics covered include the seamless integration process, practical use cases, and the benefits of harnessing AI-driven automation for UiPath testing initiatives. By attending this webinar, testers, and automation professionals can gain valuable insights into harnessing the power of AI to optimize their test automation workflows within the UiPath ecosystem, ultimately driving efficiency and quality in software development processes.

What will you get from this session?

1. Insights into integrating generative AI.

2. Understanding how this integration enhances test automation within the UiPath platform

3. Practical demonstrations

4. Exploration of real-world use cases illustrating the benefits of AI-driven test automation for UiPath

Topics covered:

What is generative AI

Test Automation with generative AI and Open AI.

UiPath integration with generative AI

Speaker:

Deepak Rai, Automation Practice Lead, Boundaryless Group and UiPath MVP

GraphSummit Singapore | Neo4j Product Vision & Roadmap - Q2 2024

Maruthi Prithivirajan, Head of ASEAN & IN Solution Architecture, Neo4j

Get an inside look at the latest Neo4j innovations that enable relationship-driven intelligence at scale. Learn more about the newest cloud integrations and product enhancements that make Neo4j an essential choice for developers building apps with interconnected data and generative AI.

Pushing the limits of ePRTC: 100ns holdover for 100 days

At WSTS 2024, Alon Stern explored the topic of parametric holdover and explained how recent research findings can be implemented in real-world PNT networks to achieve 100 nanoseconds of accuracy for up to 100 days.

Artificial Intelligence for XMLDevelopment

In the rapidly evolving landscape of technologies, XML continues to play a vital role in structuring, storing, and transporting data across diverse systems. The recent advancements in artificial intelligence (AI) present new methodologies for enhancing XML development workflows, introducing efficiency, automation, and intelligent capabilities. This presentation will outline the scope and perspective of utilizing AI in XML development. The potential benefits and the possible pitfalls will be highlighted, providing a balanced view of the subject.

We will explore the capabilities of AI in understanding XML markup languages and autonomously creating structured XML content. Additionally, we will examine the capacity of AI to enrich plain text with appropriate XML markup. Practical examples and methodological guidelines will be provided to elucidate how AI can be effectively prompted to interpret and generate accurate XML markup.

Further emphasis will be placed on the role of AI in developing XSLT, or schemas such as XSD and Schematron. We will address the techniques and strategies adopted to create prompts for generating code, explaining code, or refactoring the code, and the results achieved.

The discussion will extend to how AI can be used to transform XML content. In particular, the focus will be on the use of AI XPath extension functions in XSLT, Schematron, Schematron Quick Fixes, or for XML content refactoring.

The presentation aims to deliver a comprehensive overview of AI usage in XML development, providing attendees with the necessary knowledge to make informed decisions. Whether you’re at the early stages of adopting AI or considering integrating it in advanced XML development, this presentation will cover all levels of expertise.

By highlighting the potential advantages and challenges of integrating AI with XML development tools and languages, the presentation seeks to inspire thoughtful conversation around the future of XML development. We’ll not only delve into the technical aspects of AI-powered XML development but also discuss practical implications and possible future directions.

UiPath Test Automation using UiPath Test Suite series, part 5

Welcome to UiPath Test Automation using UiPath Test Suite series part 5. In this session, we will cover CI/CD with devops.

Topics covered:

CI/CD with in UiPath

End-to-end overview of CI/CD pipeline with Azure devops

Speaker:

Lyndsey Byblow, Test Suite Sales Engineer @ UiPath, Inc.

Securing your Kubernetes cluster_ a step-by-step guide to success !

Today, after several years of existence, an extremely active community and an ultra-dynamic ecosystem, Kubernetes has established itself as the de facto standard in container orchestration. Thanks to a wide range of managed services, it has never been so easy to set up a ready-to-use Kubernetes cluster.

However, this ease of use means that the subject of security in Kubernetes is often left for later, or even neglected. This exposes companies to significant risks.

In this talk, I'll show you step-by-step how to secure your Kubernetes cluster for greater peace of mind and reliability.

Encryption in Microsoft 365 - ExpertsLive Netherlands 2024

In this session I delve into the encryption technology used in Microsoft 365 and Microsoft Purview. Including the concepts of Customer Key and Double Key Encryption.

20240605 QFM017 Machine Intelligence Reading List May 2024

Everything I found interesting about machines behaving intelligently during May 2024

National Security Agency - NSA mobile device best practices

Threats to mobile devices are more prevalent and increasing in scope and complexity. Users of mobile devices desire to take full advantage of the features

available on those devices, but many of the features provide convenience and capability but sacrifice security. This best practices guide outlines steps the users can take to better protect personal devices and information.

Mind map of terminologies used in context of Generative AI

Mind map of common terms used in context of Generative AI.

20240607 QFM018 Elixir Reading List May 2024

Everything I found interesting about the Elixir programming ecosystem in May 2024

Video Streaming: Then, Now, and in the Future

In his public lecture, Christian Timmerer provides insights into the fascinating history of video streaming, starting from its humble beginnings before YouTube to the groundbreaking technologies that now dominate platforms like Netflix and ORF ON. Timmerer also presents provocative contributions of his own that have significantly influenced the industry. He concludes by looking at future challenges and invites the audience to join in a discussion.

Why You Should Replace Windows 11 with Nitrux Linux 3.5.0 for enhanced perfor...

The choice of an operating system plays a pivotal role in shaping our computing experience. For decades, Microsoft's Windows has dominated the market, offering a familiar and widely adopted platform for personal and professional use. However, as technological advancements continue to push the boundaries of innovation, alternative operating systems have emerged, challenging the status quo and offering users a fresh perspective on computing.

One such alternative that has garnered significant attention and acclaim is Nitrux Linux 3.5.0, a sleek, powerful, and user-friendly Linux distribution that promises to redefine the way we interact with our devices. With its focus on performance, security, and customization, Nitrux Linux presents a compelling case for those seeking to break free from the constraints of proprietary software and embrace the freedom and flexibility of open-source computing.

Generative AI Deep Dive: Advancing from Proof of Concept to Production

Join Maher Hanafi, VP of Engineering at Betterworks, in this new session where he'll share a practical framework to transform Gen AI prototypes into impactful products! He'll delve into the complexities of data collection and management, model selection and optimization, and ensuring security, scalability, and responsible use.

Recently uploaded (20)

Goodbye Windows 11: Make Way for Nitrux Linux 3.5.0!

Goodbye Windows 11: Make Way for Nitrux Linux 3.5.0!

Alt. GDG Cloud Southlake #33: Boule & Rebala: Effective AppSec in SDLC using ...

Alt. GDG Cloud Southlake #33: Boule & Rebala: Effective AppSec in SDLC using ...

Cosa hanno in comune un mattoncino Lego e la backdoor XZ?

Cosa hanno in comune un mattoncino Lego e la backdoor XZ?

UiPath Test Automation using UiPath Test Suite series, part 6

UiPath Test Automation using UiPath Test Suite series, part 6

GraphSummit Singapore | Neo4j Product Vision & Roadmap - Q2 2024

GraphSummit Singapore | Neo4j Product Vision & Roadmap - Q2 2024

Pushing the limits of ePRTC: 100ns holdover for 100 days

Pushing the limits of ePRTC: 100ns holdover for 100 days

UiPath Test Automation using UiPath Test Suite series, part 5

UiPath Test Automation using UiPath Test Suite series, part 5

Securing your Kubernetes cluster_ a step-by-step guide to success !

Securing your Kubernetes cluster_ a step-by-step guide to success !

Encryption in Microsoft 365 - ExpertsLive Netherlands 2024

Encryption in Microsoft 365 - ExpertsLive Netherlands 2024

20240605 QFM017 Machine Intelligence Reading List May 2024

20240605 QFM017 Machine Intelligence Reading List May 2024

National Security Agency - NSA mobile device best practices

National Security Agency - NSA mobile device best practices

Mind map of terminologies used in context of Generative AI

Mind map of terminologies used in context of Generative AI

Why You Should Replace Windows 11 with Nitrux Linux 3.5.0 for enhanced perfor...

Why You Should Replace Windows 11 with Nitrux Linux 3.5.0 for enhanced perfor...

Generative AI Deep Dive: Advancing from Proof of Concept to Production

Generative AI Deep Dive: Advancing from Proof of Concept to Production

What is parting lock?

- 1. www.moldclamps.net info@moldclamps.net 0086-17322110281 DGMF Mold Clamps Co., Ltd mingfeng425@gmail.com Please browse our website or contact us for more articles, thank you. What is parting lock? Parting lock is also called nylon mold clamp, resin shutter, nylon mold lock, resin mold clamp, nylon resin shutter, etc. It is a mold component that adjusts the friction between the template and the nylon sleeve by locking the tapered bolts. Parting lock function and characteristics: 1. Adjust the friction between the template and the resin by the inclined screw, and the mold can be closed about 50,000 times for about 1/4 turn; 2. It is easy and simple to take off and unload the mold device; 3. This device can also be used on the workpiece with a small nozzle plate and hitting plate or the second section to eject the small nozzle or slide; 4. For mold weight below 100KG, use 4 pieces of 12D, under 500KG, use 4 pieces of 16D, and under 1000KG, use 4 pieces of 20D; 5. Colors: four kinds of color, white, yellow, orange, blue, blue one can withstand a high temperature of 160 degrees. The parting lock uses special nylon material, which has good wear resistance and heat resistance. Although the heat resistance temperature of the nylon sleeve is 150 ° C, in actual use, it is

- 2. www.moldclamps.net info@moldclamps.net 0086-17322110281 DGMF Mold Clamps Co., Ltd mingfeng425@gmail.com Please browse our website or contact us for more articles, thank you. constantly subject to the locking stress of the tapered bolt The effect of this will lead to a decrease in the durability of the nylon sleeve. Generally, the normal use temperature is below 80 ℃. Material: nylon resin + high strength alloy steel Tolerance: ± 0.002 ㎜ Material and hardness Material SCM435 resin nylon Hardness 33-38HRC How to install the parting lock on the mold? Parting lock installation: The surface roughness of apex mirror processing can reach 0.1s or less and can carry out text engraving processing, which is widely used in semiconductor packaging molds. It can carry out a variety of post-processing such as surface chrome plating, tip lettering, etc. These products have high hardness, good toughness, excellent wear resistance, and heat resistance, and are more suitable for precision molds, which can significantly increase their service life, especially the hot shape of precision molds has been effectively controlled. After the surface treatment of this type of product, the surface of the product has higher hardness, wear-resistance and corrosion resistance. The internal hardness is low and the toughness is particularly good. It is suitable for molds in high-temperature operating environments. Installation method and precautions • Embed the nylon sleeve to about 3mm of the movable mold template. • Finish the inner surface roughness of the fixed template hole to 1.6-0.2. Round the R of the template face insertion opening. If the C chamfer is processed, its durability will be reduced. • Dimensional tolerance reference of the hole: H7 reaming, based on H7 reaming ~ +0.1. • If special bushings are used, the above rounding R and polishing steps can be omitted. • Adjust the required pulling force according to the tightening amount of the cone bolt. Parting lock Installation warning: No need to use a lubricant. Otherwise, it will reduce friction and reduce its original function. Rough standard of parting locks usage: Parting lock model usage quantity Mold weight DGMF-PL10 4 sets under 100kg DGMF-PL13 4 sets under 250kg DGMF-PL16 4 sets over 250kg DGMF-PL20 4 sets over 300kg If you need to purchase the parting locks, please do not hesitate to contact us, thanks.