The document outlines various experiments related to the testing of hydraulic cement and aggregates, detailing procedures, apparatus, and specifications for tests such as determining normal consistency, setting times, and fineness modulus. Each experiment is referenced by a specific ASTM code and includes essential information about materials and environmental conditions necessary for accurate results. Key aspects include methodologies for assessing properties vital for concrete quality and performance.

![Plain and Reinforced Concrete I Experiment No. 2

4

The time elapsed between the initial contact of cement and water and the time when a

1mm2

cross-section needle gives a reading between 4-7mm from the bottom in a standard Vicat

apparatus is known as initial setting time of that particular cement paste.

FINAL SETTING TIME

It is the time elapsed between the initial contact of cement and water and the time when

the smaller needle (1mm2

cross-section and 1mm deep) completely penetrates into the paste and

the outer metal attachment of 5mm diameter does not leave an impression on the cement paste.

According to specifications;

Maximum final setting time = 10hrs

Minimum final setting time = [90 + 1.2 (initial setting time)] min

TEST SPECIFICATIONS:

NEEDLE SIZES

1- For Initial Setting Time

1mm x 1mm cross-section

50mm length

2- For Final Setting Time

1mm2

cross-section and 1mm deep inner needle

5mm diameter outer metal attachment

MIXING WATER

Portable water is satisfactory for the routine tests.

TEMPERATURE & HUMIDITY

The temperature of the air in the vicinity should be between 23±3 °C. The temperature

of the mixing water should be 23±2 °C.

The relative humidity of the laboratory should not be less than 50%.

AMOUNT OF CEMENT

Amount of cement required for the test according to various specifications are

mentioned below.

BS = 500gm

ASTM = 650gm](https://image.slidesharecdn.com/manualprc-1-180721012233/75/PLAIN-AND-REINFORCED-CONRETE-LAB-MANUAL-6-2048.jpg)

![Plain and Reinforced Concrete I Experiment No. 8

21

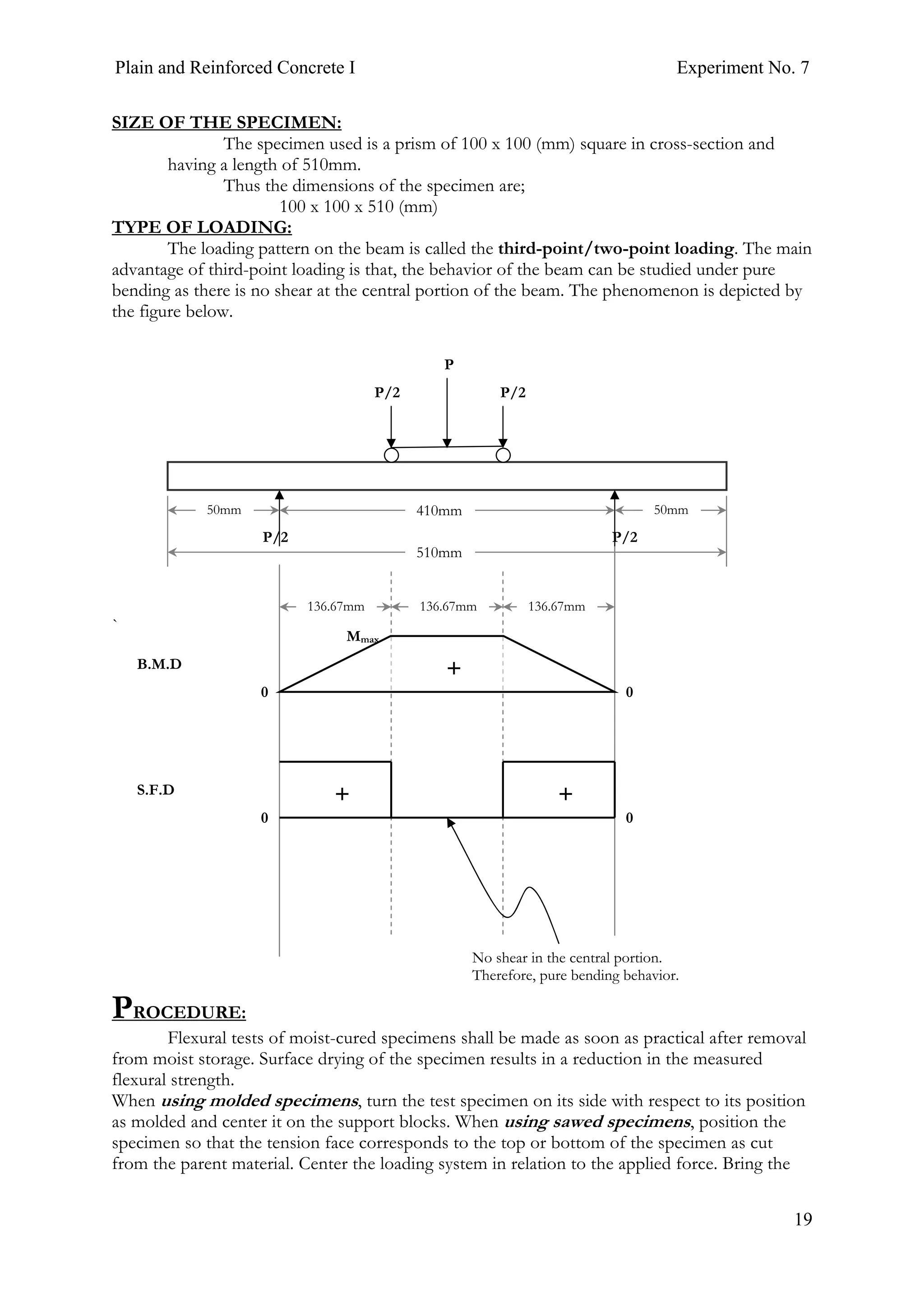

8. EXPERIMENT NO. 8:

Standard Test Method For The Determination Of The Splitting Tensile

Strength Of Cylindrical Concrete Specimen.

Code: ASTM C 496/C 496 M-04

SCOPE & SIGNIFICANCE:

This test method is used for the determination of splitting tensile strength of cylindrical

concrete specimen.

Splitting tensile strength is helpful for the following purposes;

1- Splitting tensile strength is generally greater than the direct tensile strength

and lower than the flexural strength (modulus of rupture).

2- Splitting tensile strength is used in the design of structural light weight

concrete members to evaluate the shear resistance provided by concrete and to

determine the development length of the reinforcement.

where,

T = Splitting tensile strength (to be reported in 0.05 MPa multiples)

P = Applied load

l = length of the specimen (mm)

d = Diameter of the specimen (mm)

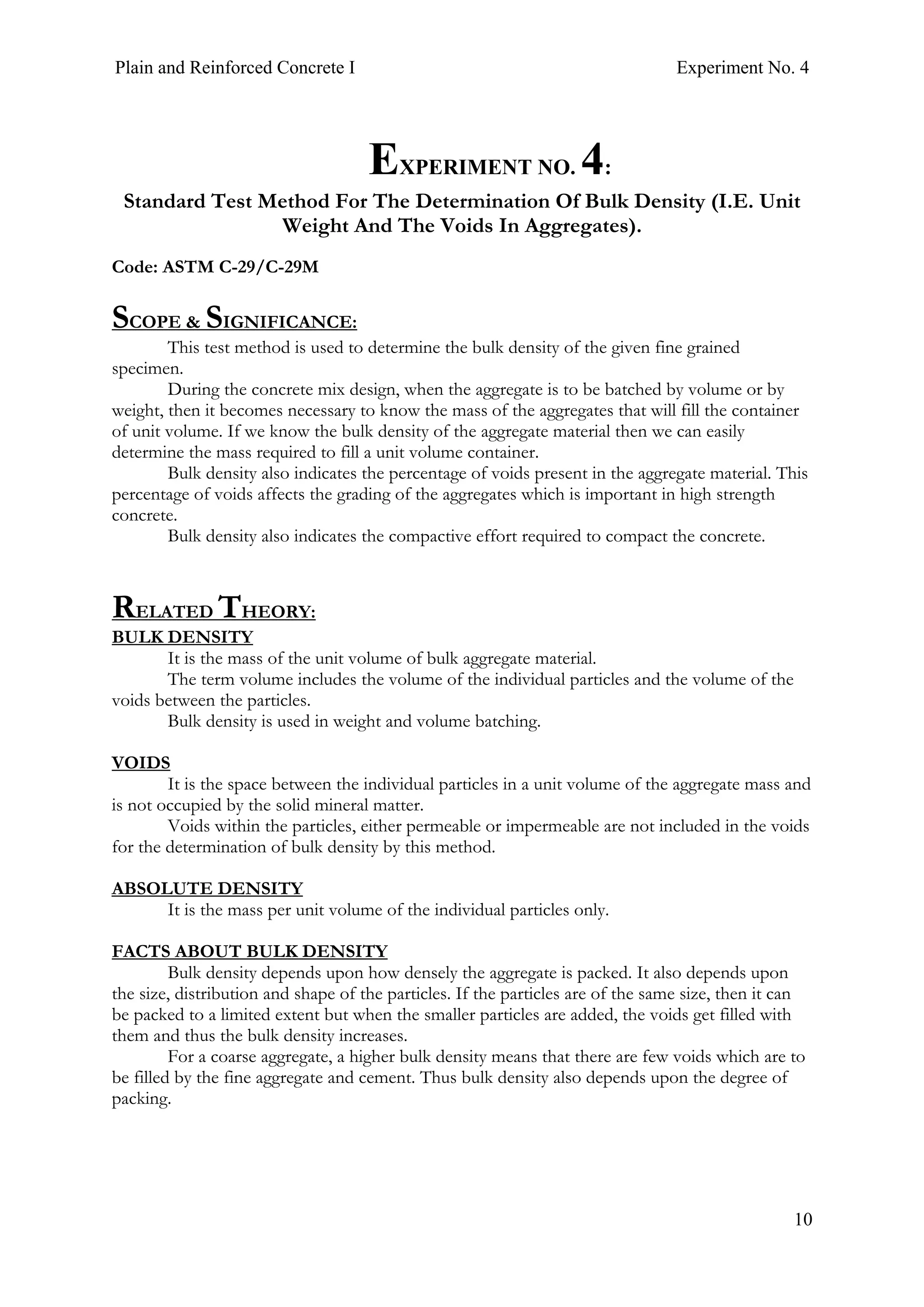

APPARATUS:

• Testing Machine

• Supplementary Bearing Bar Or Plates (If the diameter or the largest dimension of the upper

bearing face or the lower bearing block is less than the

length of the cylinder to be tested, a supplementary bearing

bar or plate of machined steel shall be used. The bar or

plate shall be manner that the load will be applied over the

specimen.)

• Bearing Strips (Two bearing strips of nominal 1 /8 in [3.2 mm] thick

plywood, free of imperfections, approximately 1 in. [25

mm] wide, and of a length equal to, or slightly longer than,

that of the specimen shall be provided for each specimen.

The bearing strips shall be placed between the specimen

and both the upper and lower bearing blocks of the testing

machine or between the specimen and supplemental bars or

plates, when used (see 5.2). Bearing strips shall not be

reused.)

ld

P2

T

π

=](https://image.slidesharecdn.com/manualprc-1-180721012233/75/PLAIN-AND-REINFORCED-CONRETE-LAB-MANUAL-23-2048.jpg)

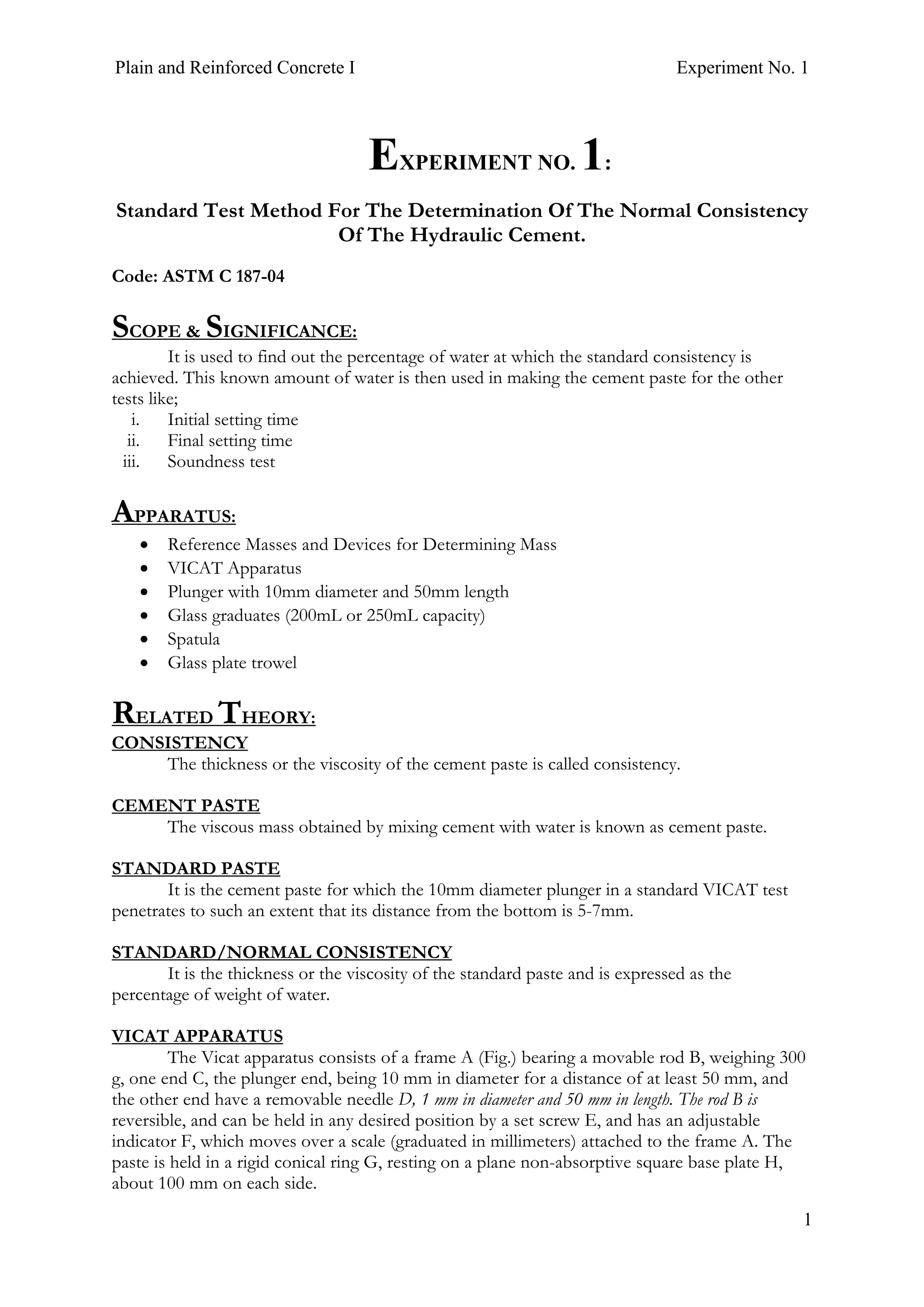

![Plain and Reinforced Concrete I Experiment No. 9

24

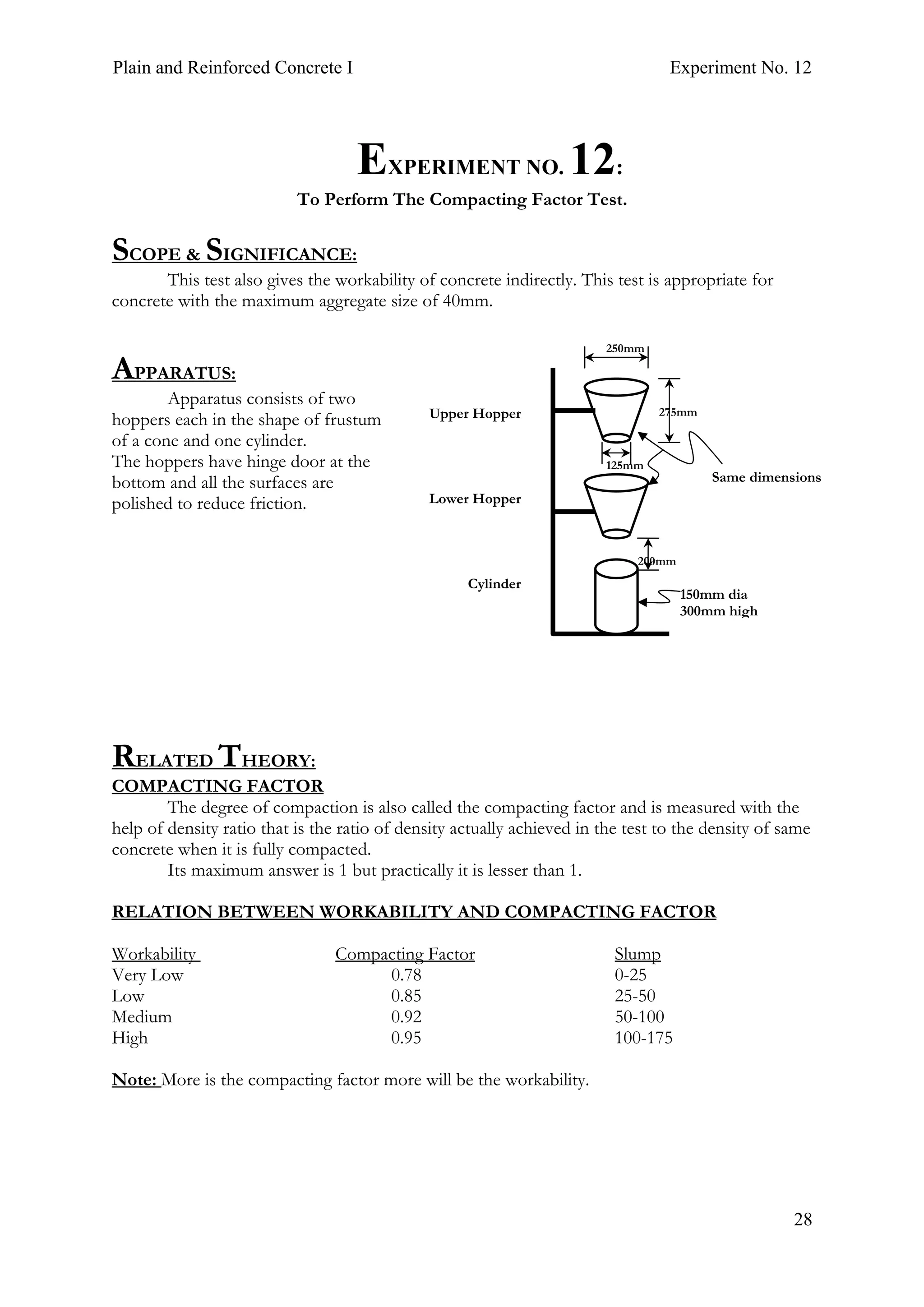

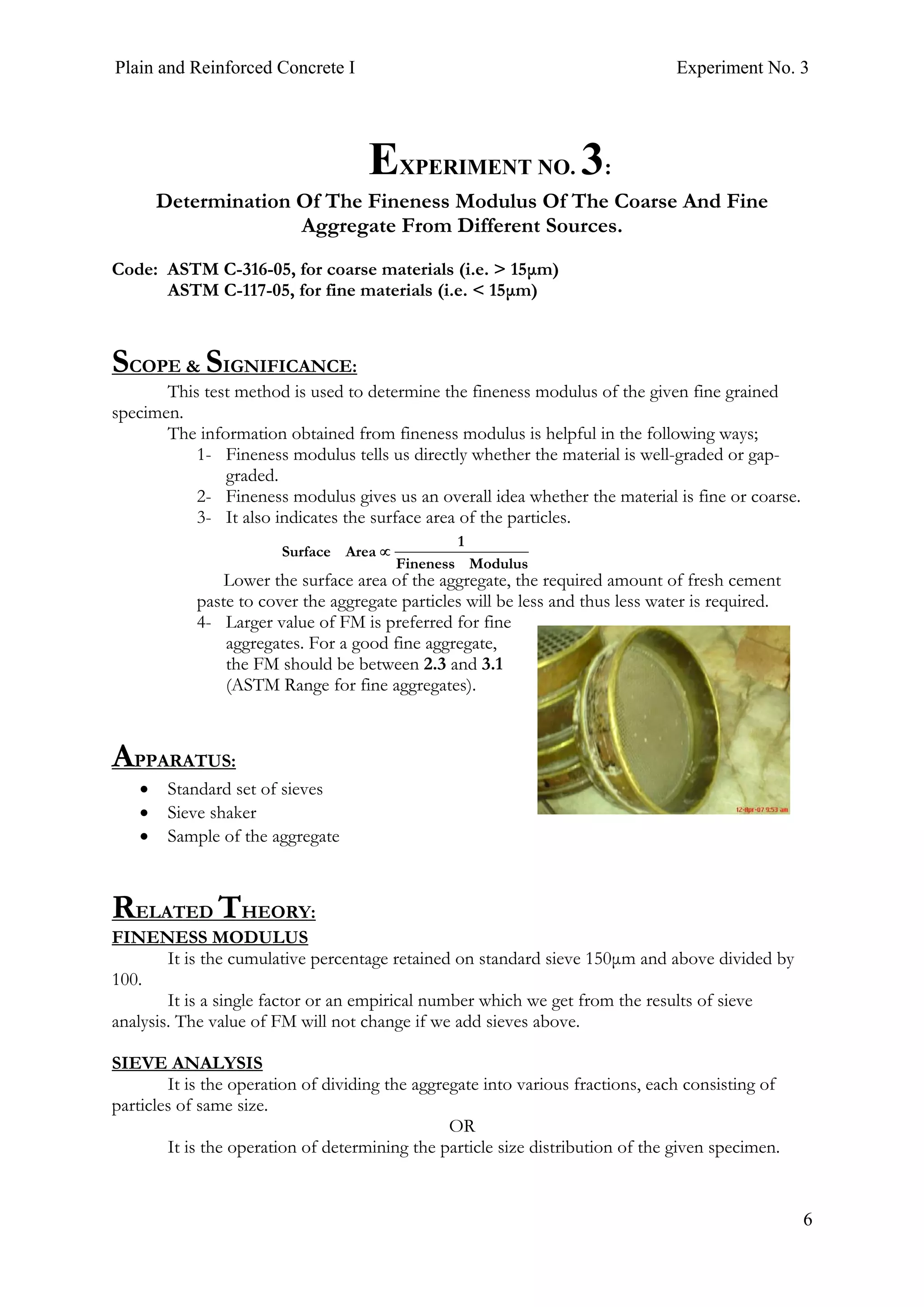

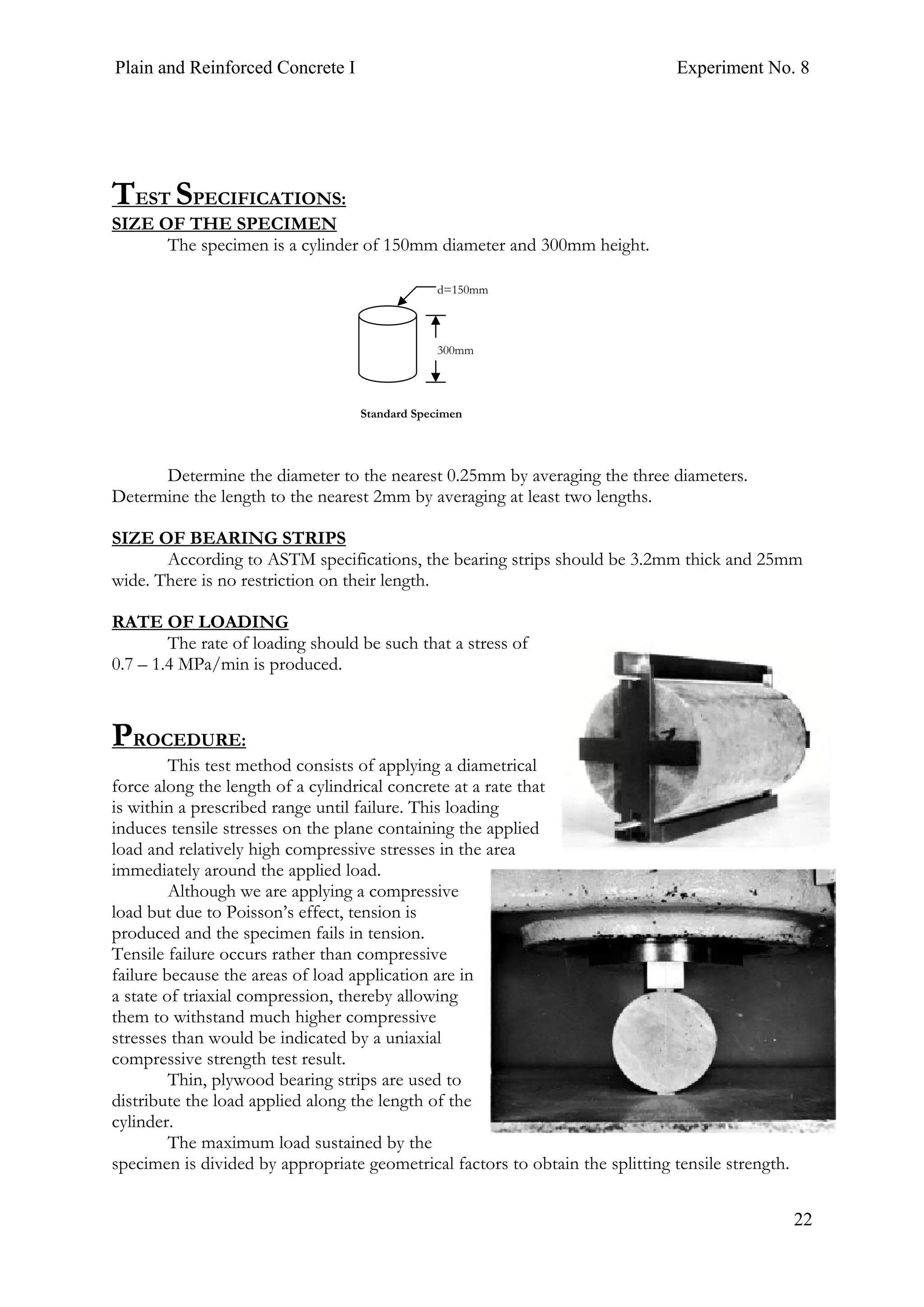

9. EXPERIMENT NO. 9:

Determination Of The Tensile Strength Of Concrete By Double Punch

Test. (Non-Standard Test)

APPARATUS:

• Testing Machine

• Testing Samples

• Punches (2 in number, to be placed at the top and bottom of the sample)

TEST SPECIFICATIONS:

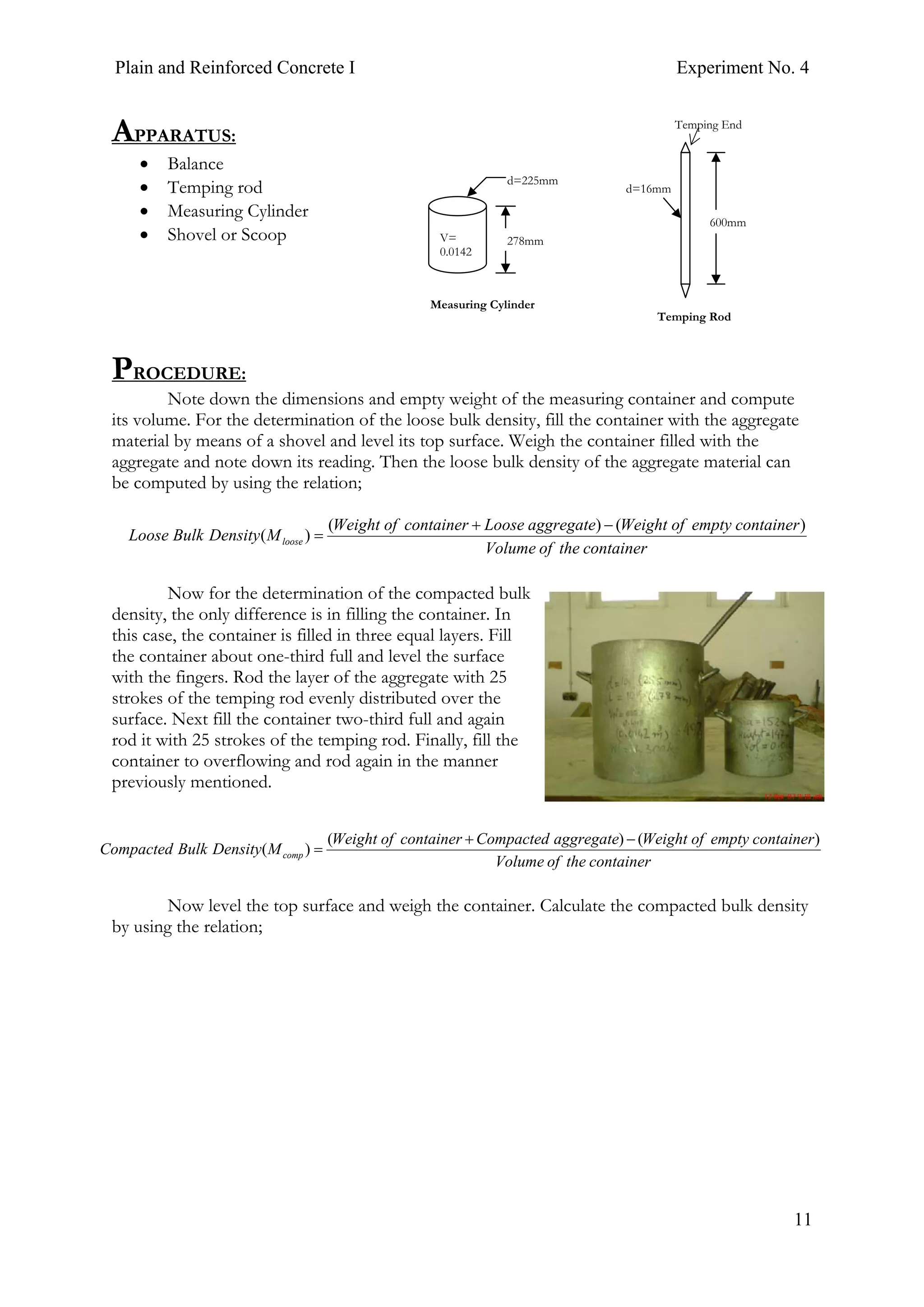

SIZE OF THE SPECIMEN

The specimen is a cylinder of 150mm diameter and 150mm height.

PROCEDURE:

It is an indirect method in which we determine the tensile strength

of concrete based on the theory of perfect plasticity.

In this test a concrete cylinder is placed vertically between the

loading platens of the machine and is compressed by two steel punches

placed parallel to the top and bottom end surfaces.

The sample splits across many vertical diametrical planes radiating

from central axis.

Samples should be placed under wet conditions for 24 hours and

later on in a curing tank for 28 days.

CALCULATION

The tensile strength can be computed as;

ft = Q / [Π (1.2bH - a2

)]

where,

Q = Crushing Load

H

Q

Q

2b

2a

150mm

d=150mm

Specimen](https://image.slidesharecdn.com/manualprc-1-180721012233/75/PLAIN-AND-REINFORCED-CONRETE-LAB-MANUAL-26-2048.jpg)