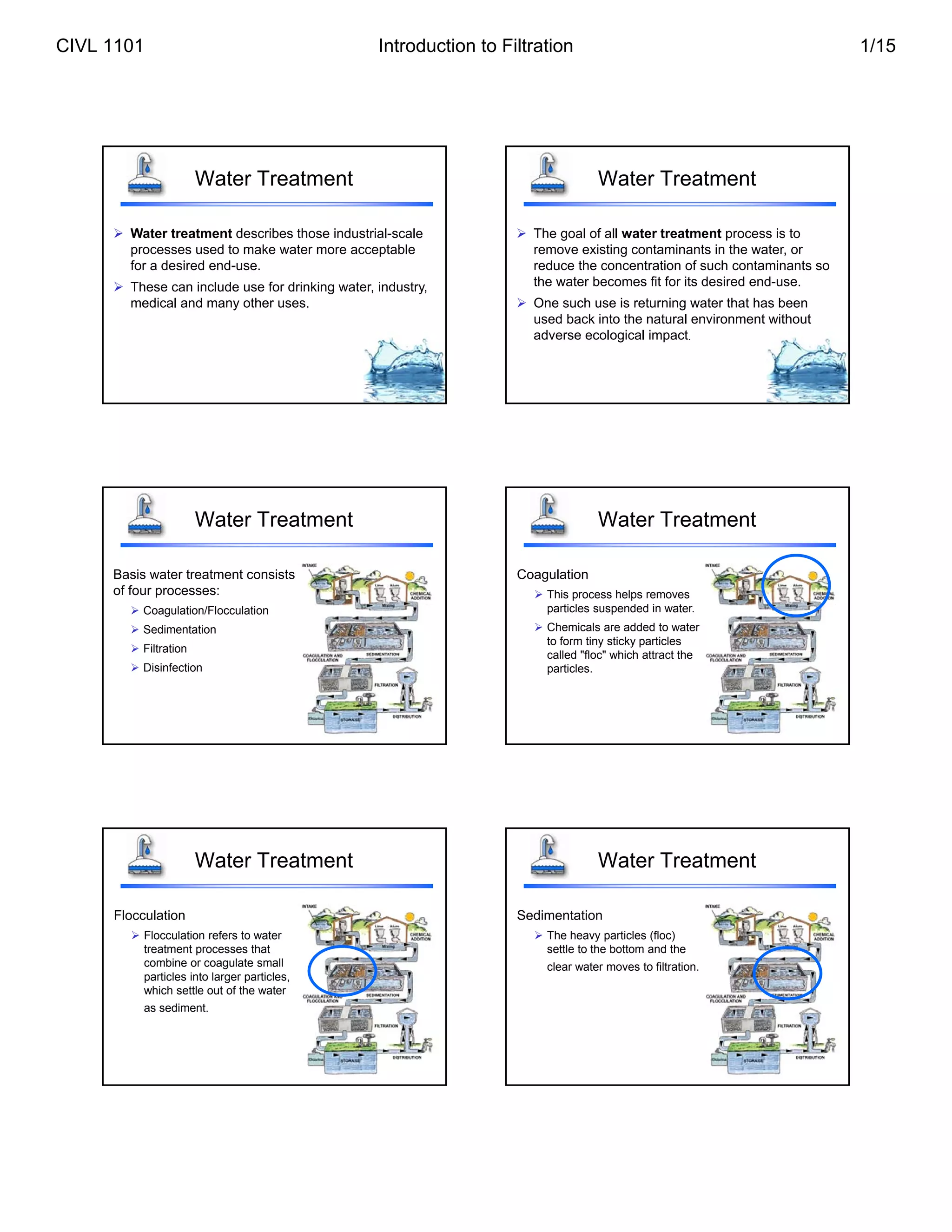

The document discusses water treatment and filtration processes. It provides information on various steps in water treatment including coagulation, flocculation, sedimentation, filtration and disinfection. It also describes different types of filtration such as slow sand filtration and rapid sand filtration. Rapid sand filtration uses higher flow rates than slow sand filtration. Key aspects of rapid sand filtration covered include the filter media layers, backwashing process, and calculating the hydraulic loading rate.